Overview

This article delineates ten pivotal advantages of blower exhaust fans tailored for engineers, accentuating their significance in augmenting air quality, energy efficiency, and workplace productivity. It substantiates these claims by elaborating on how these fans enhance health outcomes and operational efficiency. Furthermore, it underscores financial incentives, including diminished energy costs and heightened employee productivity, establishing them as a judicious investment across diverse industrial applications.

Introduction

Blower exhaust fans have emerged as a critical component in modern engineering, particularly within the electronics industry, where the maintenance of air quality is paramount. These innovative devices not only enhance workplace safety and productivity but also offer significant energy savings and reduced maintenance requirements. However, the pressing question remains: how can engineers leverage these benefits to optimize their operations and ensure a healthier work environment? This article delves into the ten key advantages of blower exhaust fans, providing insights that empower engineers to make informed decisions for their projects and workplaces.

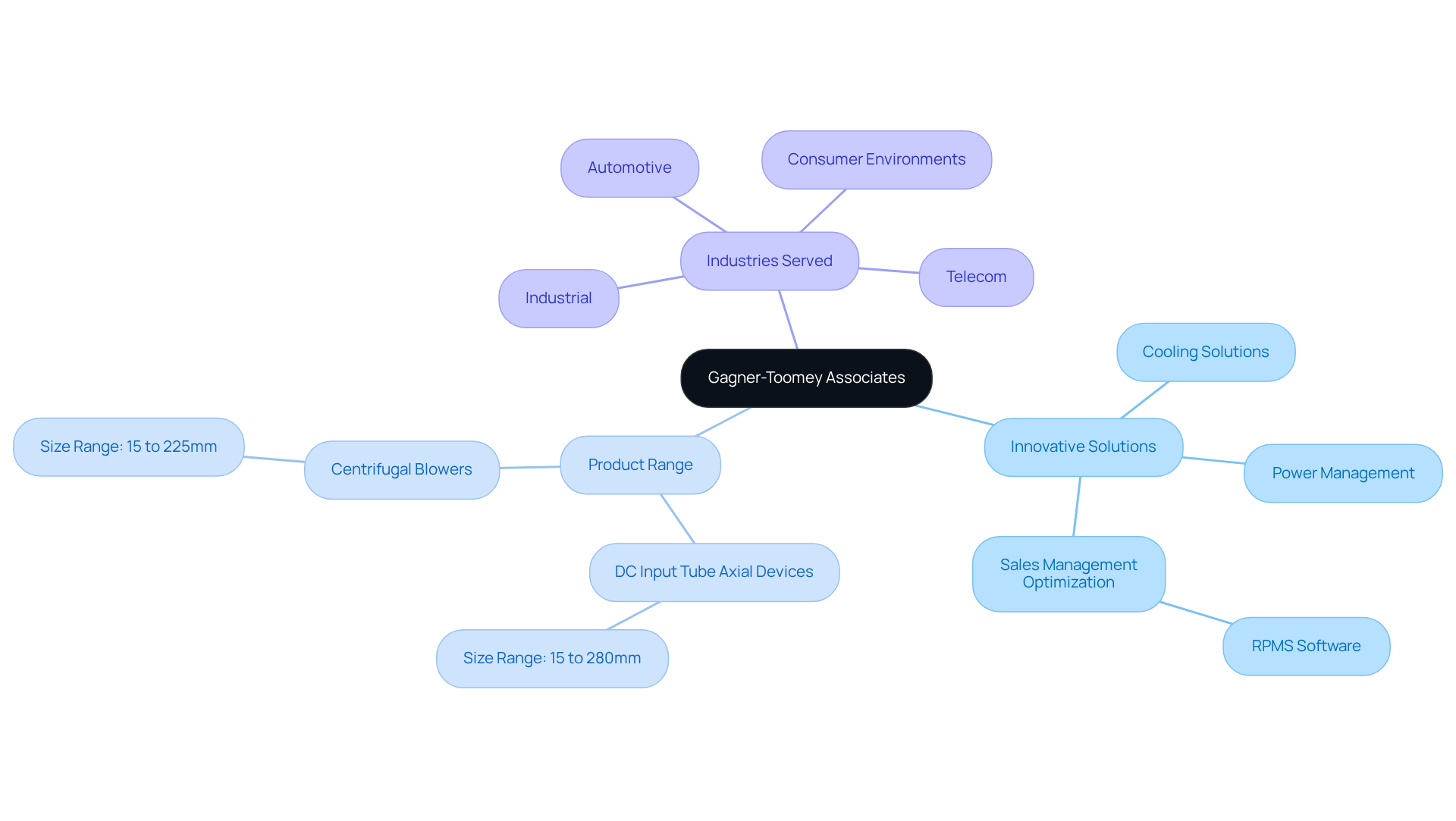

Gagner-Toomey Associates: Innovative Solutions for Blower Exhaust Fans

Gagner-Toomey Associates stands at the forefront of delivering innovative solutions meticulously crafted for engineers within the electronics industry. As the world’s largest producer of both standard and custom air-movers, their expertise in cooling and power management plays a pivotal role in the development of efficient ventilating systems. includes:

- DC input tube axial devices spanning from 15 to 280mm

- Centrifugal blowers from 15 to 225mm

This ensures that clients have access to cutting-edge technologies that enhance performance and reliability across diverse applications, such as industrial, automotive, telecom, and consumer environments. Moreover, by harnessing advanced IT solutions like the RPMS software, Gagner-Toomey optimizes their sales management processes, positioning themselves as a leader in the industry while adeptly addressing the evolving needs of their customers.

