Overview

The article underscores the critical advantages of cold plates for electronics engineers, highlighting their pivotal role in enhancing thermal efficiency and reliability within electronic systems. It articulates how cold plates enable effective heat dissipation through cutting-edge liquid temperature management technologies, which are indispensable for high-density applications. This not only contributes to the longevity of electronic devices but also optimizes their performance, making cold plates an essential component in modern electronic design.

Introduction

Chilled surfaces, commonly referred to as cold plates, are swiftly becoming indispensable in the field of electronics engineering, where effective thermal management is paramount for optimal performance and reliability. These innovative cooling solutions not only significantly enhance thermal efficiency but also provide customizable designs tailored to specific applications, establishing their necessity in high-density environments.

However, as the demand for advanced cooling technologies continues to escalate, the question arises: can engineers fully harness the advantages of cold plates while adeptly navigating the complexities of integration and cost-effectiveness?

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates stands at the forefront of innovative temperature control systems specifically designed for the electronics sector. As the world’s largest producer of both standard and custom air-movers, Gagner-Toomey is committed to advanced temperature management technologies. Their extensive product range includes:

- DC input tube axial fans

- Centrifugal blowers

All optimized for superior performance, efficiency, and minimal noise. This dedication to excellence empowers engineers with access to state-of-the-art products that effectively address complex thermal management challenges. Notably, recent advancements in temperature regulation technologies, such as the integration of PWM fans, have led to an impressive improvement in temperature management efficiency by up to 30%. This underscores the crucial role these methods play in enhancing the performance and reliability of electronic systems.

With over 70% of electronics engineers currently incorporating PWM fans into their designs, Gagner-Toomey remains a trusted partner in navigating the evolving landscape of electronics temperature regulation, providing a comprehensive array of air-movers and thermal management solutions tailored for diverse applications.

