Overview

The article delineates ten compelling benefits of circular fans in electronics cooling solutions, underscoring their energy efficiency, design flexibility, low noise operation, and cost-effectiveness. These advantages are substantiated by evidence demonstrating improved airflow efficiency, reduced energy consumption, and adaptability to diverse electronic applications. Consequently, circular fans emerge as a crucial element in contemporary temperature management systems.

Introduction

In the realm of electronics cooling, Gagner-Toomey Associates emerges as a leader in innovation, offering advanced circular fan solutions meticulously designed to address the dynamic demands of contemporary technology. Their extensive portfolio ranges from compact blowers to powerful centrifugal fans, underscoring the company’s dedication to improving the performance and reliability of electronic devices.

As the need for efficient cooling solutions escalates—prompted by the intricacies of electronics design—Gagner-Toomey’s profound expertise guarantees that engineers gain access to the forefront of advancements in airflow efficiency, energy conservation, and low-noise operation.

This article explores the numerous advantages of circular fans, examining their critical role in optimizing cooling performance across diverse applications while showcasing the technological innovations that are transforming the industry landscape.

Gagner-Toomey Associates: Leading Provider of Circular Fan Solutions for Electronics Cooling

Gagner-Toomey Associates stands out as a leading supplier of innovative refrigeration methods, providing a comprehensive range of standard and customized circular fans systems designed specifically for electronics temperature management. By leveraging advanced technologies and collaborating with top manufacturers, the firm delivers high-performance temperature control systems that meet the diverse needs of engineers. Their extensive portfolio includes:

- DC input tube axial fans, available in sizes ranging from 15 to 280mm

- Centrifugal blowers from 15 to 225mm

- Miniature blower options optimized for performance, efficiency, and low noise

Moreover, most models can be equipped with IP protection upon request. According to the Ventilation, Heating, Air-Conditioning, And Commercial Refrigeration Equipment Global Market Report 2025, the demand for effective temperature control solutions is on the rise, underscoring the importance of innovative technologies within the electronics sector. This dedication to innovation not only enhances the reliability and efficiency of electronic devices but also positions Gagner-Toomey at the leading edge of the industry. Their expertise in temperature management applications guarantees that clients receive tailored solutions that improve performance and address the complexities inherent in modern electronics. This perspective reinforces Gagner-Toomey’s pivotal role in advancing electronics temperature management.

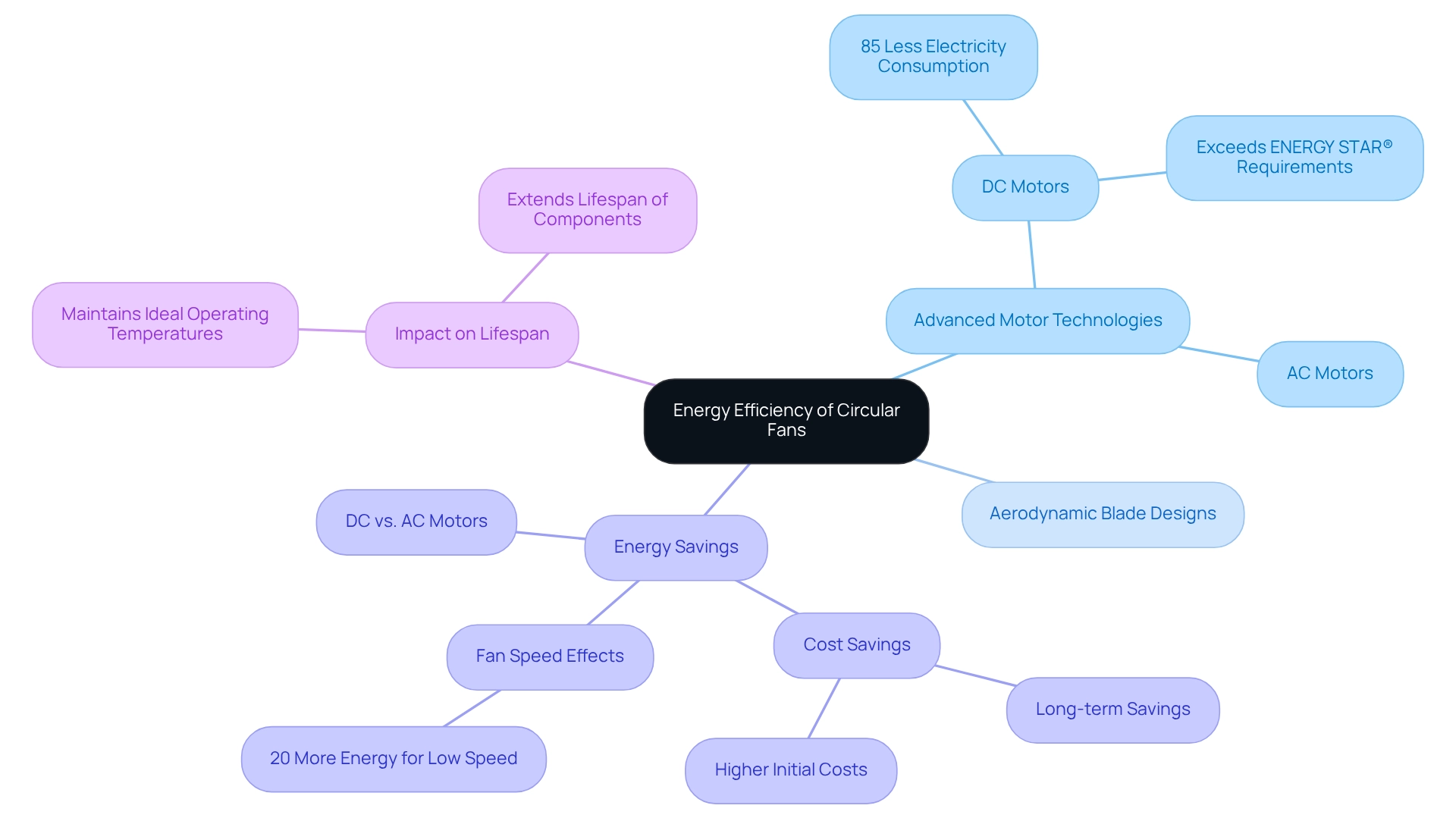

Energy Efficiency: How Circular Fans Reduce Power Consumption in Electronics

Circular fans are designed to optimize airflow while significantly reducing energy consumption. By leveraging advanced motor technologies alongside innovative aerodynamic blade designs, these circular fans operate efficiently at lower speeds, ensuring robust cooling performance without incurring excessive energy costs.