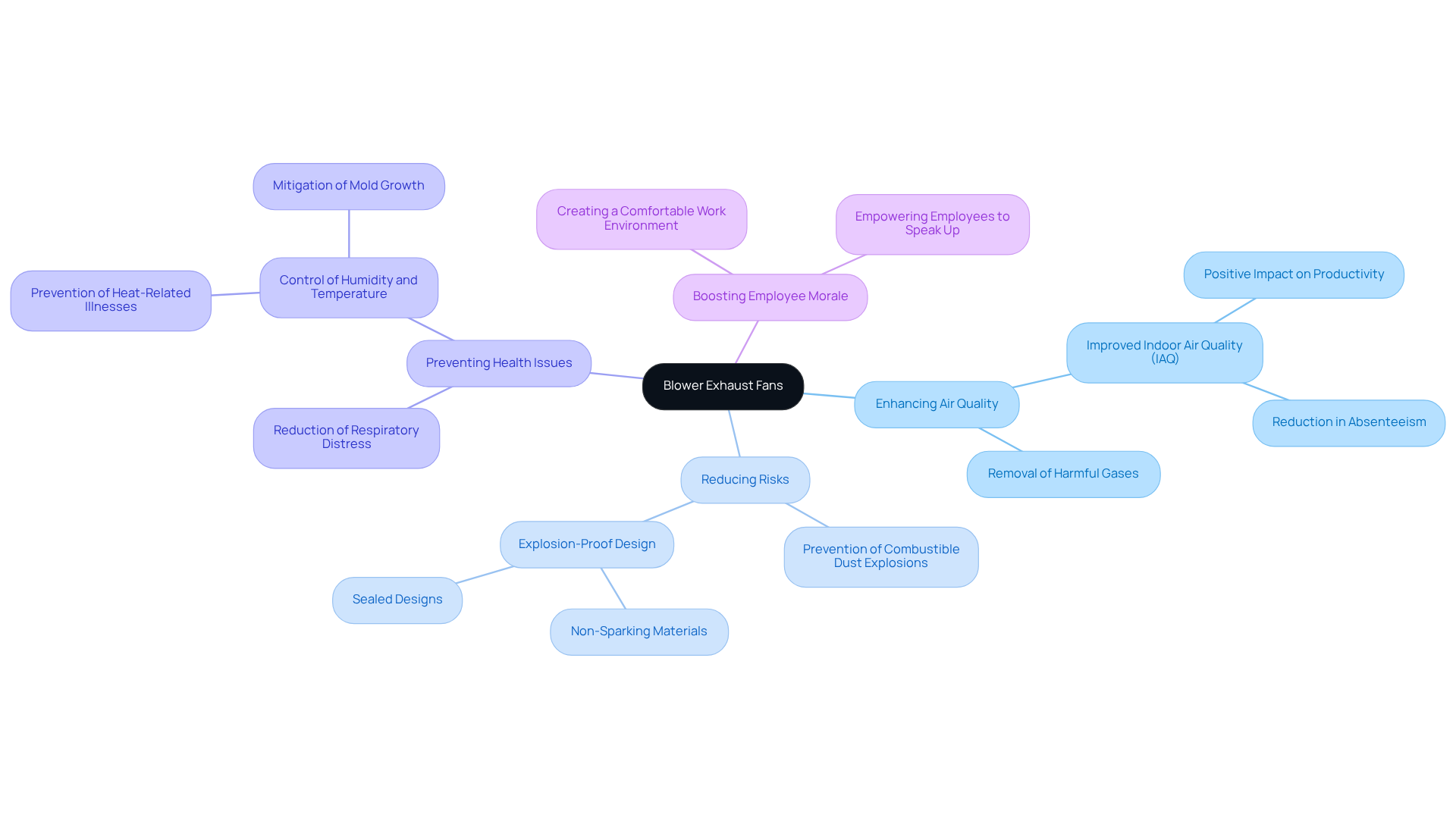

Enhanced Air Quality: The Primary Benefit of Blower Exhaust Fans

Blower exhaust fans are essential in blower ventilation systems for enhancing air quality by effectively eliminating dust, fumes, and airborne contaminants from work environments, particularly in electronics production where delicate components are prevalent. These devices not only foster a cleaner environment but also significantly .

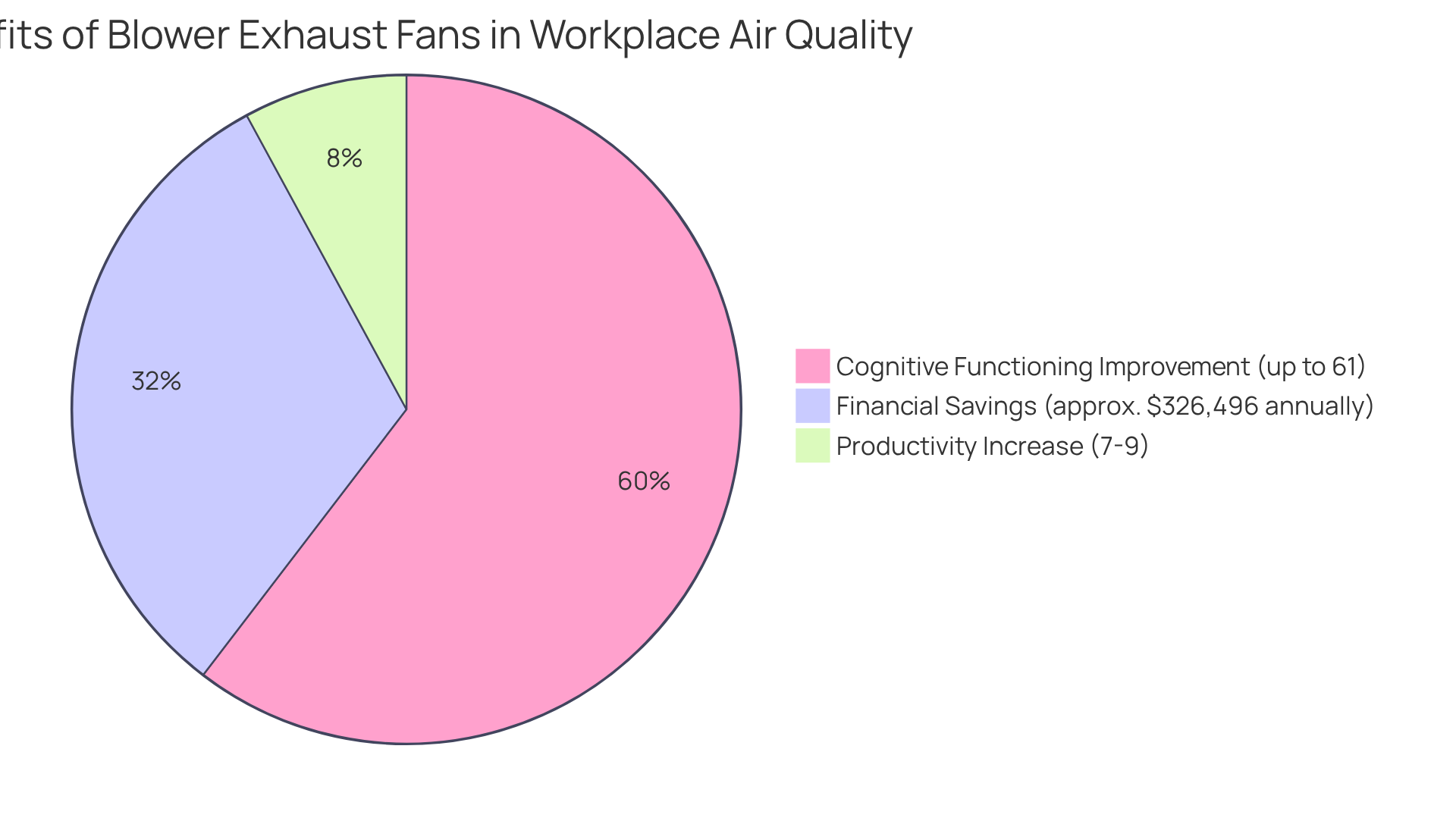

Studies indicate that improved indoor air quality can lead to a productivity increase of 7-9%, and enhancing ventilation can further boost workplace performance by up to 10%, translating to substantial financial savings for companies. Moreover, the continuous flow of air mitigates the risk of respiratory illnesses and allergies, as industrial ventilation systems reduce the likelihood of these health concerns.