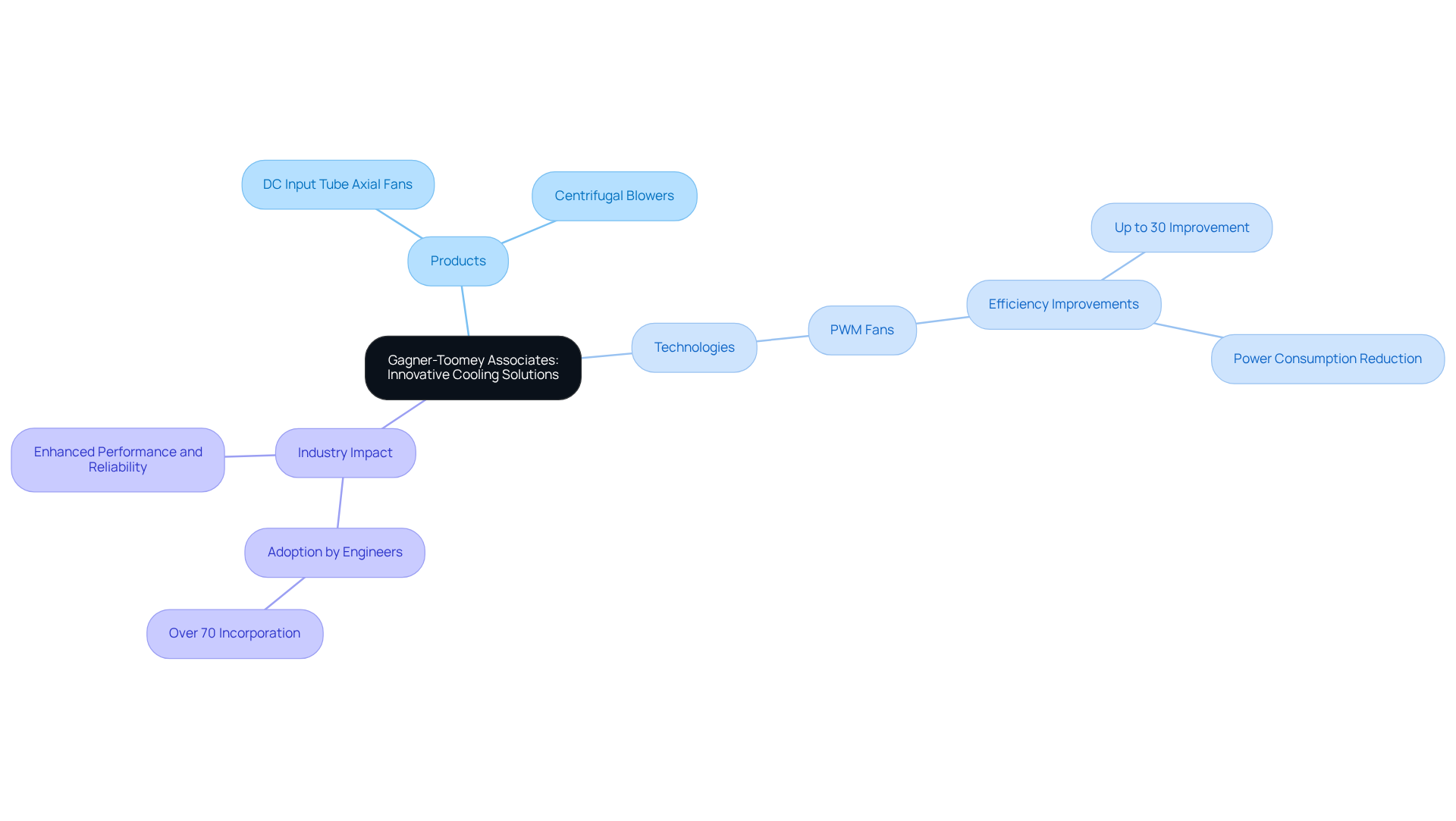

Enhanced Thermal Efficiency: Maximizing Performance with Cold Plates

Chilled surfaces, often referred to as coldplates, are engineered to significantly enhance thermal efficiency by facilitating effective heat dissipation from electronic components. By employing advanced liquid temperature management technology, these components adeptly transfer heat away from critical areas, preventing overheating and ensuring optimal performance. This localized cooling strategy using coldplates proves particularly beneficial in high-density applications, where traditional air cooling methods often fall short. As a result, chilled surfaces substantially bolster the reliability and longevity of electronic devices, establishing themselves as indispensable elements in contemporary electronics design.

Recent research indicates that the chilled surfaces market is projected to reach USD 534 million by 2032, driven by the increasing demand for efficient thermal control solutions in high-powered electronics. For example, the drilled hole thermal component design has exhibited effective heat transfer coefficients ranging from 7,000 to 27,000 W/m·K, demonstrating its effectiveness in managing heat within densely packed electronic assemblies. Furthermore, the rise of liquid thermal solutions, particularly coldplates in microchannel designs, highlights a shift towards more efficient heat management strategies, as they offer superior heat dissipation compared to conventional methods. This progression in temperature regulation technology not only optimizes performance but also prolongs the operational lifespan of vital electronic components.

