Overview

The article delineates ten significant benefits of centrifugal industrial blowers for engineers, underscoring their efficiency, versatility, reliability, low maintenance, and environmental advantages. Each benefit is substantiated by specific features, including high airflow capabilities and durability in harsh conditions. These attributes collectively enhance operational efficiency and cost-effectiveness across diverse industrial applications.

Introduction

Centrifugal industrial blowers are revolutionizing the field of engineering, delivering an exceptional combination of efficiency and versatility that cannot be overlooked. As industries increasingly seek sustainable solutions in the face of escalating operational costs, these blowers offer engineers a remarkable opportunity to optimize performance across a multitude of applications—from HVAC systems to food processing. Yet, with a plethora of options available, it is essential to explore the specific advantages that centrifugal blowers provide and how they can effectively tackle the evolving challenges encountered in modern engineering.

Gagner-Toomey Associates: Innovative Solutions for Centrifugal Industrial Blowers

Gagner-Toomey Associates is leading the way in offering advanced centrifugal industrial blowers specifically designed for the electronics sector. As the leading producer of both standard and custom air-movers globally, they empower engineers with access to an extensive array of products, including centrifugal industrial blowers with DC input ranging from 15 to 225mm.

By partnering with top manufacturers, Gagner-Toomey guarantees that engineers benefit from cutting-edge innovations in cooling and power management technologies. Their commitment to excellence is reflected in their ability to deliver both standard and customized solutions, such as integrated cooling systems that enhance performance and efficiency across diverse applications.

Moreover, Gagner-Toomey harnesses sophisticated IT tools, including the RPMS software, to optimize sales management and foster growth, solidifying their position as a trusted partner for engineers in search of reliable airflow solutions.

