Overview

The article presents a comprehensive overview of the diverse applications of 12v blower fans, specifically tailored for electronics engineers. It underscores their critical role in enhancing efficiency and performance across various sectors. These fans are essential components in:

- Cooling systems for electronics

- Automotive applications

- HVAC improvements

- Innovative art installations

This showcases their remarkable versatility and underscores their importance in sustaining optimal operational conditions.

Introduction

The integration of 12v blower fans into various applications signifies a pivotal advancement in electronics engineering. These versatile devices not only enhance cooling efficiency but also play a crucial role in improving the performance and longevity of electronic components across multiple sectors. As technology continues to evolve, however, the challenge lies in identifying the most effective strategies to leverage these fans for optimal results.

What innovative solutions can engineers explore to maximize the benefits of 12v blower fans in their designs?

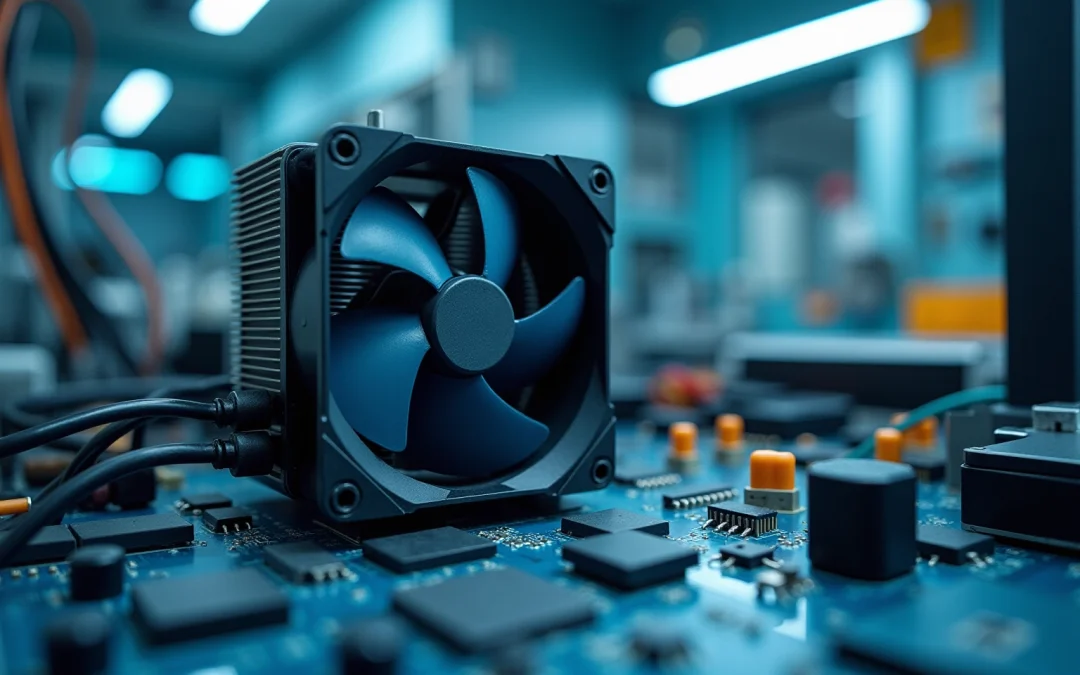

Gagner-Toomey Associates: Innovative Cooling Solutions with 12v Blower Fans

Gagner-Toomey Associates stands at the forefront of delivering innovative cooling solutions tailored for the electronics industry. The integration of 12v blower fans is pivotal in boosting the efficiency and performance of various electronic components. These units play a vital role in effective heat dissipation, ensuring devices operate within optimal temperature ranges, thereby significantly enhancing their longevity and reliability. Notably, advanced temperature regulation technologies, including the 12v blower fan, have been shown to improve energy efficiency by as much as 20%, as demonstrated by recent industry applications.

to excellence is underscored by strategic partnerships with leading manufacturers, empowering them to provide that align with the evolving requirements of engineers and designers. Furthermore, the latest advancements in cooling technologies, including thermoelectric coolers and phase change materials, enhance the capabilities of the 12v blower fan, making it indispensable in modern electronic applications.

