Overview

This article delineates ten compelling benefits of inline centrifugal fans, meticulously designed for electronics engineers. It underscores their efficiency, compact design, quiet operation, and versatility. These advantages are substantiated by an in-depth discussion of:

- Energy savings

- Ease of installation

- Durability

- Cost-effectiveness

- Enhanced safety features

Such insights illustrate how these fans effectively address the diverse needs of contemporary electronic applications, all while optimizing performance and ensuring compliance with industry standards.

Introduction

The rapid advancement of technology in the electronics sector presents a critical demand for innovative cooling solutions. Inline centrifugal fans, particularly those developed by Gagner-Toomey Associates, emerge as a transformative answer to the challenges of thermal management in increasingly compact and powerful electronic systems. These fans promise not only significant energy savings and enhanced airflow performance but also effectively address the vital requirements for space efficiency and noise reduction. However, with a plethora of options available, engineers must consider how to determine the best fit for their specific applications.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Projects

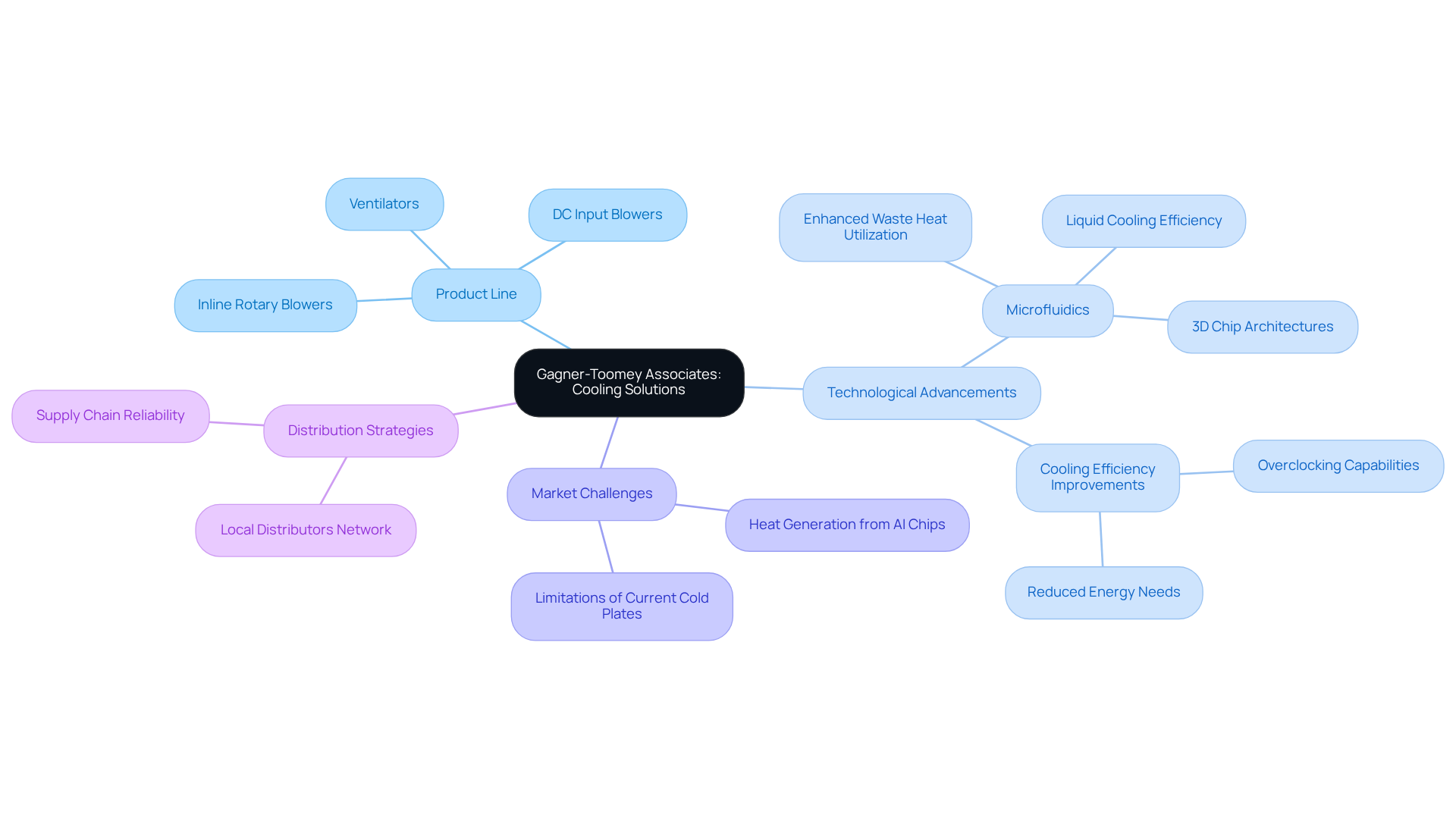

Gagner-Toomey Associates stands at the forefront of providing cutting-edge cooling solutions tailored for the electronics sector. As the world’s largest manufacturer of standard and custom air-movers, they equip technicians with access to the latest innovations in inline rotary blowers, which are crucial for maintaining optimal temperatures within electronic components. This significantly boosts efficiency and reliability across a multitude of applications.