Energy Efficiency: Reducing Operational Costs with Centrifugal Blowers

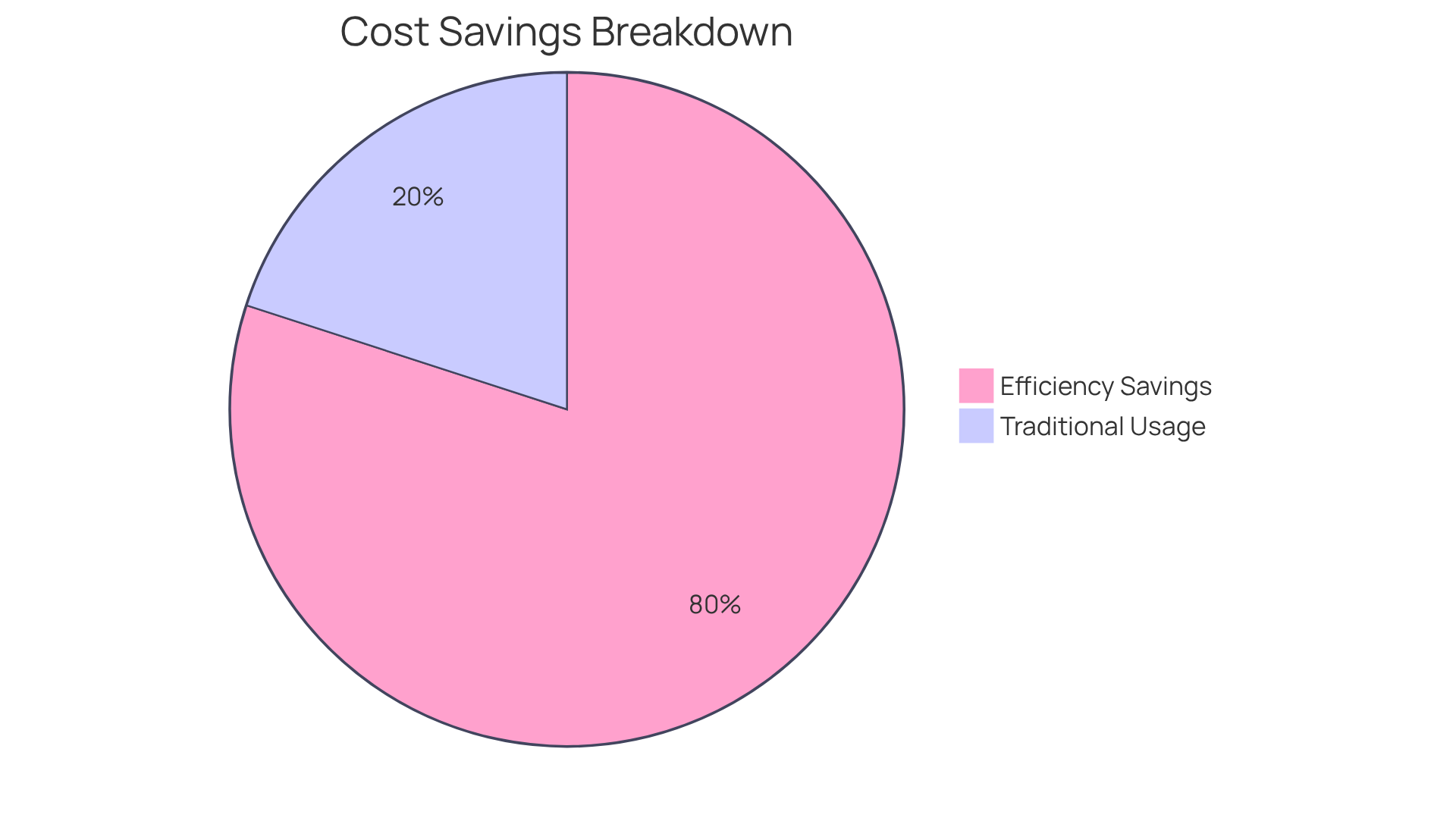

Centrifugal industrial blowers are engineered for high efficiency, often achieving performance levels of up to 80%. This remarkable efficiency translates into significant cost savings on utility bills, positioning them as an attractive option for industries focused on reducing operational expenses.

By leveraging advanced motor technologies and optimized impeller designs, these devices effectively minimize energy consumption while sustaining high airflow rates. Consequently, they provide a sustainable solution for industrial applications with a centrifugal industrial blower. The integration of such technology not only enhances operational efficiency but also aligns with the growing demand for environmentally responsible practices.