For instance, advanced DC motor devices can consume up to 85% less electricity compared to traditional AC models, leading to substantial savings on energy expenses for both residential and commercial applications. This efficiency not only reduces electricity bills but also extends the lifespan of electronic components by maintaining ideal operating temperatures through the use of circular fans.

Additionally, a dedicated collector positioned near a dust source may require approximately 20% more energy than one with increased fan speed, highlighting the pivotal role of fan design in enhancing energy efficiency.

As John W. Snow noted, “increased energy costs result in enhanced conservation, improved energy efficiency,” reflecting the growing adoption of these advanced devices in new construction and renovation projects. While the initial investment in these improved products may be higher, the long-term energy savings they offer render them a prudent investment, advancing energy conservation and overall system performance.

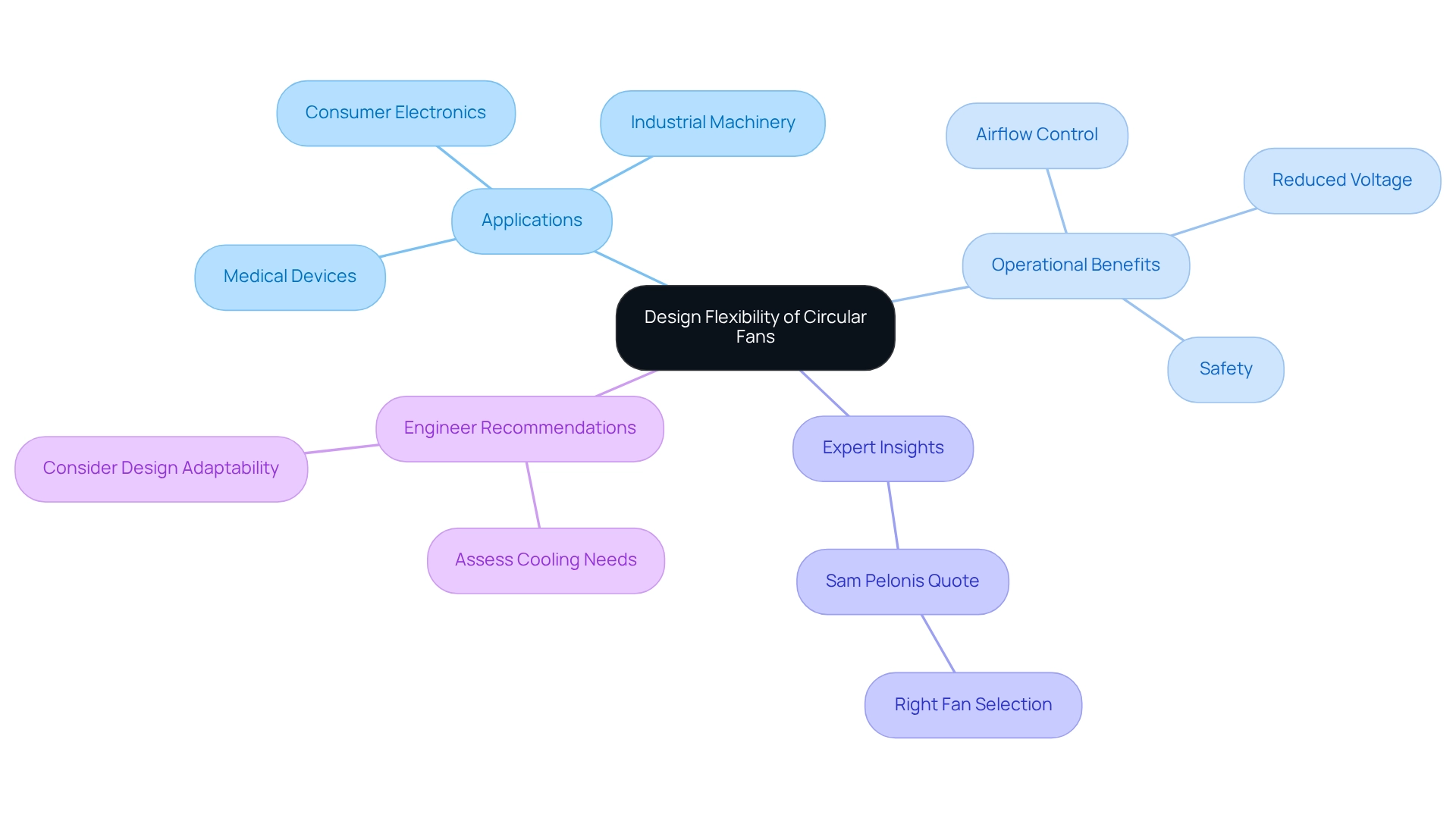

Design Flexibility: Adapting Circular Fans to Various Electronics Applications

Circular devices are distinguished by their remarkable design flexibility, enabling seamless integration into a wide range of electronic systems, from compact consumer items to expansive industrial machinery. This versatility empowers engineers to select devices tailored to specific dimensions, airflow, and noise standards, thereby enhancing cooling efficiency across various applications. Importantly, a considerable portion of engineers—over 60%—indicate using circular fans in their designs, according to industry surveys, underscoring their prevalence in the sector.

The adaptability of circular devices is further illustrated by their capability to meet varying airflow targets through advanced speed control functions, particularly in DC models. These devices operate at reduced voltages, which enhances safety in challenging conditions, as evidenced by case studies focusing on voltage and safety factors in design. For instance, the reduced voltage operation of DC units minimizes electrical hazards, rendering them suitable for delicate applications, such as medical devices and industrial controls.

Expert opinions reinforce this adaptability, with industry leaders emphasizing that the right fan selection hinges on specific project requirements. As Sam Pelonis of Pelonis Technologies, which has been designing and manufacturing AC axial devices and brushless DC units for over 25 years, aptly states, “The bottom line is that the right device for you will depend on your specific needs.” This insight highlights the essential role of circular fans in achieving effective thermal control in electronic systems. Engineers are urged to assess their particular cooling needs and consider the design adaptability of circular fans as a critical element in their projects.