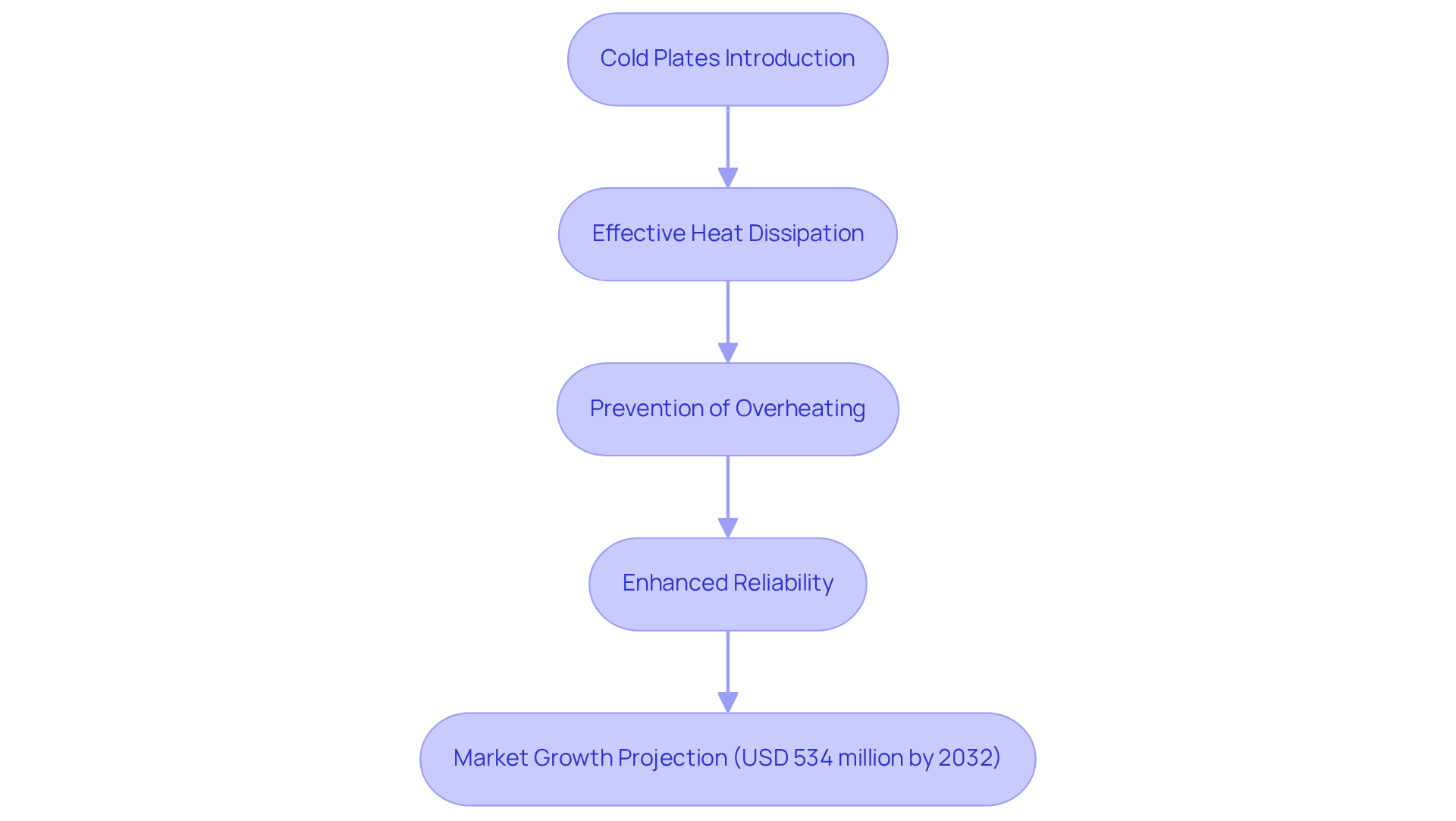

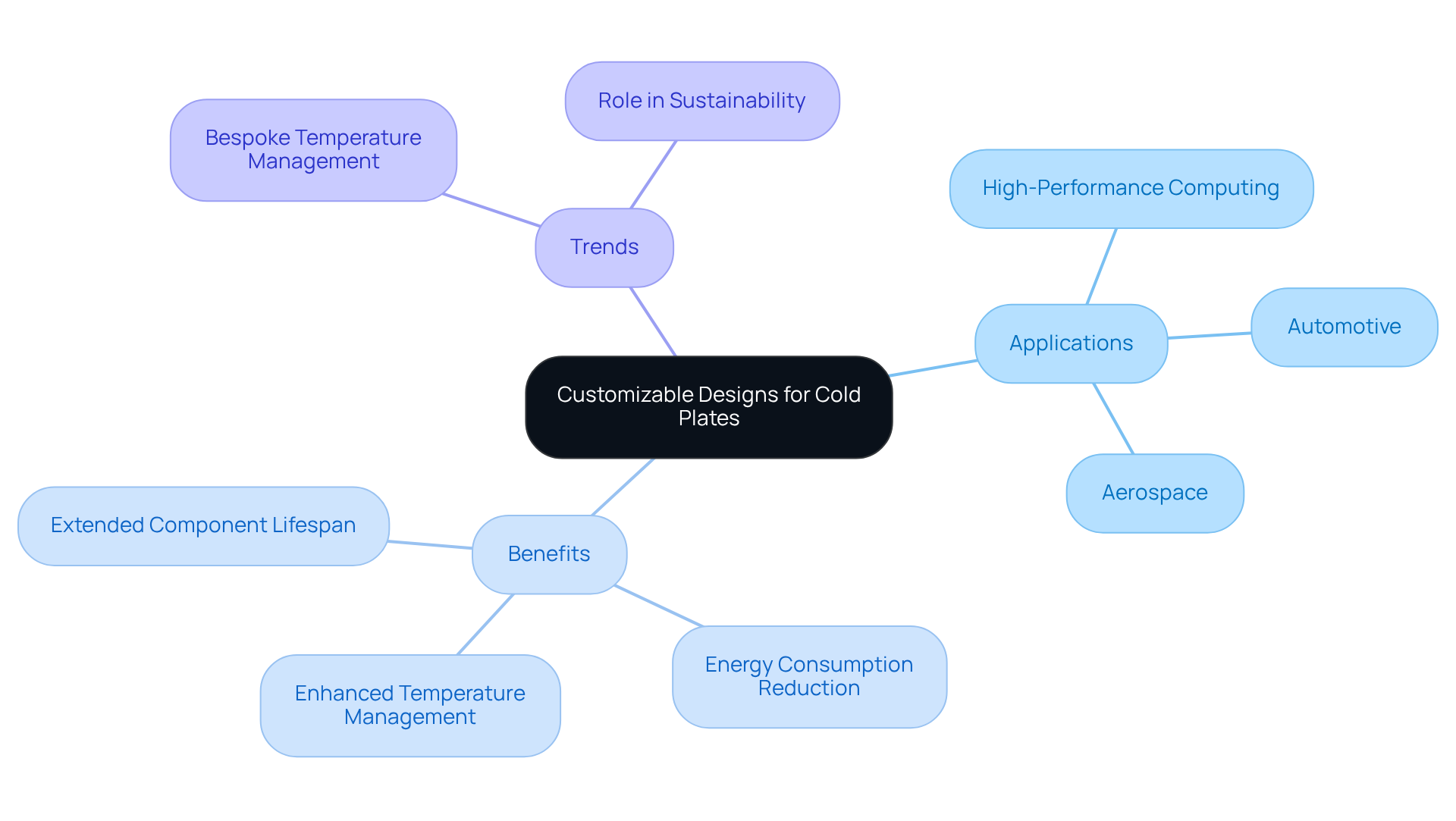

Customizable Designs: Tailoring Cold Plates to Meet Unique Needs

Chilled surfaces are distinguished by their highly adaptable designs, which empower engineers to tailor them to specific dimensions, temperature requirements, and fluid types. This adaptability is vital for addressing the unique demands of various applications, particularly within high-performance computing, automotive, and aerospace sectors. The ability to customize chilled surfaces not only enhances temperature management but also elevates the overall aesthetic of electronic systems.

Recent trends indicate that bespoke temperature management systems are becoming increasingly critical, as they can significantly reduce energy consumption and extend the lifespan of hardware components. Indeed, liquid cooling systems, often incorporating customized coldplates, can maintain lower temperatures more effectively than traditional air cooling methods, thereby preventing thermal throttling and ensuring consistent performance.