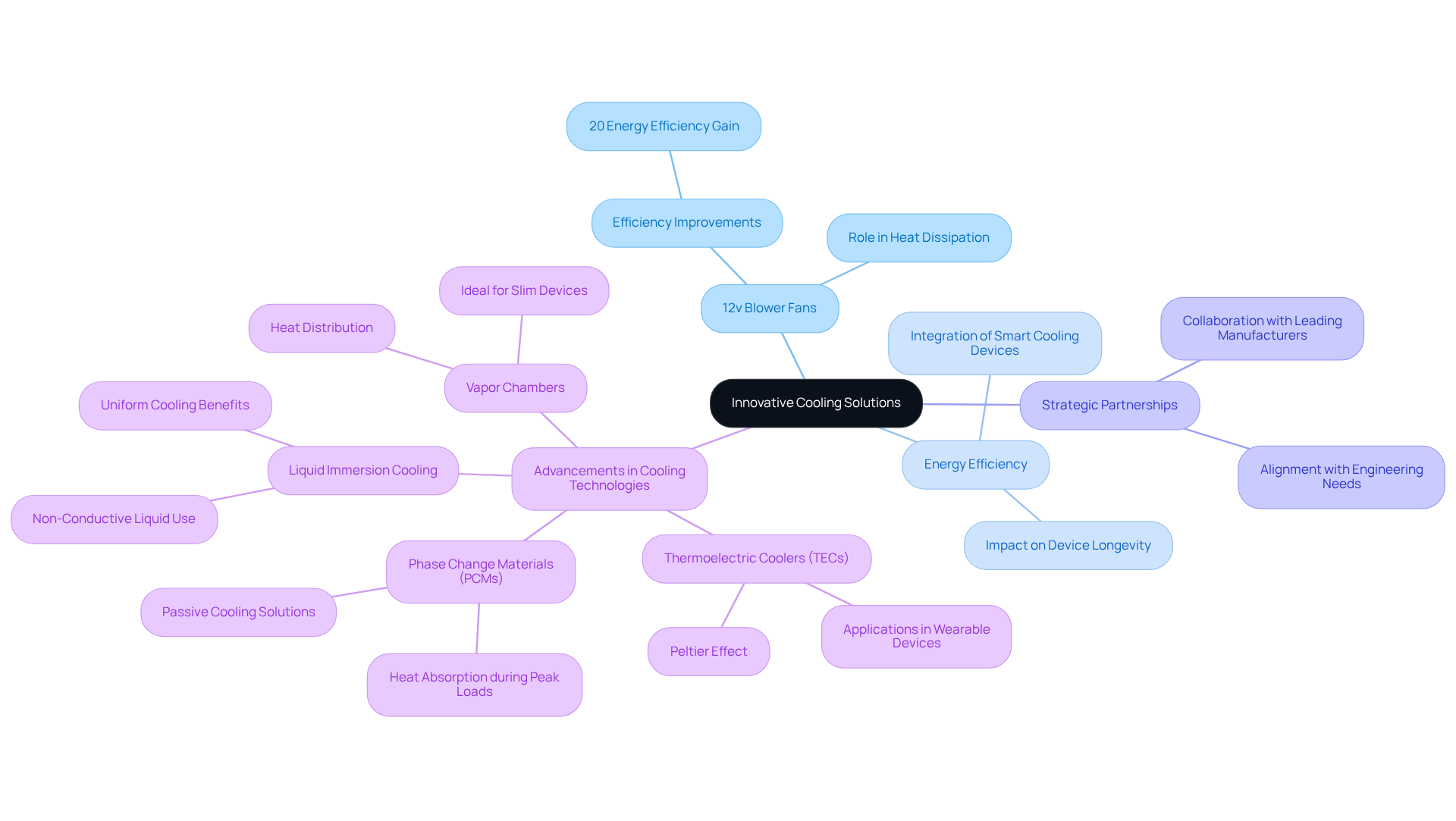

Improve Air Circulation in Electronic Enclosures with 12v Blower Fans

The critical role of 12v blower fans is to optimize air movement within electronic enclosures. By strategically positioning these devices, engineers can create a consistent airflow that effectively dissipates heat generated by electronic components. This becomes especially vital in where natural convection may fall short.

The implementation of a 12v blower fan not only enhances temperature regulation but also significantly contributes to the overall reliability of the system by preventing thermal accumulation, which can lead to component failure. Employing these devices can markedly enhance the efficiency and longevity of electronic equipment.

Utilize 12v Blower Fans for Efficient Cooling in Small Appliances

In the realm of small appliances, the 12v blower fan emerges as a highly efficient cooling solution, adeptly addressing space constraints while optimizing performance. These devices are engineered to deliver significant airflow, exemplified by the Vornado 660DC model, which achieves an impressive 23 CFM per watt. This makes them particularly suitable for appliances such as:

- Microwaves

- Toasters

- Coffee makers

By integrating ventilators, manufacturers can effectively manage heat, thereby reducing the risk of overheating and ensuring that appliances operate safely and efficiently. This application not only enhances the user experience but also significantly prolongs the appliance’s lifespan by on internal components.

For instance, in microwaves, the inclusion of blower motors helps maintain consistent temperatures, thereby improving cooking efficiency and reliability. Similarly, in toasters, these devices facilitate rapid heat dissipation, preventing damage to sensitive electronic components and enhancing overall durability.

Moreover, the low power consumption of the 12v blower fan alleviates strain on the electrical system, rendering it an optimal choice for compact designs. The strategic deployment of 12v blower fans ultimately culminates in improved performance and durability within compact appliances, establishing these fans as invaluable assets in modern design.