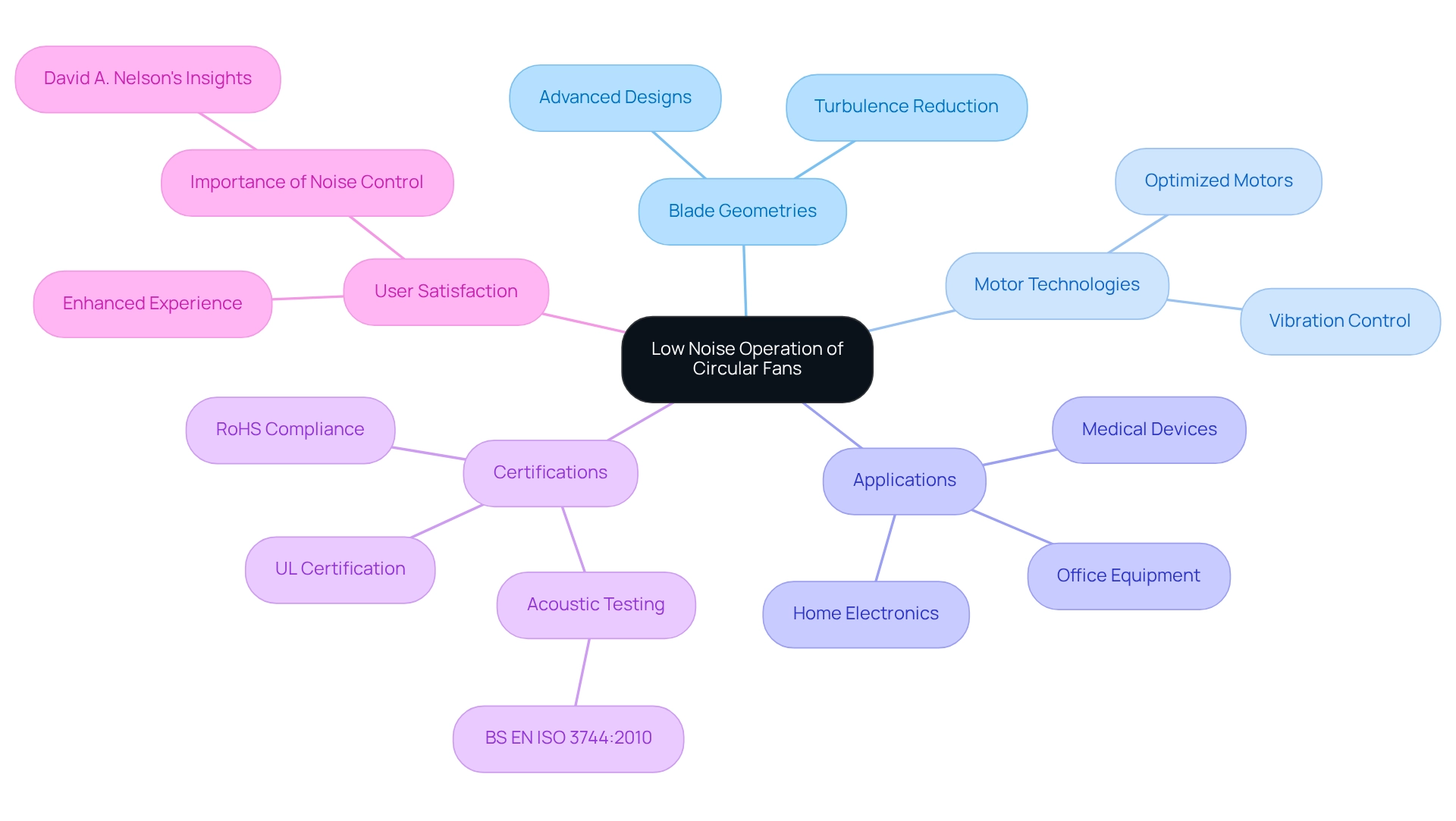

Low Noise Operation: The Quiet Advantage of Circular Fans in Electronics Cooling

Circular fans are meticulously engineered for low noise operation, making them particularly suitable for environments where sound reduction is critical. By employing advanced blade geometries and optimized motor technologies, these devices significantly diminish turbulence and vibration, resulting in quieter performance. This attribute is especially advantageous in applications such as home electronics, medical devices, and office equipment, where user comfort and satisfaction are paramount, especially in the case of circular fans.

For instance, the VES Colourfan Extract Acoustic has undergone independent testing to meet the rigorous acoustic standard BS EN ISO 3744:2010, demonstrating the effectiveness of contemporary circular fans in minimizing noise. Moreover, companies like Sofasco have established themselves as leaders in the industrial fan sector by prioritizing RoHS compliance and UL certification. These certifications are essential for ensuring that their products not only operate effectively but also adhere to safety and environmental regulations, thereby promoting low noise operation.

The impact of noise reduction on user satisfaction is substantial; quieter ventilation options enhance the overall experience, particularly in sensitive settings. The demand for circular fans continues to rise, with numerous manufacturers emphasizing low noise functionality in their designs. This trend is evident in the average noise levels of circular fans, which are significantly lower than those of conventional models, making them a preferred choice for engineers seeking efficient and discreet cooling solutions. As David A. Nelson, a principal consultant in acoustics, asserts, effective noise control is crucial for enhancing user satisfaction in electronic applications.