Health experts emphasize that maintaining optimal air quality is crucial for employee well-being, with evidence showing that environments equipped with effective ventilation systems can enhance cognitive functioning by up to 61%. Notably, employees in buildings with 1,400 ppm of CO2 score 50% lower on cognitive tests compared to those in buildings with 550 ppm.

By investing in ventilation systems such as a blower exhaust fan, organizations can promote a healthier, more productive work environment, ultimately benefiting both staff and financial performance. Additionally, poor indoor air quality costs a typical office of 100 employees approximately $326,496 annually in wasted salaries and benefits, highlighting the financial incentive for such investments. Furthermore, these devices play a vital role in managing indoor humidity and temperature, assisting in the prevention of heat exhaustion and dehydration among workers.

Energy Efficiency: Cost Savings with Blower Exhaust Fans

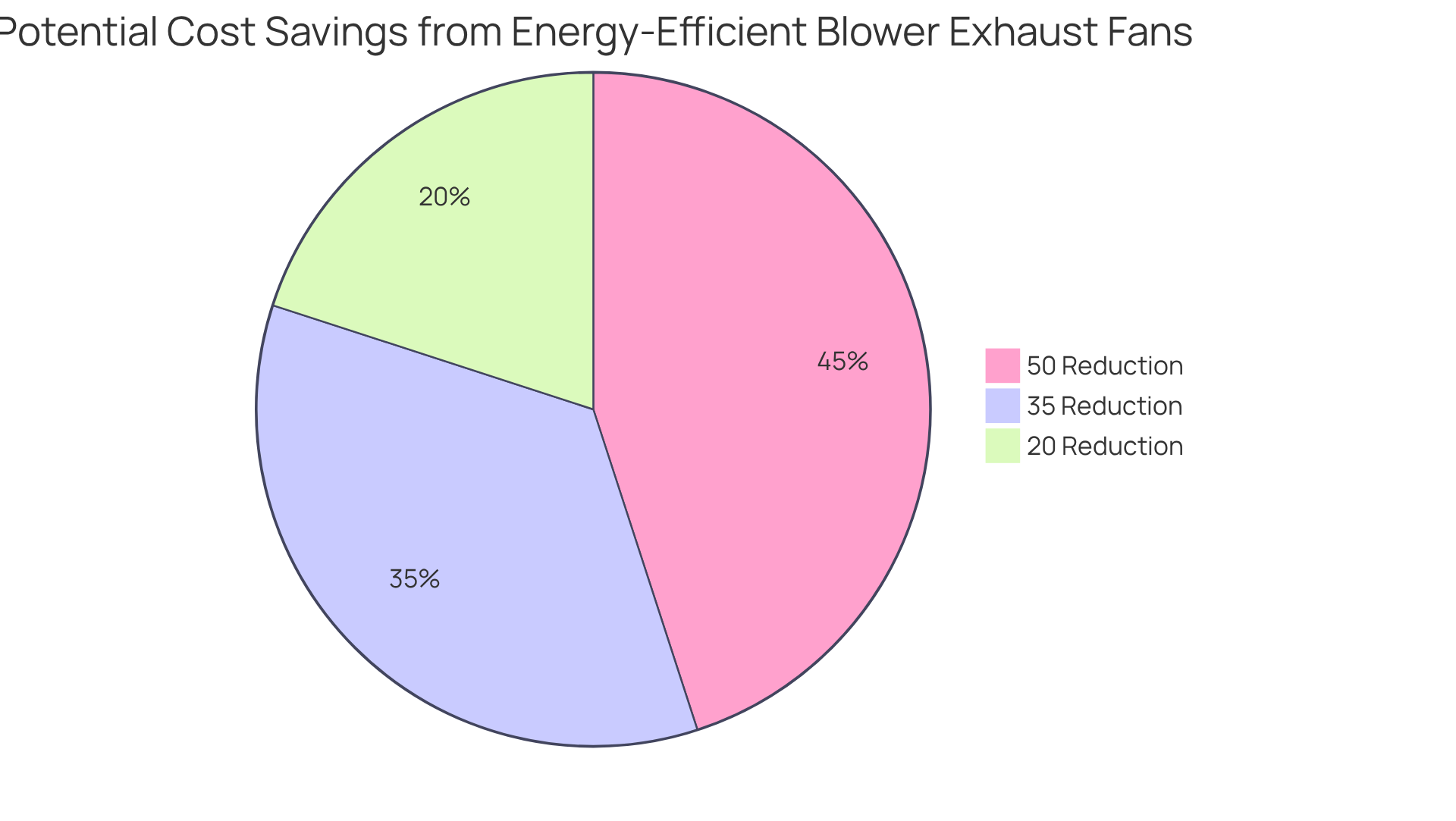

Contemporary blower exhaust fan devices are engineered for energy efficiency, leveraging advanced motor technologies and aerodynamic designs that significantly reduce power consumption. By adopting these devices, companies can achieve substantial cost savings on energy expenses, with reports indicating reductions of 20-50% compared to traditional systems. This improvement is primarily attributed to and optimized airflow patterns. Such efficiency not only lowers operational costs but also bolsters the overall return on investment, as industrial air circulators typically recoup their costs within 8 to 18 months through energy savings, diminished reliance on air conditioning, and reduced maintenance expenses.

Experts in sustainability emphasize that transitioning to energy-efficient ventilation systems transcends mere cost-saving measures; it represents a critical step toward a more sustainable future. Environmental activist Gloria Reuben asserts that investing in clean energy is a commitment to our future, underscoring the necessity of integrating energy efficiency into operational strategies.