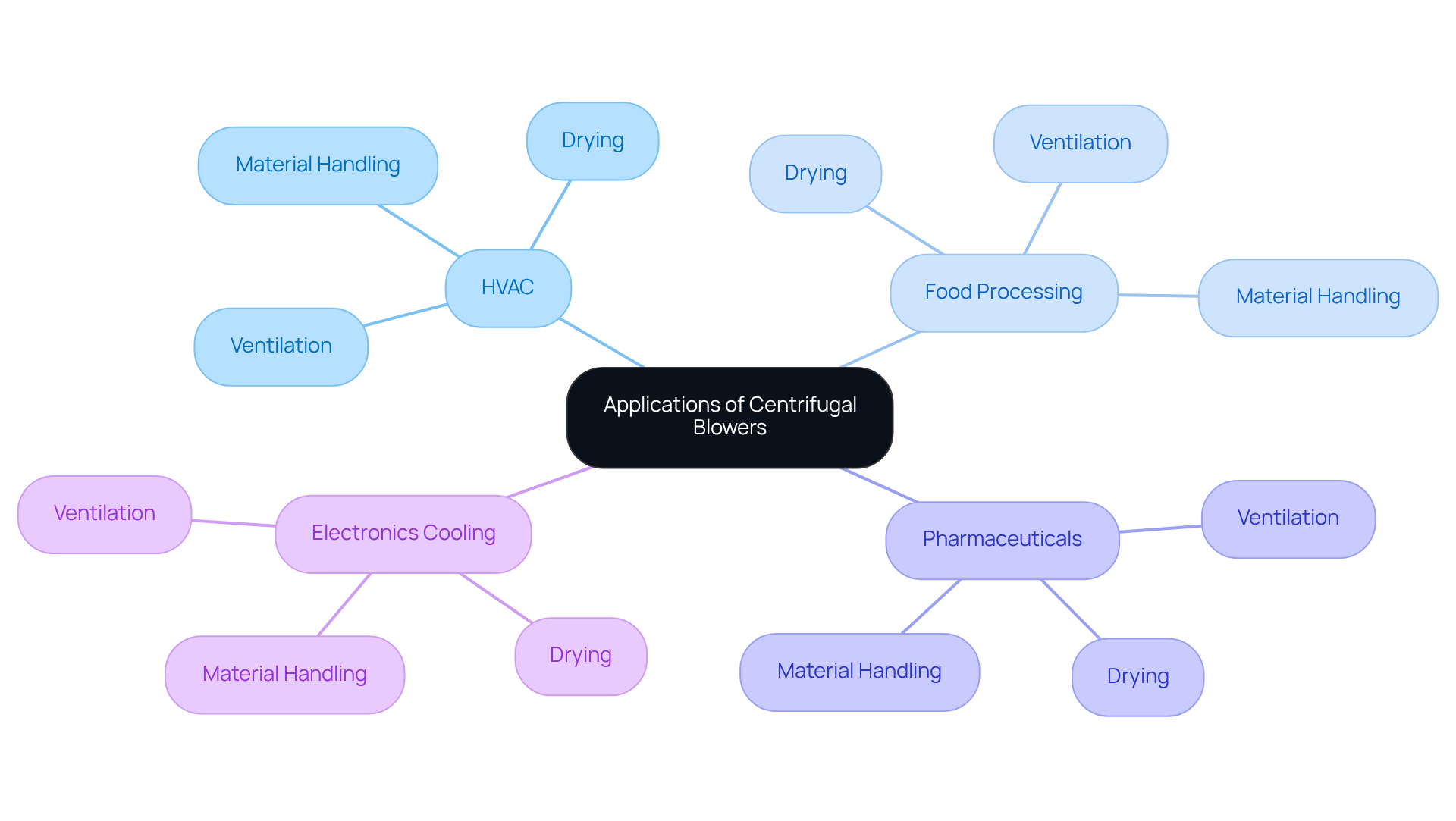

Versatility: Applications of Centrifugal Blowers in Diverse Industries

Centrifugal industrial blowers are integral to a wide array of sectors, including HVAC, food processing, pharmaceuticals, and electronics cooling. The capacity of a centrifugal industrial blower to generate significant pressure and airflow renders it indispensable for applications such as:

- Drying

- Ventilation

- Material handling

This versatility empowers engineers to seamlessly integrate centrifugal fans into diverse systems, thereby enhancing performance and efficiency across numerous industries.