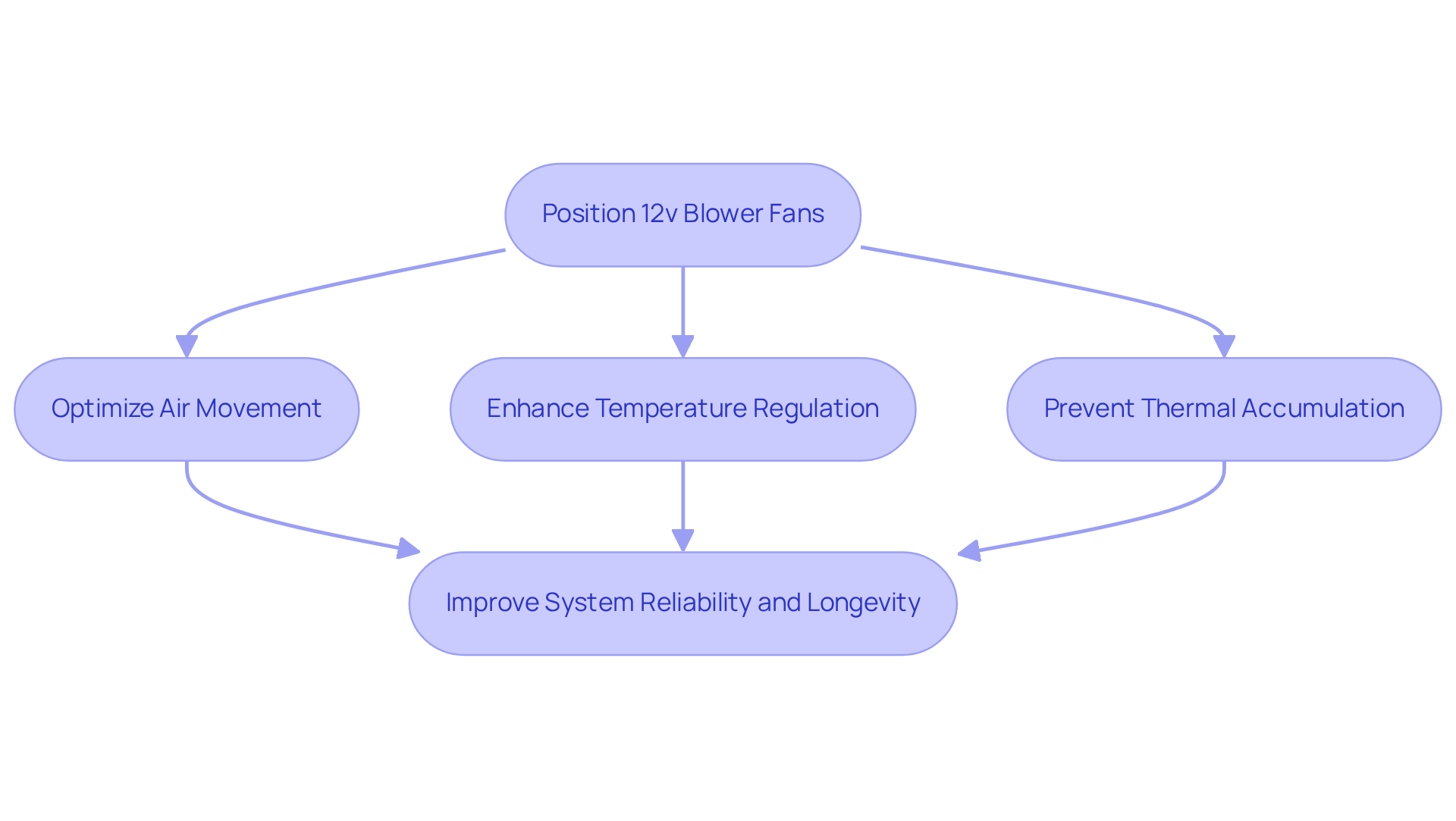

Enhance Greenhouse Ventilation Using 12v Blower Fans

The optimization of is significantly enhanced by 12v blower fans. By facilitating efficient air circulation, these devices help maintain ideal temperature and humidity levels, which are crucial for plant growth. Sufficient airflow not only prevents heat buildup but also ensures that plants receive the essential conditions for photosynthesis and overall vitality.

Agricultural engineers underscore the significance of proper ventilation, noting that it substantially influences plant health by mitigating disease risks and fostering vigorous growth.

Integrating a 12v blower fan into greenhouse systems not only improves air circulation but also enhances crop yields, demonstrating the fan’s versatility beyond conventional electronic applications.