Airflow Efficiency: Maximizing Cooling Performance with Circular Fans

Airflow Efficiency: Maximizing Cooling Performance with Circular Fans

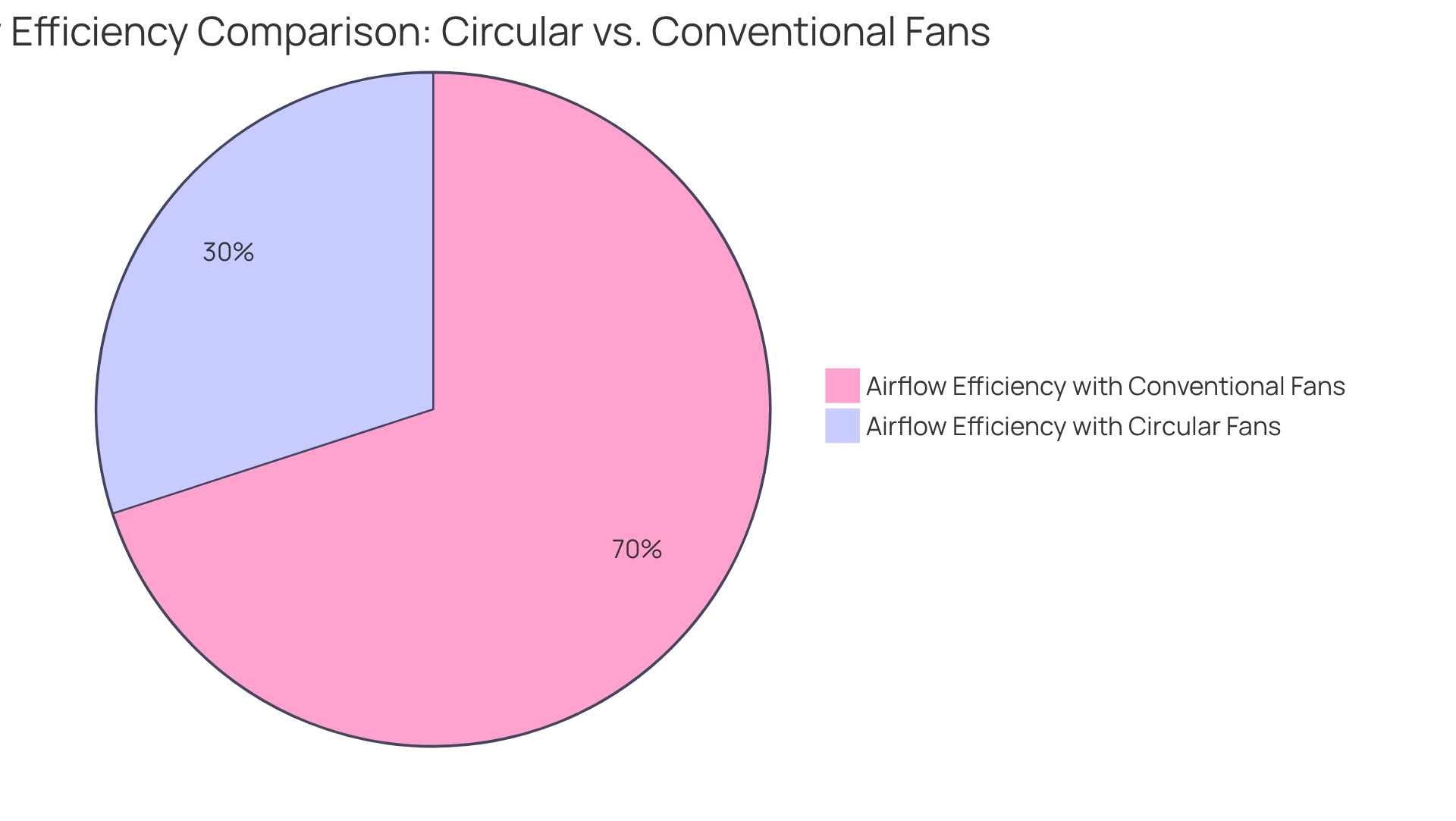

Circular fans from Gagner-Toomey Associates are meticulously engineered to maximize airflow efficiency, ensuring that cool air effectively reaches critical electronic components. Their distinctive design promotes a more uniform air distribution, significantly mitigating hotspots and enhancing overall thermal management. This optimization is vital for sustaining the performance and longevity of electronic devices.

Research indicates that circular fans can improve airflow efficiency by as much as 30% compared to conventional designs, establishing them as a preferred choice among engineers. In the context of the House of the Future in Cleveland, where air leakage was measured at 700 cfm50, the significance of effective airflow becomes increasingly evident.

Furthermore, real-world applications demonstrate that facilities utilizing circular fans have reported substantial improvements in thermal management, leading to enhanced operational efficiency and reduced energy costs. By leveraging Gagner-Toomey’s advanced ventilation systems, which include a diverse array of DC input Tube Axial devices ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, engineers can achieve exceptional thermal management, ultimately bolstering the reliability and durability of their electronic systems.

It is also essential to recognize that the overall airflow and air speed are directly proportional to the rotational speed, further underscoring the operational advantages of circular fans.

