Introduction

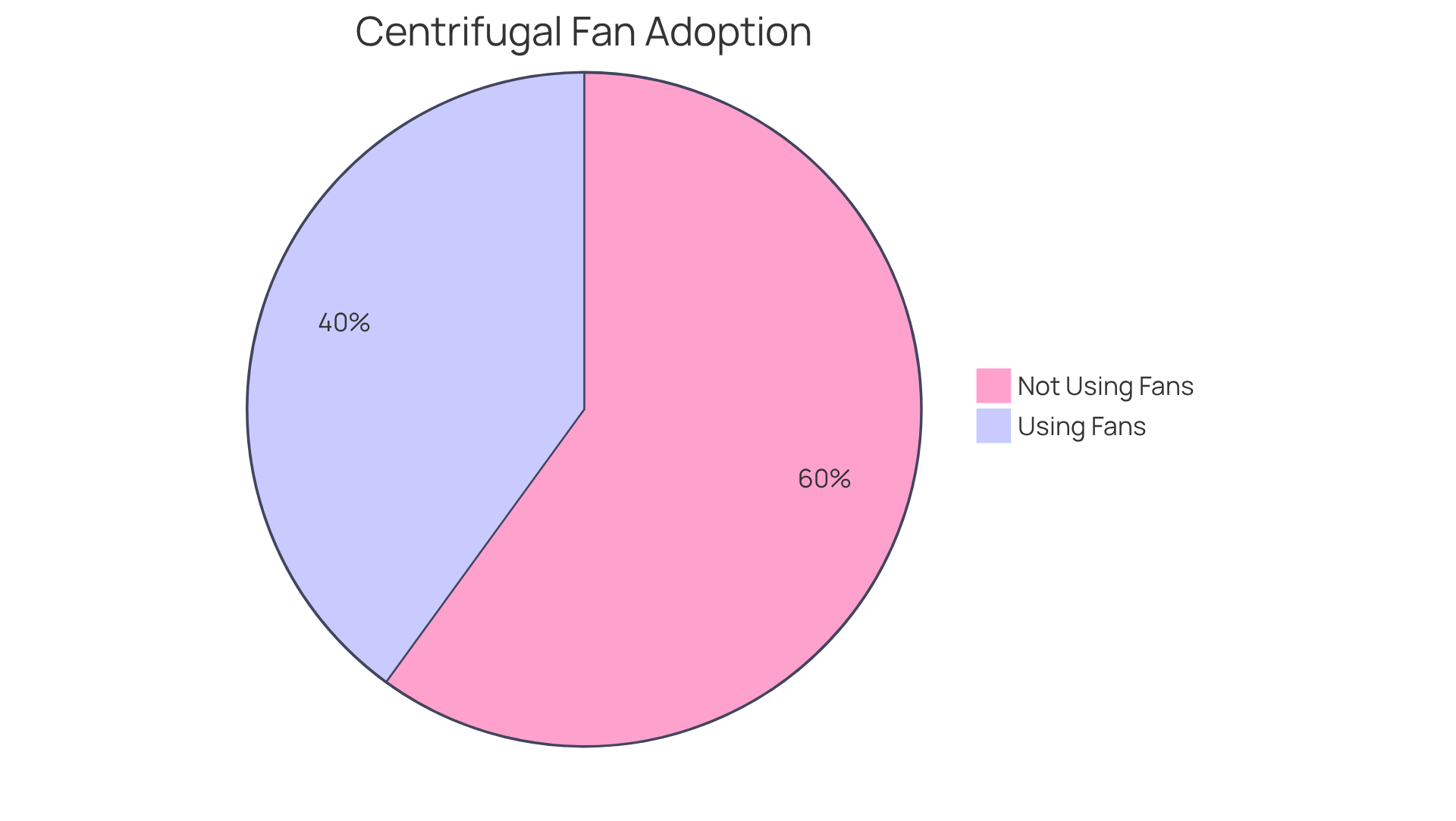

Quiet centrifugal fans are transforming the electronics industry, addressing the critical issue of noise pollution that can undermine product performance and user experience. With nearly 40% of manufacturers adopting these innovative cooling solutions, engineers are uncovering the extensive benefits that quiet centrifugal fans contribute to their designs. This raises an important question: how can these fans not only boost efficiency and reliability but also set new benchmarks for user satisfaction in an increasingly competitive market?

As the demand for quieter, more efficient technology grows, the integration of quiet centrifugal fans becomes essential. These fans not only minimize noise but also enhance thermal management, leading to improved product longevity and performance. By leveraging advanced materials and design techniques, manufacturers can create systems that operate quietly without sacrificing power or efficiency.

The implications of this technology extend beyond mere functionality; they redefine user expectations. In a landscape where consumer satisfaction is paramount, the ability to deliver a quieter experience can be a significant differentiator. As engineers and designers explore these solutions, they must consider how quiet centrifugal fans can be seamlessly integrated into existing systems, ensuring that performance and user experience are elevated.

In conclusion, the adoption of quiet centrifugal fans represents a pivotal shift in the electronics industry. By embracing this technology, manufacturers can not only meet the growing demand for quieter products but also enhance overall user satisfaction, positioning themselves as leaders in a competitive market.

Gagner-Toomey Associates: Leading Provider of Quiet Centrifugal Fans for Electronics

Gagner-Toomey Associates excels in delivering innovative cooling solutions, particularly through its extensive range of blowers and ventilators designed for the electronics industry. As the largest manufacturer of both standard and custom air-movers globally, Gagner-Toomey provides products that not only comply with rigorous industry standards but also significantly boost operational efficiency and user comfort.

The trend towards quiet centrifugal fans is gaining momentum, with nearly 40% of electronics manufacturers now incorporating these quiet centrifugal fan solutions into their designs. This shift aims to mitigate noise pollution and enhance product reliability. According to the U.S. Energy Information Administration, energy consumption in industrial sectors is projected to rise by 1.4% annually, underscoring the urgent need for efficient air handling solutions.

Leading manufacturers have successfully demonstrated that quiet centrifugal fans can reduce operational noise levels by as much as 50%, making them particularly suitable for sensitive electronic environments. Gagner-Toomey’s diverse portfolio includes a comprehensive range of DC input blowers, available in sizes from 15 to 225mm, alongside innovative thermal management solutions such as extruded aluminum heatsinks and integrated cooling devices.

This positions Gagner-Toomey Associates as a premier supplier of high-performance products, ensuring that engineers have access to cutting-edge solutions that enhance the efficiency of electronic frameworks.