As the digital landscape evolves, the importance of such tailored approaches in electronics continues to grow, underscoring their role in advancing technology and promoting sustainability.

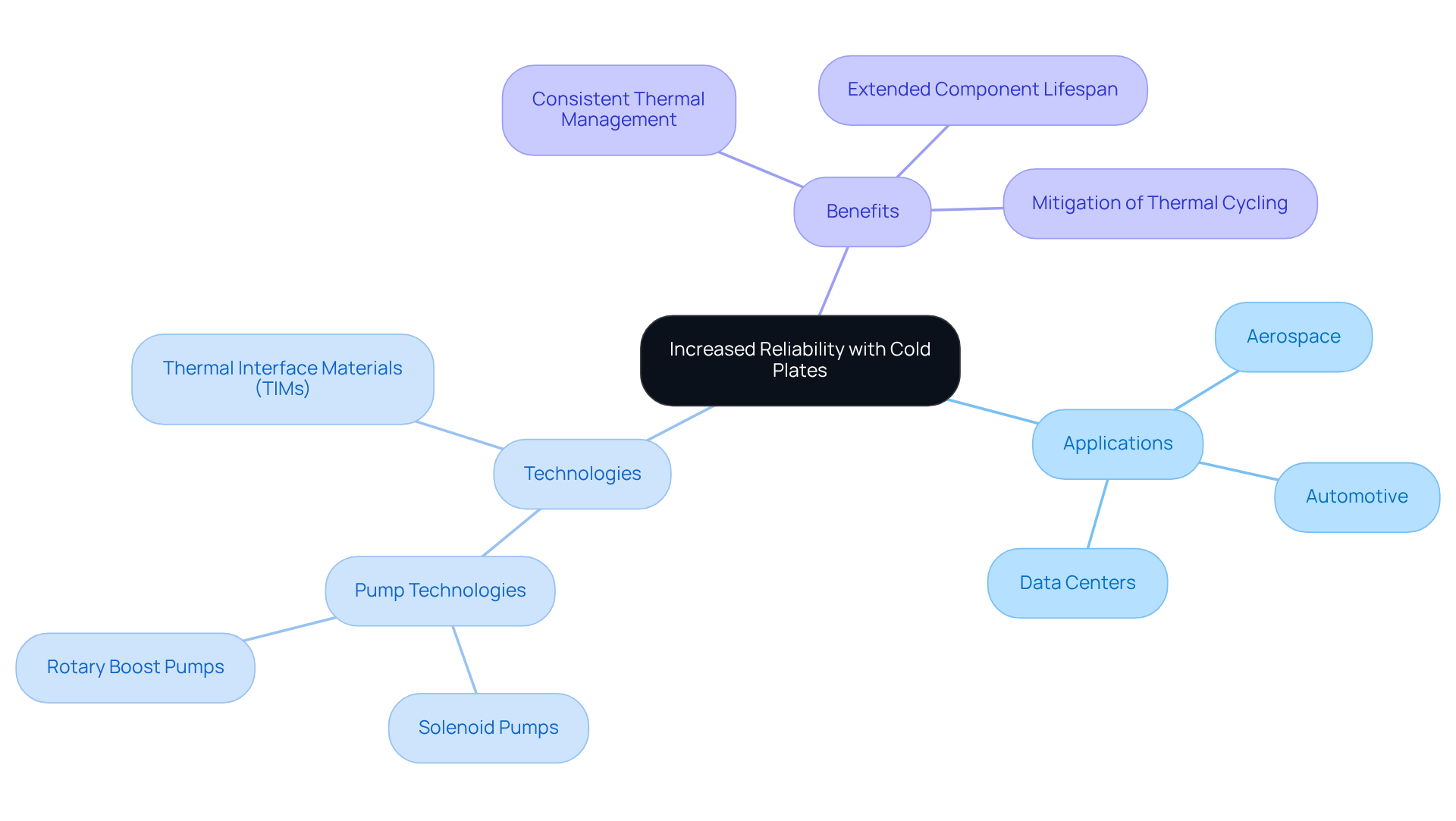

Increased Reliability: Ensuring Consistent Performance with Cold Plates

Chilled surfaces, such as coldplates, significantly enhance the reliability of electronic systems by providing consistent thermal management. They efficiently dissipate heat using coldplates, mitigating thermal cycling and hotspots that can lead to component failure—an aspect that is particularly crucial in high-power applications.

Statistics reveal that thermal issues account for a substantial percentage of component failures, underscoring the necessity for effective cooling solutions. In industries such as aerospace and automotive, where high-performance electronics are vital, coldplates are meticulously engineered to withstand severe operating conditions, thus guaranteeing optimal performance.

Similarly, in data centers, where heat production is considerable due to high-density computing, coldplates play an essential role in preserving system integrity. Their robust design of coldplates not only prevents overheating but also extends the lifespan of critical components, making them an indispensable choice for engineers focused on reliability and performance.