Durability: The Long-Lasting Performance of Circular Fans in Electronics

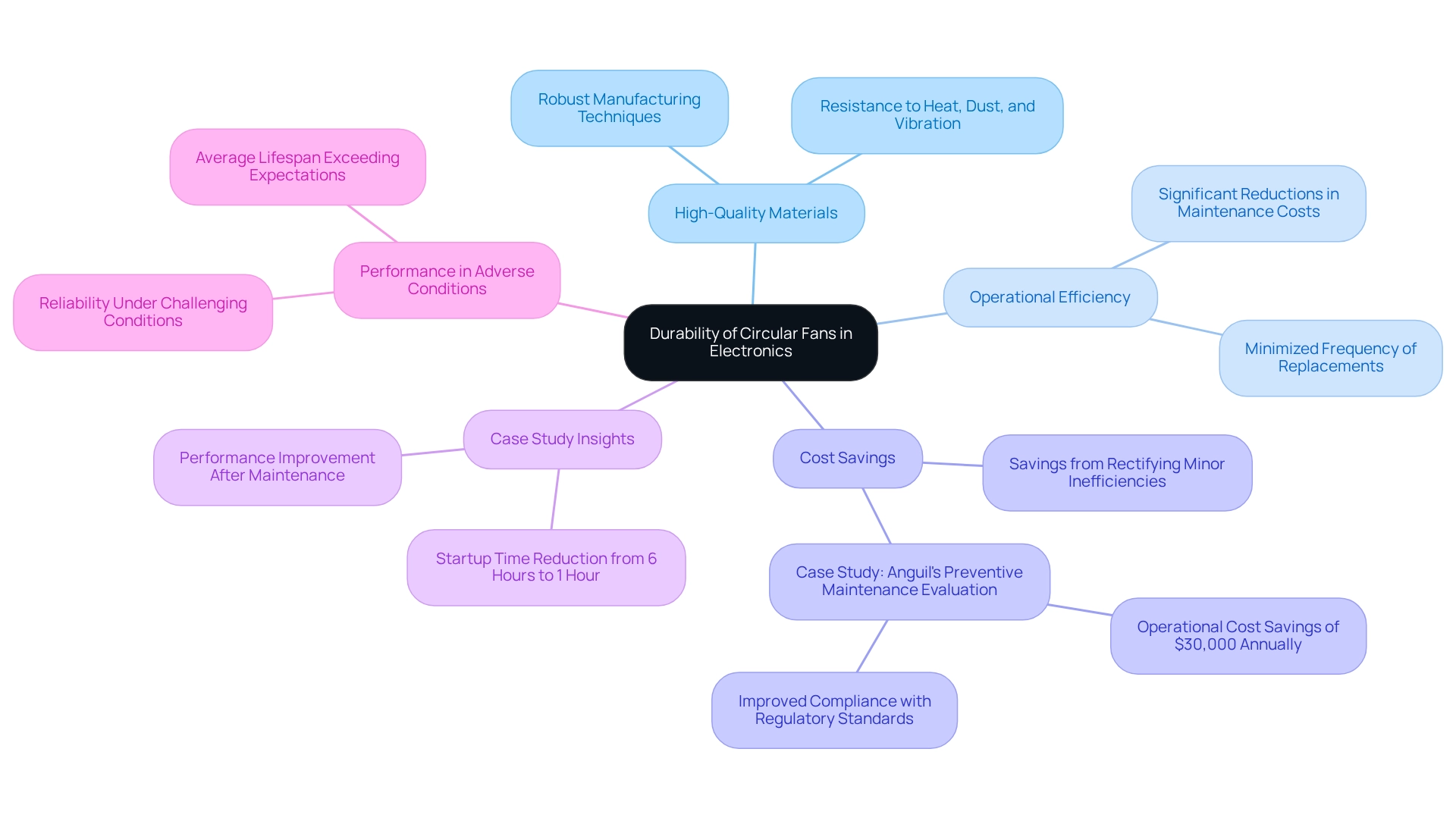

Circular blowers are engineered to endure the rigors of continuous operation in demanding environments, establishing them as an optimal choice for electronics temperature regulation. The process of heat removal initiates with a chip within electronic devices, underscoring the essential role of effective cooling solutions.

Constructed from high-quality materials and utilizing robust manufacturing techniques, these devices are designed to resist heat, dust, and vibration, ensuring dependable performance over time. This exceptional durability not only leads to significant reductions in maintenance costs but also minimizes the frequency of replacements, positioning circular fans as a wise investment for sustained operational efficiency.

For instance, a case study involving Anguil’s Preventive Maintenance Evaluation demonstrated that rectifying minor inefficiencies in heat exchangers yielded substantial operational cost savings and enhanced compliance with regulatory standards. As highlighted by Anguil Environmental, “The most urgent recommendation saved the company thousands of dollars in operating costs and put the company in compliance.”

Such instances illustrate the reliability of circular fans in maintaining optimal performance under challenging conditions, with an average lifespan that often exceeds expectations in electronic applications. Furthermore, performance analyses of air-breathing engines emphasize the importance of durability in adverse environments, further supporting the case for round blowers.

Cost-Effectiveness: Why Circular Fans Are a Smart Investment for Electronics Cooling

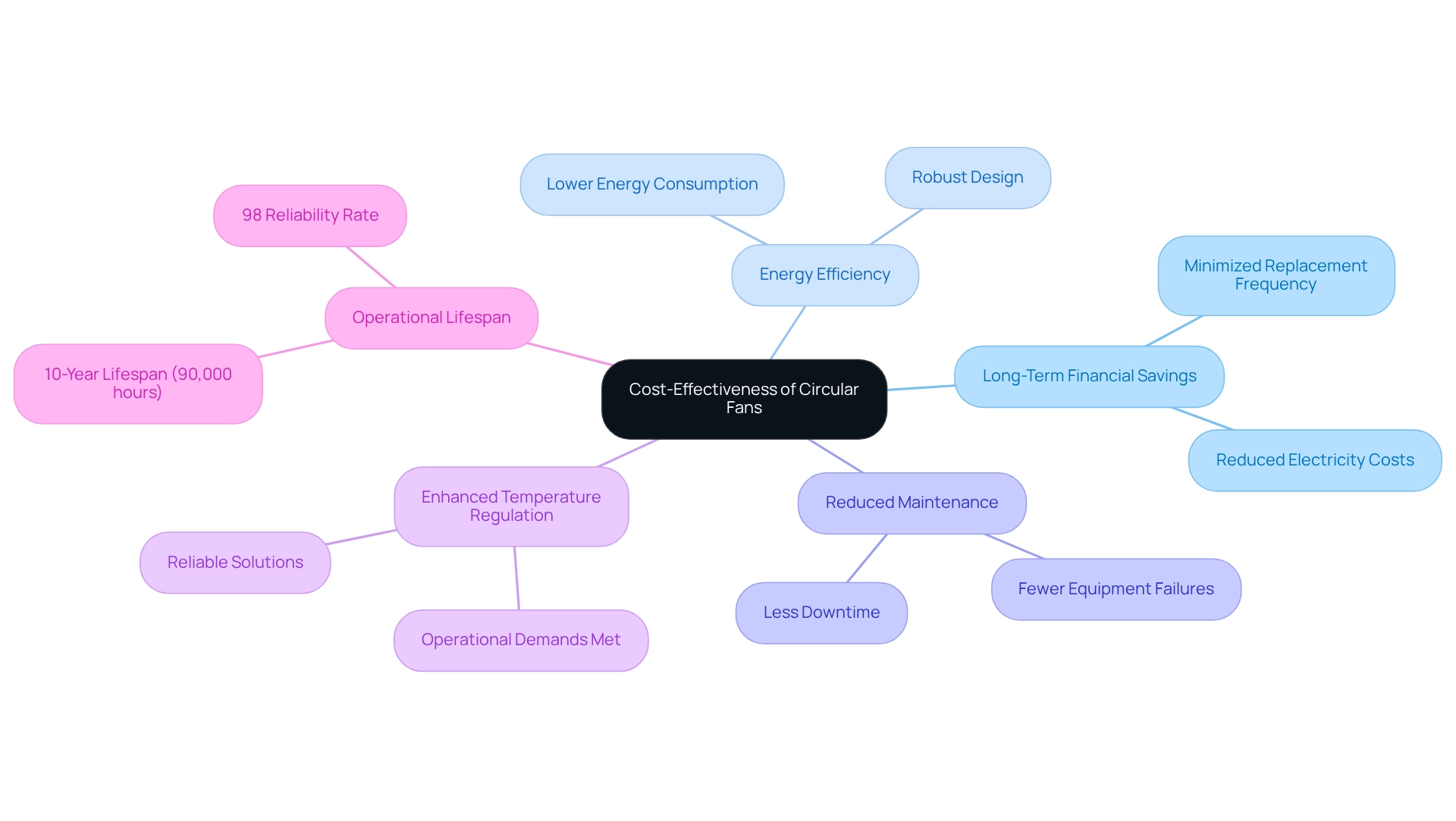

Investing in circular fans yields substantial long-term financial savings. The energy-efficient design of their circular fans significantly reduces electricity costs, while their robust construction minimizes the frequency of replacements and maintenance needs. Enhanced temperature regulation leads to fewer equipment failures and reduced downtime, contributing to overall savings.

For producers, the cost-efficiency of round devices is underscored by their ability to deliver reliable temperature regulation solutions that not only meet operational demands but also optimize financial resources. A pertinent case study from the City of Ann Arbor illustrates the financial advantages of adopting energy-efficient technologies; the city discovered that synchronizing fleet replacements with end-of-life cycles bolstered the business case for electric vehicles. This principle is equally applicable to the implementation of circular fans in electronic temperature regulation.