Furthermore, the Fan Energy Index (FEI) serves as a valuable metric for design professionals in selecting energy-efficient devices, reinforcing the case for these modern solutions. Regular maintenance is also essential to optimize the efficiency and longevity of the blower exhaust fan systems, ensuring they consistently deliver peak performance.

Versatile Applications: Blower Exhaust Fans for Diverse Workspaces

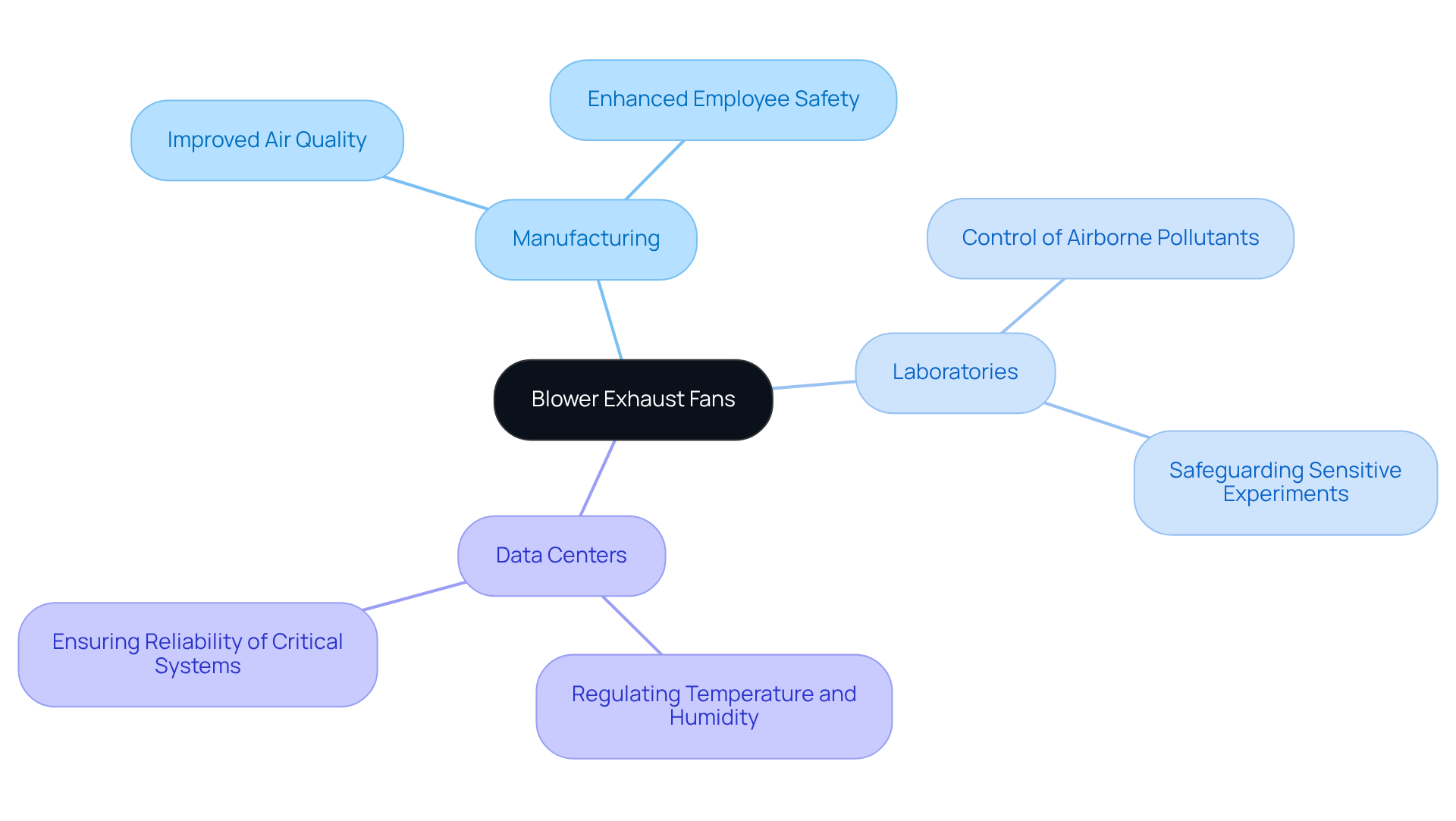

Blower exhaust fans are essential in various environments, including manufacturing plants, laboratories, and data centers. Their adaptability is vital for maintaining optimal conditions, whether for cooling electronic components or ensuring a safe workspace.

In manufacturing, for instance, these devices effectively manage heat and fumes, resulting in improved air quality and enhanced employee safety. In laboratories, air circulation systems are crucial for controlling airborne pollutants, thereby safeguarding sensitive experiments and equipment.

Notably, statistics indicate that approximately 70% of industrial facilities utilize ventilation systems to boost operational efficiency and safety. Additionally, case studies highlight their effectiveness in data centers, where they play a key role in regulating temperature and humidity, thus ensuring the reliability of critical systems.

Engineers have noted that the adaptability of blower exhaust fans allows for tailored solutions that meet specific operational requirements, making them indispensable in various work environments. Their capacity to while delivering robust performance underscores their significance in contemporary industrial applications.

Safety Assurance: Protecting Workers with Blower Exhaust Fans

Blower exhaust fans are pivotal in enhancing workplace safety by effectively removing harmful gases and vapors from the environment. In environments where chemicals are present or heat is generated, the blower exhaust fan plays a crucial role in maintaining safe air quality standards. This proactive approach significantly and health issues. By prioritizing safety, organizations can cultivate a more secure working environment, which is vital for boosting employee morale and productivity.