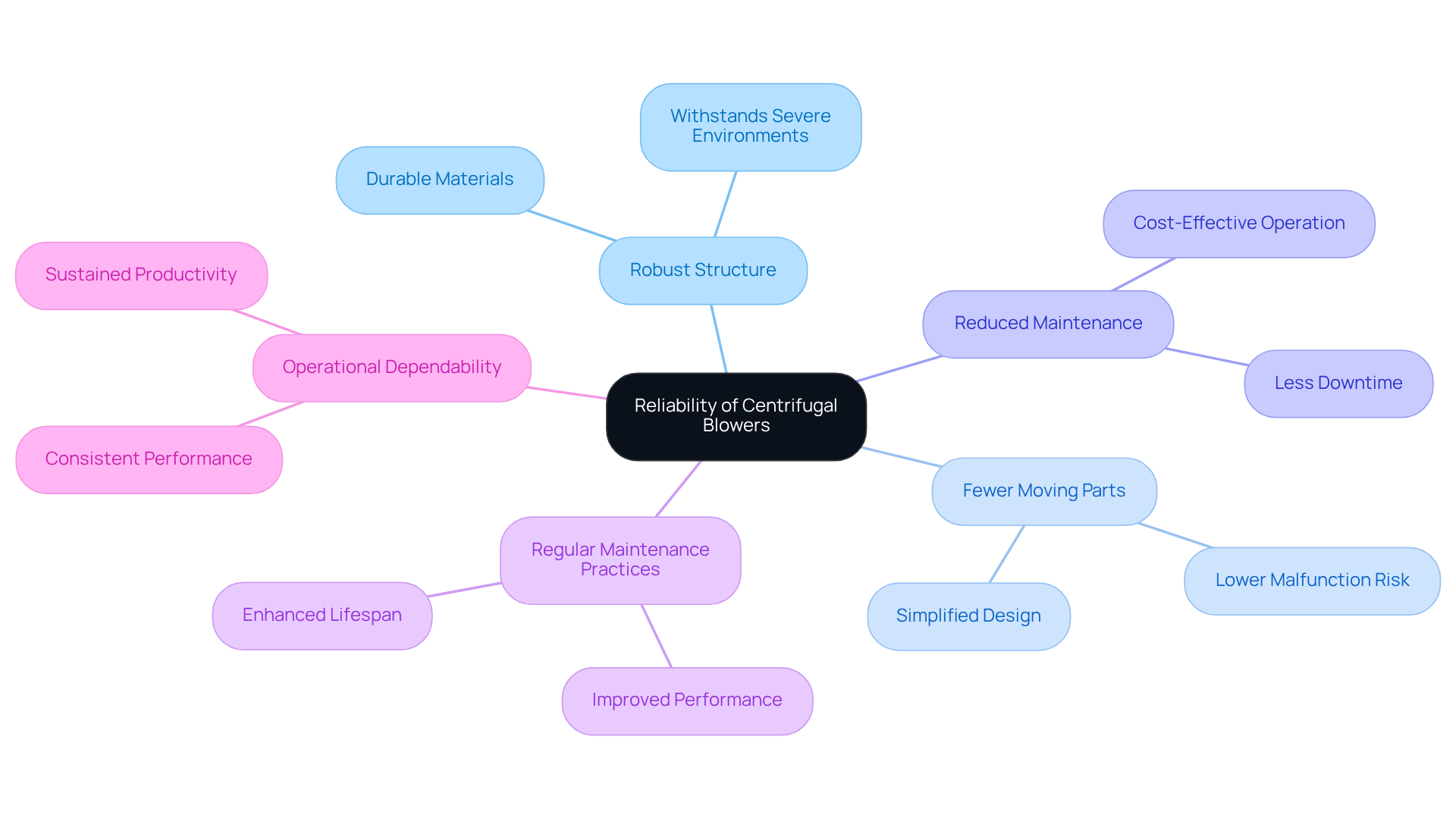

Reliability: Ensuring Consistent Performance with Centrifugal Blowers

Centrifugal industrial blowers exemplify dependability, featuring robust structures engineered to withstand severe operating environments. Their design incorporates fewer moving components than other fan types, resulting in reduced maintenance needs and a lower susceptibility to malfunction. The inherent reliability of the centrifugal industrial blower guarantees consistent performance, enabling industries to sustain productivity without interruptions. Furthermore, implementing regular maintenance practices not only enhances their lifespan but also bolsters operational dependability.

Low Maintenance: Simplifying Operations with Centrifugal Blowers

One of the most notable characteristics of centrifugal fans is their minimal maintenance requirement. Designed with longevity as a primary focus, the centrifugal industrial blower often features self-cleaning systems and robust materials that significantly reduce wear and tear. Typically, regular inspections and basic upkeep suffice to ensure their efficient operation. This allows engineers to concentrate on core operations rather than being burdened by extensive maintenance tasks.

Enhanced Airflow: Improving Ventilation with Centrifugal Blowers

Fans excel at enhancing airflow, making them indispensable for effective ventilation. By generating high static pressure, centrifugal industrial blowers efficiently move substantial volumes of air, ensuring that environments remain well-ventilated and free of contaminants. This functionality is especially critical in industrial settings, where a centrifugal industrial blower plays a vital role in maintaining air quality, which is paramount for both worker safety and optimal equipment performance.