In light of the escalating thermal challenges confronting the industry, particularly with the anticipated heat generation from future AI chips surpassing the capabilities of current cold plates, Gagner-Toomey’s forward-thinking strategies not only tackle existing issues but also prepare for the evolving demands within the dynamic electronics landscape.

Their extensive product lineup includes DC input blowers and ventilators, available in sizes ranging from 15 to 225mm, meticulously designed for performance, efficiency, and low noise, ensuring that professionals are equipped with the finest tools available.

Recent breakthroughs in cooling technologies, such as microfluidics, enhance the efficiency of inline rotary blowers by facilitating superior waste heat utilization, thereby enabling denser server configurations and improved heat management—critical factors for next-generation AI chips and advanced chip architectures.

Moreover, Gagner-Toomey’s robust network of local distributors guarantees a reliable supply of components precisely when and where engineers require them, reinforcing their pivotal role in the electronics supply chain.

Energy Efficiency: Reduce Power Consumption with Inline Centrifugal Fans

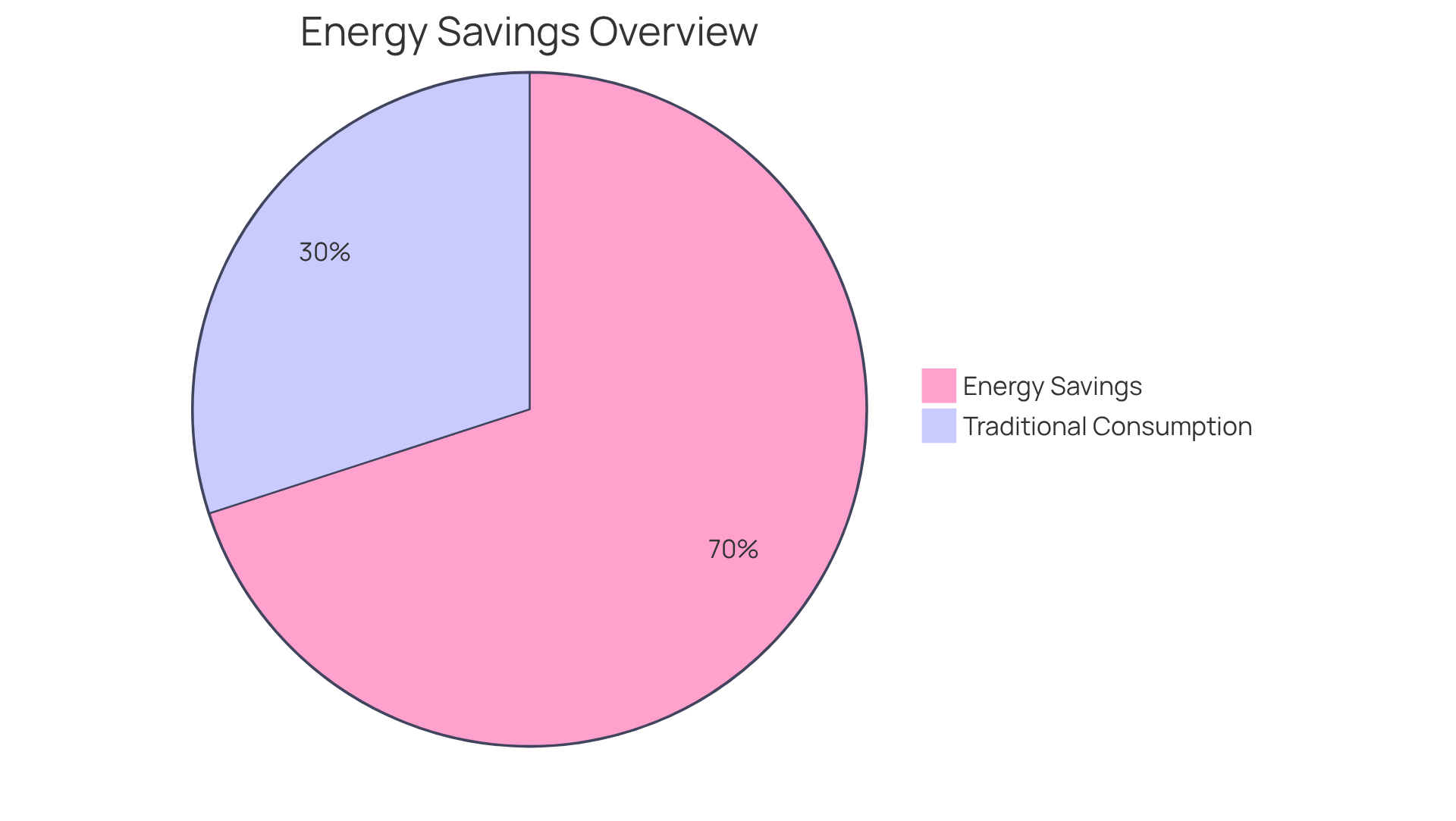

In line centrifugal fans from Gagner-Toomey Associates are engineered to significantly enhance airflow while concurrently reducing energy consumption. By leveraging advanced motor technologies, these devices achieve energy savings of up to 70% compared to conventional systems. This remarkable reduction in power consumption not only diminishes operational costs but also fosters a more sustainable engineering practice.

Electronics specialists can effectively deploy in line centrifugal fans across various applications, including:

- Automotive

- Telecom

- Industrial sectors

This ensures their projects meet energy efficiency standards without compromising performance. Gagner-Toomey’s extensive portfolio features a wide array of standard and custom solutions, with fan sizes ranging from 15 to 280mm, thereby enhancing adaptability to meet diverse industrial requirements.