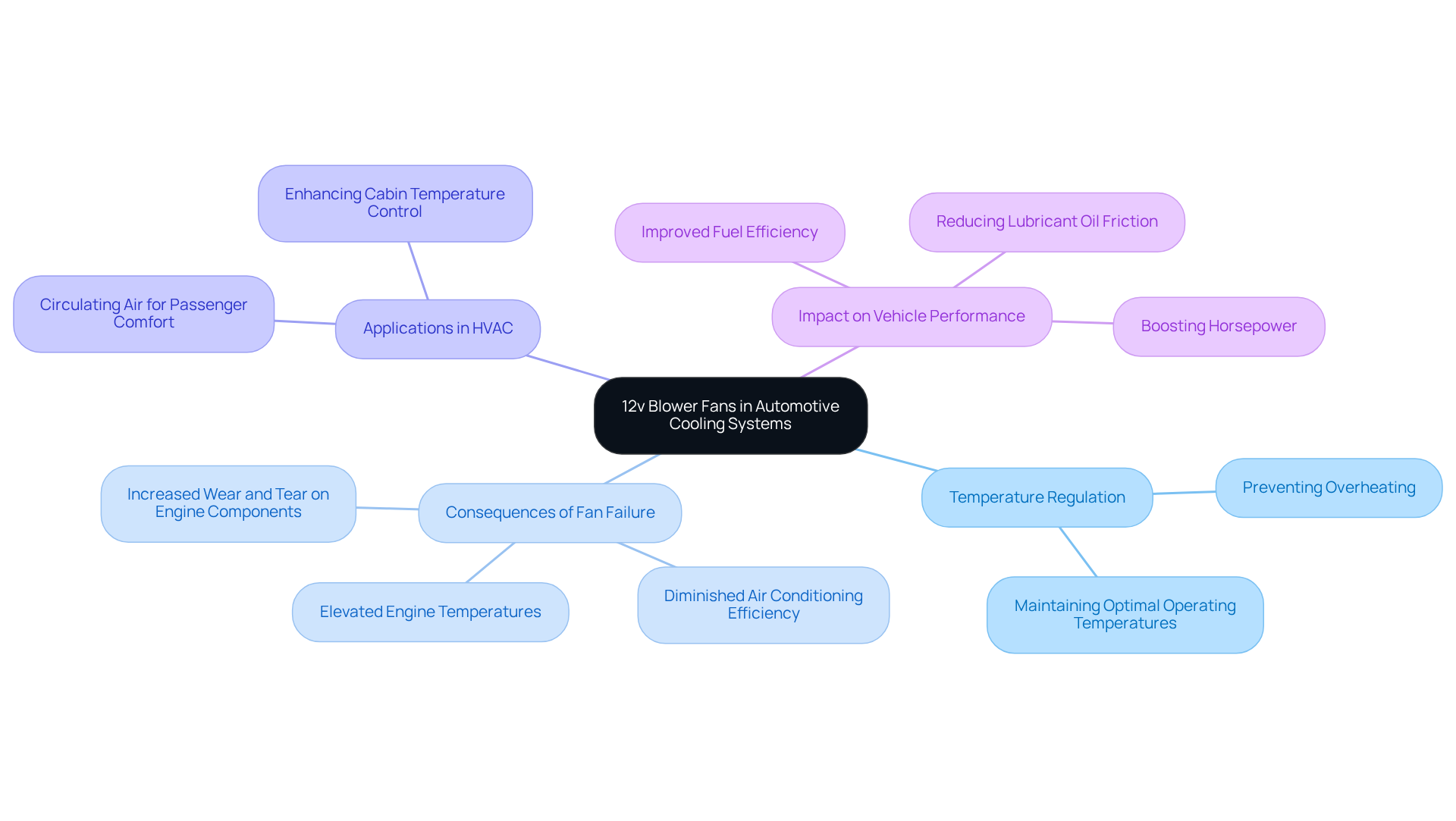

Incorporate 12v Blower Fans in Automotive Cooling Systems

In automotive applications, the 12v blower fan units play a crucial role in temperature regulation systems, ensuring that engines and electronic components maintain optimal operating temperatures. These devices effectively disperse heat generated during engine operation, —a leading cause of mechanical failure that can result in severe engine damage.

Statistics reveal that the immediate consequences of fan failure include elevated engine temperatures and diminished air conditioning efficiency, underscoring the critical need for reliable temperature control solutions. Furthermore, air movement devices are indispensable in HVAC systems within vehicles, where they circulate air to enhance passenger comfort by maintaining optimal cabin temperatures.

The efficiency and reliability of the 12v blower fan position it as the preferred choice for automotive engineers focused on advancing thermal management in modern vehicles. By facilitating effective airflow, these devices not only protect engine components but also contribute to improved fuel efficiency and overall vehicle performance, which includes reducing lubricant oil friction and enhancing conditioning.

Optimize 3D Printing Processes with 12v Blower Fans

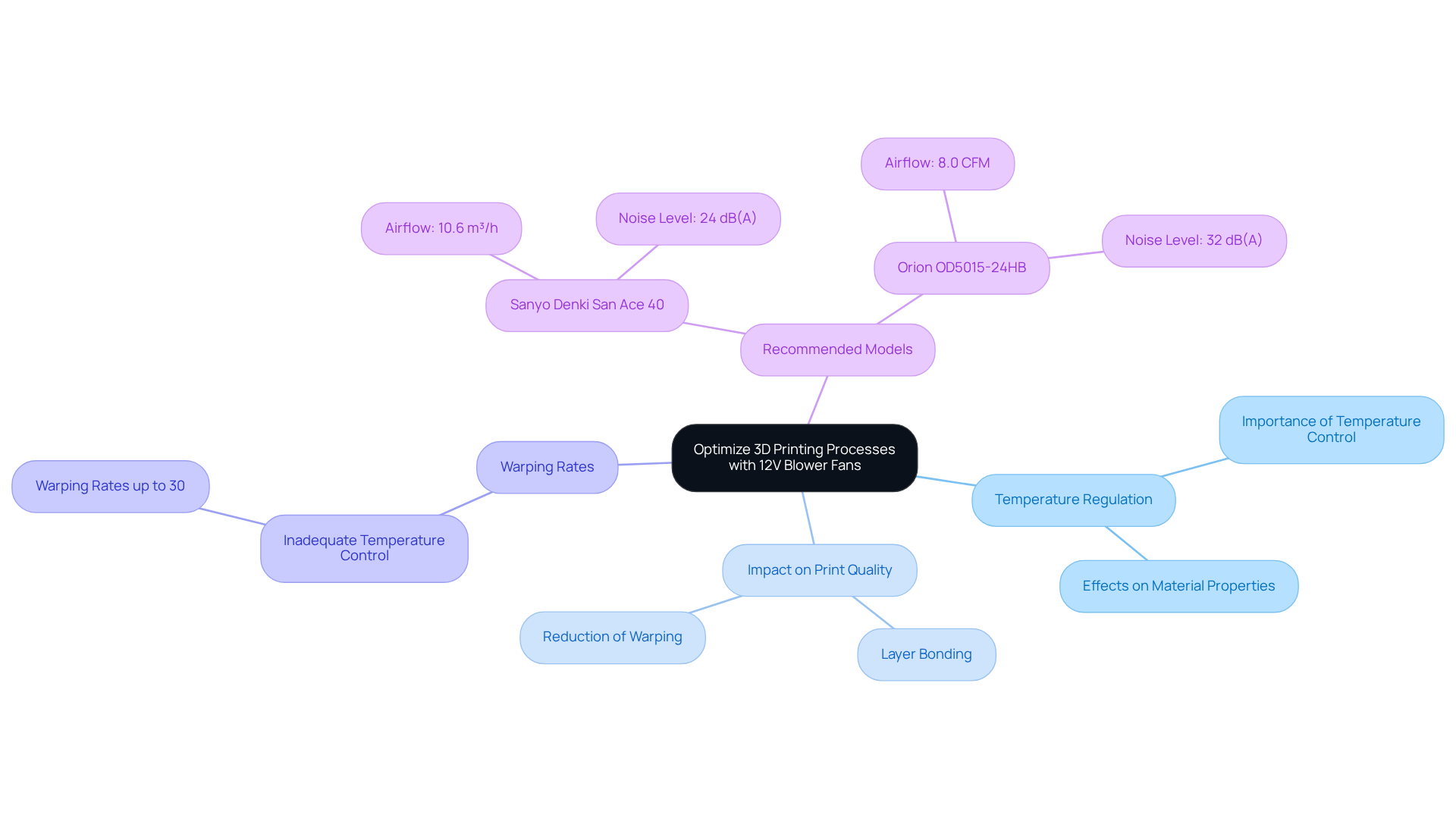

12V ventilation devices play a crucial role in optimizing 3D printing operations by delivering precise temperature regulation to printed parts. Effective temperature management is vital in mitigating warping, a common issue in 3D printed components. Research indicates that inadequate temperature control can lead to warping rates as high as 30%, significantly compromising the structural integrity of prints and resulting in functional failures.