Durability: Robust Performance of Centrifugal Blowers in Harsh Environments

These fans are engineered to withstand challenging conditions, featuring robust construction and high-quality materials that resist rust and deterioration. This exceptional durability of the centrifugal industrial blower guarantees effective operation in extreme temperatures, elevated humidity, and dusty environments, making it ideal for applications in industries such as:

- Mining

- Agriculture

- Manufacturing

Their extended lifespan minimizes the necessity for frequent replacements, significantly enhancing their cost-effectiveness.

Noise Reduction: Creating Quieter Workspaces with Centrifugal Blowers

Fans are engineered with noise reduction as a paramount concern, employing advanced engineering techniques to minimize sound levels during operation. By incorporating features such as sound-absorbing materials and optimized blade designs, these fans significantly mitigate noise, fostering a more comfortable working environment. This aspect is particularly crucial in settings where excessive noise can distract workers or impair the performance of sensitive equipment. The integration of these innovative solutions not only enhances workplace comfort but also safeguards the efficiency of operations.

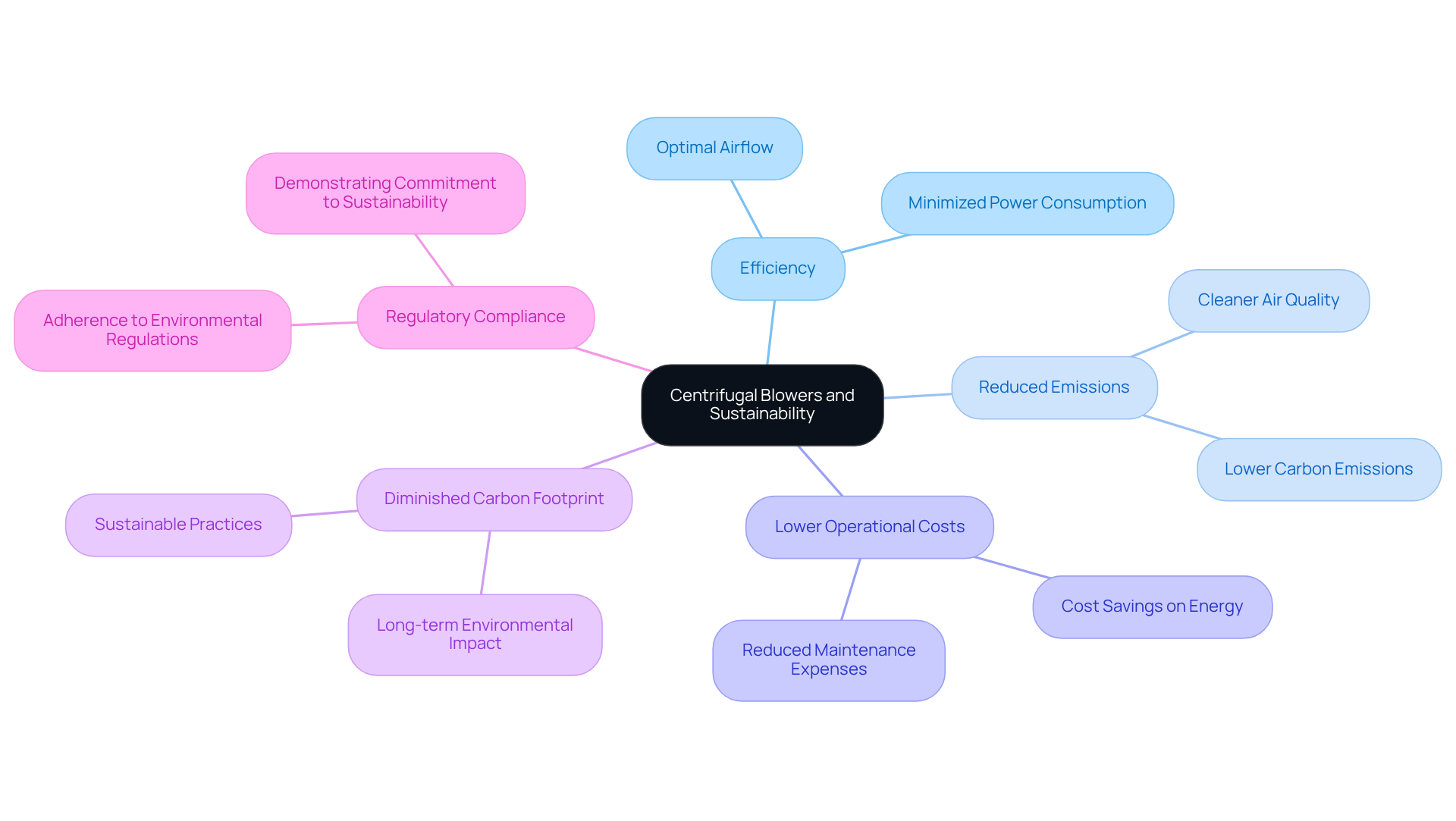

Environmental Benefits: Promoting Sustainability with Centrifugal Blowers

Centrifugal industrial blowers play a pivotal role in promoting environmental sustainability by significantly enhancing efficiency and reducing emissions. The innovative design of the centrifugal industrial blower facilitates optimal airflow while minimizing power consumption, which not only lowers operational costs but also diminishes the carbon footprint associated with industrial processes. By integrating these fans into their operational systems, companies can effectively comply with stringent environmental regulations and demonstrate a strong commitment to sustainable practices.