Minimize Noise: Enhance Project Performance with Quiet Centrifugal Fans

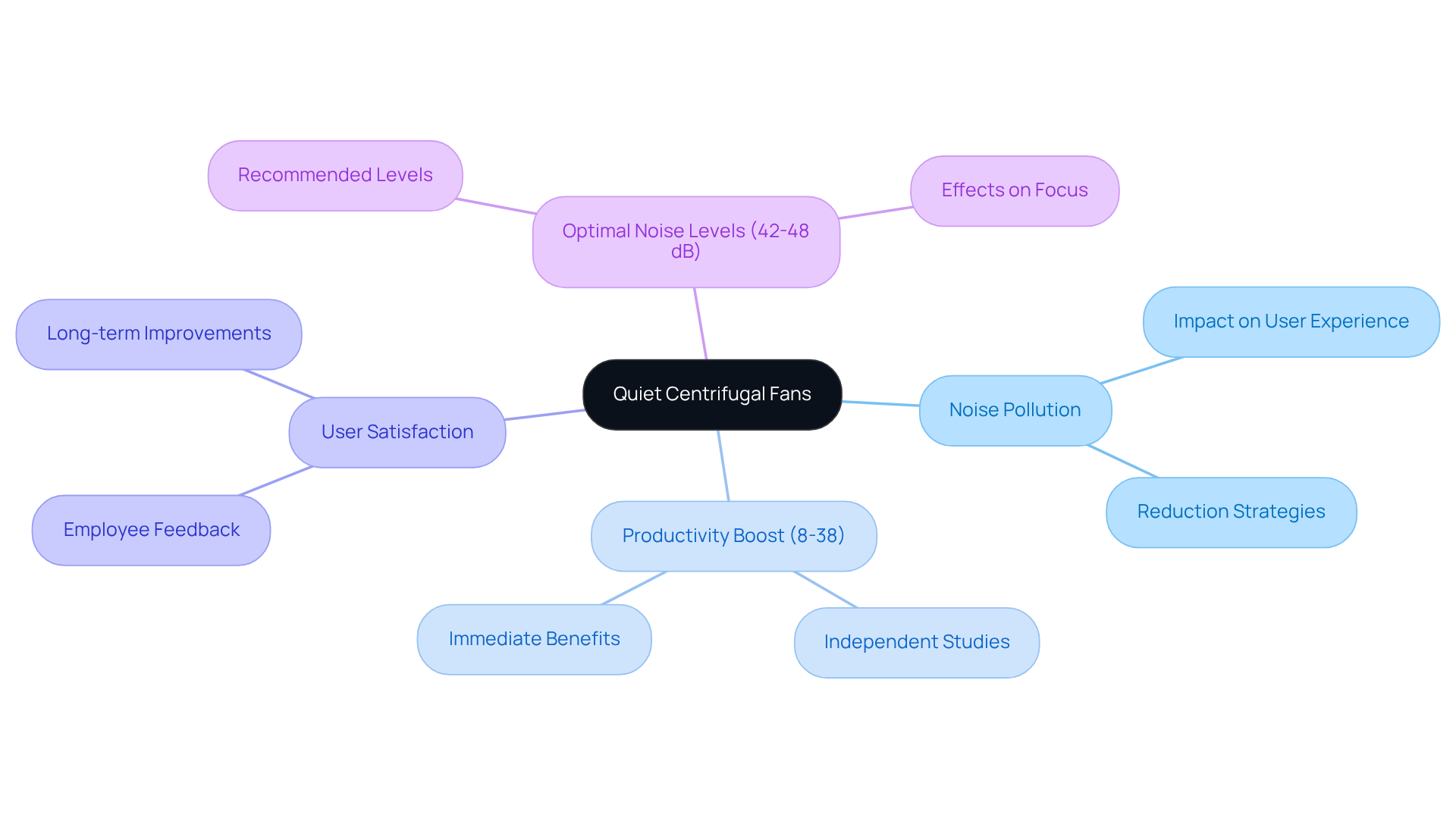

Quiet centrifugal fans address a significant challenge: noise pollution in environments where sound levels can greatly impact user experience and system performance. By minimizing noise, the quiet centrifugal fan enables engineers to develop products that are not only efficient but also enjoyable to use. In the realm of consumer electronics, where user satisfaction is paramount, the integration of a quiet centrifugal fan can significantly enhance focus and productivity in workspaces.

Research underscores this point, revealing that reducing background noise can boost productivity by an impressive 8% to 38%, according to independent studies on sound masking. Moreover, environments equipped with a quiet centrifugal fan often experience immediate benefits in employee satisfaction and concentration, with many companies reporting noticeable improvements within days of implementing sound-related changes. This highlights the essential role of quiet centrifugal fans in the design of modern electronic devices, particularly since excessive ambient noise can lead to a staggering 66% decrease in efficiency.

For optimal performance, it is advisable to maintain noise levels between 42-48 dB. This range ensures an effective acoustic environment conducive to focused work, ultimately fostering a more productive and pleasant workspace.