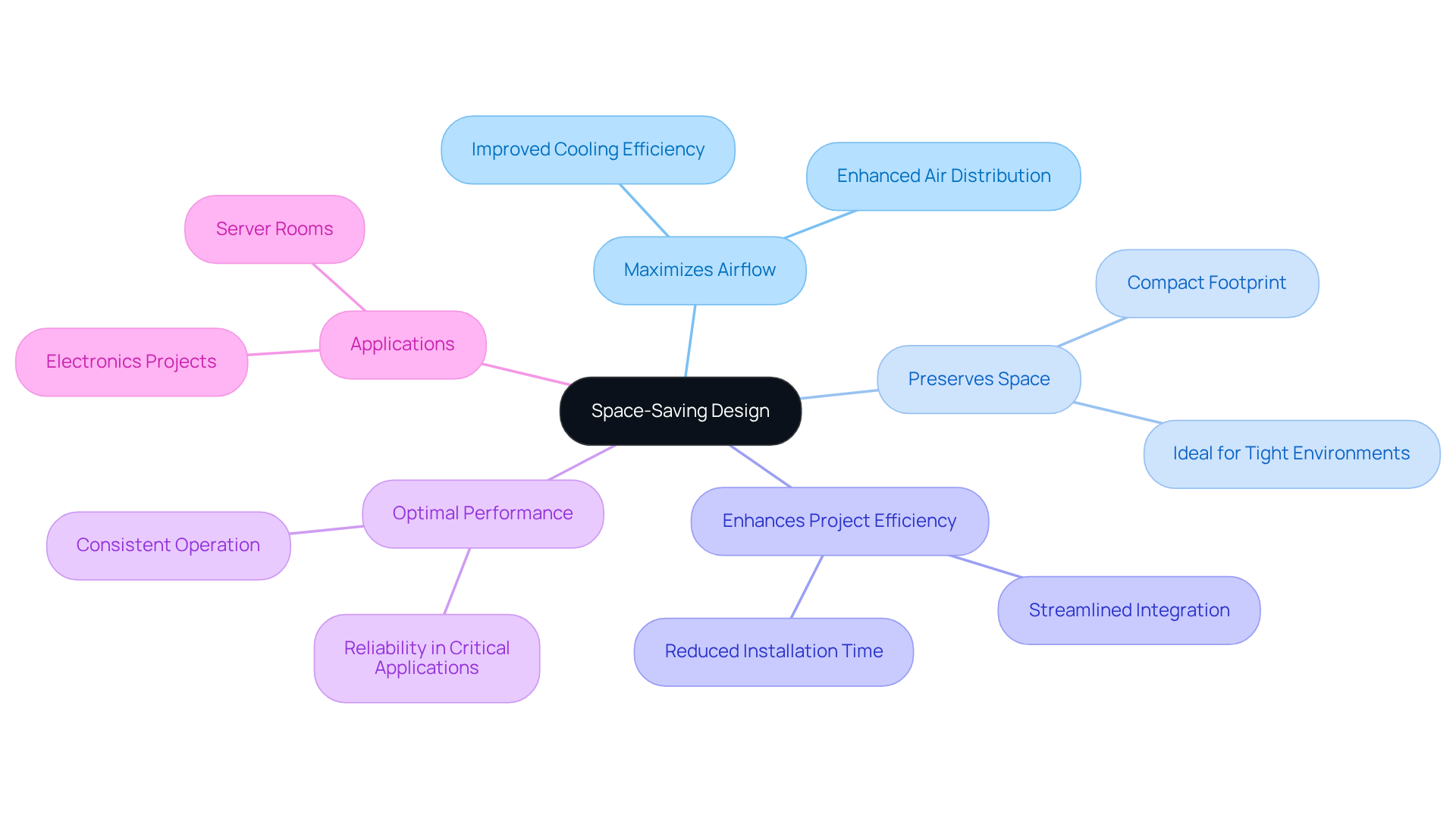

Space-Saving Design: Maximize Project Efficiency with Compact Inline Fans

The compact design of the in line centrifugal fan presents a solution to the challenge of integrating technology into tight spaces, making it indispensable for electronics projects where real estate is at a premium. Their streamlined profiles not only maximize airflow but also preserve valuable space, which is critical in environments such as server rooms where an in line centrifugal fan is vital for efficient cooling. By opting for an in line centrifugal fan, engineers can enhance project efficiency while ensuring optimal performance, thereby addressing both space constraints and operational effectiveness.

Quiet Operation: Enhance Comfort with Low-Noise Inline Centrifugal Fans

Inline blowers are engineered for quiet operation, making them ideal for environments where noise reduction is paramount. With innovative design features that minimize vibration and sound, these devices can function at sound levels as low as 30 dB. This capability is particularly beneficial in applications such as:

- Home theaters

- Offices

- Laboratories

where maintaining a serene atmosphere is crucial. By opting for low-noise inline blowers, engineers can ensure their projects not only excel in performance but also foster a comfortable environment.

Versatility: Adapt Inline Centrifugal Fans for Diverse Applications

Inline axial blowers exemplify exceptional versatility, making them ideal for a wide range of applications, including HVAC systems and industrial processes. Their design seamlessly merges the functionality of centrifugal airfoil wheels with the compactness of axial-flow fan design, enabling effective handling of varying airflow needs and static pressures—an essential requirement for both residential and commercial projects.

For example, these devices are routinely employed in:

- Data centers to ensure optimal cooling

- Manufacturing facilities for effective ventilation

- Specialized environments such as grow rooms, where precise airflow control is critical

Recent applications have demonstrated their effectiveness in enhancing energy efficiency and functionality across various engineering projects, underscoring their adaptability to meet unique operational demands. Furthermore, these units are certified by The New York Blower Company to bear the AMCA Seal, ensuring compliance with AMCA Publication 211 and the AMCA Certified Ratings Program.