Furthermore, the incorporation of advanced pump technologies, such as solenoid pumps capable of functioning up to 16 Bar and rotary boost pumps featuring DC brushless motors, markedly enhances these systems by offering precise control and effective temperature management.

These pumps, equipped with EMI suppression circuits and PWM for control precision, ensure optimal thermal performance in diverse applications. Moreover, Thermal Interface Materials (TIMs) facilitate efficient heat transfer between the chilled surface and the heat source, leading to optimal thermal performance across various applications.

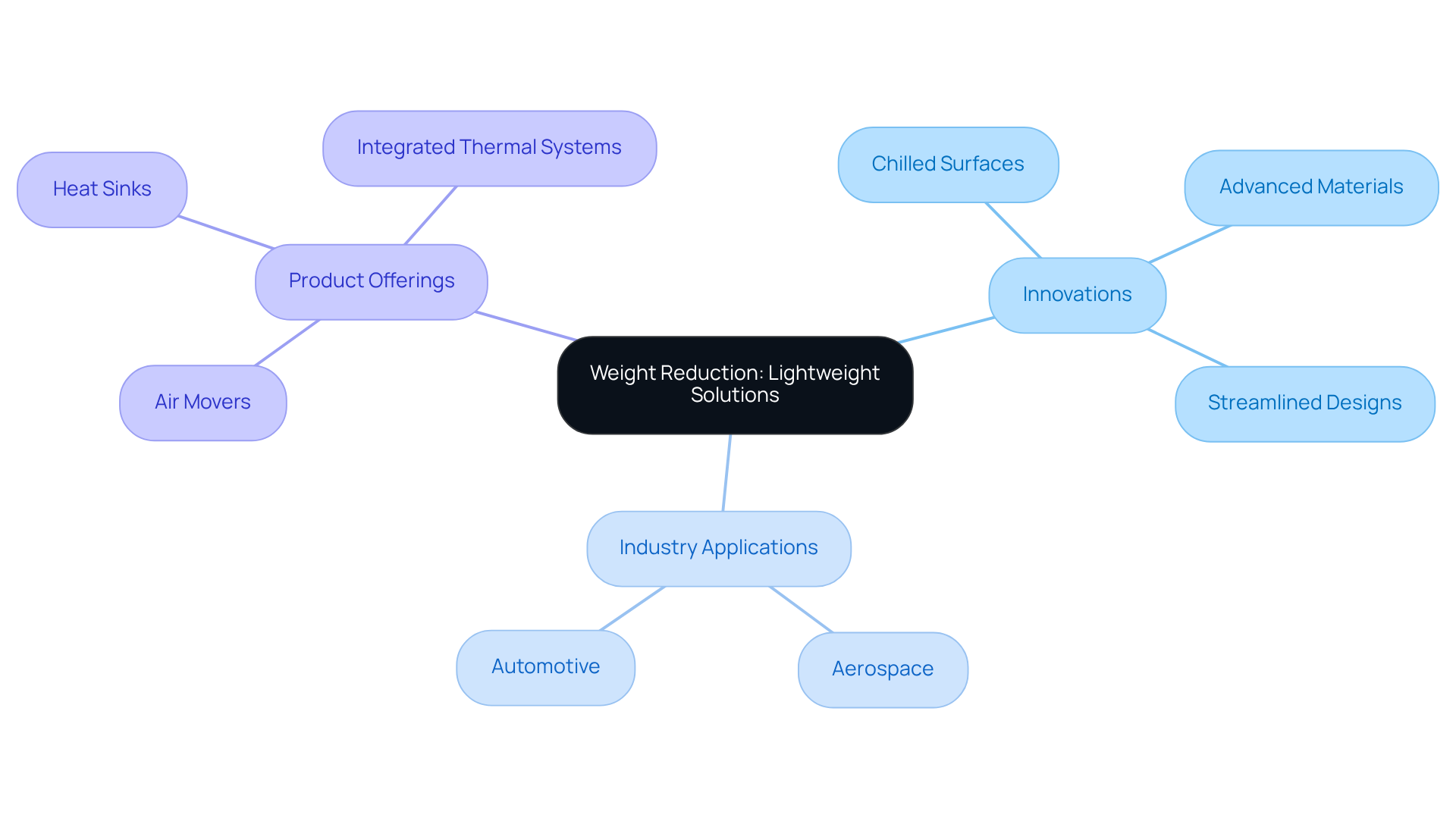

Weight Reduction: Lightweight Solutions for Efficient Cooling

Chilled surfaces present a lightweight and effective method for dissipating heat in high-power electronics, particularly in scenarios where weight reduction is critical. Gagner-Toomey Associates, the world’s largest supplier of thermal management solutions for electronic temperature regulation, utilizes advanced materials and innovative designs to create coldplates that achieve significant weight reductions compared to traditional air temperature control systems. This reduction not only enhances the portability of electronic devices but also significantly improves energy efficiency.

In industries such as aerospace and automotive, where performance and weight are paramount, the adoption of lightweight thermal management options is essential. Recent advancements in thermally conductive materials from Gagner-Toomey Associates have facilitated the replacement of bulky heat sinks with more streamlined designs, thereby enhancing thermal management. These innovations optimize the functionality of electronic components and contribute to overall system reliability and performance.