Maximize Efficiency: The Role of Centrifugal Fans in Electronics Cooling

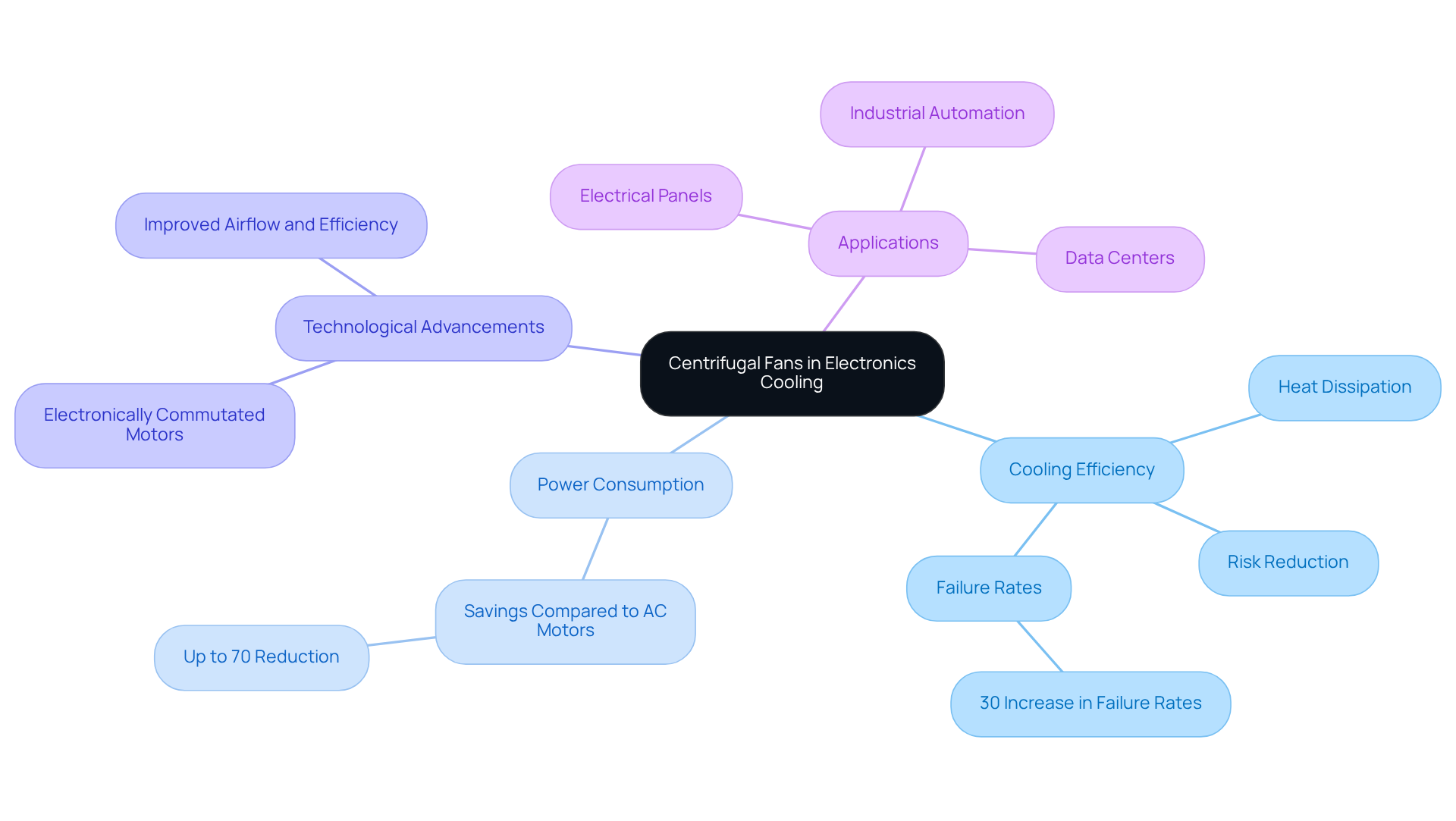

Quiet centrifugal fans play a vital role in ensuring efficient cooling for electronic components by delivering a steady airflow that effectively dissipates heat. Their unique design enables high static pressure, making them ideal for scenarios where airflow must overcome resistance. By improving cooling efficiency through the use of a quiet centrifugal fan, these devices significantly reduce the risk of overheating, which can lead to component failure and a shortened lifespan. Studies show that inadequate cooling can increase failure rates for electronic devices by as much as 30%.

Moreover, a quiet centrifugal fan can reduce power consumption by up to 70% compared to traditional AC motors, thereby enhancing overall energy efficiency. Integrating a quiet centrifugal fan into engineering designs not only optimizes thermal management but also enhances overall reliability. The quiet centrifugal fan is essential among these cooling devices for managing temperature and preventing excessive heat in electrical panels, showcasing their broader applications.

Recent advancements in ventilation technology, including electronically commutated motors, further improve energy efficiency and operational performance, solidifying these devices as crucial components in modern electronic setups. Gagner-Toomey Associates is dedicated to providing access to the latest technological innovations in this field, ensuring that you stay at the forefront of efficient cooling solutions.

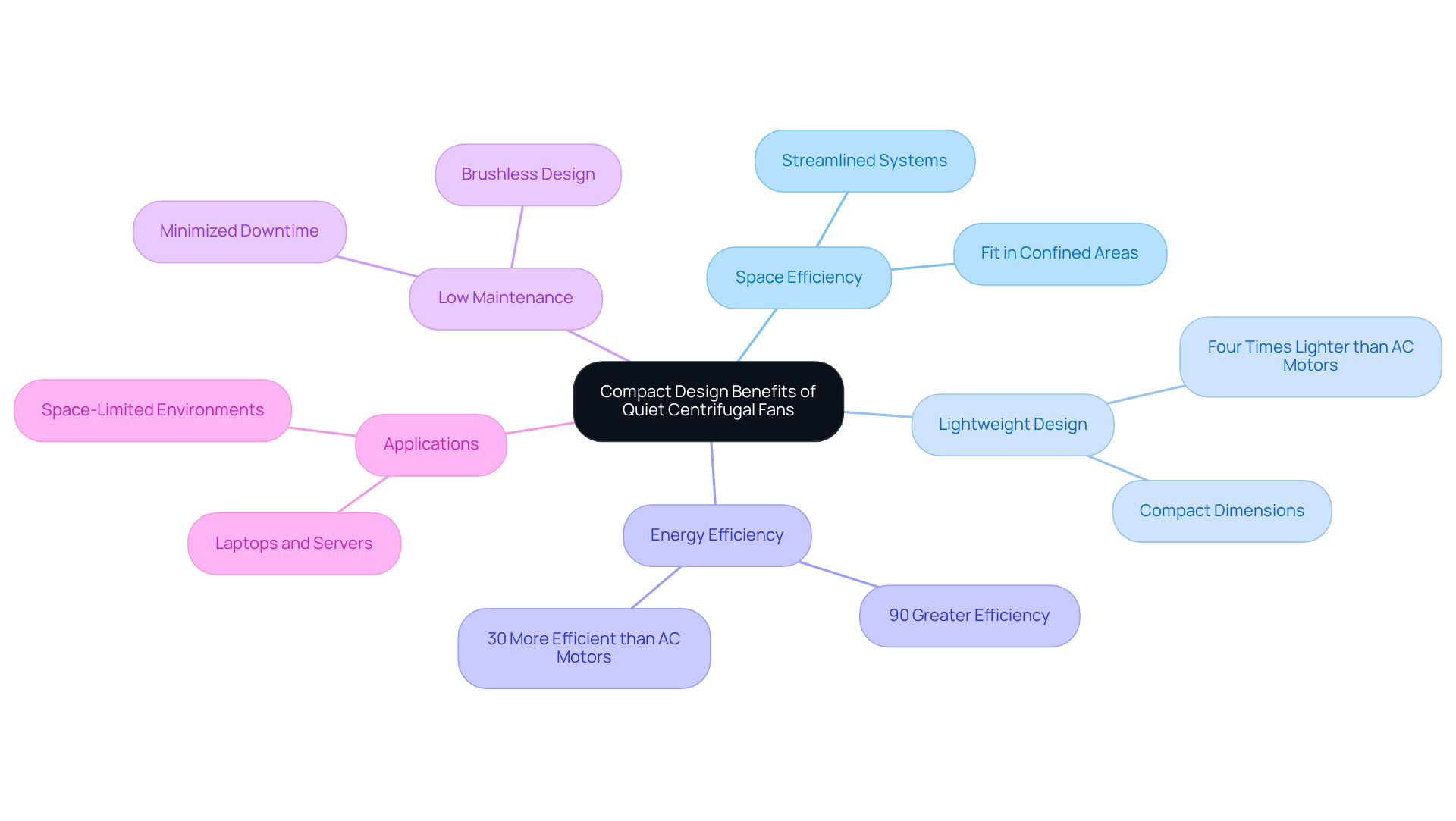

Optimize Space: Compact Design Benefits of Quiet Centrifugal Fans

Quiet centrifugal fans tackle the pressing challenge of space constraints in electronic devices. Designed with compact dimensions, these units fit effortlessly into confined areas, conserving valuable real estate. This innovative layout empowers engineers to create more streamlined and efficient systems, enhancing overall performance.