By incorporating air circulation devices into 3D printers, engineers can finely tune temperature regulation, which is essential for materials sensitive to thermal variations. This capability not only enhances print quality but also improves the efficiency of the 3D printing workflow, establishing the as an indispensable asset for both manufacturers and hobbyists.

Experts emphasize that proper temperature management methods are critical for achieving optimal results. Cameron Coward notes, “Effective temperature regulation is essential in ensuring that layers bond properly, which is crucial for high-quality prints.”

Moreover, with the global 3D printing industry projected to reach USD 19.8 billion in 2023, the significance of integrating air circulation devices into 3D printing systems is more pronounced than ever. Specific models, such as the Sanyo Denki San Ace 40 and the Orion OD5015-24HB, represent excellent options for engineers seeking to enhance their 3D printing capabilities.

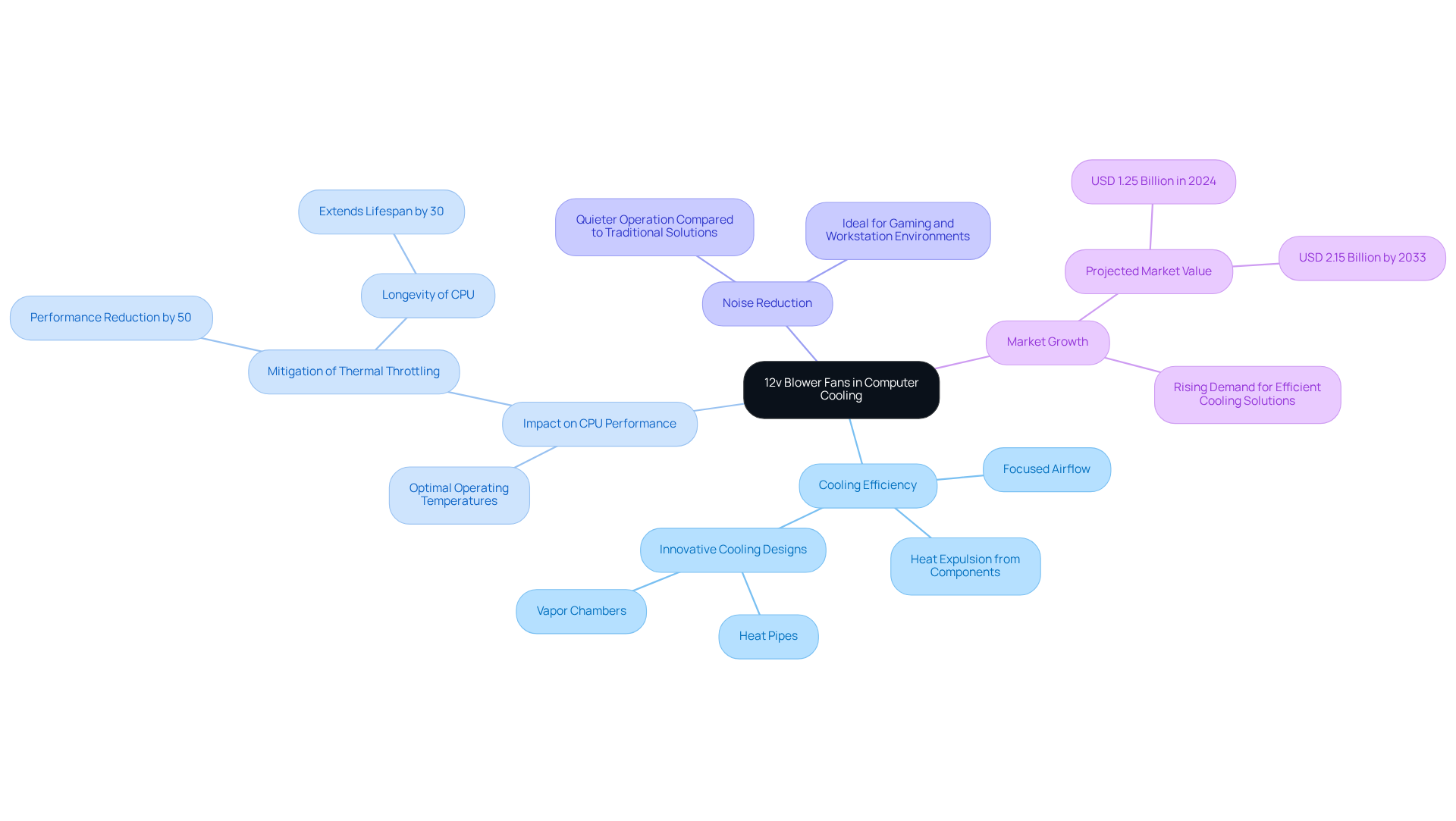

Enhance Computer Cooling Efficiency with 12v Blower Fans

In high-performance computer systems, the 12v blower fan serves a pivotal role in enhancing cooling efficiency. These devices are engineered to produce , effectively expelling hot air from critical components such as CPUs and GPUs. By sustaining optimal operating temperatures, a 12v blower fan significantly mitigates the risk of thermal throttling, which can diminish CPU performance by as much as 50%.

IT professionals assert that effective thermal management is essential for maintaining peak performance during demanding tasks. Moreover, ventilation devices often operate more quietly than traditional temperature control solutions, making them ideal for gaming and workstation environments where noise reduction is paramount.

The CPU fan cooling market is projected to expand from USD 1.25 billion in 2024 to USD 2.15 billion by 2033, underscoring the rising demand for efficient cooling solutions. Their application spans various high-performance setups, ensuring reliability and efficiency in demanding computing scenarios.