Furthermore, Gagner-Toomey Associates offers a comprehensive range of products, including:

- air movers

- heat sinks

- integrated thermal systems

ensuring effective thermal management for various applications.

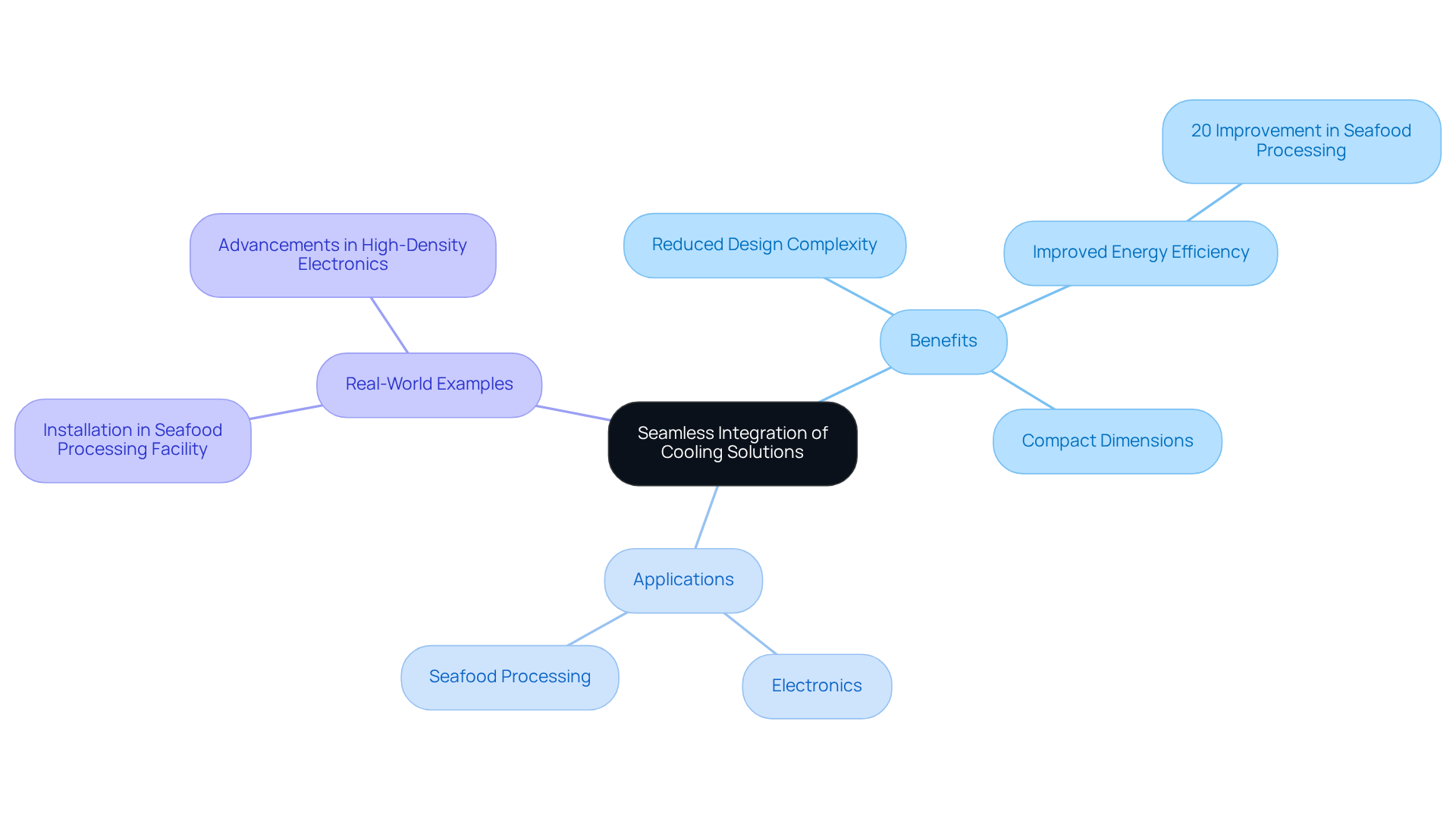

Seamless Integration: Simplifying Cooling Solutions in Electronics

Chilled surfaces are engineered for seamless integration into electronic systems, empowering engineers to implement efficient thermal management with minimal alterations to existing designs. Their compact dimensions and customizable features enable installation in confined spaces, making them suitable for a variety of applications. This streamlined integration not only accelerates the design process but also reduces overall system complexity, allowing engineers to focus on other critical project components.

For example, recent advancements have demonstrated a notable reduction in design complexity when using cold plates, which is crucial in high-density electronic environments. Moreover, the ability to implement these temperature-regulating systems in restricted areas has been demonstrated across several projects, underscoring their adaptability and effectiveness.

As one specialist noted, “Simplifying temperature control solutions is essential for engineers aiming to enhance performance while managing space constraints effectively.”

In a recent endeavor, the installation of chilled surfaces in a seafood processing facility led to a 20% improvement in energy efficiency, illustrating their practical benefits in real-world applications.