By utilizing compact airflow solutions, engineers can significantly improve ventilation without sacrificing effectiveness. This makes these devices, especially those equipped with a quiet centrifugal fan, particularly suitable for applications in laptops, servers, and other environments where space is at a premium. Notably, electronically commutated (EC) motors weigh four times less than traditional AC motors, further contributing to the compactness of these cooling solutions.

Moreover, the brushless configuration of EC motors minimizes maintenance requirements, ensuring reliability in space-limited applications. The advanced control capabilities of these devices enable precise airflow management, optimizing energy usage while maintaining high efficiency. According to industry expert Sam Pelonis, EC fan motors can achieve up to 90% greater efficiency due to these advanced control methods, sustaining high performance even at partial speeds.

Additionally, the soft start feature of EC motors allows them to quickly reach speed control voltage, enhancing their reliability. Overall, the integration of quiet centrifugal fans not only meets the demands of modern electronics but also encourages innovative designs that prioritize both performance and space efficiency. This approach aids environmental sustainability through reduced energy consumption and lower carbon emissions.

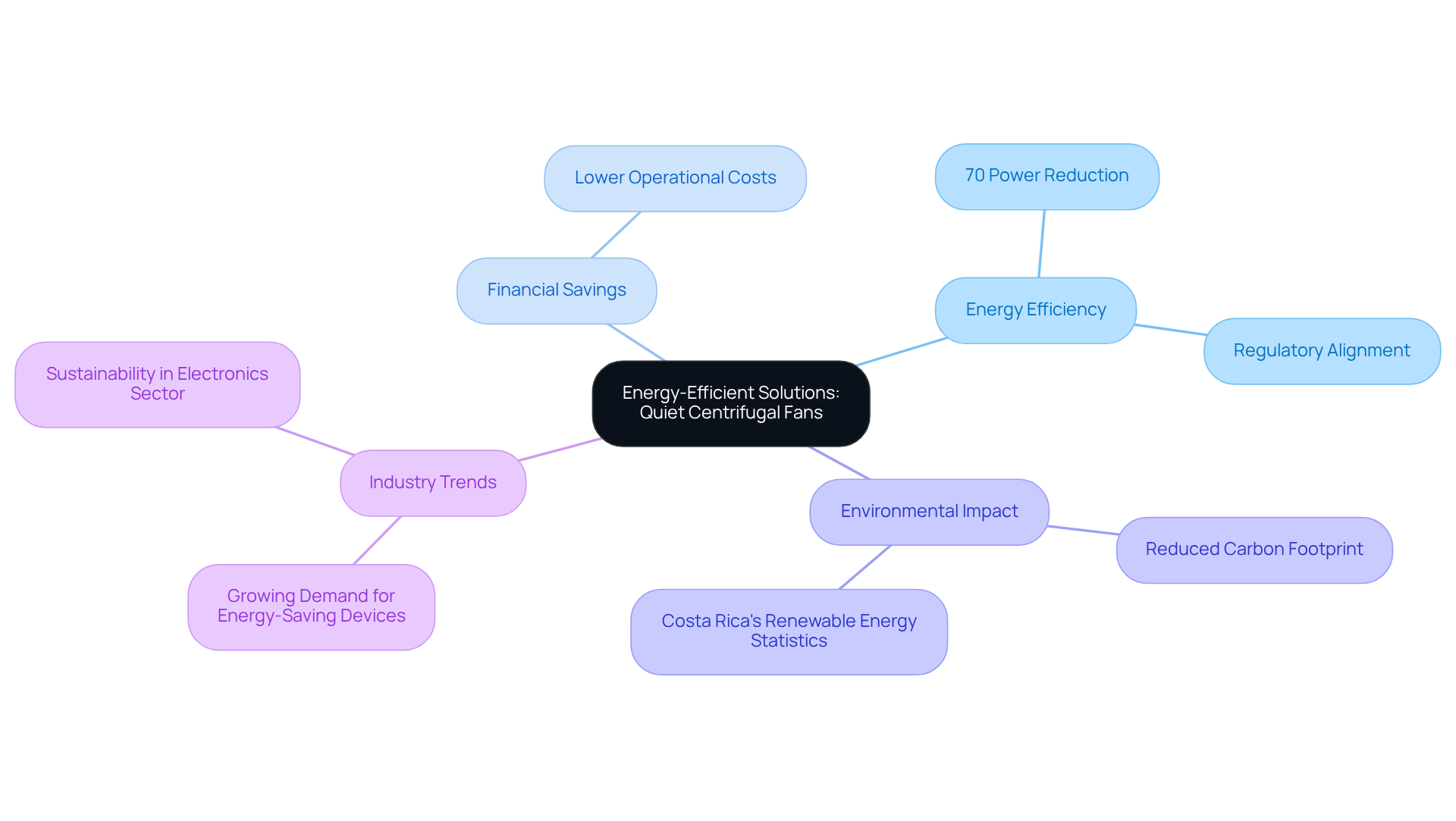

Promote Sustainability: Energy-Efficient Solutions with Quiet Centrifugal Fans

Quiet centrifugal fans stand out for their remarkable energy efficiency, boasting power consumption reductions of up to 70% compared to traditional models. This significant advantage not only captures attention but also highlights a pressing need in today’s electronic systems. By integrating these advanced devices, engineers can dramatically lower operational expenses while simultaneously reducing the environmental impact of their products.

This commitment to sustainability aligns seamlessly with regulatory standards and resonates with consumers who are increasingly prioritizing eco-friendly solutions. For instance, Costa Rica exemplifies this potential, with over 98% of its electricity sourced from renewable energy. Such statistics underscore the industry’s capacity for sustainable practices.

The incorporation of energy-efficient devices not only fosters a sustainable future but also ensures optimal performance, making them an essential choice for contemporary electronics applications. As emphasized by the Department of Energy, evaluating energy-efficient options can yield substantial financial and environmental benefits, reinforcing the critical importance of adopting these technologies.

Moreover, the growing demand for energy-saving devices in refrigeration solutions reflects broader industry trends that advocate for the uptake of these technologies. Industry experts assert that embracing such innovations is vital for sustainable development in the electronics sector, showcasing the dual advantages of cost savings and environmental stewardship.

In conclusion, the integration of quiet centrifugal fans is not merely a technical upgrade; it is a strategic move towards a more sustainable and economically viable future.