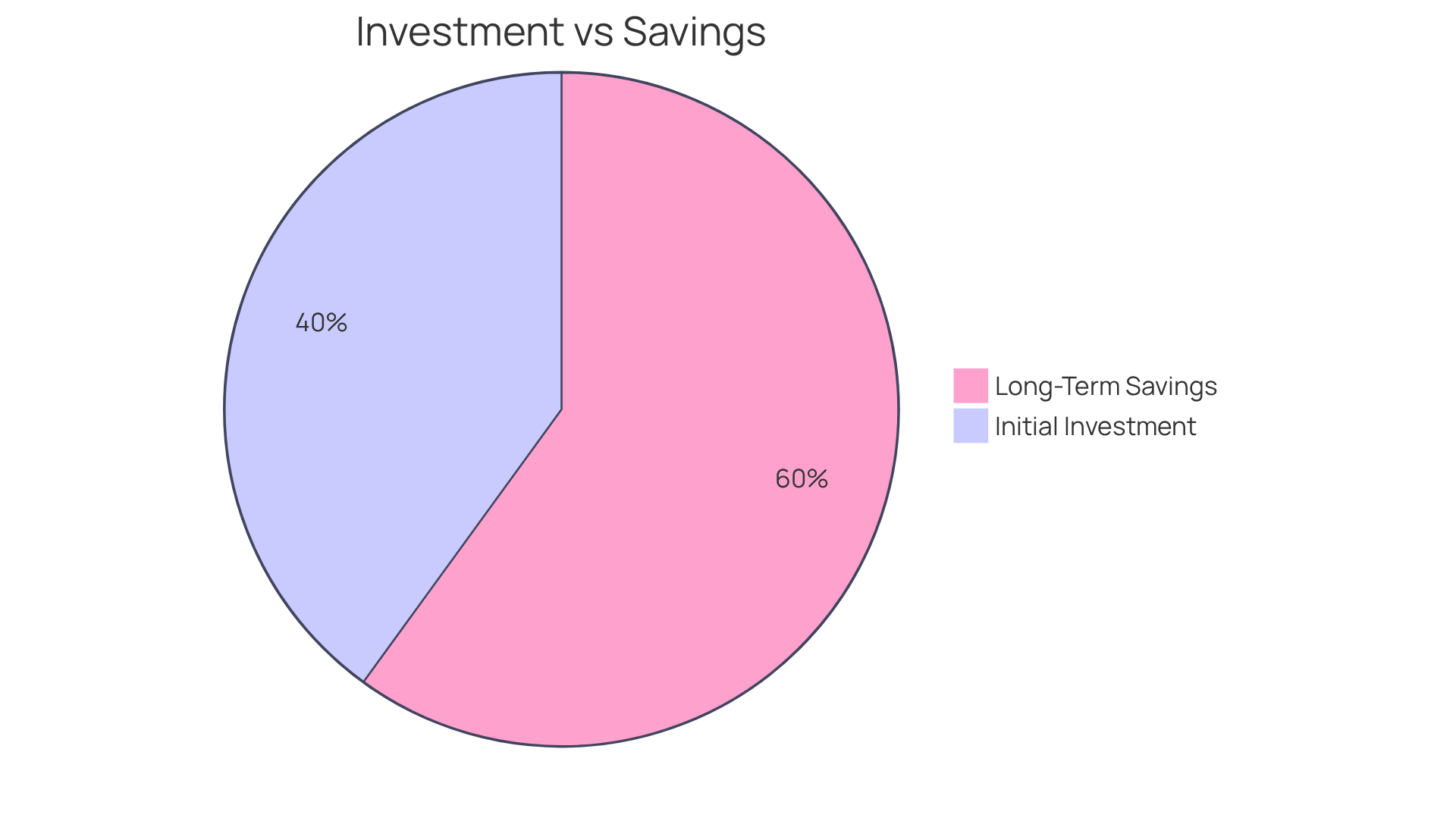

Cost-Effectiveness: Maximizing Value with Centrifugal Blowers

Centrifugal industrial blowers stand out for their remarkable cost-effectiveness, driven by their efficiency, minimal maintenance requirements, and impressive longevity. Although the initial investment in a centrifugal industrial blower may exceed that of alternative blower types, the substantial long-term savings on energy bills, along with reduced maintenance costs, make it a prudent choice for numerous industries. Furthermore, their inherent reliability and performance empower businesses to sustain productivity without facing unexpected expenses, ultimately maximizing the return on investment.

Conclusion

Centrifugal industrial blowers signify a crucial advancement in engineering solutions, delivering exceptional benefits that bolster operational efficiency and sustainability across diverse industries. Their design not only optimizes airflow and energy efficiency but also guarantees reliability and minimal maintenance, establishing them as an indispensable component for engineers striving to enhance system performance while complying with environmental standards.

Key insights from the discussion underscore the versatility of centrifugal blowers, as they serve applications in sectors ranging from HVAC to food processing, illustrating their capability to address varied industrial needs. The focus on energy savings and diminished operational costs further underscores the practicality of these blowers, while their durability assures long-lasting performance even in demanding environments. Moreover, the noise reduction features foster a more conducive working atmosphere, thereby enhancing overall productivity.