Cost-Effectiveness: Reducing Cooling Expenses with Cold Plates

Utilizing coldplates presents a compelling solution to the challenge of high refrigeration costs. Their superior heat transfer capabilities significantly reduce the need for additional temperature regulation components—such as fans and heat sinks—that can incur substantial operational and maintenance expenses. Moreover, the energy efficiency of coldplates leads to diminished operational costs over time, making them an economically advantageous option for businesses seeking to optimize their thermal management strategies. This cost-effectiveness is particularly advantageous in large-scale applications, including data centers and industrial systems, where efficiency is paramount.

Environmental Benefits: Sustainable Cooling Solutions with Cold Plates

Chilled surfaces significantly enhance environmental sustainability by reducing energy consumption and minimizing the carbon footprint associated with refrigeration systems. Their superior thermal management capabilities facilitate lower energy usage compared to conventional air cooling methods, which typically demand greater power to function effectively. Additionally, the integration of eco-friendly coolants within refrigeration systems further elevates their sustainability profile. By adopting coldplates, companies can align their operations with green initiatives, thereby contributing to a more sustainable future.

Versatile Applications: Cold Plates in Diverse Electronics Fields

Coldplates play a crucial role in a wide array of applications within the electronics sector, especially in telecommunications, automotive, aerospace, and data centers. Their capacity for effective temperature regulation of high-power components, particularly through the use of coldplates, is vital in electric vehicles, where they manage battery temperatures to ensure optimal performance and safety.

The electric vehicle battery temperature regulation plate market was valued at USD 1.43 billion in 2022 and is projected to reach USD 7.26 billion by 2030, reflecting a compound annual growth rate (CAGR) of 21.4%. This growth is propelled by the surging demand for electric vehicles and advancements in thermal management solutions, including innovative pump technologies such as solenoid and rotary boost pumps. These pumps, recognized for their precision control and low noise operation, are integral to enhancing cooling system efficiency.

In telecommunications, coldplates are utilized to create chilled surfaces in high-performance computing systems, guaranteeing reliable operation under demanding conditions. Additionally, in aerospace, coldplates are used to enhance the thermal control of critical systems, supporting mission readiness and safety in extreme environments.

The chilled surfaces market in the United States is expected to expand at a CAGR of 5.3% from 2025 to 2035, further underscoring the growing demand for these solutions. The versatility of coldplates empowers engineers to design and enhance the efficiency and reliability of their systems across these diverse sectors, establishing them as a fundamental component in modern electronics. Furthermore, collaboration between manufacturers and research institutions in Germany fosters advanced product development, exemplifying the industry’s dedication to innovation.