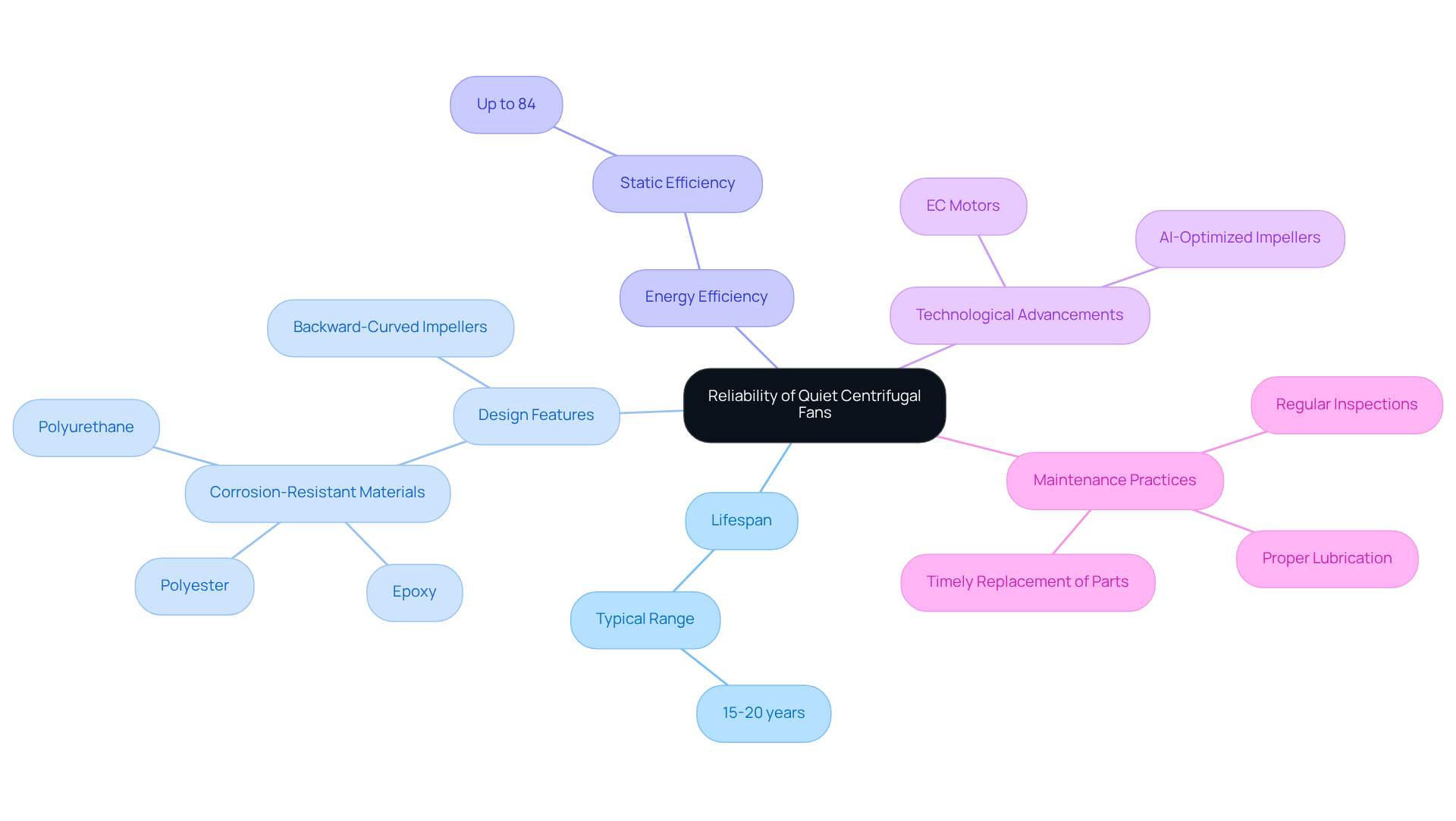

Ensure Reliability: Dependable Performance of Quiet Centrifugal Fans

Quiet centrifugal fans stand out for their exceptional reliability, boasting a lifespan of 15 to 20 years under optimal conditions. Their robust design, enhanced by corrosion-resistant layers such as epoxy, polyester, and polyurethane, ensures dependable performance. This makes them ideal for critical electronic applications, where any failure could lead to significant disruptions.

Numerous industrial plants have successfully utilized quiet centrifugal fans to maintain airflow and cooling, resulting in substantial reductions in operational costs and enhanced efficiency. With energy-saving designs achieving up to 84% static efficiency, engineers can confidently integrate these devices into their systems, knowing they will deliver reliable performance over extended periods.

Recent advancements in fan motor technology, particularly the incorporation of EC motors and AI-optimized impellers, further boost their efficiency and reliability. This solidifies their position as vital components in contemporary electronic systems. Additionally, backward rotating blowers are recognized for their efficiency and lower maintenance needs, providing engineers with versatile options for various applications.

To maximize the lifespan of these devices, proper maintenance practices are crucial. By ensuring they operate effectively in challenging environments, engineers can maintain their performance and reliability.