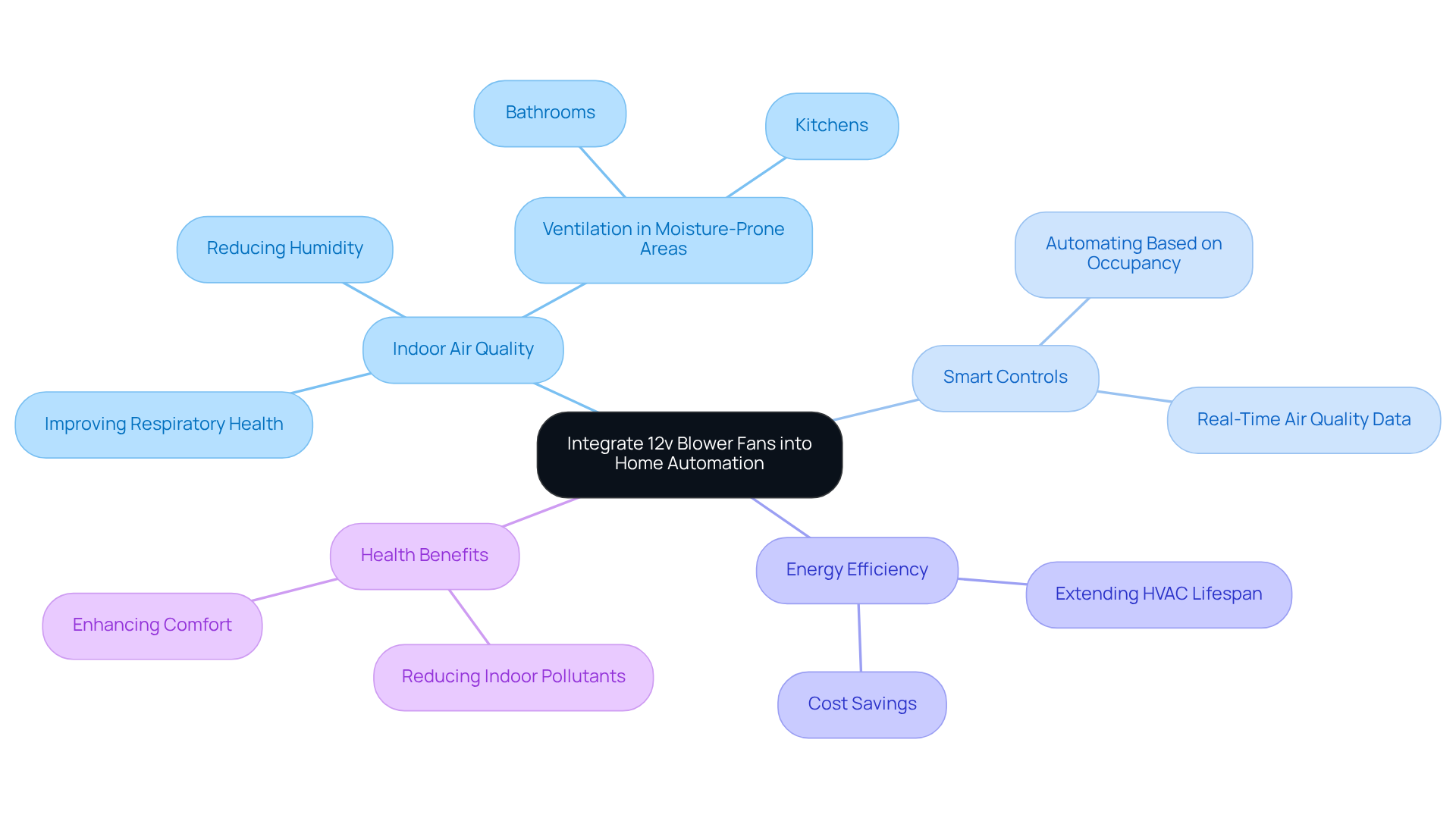

Integrate 12v Blower Fans into Home Automation Systems

Incorporating a 12v blower fan into home automation systems significantly enhances indoor air quality and overall comfort. With the average person spending approximately , it’s crucial to recognize that indoor air can often be more contaminated than outdoor air. These devices, such as the 12v blower fan, facilitate consistent airflow, which is essential for reducing humidity levels and improving ventilation, particularly in moisture-prone areas such as bathrooms and kitchens.

By utilizing smart controls, homeowners can automate fan operation based on occupancy or real-time air quality data, resulting in energy-efficient solutions that promote a healthier living environment. This automation not only aids in maintaining optimal humidity levels but also reduces the accumulation of indoor pollutants, which is vital for better respiratory health and comfort.

As C&C Myers states, “Our team has a strong commitment to customer satisfaction and strives to go above and beyond in providing exceptional service,” underscoring the significance of effective air quality solutions. Moreover, implementing a smart ventilation system can further improve indoor air quality while ensuring energy efficiency by adjusting ventilation rates according to real-time air quality conditions.

Utilize 12v Blower Fans in HVAC System Enhancements

In HVAC systems, the use of a 12v blower fan is crucial for enhancing airflow and increasing overall system efficiency. These devices integrate seamlessly into ductwork, facilitating the effective circulation of conditioned air throughout a structure. This integration guarantees that every area receives , significantly elevating occupant comfort.

By improving airflow, air circulation devices can lead to energy consumption reductions of up to 50%, as enhanced performance can decrease energy use by an average of 12%. Their compact design offers flexible installation options across various configurations, highlighting their versatility in modern HVAC applications.

Furthermore, HVAC engineers stress that optimizing airflow with a 12v blower fan through proper techniques is vital for maximizing system performance; even minor adjustments can result in significant energy savings and improved indoor air quality.