Moreover, the SANYO DENKI Long Life Cooling Fan ensures an operational lifespan of 10 years (90,000 hours) with a 98% reliability rate, thereby enhancing device dependability without exaggerating capabilities. Such examples reinforce the concept that circular fans are not merely a prudent choice; they represent a strategic investment in the future of electronics cooling.

As Southern California Edison noted, “Without a utility-approved Charge Ready program, the project would have faced delays and been considered cost-prohibitive,” highlighting the importance of supportive programs in advancing energy-efficient solutions.

Ease of Installation: Simplifying Electronics Cooling with Circular Fans

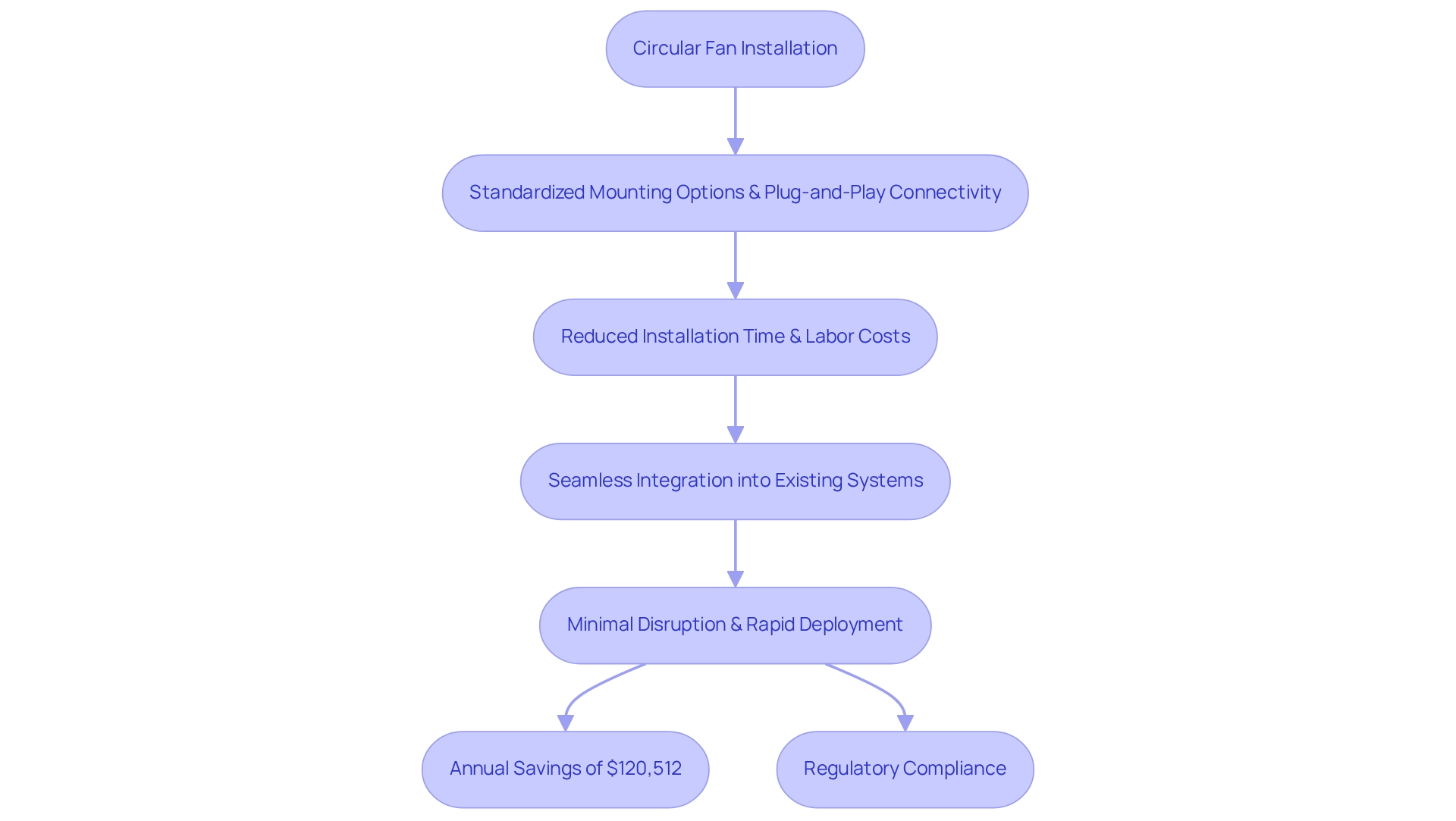

Circular devices are engineered for effortless installation, commonly featuring standardized mounting options and plug-and-play connectivity. This design simplicity allows engineers to seamlessly integrate them into existing systems, significantly reducing installation time and labor costs.

Whether employed in new designs or upgrading current equipment, round blowers provide a convenient method for efficient temperature regulation. Engineers frequently comment on the ease of installation, with many noting that the process is markedly faster compared to other systems.

For example, case studies illustrate that companies have successfully implemented circular fans, which led to minimal disruption, facilitating rapid deployment and enhanced operational efficiency. A notable instance involved an insulation film producer that engaged Anguil Environmental Systems for a comprehensive assessment of their refrigeration methods, resulting in substantial cost savings and ensuring compliance with regulatory requirements.

Furthermore, the projected overall savings from the energy recovery system totals $120,512 annually, underscoring the cost-effectiveness associated with these temperature control methods. Ultimately, the straightforward nature of installing circular fans not only streamlines the ventilation process but also contributes to significant cost savings and improved adherence to regulatory standards.

As emphasized by Anguil Environmental, ‘The most pressing suggestion saved the company thousands of dollars in operating expenses and ensured the company adhered to regulations,’ further highlighting the financial advantages of efficient temperature management.