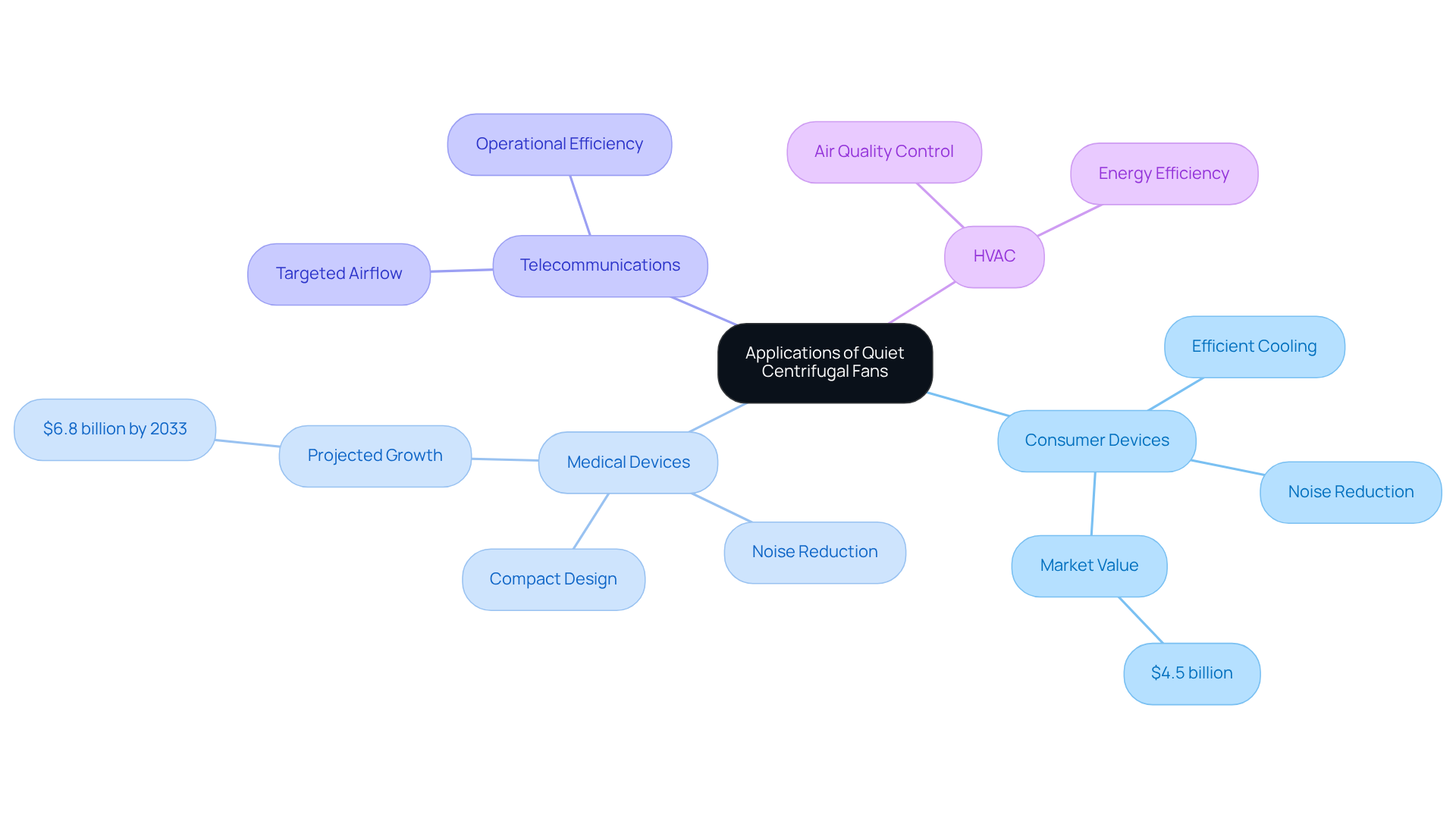

Achieve Versatility: Applications of Quiet Centrifugal Fans in Electronics

Silent rotating blowers represent a highly adaptable solution utilized across a diverse array of electronic applications, ranging from consumer devices to industrial equipment. Their ability to deliver targeted airflow is particularly advantageous for cooling sensitive components found in computers, servers, and telecommunications equipment. In the medical device sector, where noise reduction is paramount, these units excel due to their compact and silent design, facilitating seamless integration into environments such as hospitals and clinics.

The market for rotating blowers was valued at $4.5 billion in 2024 and is projected to expand significantly, reaching an estimated worth of $6.8 billion by 2033, with a compound annual growth rate (CAGR) of 5.2% from 2026 to 2033. This growth underscores the increasing demand for efficient cooling solutions across various industries. Furthermore, advancements in fan technology, including enhanced blade design and materials, have led to the emergence of quiet centrifugal fans specifically tailored for medical devices and telecommunications, thereby improving operational efficiency while maintaining a low noise profile.

Moreover, rotating blowers play a crucial role in HVAC installations and air quality control, further showcasing their versatility. This adaptability positions silent rotating devices as a vital option for engineers seeking effective cooling solutions across multiple sectors. By considering these innovative technologies, professionals can enhance performance while ensuring a quieter operational environment.

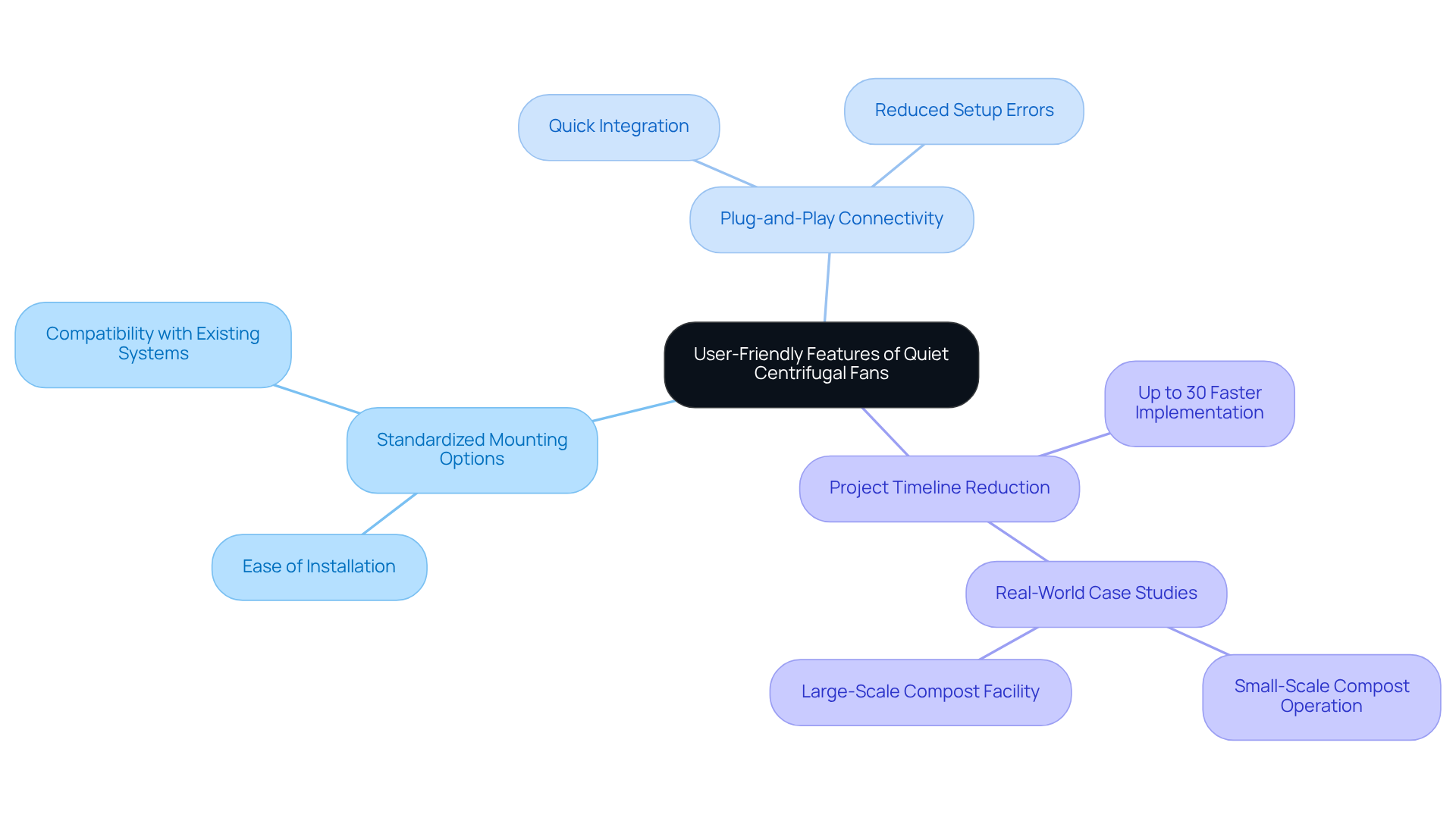

Simplify Installation: User-Friendly Features of Quiet Centrifugal Fans

Silent rotating blowers, such as a quiet centrifugal fan, present a compelling solution for engineers seeking efficiency in electronic systems. These devices are equipped with convenient attributes that streamline installation and integration, making them an essential choice for modern projects.