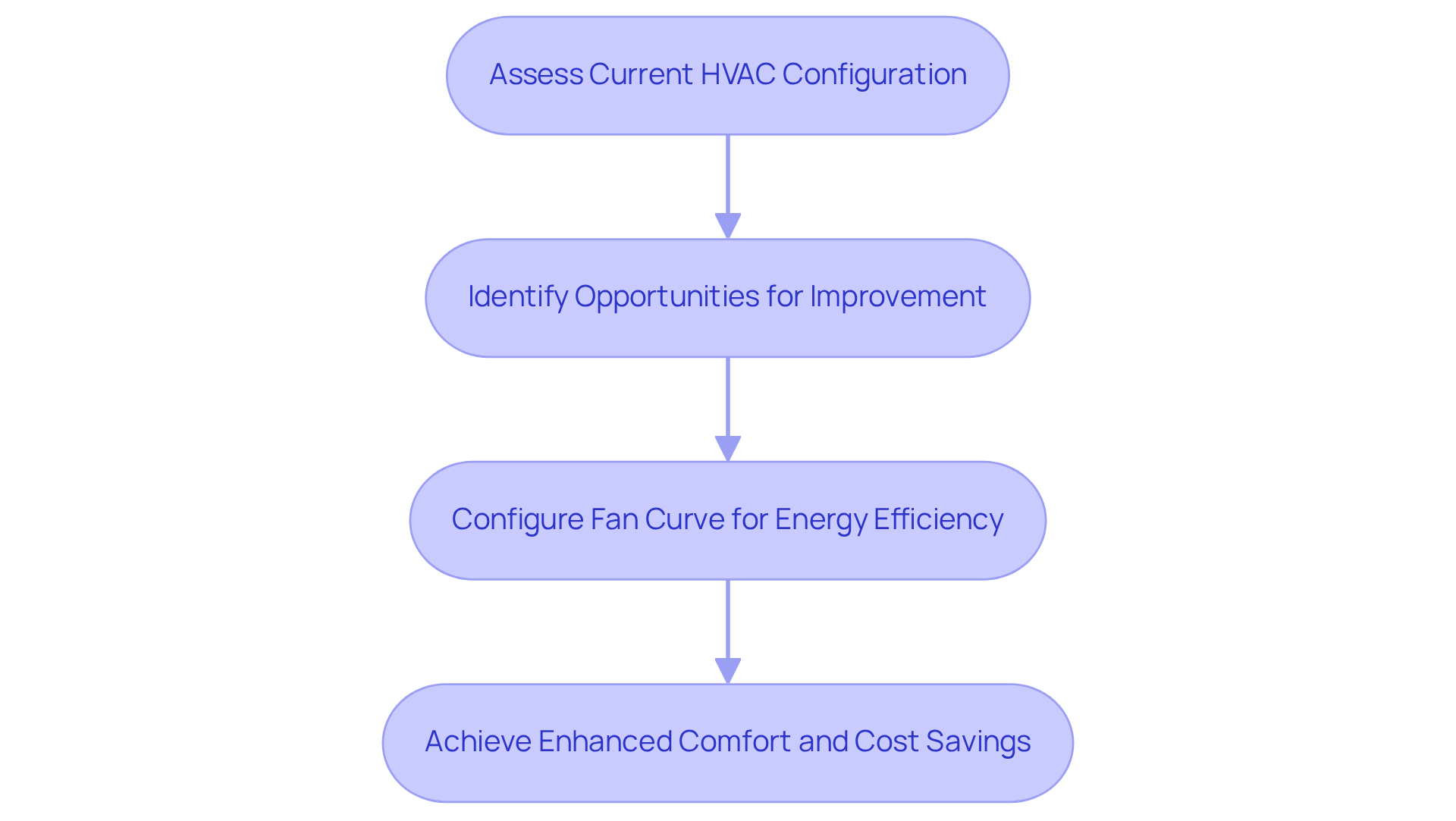

As Sarah Lee articulates, ‘To optimize your HVAC system’s fan curve, you can assess the current configuration, identify opportunities for improvement, and configure the fan curve for energy efficiency.’

Real-world applications demonstrate that strategically utilizing ventilation devices not only enhances comfort but also leads to considerable operational cost savings in commercial structures, as evidenced by the ‘Temperature Regulation in Workspaces’ case study.