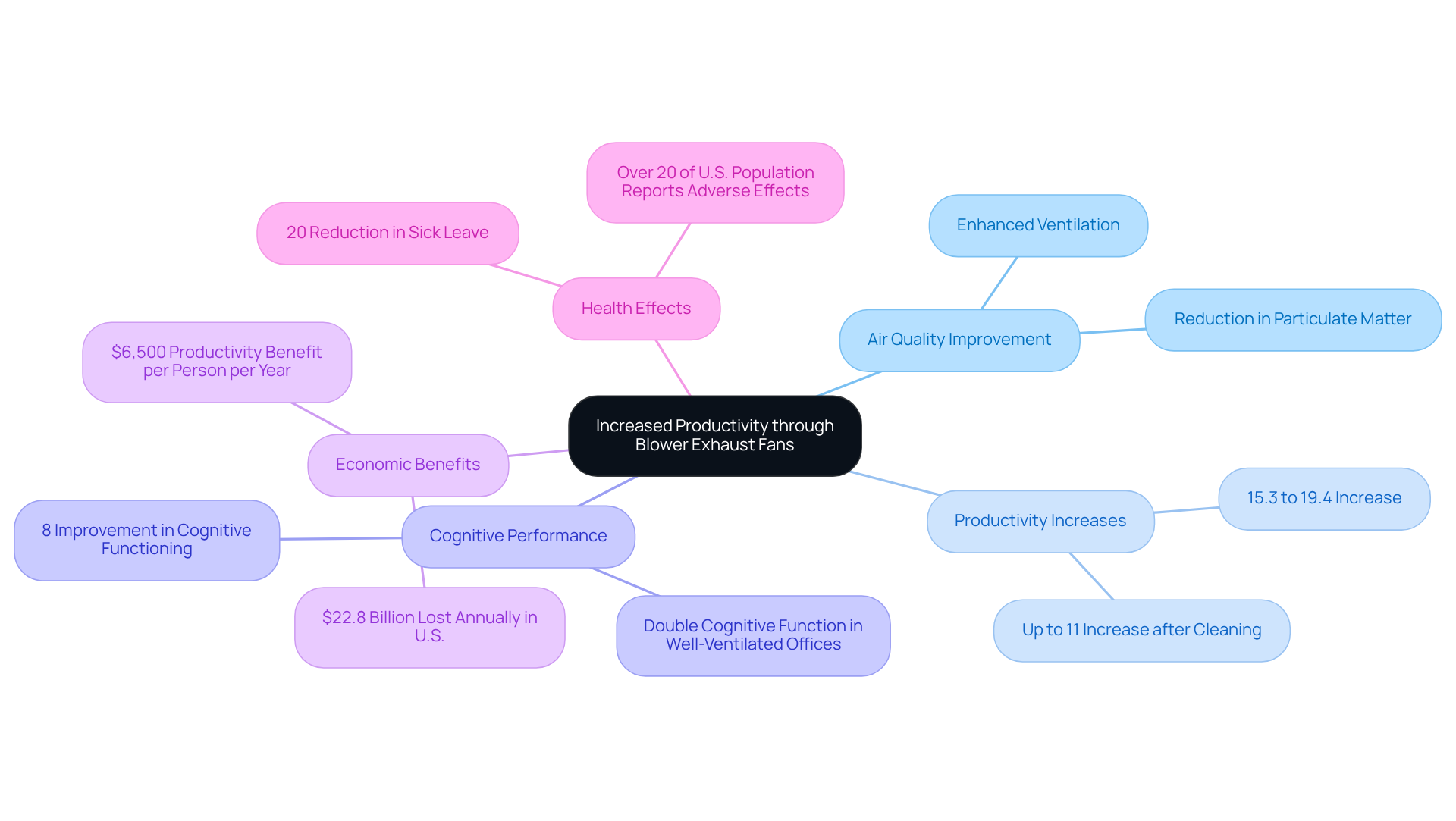

Increased Productivity: How Blower Exhaust Fans Improve Work Conditions

Blower ventilation systems are essential for enhancing air quality and regulating comfortable temperatures, both of which are critical for optimizing employee productivity. Research demonstrates that when workers are free from distractions caused by excessive heat or , they are more likely to perform at their peak.

For example, studies reveal that improving indoor air quality can lead to productivity increases ranging from 15.3% to 19.4% through a significant reduction in particulate matter. Furthermore, environments with optimal ventilation can enhance cognitive function, with employees in well-ventilated spaces displaying double the cognitive performance compared to those in average conditions.

This enhancement in working conditions not only boosts output but also improves the quality of work, ultimately benefiting the organization as a whole. By investing in blower exhaust fan systems, companies can cultivate healthier and more productive work environments, yielding substantial economic advantages.

In fact, the U.S. incurs a staggering $22.8 billion annually in lost productivity due to suboptimal ventilation levels, underscoring the financial motivation for companies to enhance air quality. Additionally, over 20% of the U.S. population reports experiencing adverse health effects from indoor air pollutants, highlighting the broader implications of air quality on employee well-being.