For those seeking replacement parts or additional information, contacting a representative from NYB can provide invaluable assistance.

Improved Airflow Performance: Optimize Ventilation with Inline Centrifugal Fans

Inline axial blowers are meticulously engineered to deliver exceptional airflow capabilities, ensuring that electronic components remain cool and function optimally. By generating high static pressure, these devices effectively push air through extensive duct runs and complex systems, overcoming any resistance that may impede airflow. This capability is crucial in applications requiring consistent ventilation, such as server rooms and industrial environments. Engineers can rely on inline rotary blowers to sustain optimal airflow, thereby significantly enhancing the overall performance of their systems.

Ease of Installation: Simplify Setup with Inline Centrifugal Fans

One of the most significant advantages of inline centrifugal devices lies in their ease of installation. Many models are designed for quick and straightforward setup, often requiring minimal tools and expertise. This user-friendly approach not only enables engineers to incorporate these devices into existing systems without extensive modifications but also streamlines the entire process.

Furthermore, the compact design of inline units facilitates installation in various orientations, further simplifying the setup. Such ease of use can dramatically reduce project timelines and labor costs, making these devices an invaluable asset in engineering applications.

Durability and Reliability: Trust Inline Centrifugal Fans for Long-Term Use

Inline air movers are engineered to thrive in challenging environments, ensuring long-term reliability and performance. Constructed from high-quality materials, these devices are designed to resist wear and tear, making them suitable for continuous operation across various settings. Many models incorporate corrosion-resistant coatings and robust motor designs that significantly extend their lifespan. Engineers can depend on inline air movers to deliver consistent performance over time, thereby reducing the need for frequent replacements and maintenance.