Incorporate 12v Blower Fans in Creative Art Installations

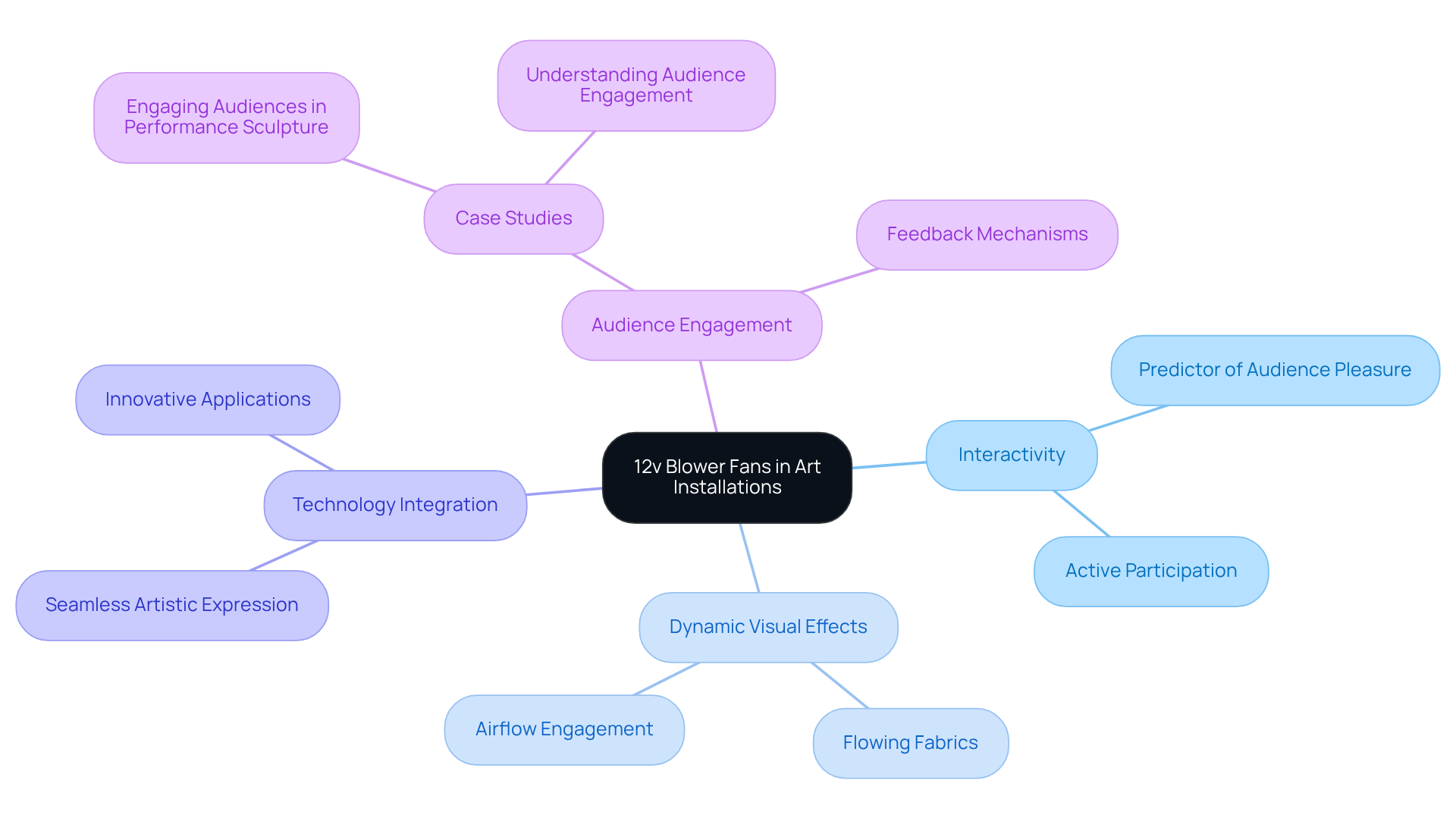

The 12v blower fan emerges as a formidable asset in the realm of interactive art installations, significantly amplifying viewer engagement and experience. Research indicates that interactivity is a strong predictor of audience pleasure in such installations, making the use of these devices particularly effective. Artists creatively harness these tools to generate dynamic visual effects, such as flowing fabrics or airflow that engages the audience directly. This innovative application not only highlights the but also exemplifies the seamless integration of technology into artistic expression.

As John Lasseter aptly stated, “The art challenges the technology, and the technology inspires the art,” reflecting the symbiotic relationship between these two fields. By leveraging the capabilities of a 12v blower fan, artists transcend conventional art forms, crafting immersive environments that actively engage and motivate participants. The incorporation of such technology fosters a profound connection between the artwork and its audience, transforming passive observation into active participation.

Furthermore, case studies on audience engagement illustrate how artists can tailor their performances to enhance interaction, reinforcing the practical applications of the 12v blower fan in creating unforgettable art experiences.

Conclusion

The versatility of 12v blower fans in various applications underscores their critical role in enhancing efficiency and performance across multiple fields, particularly in electronics engineering. These compact devices not only facilitate effective heat dissipation but also optimize airflow in electronic enclosures, small appliances, automotive systems, and even creative art installations. Their ability to maintain optimal temperatures ensures the longevity and reliability of sensitive components, making them an indispensable tool for engineers and designers alike.

Key insights illustrate how 12v blower fans improve air circulation, enhance cooling efficiency, and contribute to energy savings in diverse settings. From maintaining ideal conditions in greenhouses to optimizing 3D printing processes and integrating into home automation systems, the benefits of these fans are profound. Their application in automotive cooling systems and HVAC enhancements further highlights their role in promoting comfort and performance in everyday technology.

As industries continue to evolve, the integration of 12v blower fans will remain crucial in driving innovation and efficiency. Embracing these technologies not only leads to improved operational outcomes but also fosters a commitment to sustainability through energy-efficient solutions. Engineers and designers are encouraged to explore the myriad applications of 12v blower fans, leveraging their capabilities to create smarter, more reliable systems that meet the demands of modern technology.

Frequently Asked Questions

What is the primary function of 12v blower fans in electronic applications?

The primary function of 12v blower fans is to optimize air movement within electronic enclosures, effectively dissipating heat generated by electronic components and ensuring devices operate within optimal temperature ranges.

How do 12v blower fans contribute to energy efficiency?

Advanced temperature regulation technologies, including 12v blower fans, can improve energy efficiency by as much as 20%, as evidenced by recent industry applications.

What advantages do 12v blower fans offer in densely packed electronic enclosures?

In densely packed enclosures, 12v blower fans create consistent airflow that prevents thermal accumulation, enhancing temperature regulation and significantly contributing to the overall reliability of the system.

How do 12v blower fans enhance the performance of small appliances?

12v blower fans provide significant airflow while addressing space constraints, allowing manufacturers to manage heat effectively in small appliances like microwaves, toasters, and coffee makers, thereby reducing the risk of overheating and prolonging lifespan.

Can you provide an example of a specific model of a 12v blower fan and its performance?

The Vornado 660DC model is an example that achieves an impressive airflow rate of 23 CFM per watt, making it particularly suitable for small appliances.

What benefits do 12v blower fans provide in microwaves and toasters?

In microwaves, blower motors maintain consistent temperatures, improving cooking efficiency and reliability. In toasters, these fans facilitate rapid heat dissipation, preventing damage to sensitive components and enhancing durability.

How do 12v blower fans affect power consumption in small appliances?

The low power consumption of 12v blower fans reduces strain on the electrical system, making them an optimal choice for compact designs while improving performance and durability.