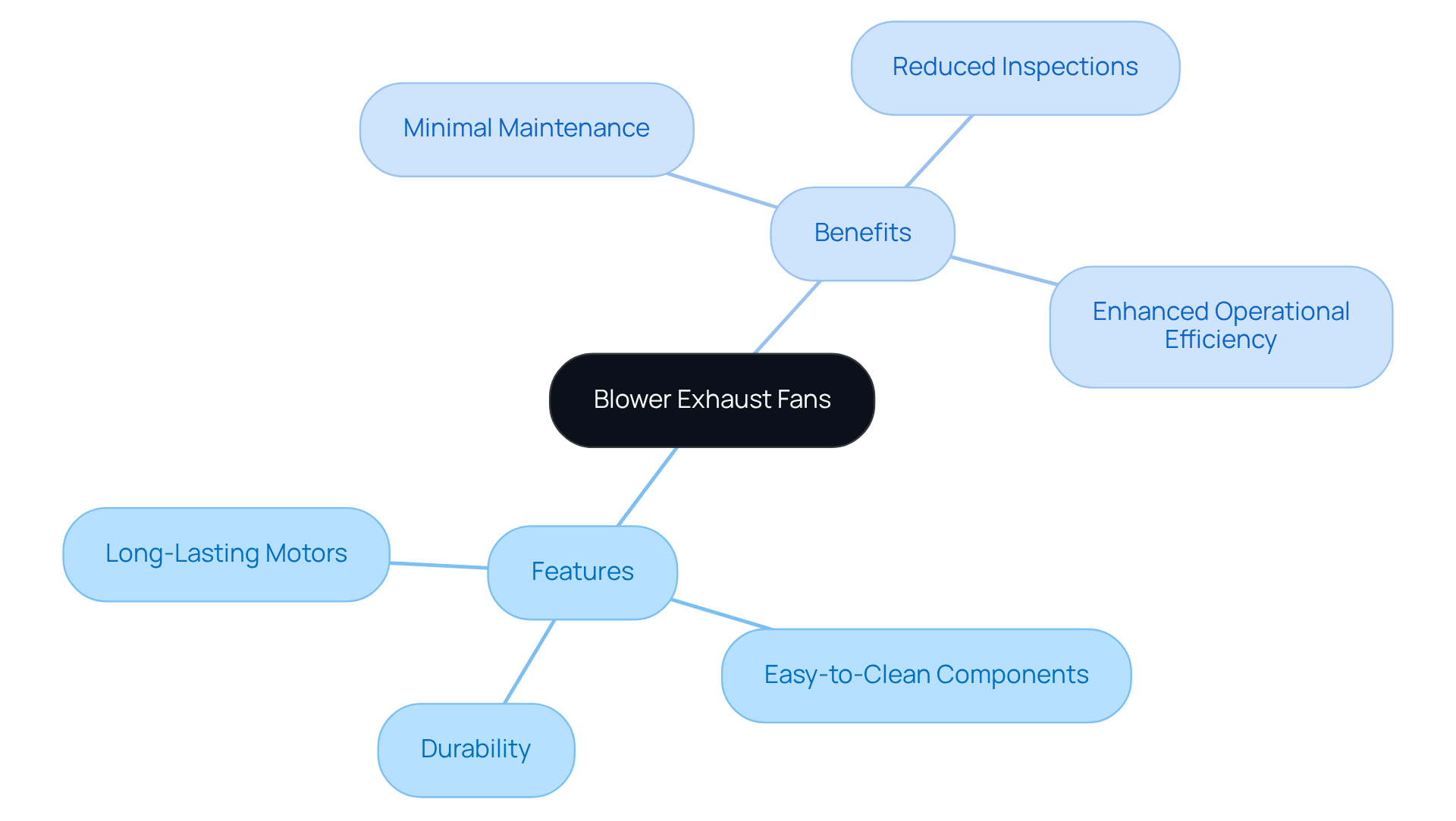

Low Maintenance: Simplifying Upkeep with Blower Exhaust Fans

Blower exhaust fans are engineered for durability and require minimal maintenance, significantly easing the workload for engineering teams. Numerous models incorporate easy-to-clean components alongside long-lasting motors that necessitate little servicing. This inherent reliability not only reduces the frequency of maintenance inspections but also ensures that the blower exhaust fan over time, thereby enhancing overall operational efficiency.

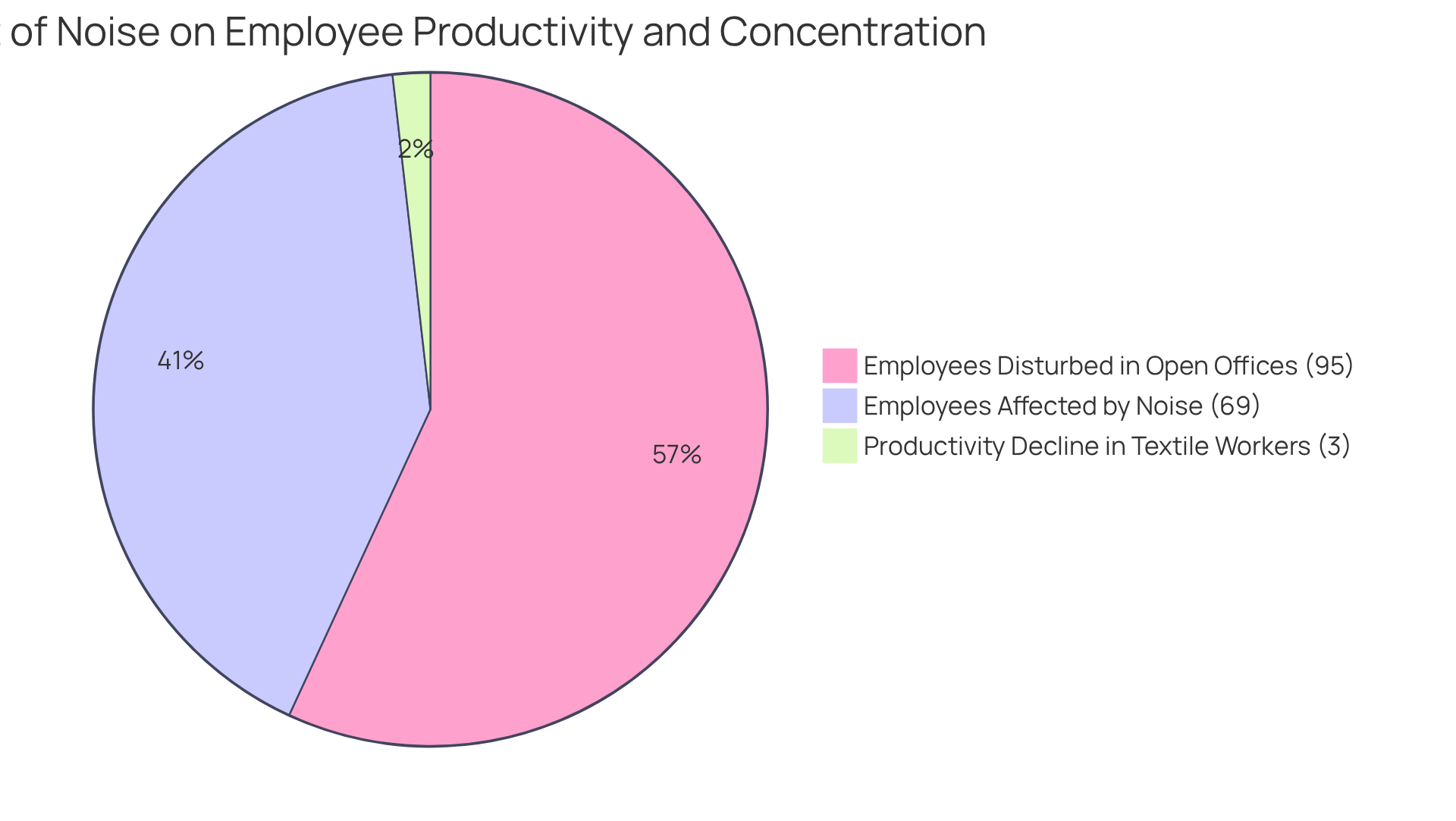

Noise Reduction: Creating a Quieter Workspace with Blower Exhaust Fans

Contemporary ventilation systems are meticulously designed for silent performance, a critical factor in fostering a pleasant and efficient workplace. By effectively minimizing noise levels, these systems enable employees to concentrate on their tasks without the distractions that excessive sound can create. This is especially crucial in settings such as offices and laboratories, where maintaining focus is essential for achieving peak productivity.

Research shows that increased noise can reduce productivity by 3% among textile factory workers learning to operate sewing machines. Additionally, a significant 69% of employees report that noise adversely affects their concentration, while 95% indicate being disturbed in open offices due to noise from conversations, ringing phones, or machinery.

Experts in workplace environments stress that mitigating noise not only enhances employee comfort but also contributes to overall workplace satisfaction and efficiency. Ben Hancock asserts, “noise may seem a minor irritant, but not addressing this could hurt your business’s bottom line and put your employees’ health at risk.”