Ultimately, the integration of centrifugal industrial blowers into engineering systems is not merely a choice but a strategic decision that aligns with the objectives of efficiency, sustainability, and cost-effectiveness. As industries increasingly prioritize eco-friendly practices and operational excellence, investing in these advanced blowers becomes increasingly imperative. Embracing this technology not only supports individual business objectives but also contributes to a broader commitment to environmental stewardship and innovation in engineering.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for offering advanced centrifugal industrial blowers specifically designed for the electronics sector, and is the leading producer of both standard and custom air-movers globally.

What types of centrifugal blowers does Gagner-Toomey offer?

Gagner-Toomey provides centrifugal industrial blowers with DC input ranging from 15 to 225mm, along with both standard and customized solutions.

How does Gagner-Toomey ensure innovation in their products?

Gagner-Toomey partners with top manufacturers to guarantee that engineers benefit from cutting-edge innovations in cooling and power management technologies.

What tools does Gagner-Toomey use to enhance their operations?

Gagner-Toomey utilizes sophisticated IT tools, including the RPMS software, to optimize sales management and foster growth.

What is the efficiency level of centrifugal industrial blowers?

Centrifugal industrial blowers can achieve performance levels of up to 80%, leading to significant cost savings on utility bills.

How do centrifugal blowers contribute to energy efficiency?

They leverage advanced motor technologies and optimized impeller designs to minimize energy consumption while maintaining high airflow rates, making them a sustainable solution for industrial applications.

In which industries are centrifugal blowers commonly used?

Centrifugal blowers are integral to various sectors, including HVAC, food processing, pharmaceuticals, and electronics cooling.

What applications can centrifugal blowers be used for?

They are used for applications such as drying, ventilation, and material handling, enhancing performance and efficiency in diverse systems.