Cost-Effectiveness: Achieve Quality Performance with Inline Centrifugal Fans

Inline rotary blowers present a cost-effective solution for professionals seeking high functionality without straining their budgets. Their energy efficiency leads to reduced operational costs, while their robust construction minimizes the necessity for frequent replacements. Furthermore, the versatility of these devices enables their application across various settings, thereby optimizing the return on investment. By opting for inline blowers, engineers can achieve peak efficiency while adhering to financial constraints.

Enhanced Safety Features: Ensure Compliance with Inline Centrifugal Fans

Inline air movers have been progressively developed with enhanced safety attributes that ensure compliance with industry regulations, including UL and IEC standards. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air movers, offers a comprehensive range of blowers optimized for performance, efficiency, and low noise levels. These blowers frequently feature overheat protection, electrical safety mechanisms, and improvements to structural integrity.

By selecting devices equipped with these safety measures, engineers can substantially reduce the risks associated with overheating and electrical failures. This unwavering commitment to safety not only protects the equipment but also ensures compliance with regulatory standards, establishing in line centrifugal fans as a reliable solution for various applications.

As data centers, which accounted for approximately 4.4% of total U.S. electricity consumption in 2023, continue to expand, the need for dependable cooling solutions that adhere to safety standards becomes increasingly critical.

Sherry He, Vice President and General Manager of Consumer, Medical, and Information Technologies at UL Solutions, states, “As data centers face greater demands and power consumption increases, operators urgently need safe and energy-efficient cooling solutions to maximize power-usage effectiveness, performance, and reliability.”

The integration of safety features in cooling systems is vital for maintaining operational efficiency and reliability, especially in environments where power consumption is anticipated to rise to between 6.7% and 12% by 2028.

Conclusion

Incorporating inline centrifugal fans into electronics engineering projects presents a multitude of advantages that significantly enhance performance and efficiency. These fans are meticulously designed for optimal airflow and energy savings, providing effective solutions to prevalent challenges in the electronics sector, such as space constraints and noise reduction. By leveraging these innovative cooling solutions, engineers can ensure the reliability and longevity of their systems, ultimately fostering a more sustainable approach to electronic design.

The key benefits of inline centrifugal fans are noteworthy, including their energy efficiency, compact design, quiet operation, and versatility across various applications. Engineered to deliver exceptional airflow performance, these fans are also easy to install and maintain, rendering them a valuable asset for any electronics project. Furthermore, their durability and enhanced safety features ensure compliance with industry standards, offering peace of mind for engineers and operators alike.

The importance of adopting inline centrifugal fans cannot be overstated, particularly as the demand for efficient cooling solutions in data centers and other electronic environments continues to escalate. By embracing these advanced technologies, engineers optimize their projects while contributing to a more energy-efficient and reliable future in electronics. It is essential to regard these fans as integral components in the design and implementation of modern electronic systems, paving the way for innovation and excellence in engineering practices.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for providing innovative cooling solutions tailored for the electronics sector, particularly as the world’s largest manufacturer of standard and custom air-movers.

What types of products does Gagner-Toomey offer for cooling solutions?

Gagner-Toomey offers a range of products including inline rotary blowers, DC input blowers, and ventilators, with sizes ranging from 15 to 225mm, designed for performance, efficiency, and low noise.

How do Gagner-Toomey’s cooling solutions address thermal challenges in electronics?

Their solutions tackle existing thermal challenges and prepare for future demands, especially with anticipated heat generation from AI chips that exceed current cooling capabilities.

What recent advancements in cooling technology has Gagner-Toomey implemented?

Recent advancements include microfluidics, which enhance the efficiency of inline rotary blowers by improving waste heat utilization, crucial for managing heat in denser server configurations and next-generation AI chips.

How do Gagner-Toomey’s inline centrifugal fans contribute to energy efficiency?

Inline centrifugal fans are engineered to enhance airflow while reducing energy consumption by up to 70% compared to conventional systems, leading to lower operational costs and more sustainable practices.

In which applications can Gagner-Toomey’s inline centrifugal fans be deployed?

These fans can be effectively deployed across various applications, including automotive, telecom, and industrial sectors.

What is the design advantage of Gagner-Toomey’s inline centrifugal fans?

The compact design of the inline centrifugal fans allows for integration into tight spaces, maximizing airflow while preserving valuable space, making them ideal for environments like server rooms.

How does Gagner-Toomey ensure reliable supply of components?

Gagner-Toomey maintains a robust network of local distributors to guarantee a reliable supply of components when and where engineers need them, reinforcing their role in the electronics supply chain.