Versatility: Circular Fans for Diverse Electronics Cooling Needs

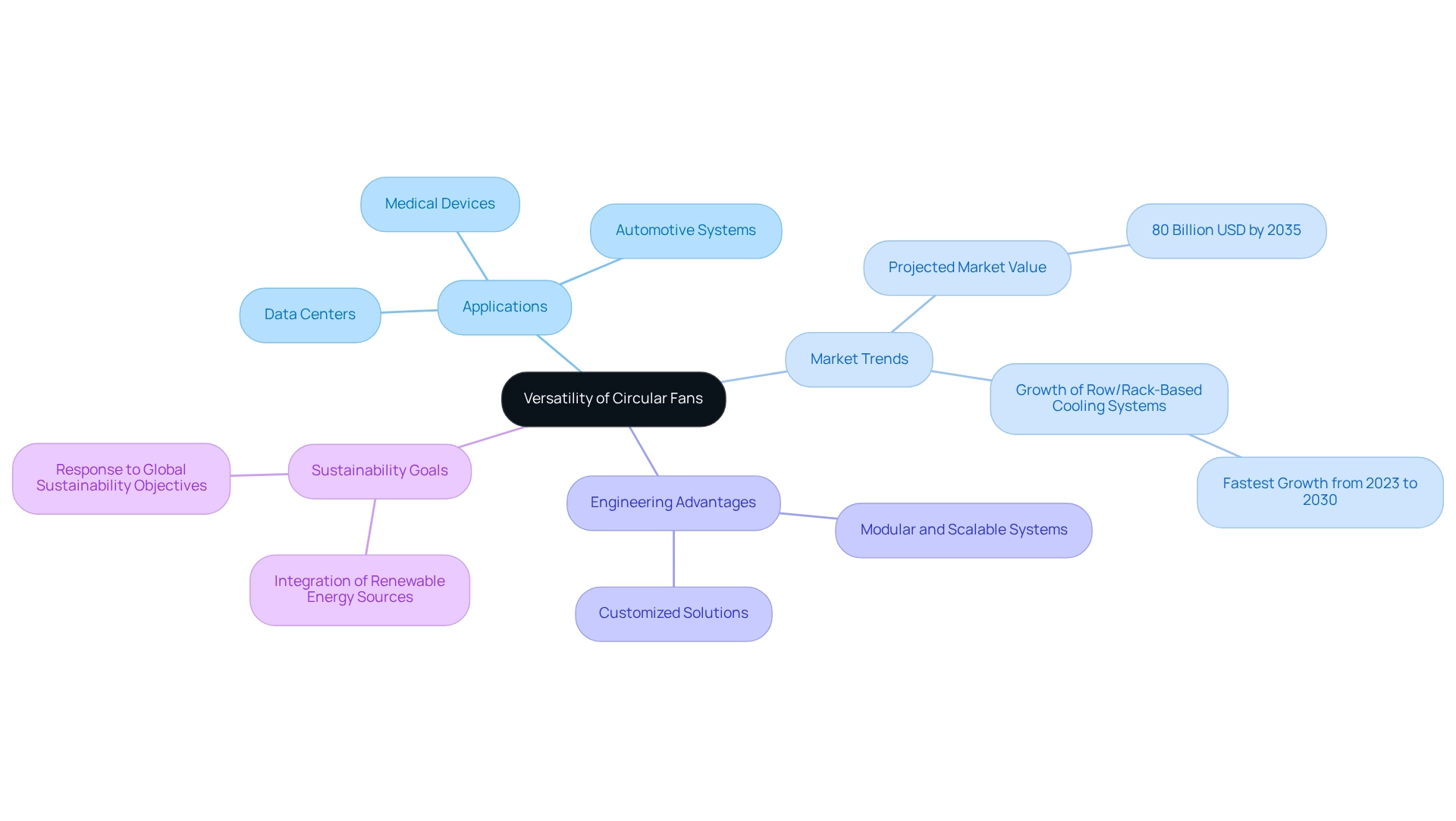

In the electronics industry, circular fans are recognized for their versatility across a wide array of applications, ranging from consumer electronics to industrial machinery. Their design facilitates efficient temperature regulation in various environments, making them ideal for settings such as data centers, automotive systems, and medical devices. This adaptability is vital, as the market for temperature regulation is projected to reach an impressive $80 billion in the APAC region by 2035, highlighting an escalating demand for effective thermal management.

Experts assert that the ability of circular fans to address specific temperature regulation challenges offers significant advantages for engineers. For instance, the emergence of modular and scalable temperature control systems allows for customized solutions that can adapt to diverse operational requirements. This trend is particularly relevant in high-density data centers, where row/rack-based temperature regulation systems are expected to experience the most rapid growth from 2023 to 2030 due to their efficiency. As noted, “This change makes things run better and greatly helps the data center cooling market grow.”

Case studies illustrate the successful application of round ventilators across various sectors. In automotive systems, these devices help maintain optimal temperatures, enhancing performance and reliability. Likewise, in medical devices, they ensure that critical components function within safe thermal limits, thereby improving patient safety and extending device longevity. Jaiswal’s expertise in this domain has been pivotal in preventing business failures, emphasizing the value of expert insights within the industry.

The versatility of circular fans not only addresses urgent temperature control needs but also aligns with global sustainability goals, as manufacturers increasingly integrate renewable energy sources into their designs. The current shift towards modular and scalable temperature control systems reflects the industry’s response to these objectives, positioning circular fans as essential solutions for addressing various temperature management challenges in the electronics sector. This comprehensive approach ensures that engineers can confidently select the appropriate fan for their specific applications.

Technological Advancements: Innovations in Circular Fan Design for Enhanced Cooling