As organizations increasingly acknowledge the link between a quieter workspace and enhanced employee performance, investing in noise-reduction technologies becomes imperative for sustaining high productivity levels. The financial burden of is substantial, averaging 3,840 euros per employee annually, underscoring the importance of silent ventilation systems in achieving both comfort and efficiency.

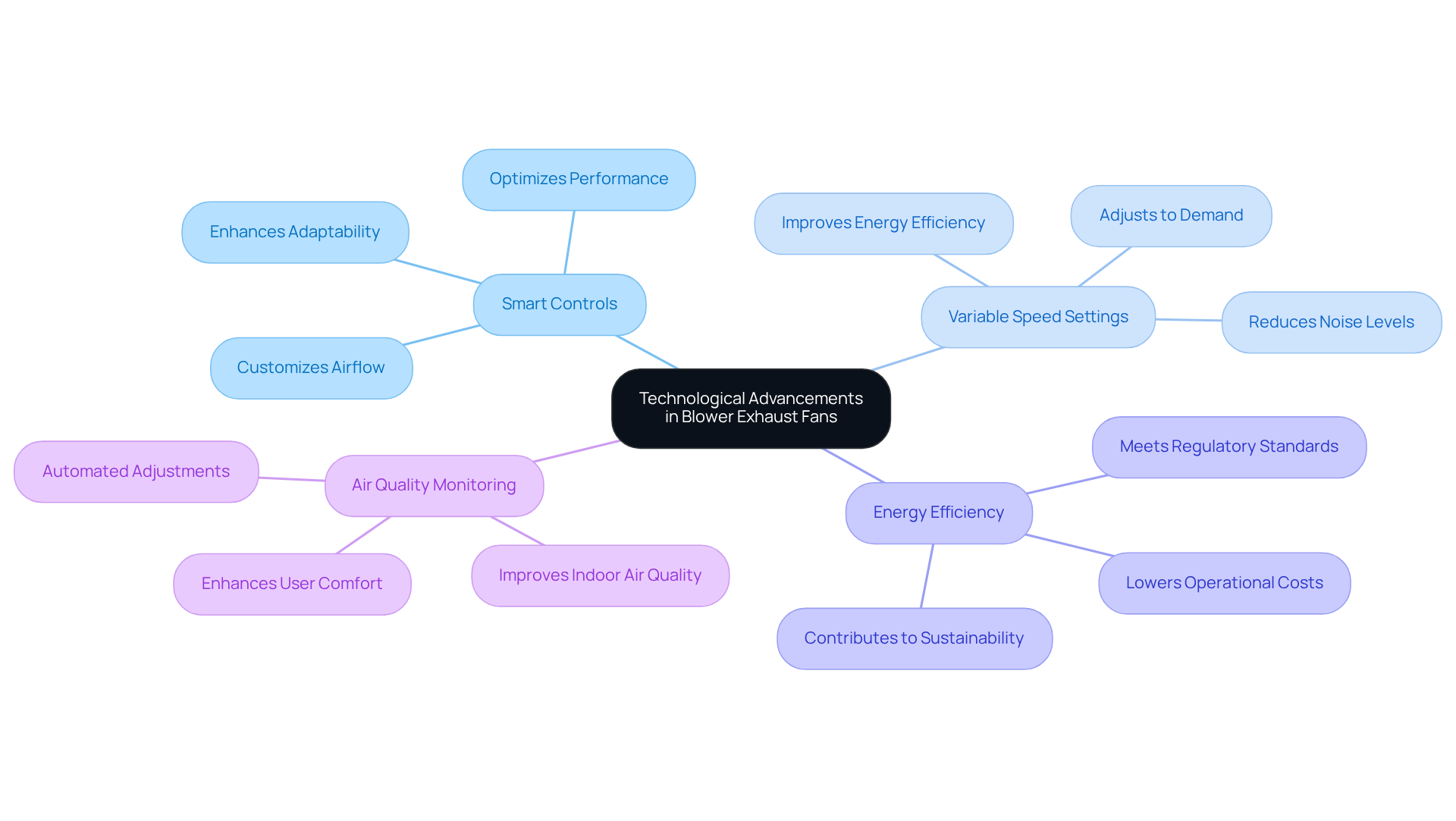

Technological Advancements: Modern Features of Blower Exhaust Fans

Recent advancements in blower exhaust fan technology have introduced smart controls, variable speed settings, and energy-efficient designs, significantly enhancing their functionality. These innovations empower engineers to customize airflow to meet specific operational requirements, thereby optimizing both performance and energy consumption. For instance, many contemporary devices, such as a blower exhaust fan, are now equipped with sensors that continuously monitor air quality, automatically adjusting their operation to maintain optimal conditions. This capability not only improves air quality but also contributes to , aligning with the increasing demand for sustainable solutions.

The centrifugal fan market is projected to expand from USD 2.69 billion in 2023 to USD 4.01 billion by 2032, reflecting a CAGR of 4.54%. As the market for intelligent ventilation systems is anticipated to grow in 2025, driven by rising regulatory demands and a focus on operational efficiency, engineers are increasingly recognizing the significance of these advanced features. Real-world applications illustrate that the integration of smart technology, such as blower exhaust fans, into ventilation systems can lead to substantial improvements in both performance and compliance with environmental standards. According to industry experts, the implementation of smart controls has been crucial in enhancing operational efficiency, with many engineers observing that these features enable better adaptability to fluctuating environmental conditions.