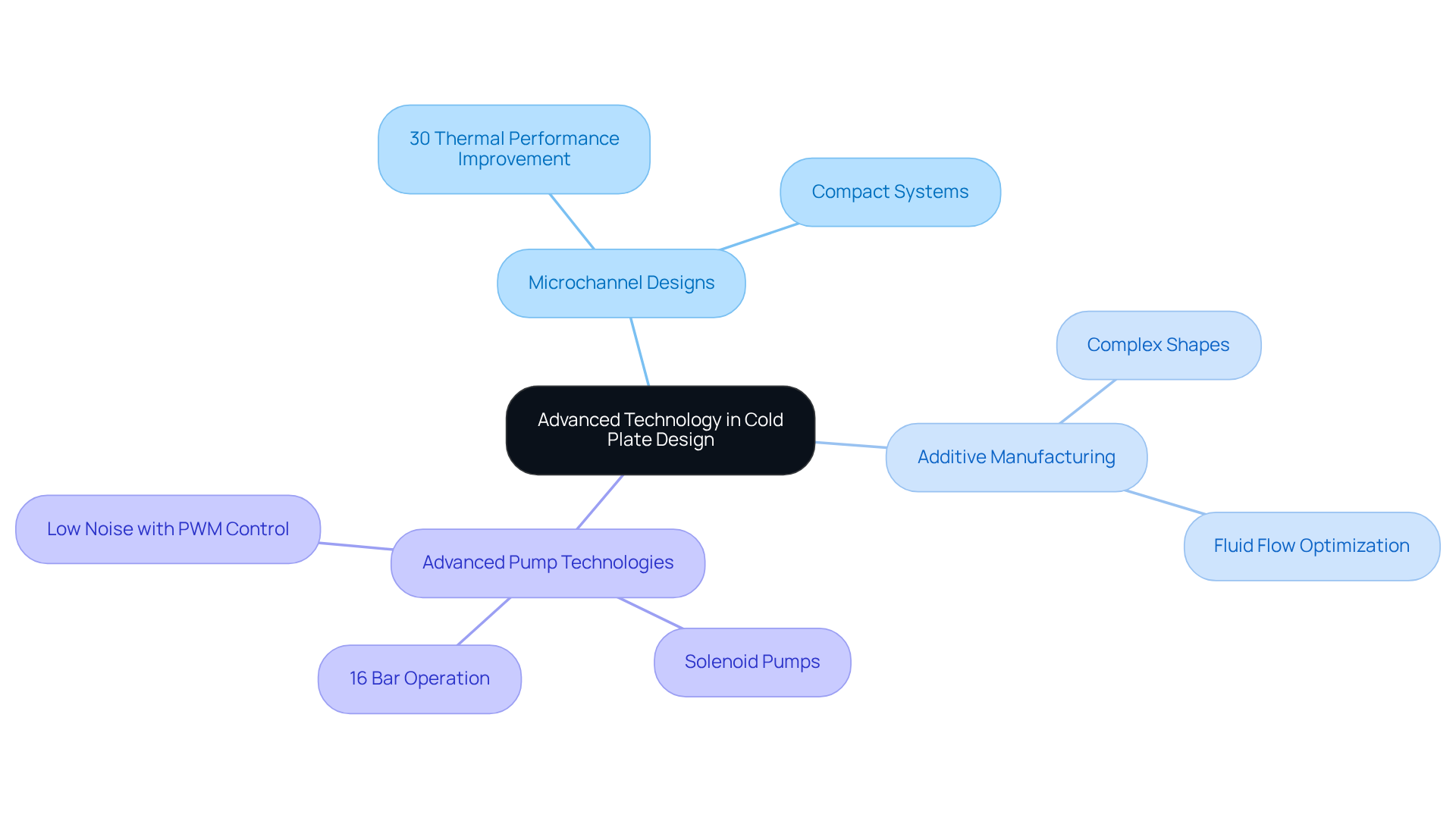

Advanced Technology: Leveraging Innovations in Cold Plate Design

Recent advancements in thermal interface technology have revolutionized temperature management, particularly through the introduction of microchannel and additive manufacturing techniques. These microchannel designs significantly enhance heat transfer efficiency, allowing for more compact and effective temperature regulation systems. For instance, studies indicate that coldplates with microchannel designs can improve thermal performance by up to 30% compared to traditional designs, making them ideal for high-performance applications in sectors such as AI and electric vehicles.

Furthermore, additive manufacturing facilitates the creation of complex shapes that optimize fluid flow and thermal management, thereby pushing the boundaries of efficiency. Advanced pump technologies, such as solenoid pumps capable of operating up to 16 Bar and rotary boost pumps equipped with DC brushless motors, are pivotal in enhancing these systems. These pumps are meticulously designed for precision applications, ensuring low noise operation while featuring PWM for precise control, along with materials compliant with NSF and WSAS standards.

As engineers adopt these innovative approaches, they can ensure their cooling solutions not only meet the rigorous demands of modern electronics but also bolster overall system reliability and performance. However, challenges such as coolant compatibility and the necessity for expert handling remain critical considerations in the integration of these advanced technologies.

Conclusion

Chilled surfaces, or cold plates, have become critical components in electronics cooling, delivering numerous advantages that bolster thermal efficiency and system reliability. By efficiently dissipating heat from electronic components, cold plates guarantee optimal performance in high-density applications, where conventional cooling methods may struggle. Their versatility and tailored designs enable engineers to meet specific temperature management requirements, rendering cold plates indispensable in contemporary electronic systems.

This article has thoroughly examined the benefits of cold plates, emphasizing their role in enhancing thermal efficiency, boosting reliability, and minimizing weight. The incorporation of cutting-edge technologies, such as microchannel designs and innovative pump systems, significantly enhances their effectiveness. Furthermore, the cost-efficiency and environmental advantages of implementing cold plates resonate with the increasing demand for sustainable solutions within the electronics sector.

In summary, the importance of cold plates in electronics is paramount. As industries progress, adopting these advanced cooling solutions will not only improve performance but also support sustainability initiatives. Engineers and manufacturers are urged to investigate the diverse applications of cold plates and harness their advantages to maintain competitiveness in a swiftly advancing technological landscape.

Frequently Asked Questions

What types of cooling solutions does Gagner-Toomey Associates offer for the electronics sector?

Gagner-Toomey Associates offers DC input tube axial fans and centrifugal blowers, optimized for superior performance, efficiency, and minimal noise.

How have recent advancements in temperature regulation technologies improved efficiency?

Recent advancements, such as the integration of PWM fans, have improved temperature management efficiency by up to 30%, enhancing the performance and reliability of electronic systems.

What percentage of electronics engineers are currently using PWM fans in their designs?

Over 70% of electronics engineers are incorporating PWM fans into their designs.

What are cold plates and how do they enhance thermal efficiency?

Cold plates are chilled surfaces engineered to enhance thermal efficiency by effectively dissipating heat from electronic components, preventing overheating and ensuring optimal performance.

What market projection exists for the chilled surfaces market by 2032?

The chilled surfaces market is projected to reach USD 534 million by 2032, driven by the increasing demand for efficient thermal control solutions in high-powered electronics.

What are some benefits of using customized cold plates?

Customized cold plates allow engineers to tailor designs to specific dimensions, temperature requirements, and fluid types, enhancing temperature management and reducing energy consumption.

In which sectors is the customization of chilled surfaces particularly important?

Customization of chilled surfaces is particularly important in high-performance computing, automotive, and aerospace sectors.

How do liquid cooling systems compare to traditional air cooling methods?

Liquid cooling systems, often incorporating customized cold plates, can maintain lower temperatures more effectively than traditional air cooling methods, preventing thermal throttling and ensuring consistent performance.