Many models feature standardized mounting options and plug-and-play connectivity, allowing engineers to swiftly incorporate them into their designs. This simplicity in installation can lead to project timeline reductions of up to 30%, significantly minimizing the potential for errors during setup. For instance, a recent case study demonstrated how a small-scale operation enhanced its output by automating aeration with rotating blowers. This example underscores the ease of integration in real-world applications, showcasing the practical benefits of these systems.

Such attributes make the quiet centrifugal fan an attractive option for busy engineering teams. By enhancing efficiency and reducing operational complexities, these devices empower engineers to focus on innovation rather than installation hurdles. In a fast-paced environment, the ability to quickly implement reliable solutions is invaluable.

Control Costs: Budget-Friendly Benefits of Quiet Centrifugal Fans

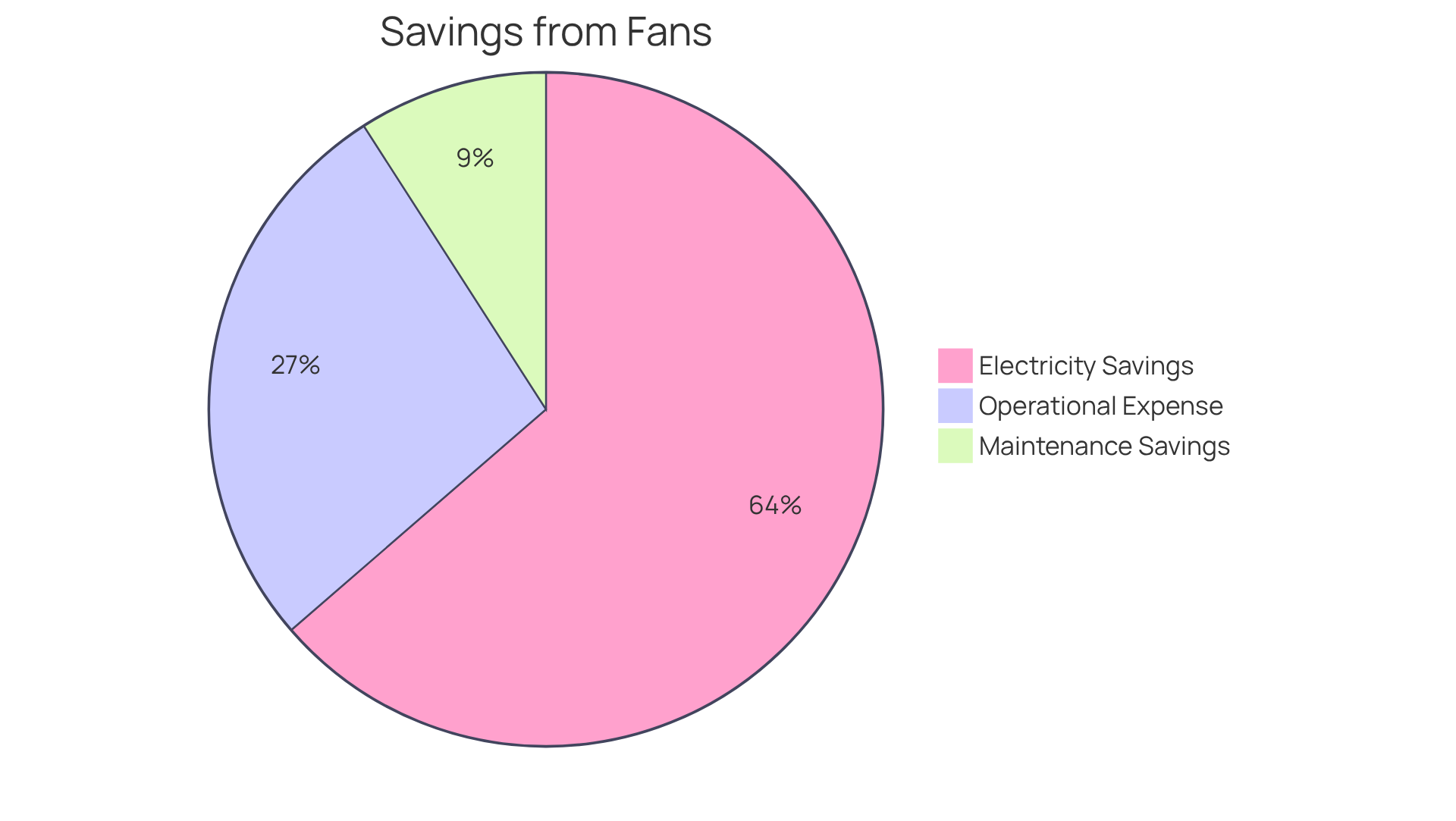

Quiet centrifugal fans present a compelling solution to the escalating costs associated with traditional cooling methods. By significantly reducing energy usage and maintenance expenses, these devices offer a cost-effective alternative that can lower electricity bills by up to 70%. This substantial reduction translates into considerable savings over time, making them an attractive option for budget-conscious projects.

Moreover, routine maintenance of HVAC systems can enhance performance and decrease power consumption by 5 to 15%. The robust construction of these blowers minimizes the need for replacements and repairs, further bolstering their cost-efficiency. For example, a global textile manufacturer that embraced energy-efficient technologies reported a remarkable decrease in power costs and carbon emissions, achieving a reduction of approximately 30% in operational expenses.

Investing in high-quality devices such as a quiet centrifugal fan not only leads to significant long-term savings but also addresses critical operational cost concerns. This financial advantage is particularly appealing in environments where managing expenses is paramount. Traditional cooling methods often incur higher operational costs and contribute to increased greenhouse gas emissions, making the transition to energy-efficient solutions not just a smart financial decision, but also an environmentally responsible one.