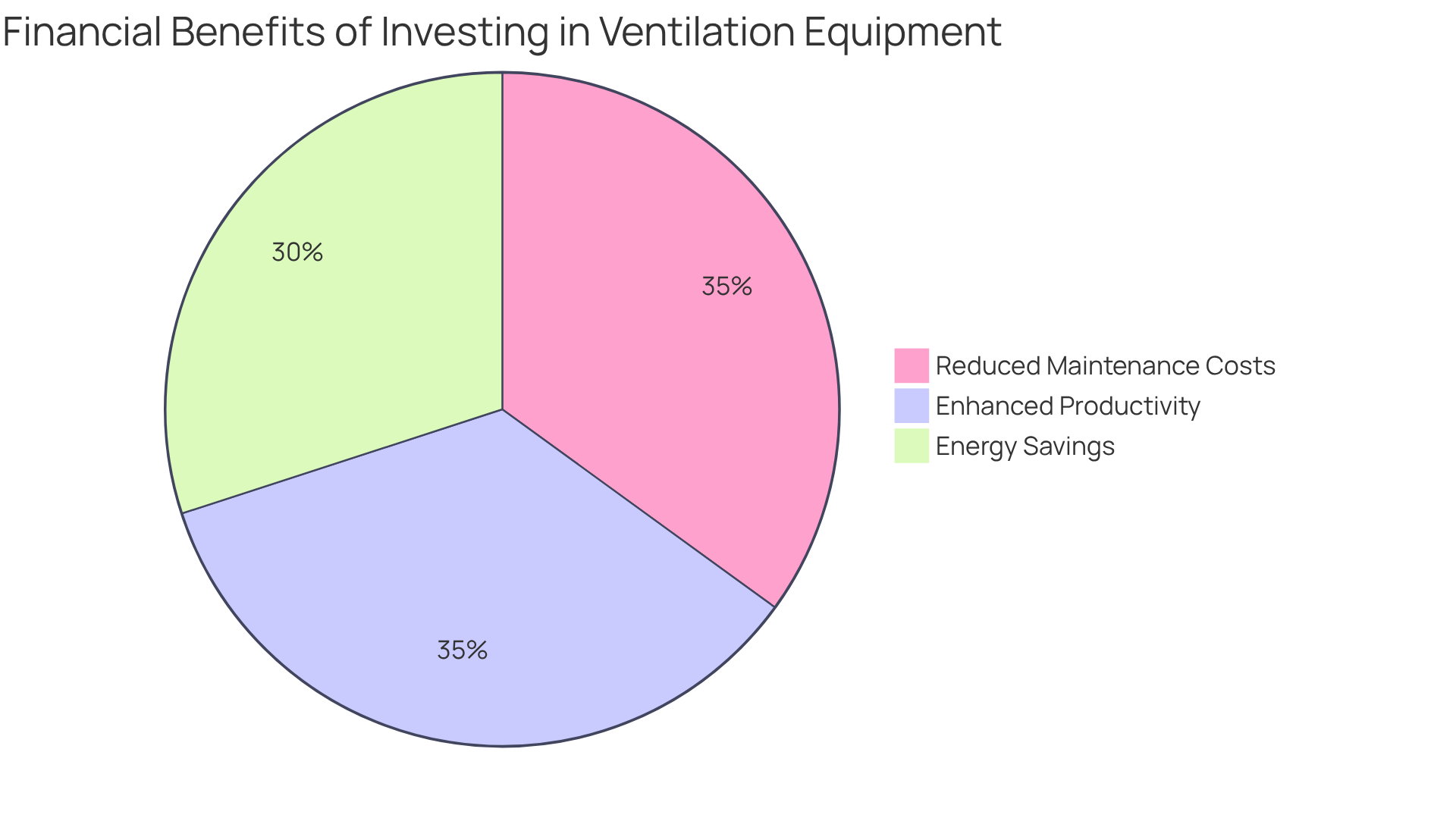

Return on Investment: Evaluating the Financial Benefits of Blower Exhaust Fans

Investing in ventilation equipment presents substantial gains through energy savings, reduced maintenance costs, and enhanced productivity. A comprehensive calculation of the total cost of ownership—including initial investment and ongoing operational expenses—enables engineers to pinpoint the financial advantages with precision. For example, energy-efficient equipment in manufacturing can yield ROI statistics demonstrating savings of up to 30% on energy bills.

Moreover, the installation of not only bolsters safety by guaranteeing optimal air quality but also fosters a more efficient work environment. Case studies indicate that companies have witnessed a notable decline in downtime and maintenance expenses, further validating the investment.

As the market for ventilation systems continues to grow, with forecasts predicting a compound annual growth rate (CAGR) of 6.8% from 2025 to 2033, the financial benefits of investing in these systems become increasingly compelling. Financial analysts assert that the long-term savings and productivity enhancements make blower exhaust fans a prudent investment for any manufacturing facility.

Conclusion

Blower exhaust fans are indispensable tools for engineers, particularly in the electronics sector, where maintaining optimal air quality is crucial. These advanced devices not only enhance workplace safety and productivity but also contribute to significant energy savings and reduced maintenance needs. By understanding and leveraging the advantages of blower exhaust fans, engineers can create healthier, more efficient work environments that benefit both employees and the bottom line.

Throughout this article, we have highlighted key benefits of blower exhaust fans, including:

- Improved air quality

- Energy efficiency

- Versatile applications

- Enhanced workplace safety

The ability of these fans to reduce operational costs while simultaneously promoting employee health and productivity underscores their value in various industrial settings. Additionally, the low maintenance requirements and modern technological advancements further solidify their status as essential components in effective ventilation systems.

Ultimately, investing in blower exhaust fans is not just a practical decision; it is a strategic move towards fostering a sustainable and productive workplace. As organizations prioritize employee well-being and operational efficiency, the integration of these innovative solutions will play a pivotal role in shaping the future of industrial environments. Embracing the benefits of blower exhaust fans can lead to a healthier workforce, increased productivity, and substantial financial gains, making them a vital consideration for any engineering project.

Frequently Asked Questions

What type of products does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a range of products including DC input tube axial devices ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, designed for cooling and power management in various applications.

How do blower exhaust fans improve air quality?

Blower exhaust fans enhance air quality by effectively removing dust, fumes, and airborne contaminants from work environments, particularly in electronics production, leading to a cleaner environment and better health outcomes for workers.

What impact does improved indoor air quality have on productivity?

Studies indicate that improved indoor air quality can lead to a productivity increase of 7-9%, with enhanced ventilation potentially boosting workplace performance by up to 10%.

What are the financial implications of poor indoor air quality?

Poor indoor air quality can cost a typical office of 100 employees approximately $326,496 annually in wasted salaries and benefits, highlighting the financial incentive for investing in ventilation systems.

How do blower exhaust fans contribute to employee health?

By maintaining optimal air quality, blower exhaust fans reduce the risk of respiratory illnesses and allergies, promoting overall employee well-being and enhancing cognitive functioning.

What energy efficiency benefits do modern blower exhaust fans provide?

Contemporary blower exhaust fans are designed for energy efficiency, achieving power consumption reductions of 20-50% compared to traditional systems, resulting in substantial cost savings on energy expenses.

What is the typical return on investment for industrial air circulators?

Industrial air circulators typically recoup their costs within 8 to 18 months through energy savings, reduced reliance on air conditioning, and lower maintenance expenses.

Why is regular maintenance important for blower exhaust fans?

Regular maintenance is essential to optimize the efficiency and longevity of blower exhaust fan systems, ensuring they consistently deliver peak performance.

What is the Fan Energy Index (FEI)?

The Fan Energy Index (FEI) is a valuable metric for design professionals to select energy-efficient devices, reinforcing the importance of modern, efficient ventilation solutions.