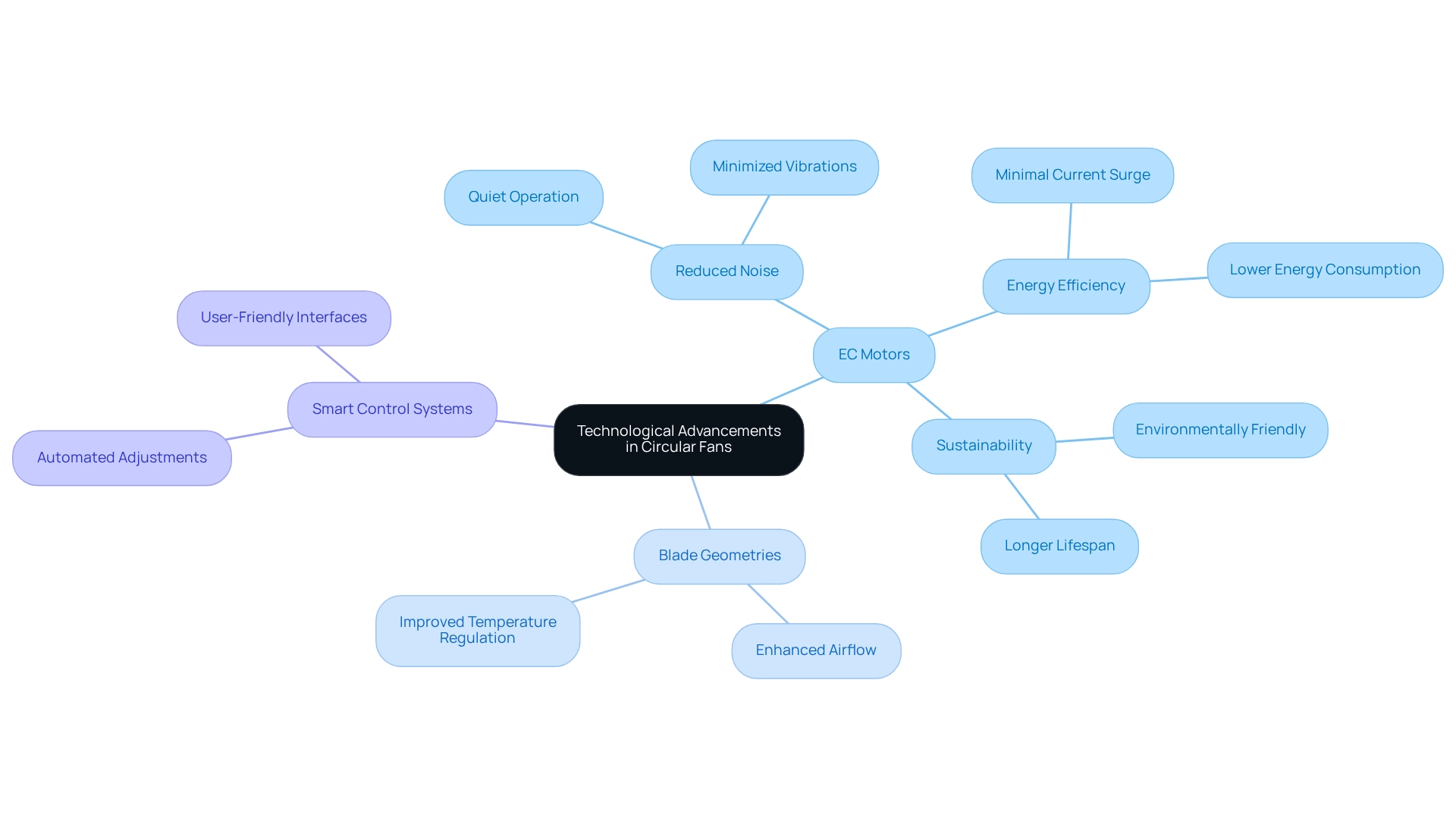

Recent advancements in circular fans have revolutionized performance and efficiency, particularly through the adoption of electronically commutated (EC) motors. These motors not only start with minimal current surge, reducing stress on electrical systems, but also operate quietly compared to traditional AC motors. This quiet operation significantly diminishes vibrations and noise levels, making them ideal for sensitive environments such as hospitals and conference rooms.

As Rita Mae Brown aptly stated, “The reward for conformity is that everyone likes you but yourself,” highlighting the importance of innovation in technology. Furthermore, innovations in blade geometries and smart control systems have further enhanced airflow in circular fans while minimizing energy consumption. Consequently, these advancements not only enhance temperature regulation but also address the growing need for sustainable and energy-efficient options in the electronics sector.

Looking ahead to 2025, the focus on these technological advancements continues to shape the landscape of cooling solutions, driving the industry towards greater efficiency and performance.

Conclusion

The impact of circular fans on electronics cooling is profound, showcasing their essential role in enhancing performance across various applications. Gagner-Toomey Associates stands out as a leader in this domain, offering a comprehensive range of advanced cooling solutions tailored to meet the dynamic needs of modern technology. The versatility, energy efficiency, and low noise operation of these fans not only optimize thermal management but also contribute to significant cost savings and reduced environmental impact.

As highlighted throughout the article, the innovative design and engineering of circular fans allow for seamless integration into diverse electronic systems, making them indispensable for engineers seeking reliable and efficient cooling solutions. The advancements in technology, particularly the adoption of electronically commutated motors and optimized blade designs, further elevate the performance of these fans, ensuring they meet the rising demands of the industry.

In conclusion, the adoption of circular fans represents a strategic investment in the future of electronics cooling. Their durability, ease of installation, and cost-effectiveness position them as the preferred choice for engineers aiming to enhance the reliability and longevity of electronic devices. As the industry continues to evolve, embracing these innovative cooling solutions will be crucial for maintaining optimal performance and driving sustainable practices in electronics design.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in innovative refrigeration methods, providing a comprehensive range of standard and customized circular fan systems specifically designed for electronics temperature management.

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers DC input tube axial fans (15 to 280mm), centrifugal blowers (15 to 225mm), and miniature blowers optimized for performance, efficiency, and low noise.

Can Gagner-Toomey fans be customized?

Yes, most models can be equipped with IP protection upon request, allowing for customization based on specific needs.

Why is there a growing demand for temperature control solutions in electronics?

The demand for effective temperature control solutions is rising due to the increasing importance of innovative technologies within the electronics sector, as highlighted in the Ventilation, Heating, Air-Conditioning, And Commercial Refrigeration Equipment Global Market Report 2025.

How do circular fans optimize energy consumption?

Circular fans optimize airflow while significantly reducing energy consumption by using advanced motor technologies and innovative aerodynamic blade designs, allowing them to operate efficiently at lower speeds.

What are the energy savings associated with advanced DC motor devices?

Advanced DC motor devices can consume up to 85% less electricity compared to traditional AC models, leading to substantial savings on energy expenses for both residential and commercial applications.

What role does fan design play in energy efficiency?

Fan design is crucial in enhancing energy efficiency; for example, a dedicated collector near a dust source may require more energy than one with increased fan speed, underscoring the importance of optimizing fan performance.

How do circular fans contribute to the lifespan of electronic components?

By maintaining ideal operating temperatures, circular fans help extend the lifespan of electronic components, reducing the risk of overheating.

What is the significance of design flexibility in circular fans?

The design flexibility of circular fans allows for seamless integration into various electronic systems, enabling engineers to select devices tailored to specific dimensions, airflow, and noise standards.

What percentage of engineers use circular fans in their designs?

Over 60% of engineers indicate using circular fans in their designs, reflecting their prevalence in the electronics sector.

How do DC models enhance safety in challenging conditions?

DC models operate at reduced voltages, which enhances safety and minimizes electrical hazards, making them suitable for delicate applications like medical devices and industrial controls.

What should engineers consider when selecting a fan for their projects?

Engineers should assess their specific cooling needs and consider the design adaptability of circular fans as a critical element in their projects, as the right fan selection depends on individual project requirements.