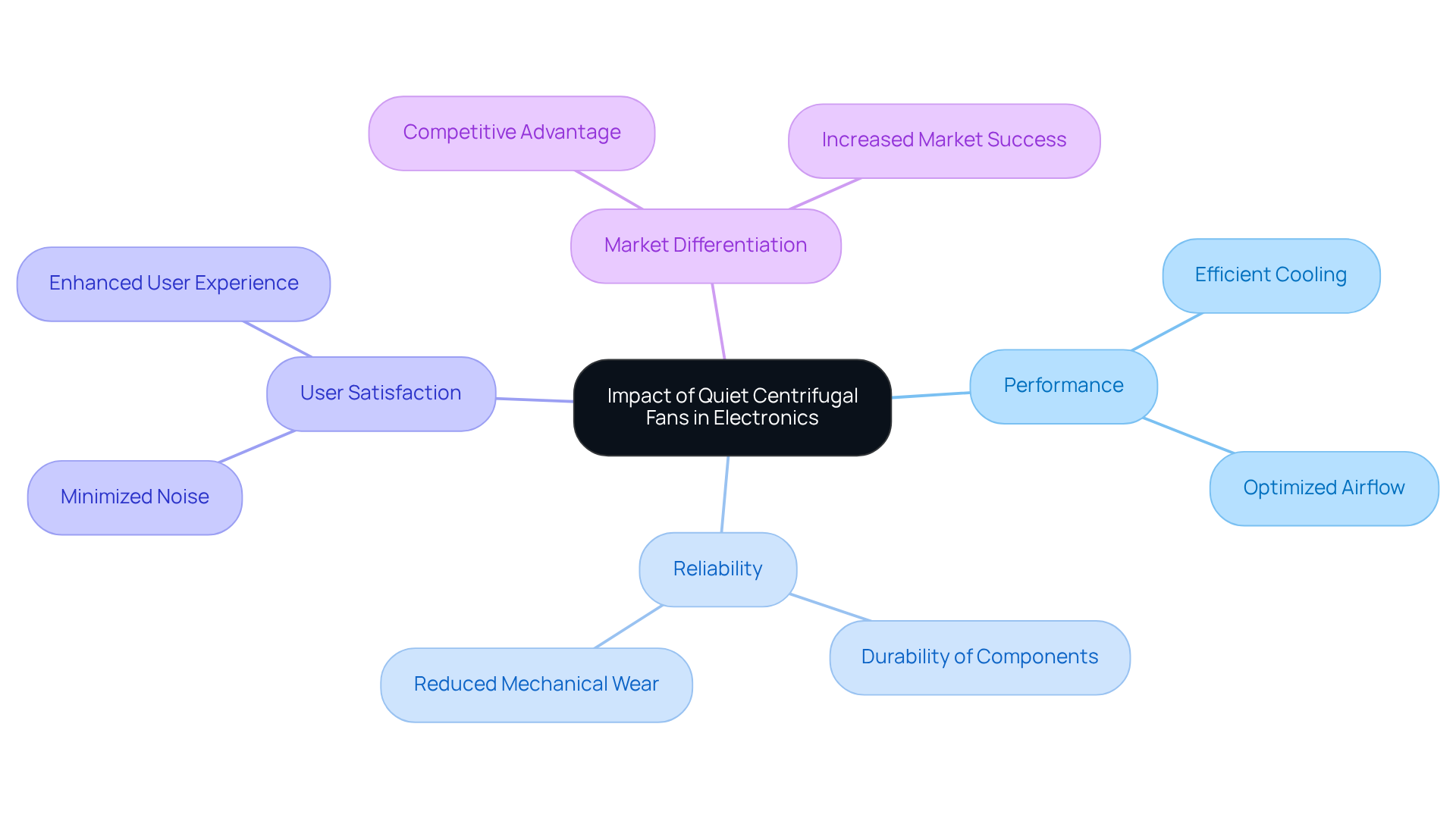

Enhance Project Success: The Impact of Quiet Centrifugal Fans in Electronics

Incorporating a quiet centrifugal fan into electronic designs significantly enhances project success by improving performance, reliability, and user satisfaction. These quiet centrifugal fans offer efficient cooling while minimizing noise, which creates a superior user experience that is essential in competitive markets. By selecting these blowers, engineers can ensure their products not only meet technical specifications but also surpass customer expectations. This strategic choice ultimately leads to greater market success.

Engineers face the challenge of balancing performance with user experience in their designs. Silent centrifugal blowers address this issue effectively. Their innovative design allows for optimal cooling by utilizing a quiet centrifugal fan, eliminating the disruptive noise often associated with traditional fans. This capability not only enhances the functionality of electronic devices but also contributes to a more pleasant user interaction.

Moreover, the integration of quiet centrifugal fans can be a game-changer in industries where noise levels are critical, such as consumer electronics and medical devices. By prioritizing the design of a quiet centrifugal fan, engineers can differentiate their products in a crowded marketplace, appealing to consumers who value both performance and tranquility.

In conclusion, the adoption of silent centrifugal blowers is not just a technical decision; it is a strategic move that can elevate a product’s market position. Engineers should consider these fans as a vital component in their designs to ensure they meet and exceed the evolving expectations of their customers.

Conclusion

The integration of quiet centrifugal fans into electronic systems marks a pivotal advancement for engineers aiming to boost both performance and user experience. These cutting-edge cooling solutions not only reduce noise pollution but also enhance the reliability and efficiency of electronic devices, establishing them as vital components in contemporary engineering designs.

Key benefits of quiet centrifugal fans include:

- Their remarkable ability to cut operational noise by up to 50%

- Improve energy efficiency with as much as 70% less power consumption

- Offer compact designs that maximize space in electronic applications

Furthermore, these fans support sustainability and cost savings, making them an appealing choice for manufacturers and engineers alike. Their versatility across various industries highlights their crucial role in addressing the evolving demands of technology and consumer expectations.

As the electronics industry increasingly prioritizes noise reduction, energy efficiency, and compact design, adopting quiet centrifugal fans transcends mere technical choice; it becomes a strategic necessity. Engineers are urged to view these solutions as integral to their designs, ensuring superior product performance and enhanced user satisfaction in a competitive market. By embracing quiet centrifugal fans, project success is not only elevated but also contributes to a more sustainable and efficient future in electronics.

Frequently Asked Questions

What products does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in innovative cooling solutions, particularly a range of blowers and ventilators designed for the electronics industry, including quiet centrifugal fans.

Why is there a growing trend towards quiet centrifugal fans in the electronics industry?

The trend is gaining momentum to mitigate noise pollution and enhance product reliability, with nearly 40% of electronics manufacturers incorporating these solutions into their designs.

How much can quiet centrifugal fans reduce operational noise levels?

Quiet centrifugal fans can reduce operational noise levels by as much as 50%, making them suitable for sensitive electronic environments.

What are the advantages of using quiet centrifugal fans for user experience?

By minimizing noise, quiet centrifugal fans enhance user satisfaction and productivity, with studies showing that reducing background noise can boost productivity by 8% to 38%.

What is the optimal noise level range for quiet centrifugal fans?

The optimal noise level range for effective acoustic environments is between 42-48 dB, which fosters a productive and pleasant workspace.

How do quiet centrifugal fans contribute to cooling electronic components?

They deliver steady airflow that effectively dissipates heat and improve cooling efficiency, significantly reducing the risk of overheating and component failure.

What impact do quiet centrifugal fans have on power consumption?

Quiet centrifugal fans can reduce power consumption by up to 70% compared to traditional AC motors, enhancing overall energy efficiency.

What recent advancements have been made in ventilation technology related to centrifugal fans?

Recent advancements include electronically commutated motors that improve energy efficiency and operational performance, making these fans crucial components in modern electronic setups.

What is the significance of Gagner-Toomey Associates in the cooling solutions market?

Gagner-Toomey Associates is the largest manufacturer of standard and custom air-movers globally, providing high-performance products that enhance the efficiency of electronic frameworks.