Overview

The article presents a compelling overview of the numerous benefits associated with the use of small blowers in electronics projects. These devices are recognized for their efficiency, portability, versatility, and cost-effectiveness. Such advantages are illustrated through specific applications in vital sectors, including:

- The cooling of sensitive components

- The enhancement of performance in medical devices

- The promotion of sustainability via energy efficiency

This underscores their essential role in the ongoing development of modern electronics, making them indispensable tools for engineers and developers alike.

Introduction

In the rapidly evolving landscape of electronics, innovation is not merely a buzzword—it’s an absolute necessity. Gagner-Toomey Associates stands at the forefront, delivering engineers cutting-edge solutions meticulously tailored to meet the complex demands of the industry. By representing a diverse array of manufacturers specializing in cooling, power management, and interconnect technologies, Gagner-Toomey empowers professionals to surmount challenges and enhance the performance of their electronic systems.

As miniaturization trends reshape the industry, the integration of advanced components into compact designs becomes crucial, particularly in sectors such as healthcare and automotive, where reliability and efficiency are paramount. This article delves into the transformative role of small blowers, exploring their versatility, cost-effectiveness, and environmental benefits while underscoring their contribution to the development of innovative electronics projects.

Gagner-Toomey Associates: Innovative Solutions for Electronics Projects

Gagner-Toomey Associates excels in delivering innovative solutions tailored specifically for the technology sector. By representing a diverse portfolio of exceptional manufacturers—including leaders in cooling, power management, timing, RF, and interconnect technologies—they empower engineers to tackle complex challenges. This commitment to excellence, combined with outstanding customer support, not only provides engineers with access to cutting-edge products but also enhances the performance and efficiency of electronic systems.

As a crucial collaborator in advancing sophisticated technology initiatives, Gagner-Toomey plays a vital role in fostering innovation and facilitating the integration of various features into compact components, a significant trend in the sector. The ongoing miniaturization of devices is particularly transformative, enabling new applications across space-constrained sectors like healthcare and automotive, where efficiency and reliability are paramount.

Gagner-Toomey’s extensive network of local distribution partners ensures a stable supply of components, further supporting engineers in their endeavors. The wearable medical devices market, projected to grow at a CAGR of 25.9% from 2025 to 2034—reaching around USD 427.05 billion—underscores the importance of this trend.

As Warren Bennis aptly stated, “Innovation—any new idea—by definition will not be accepted at first. An organization must undergo numerous trials, continuous presentations, and tedious practice sessions before it can embrace and integrate innovation. This requires courageous patience.” This perspective resonates deeply with Gagner-Toomey’s mission to foster innovation.

Furthermore, the trend towards miniaturization facilitates the integration of more features into single components, as highlighted in the case study on Miniaturized Electronics. This study illustrates how these advancements are enabling new applications across various industries, such as the development of compact medical devices that significantly enhance patient care.

Portability: Enhance Flexibility in Electronics Projects with Small Blowers

Compact fans are engineered for portability, seamlessly integrating into a diverse range of electronics projects. Their lightweight and compact design ensures easy transport, making them suitable for both stationary and mobile applications. This versatility proves particularly beneficial in constrained environments, such as portable medical devices and compact electronic systems. For instance, the integration of compact fans from Gagner-Toomey Associates in surgical robots enhances performance through high-efficiency power solutions, thereby improving healthcare accuracy and patient safety.

Gagner-Toomey Associates stands out as a leading supplier of innovative cooling solutions, offering a comprehensive range of standard and custom fans tailored for various applications. Our compact fans come in sizes ranging from 15mm to 280mm, including DC input tube axial models and centrifugal types, with options for IP protection available upon request. Current industry trends indicate a growing demand for portable device cooling solutions, with compact fans playing a pivotal role in this evolution. According to industry reports, the Portable Electronics Market is anticipated to continue its advancement with the introduction of new and innovative products.

Engineers have noted that the adaptability provided by these devices significantly enhances design options across different applications, underscoring their vital role in modern electronics development. Key features of our small blowers include:

- Lightweight and compact design for effortless integration

- High-performance power solutions for critical applications

- Custom designs available to meet specific project requirements

Andrew Bryars, Senior Product Manager at Gagner-Toomey Associates, states, “Please contact our technical support team for further information on our leading solutions for medical devices and healthcare equipment.” Additionally, the case study titled ‘Hospital Hardware Connectivity Matters’ highlights the critical importance of safety in medical hardware, particularly regarding connectivity ports, and illustrates how the incorporation of isolated DC-DC converters, alongside compact fans, is essential for maintaining safety standards.

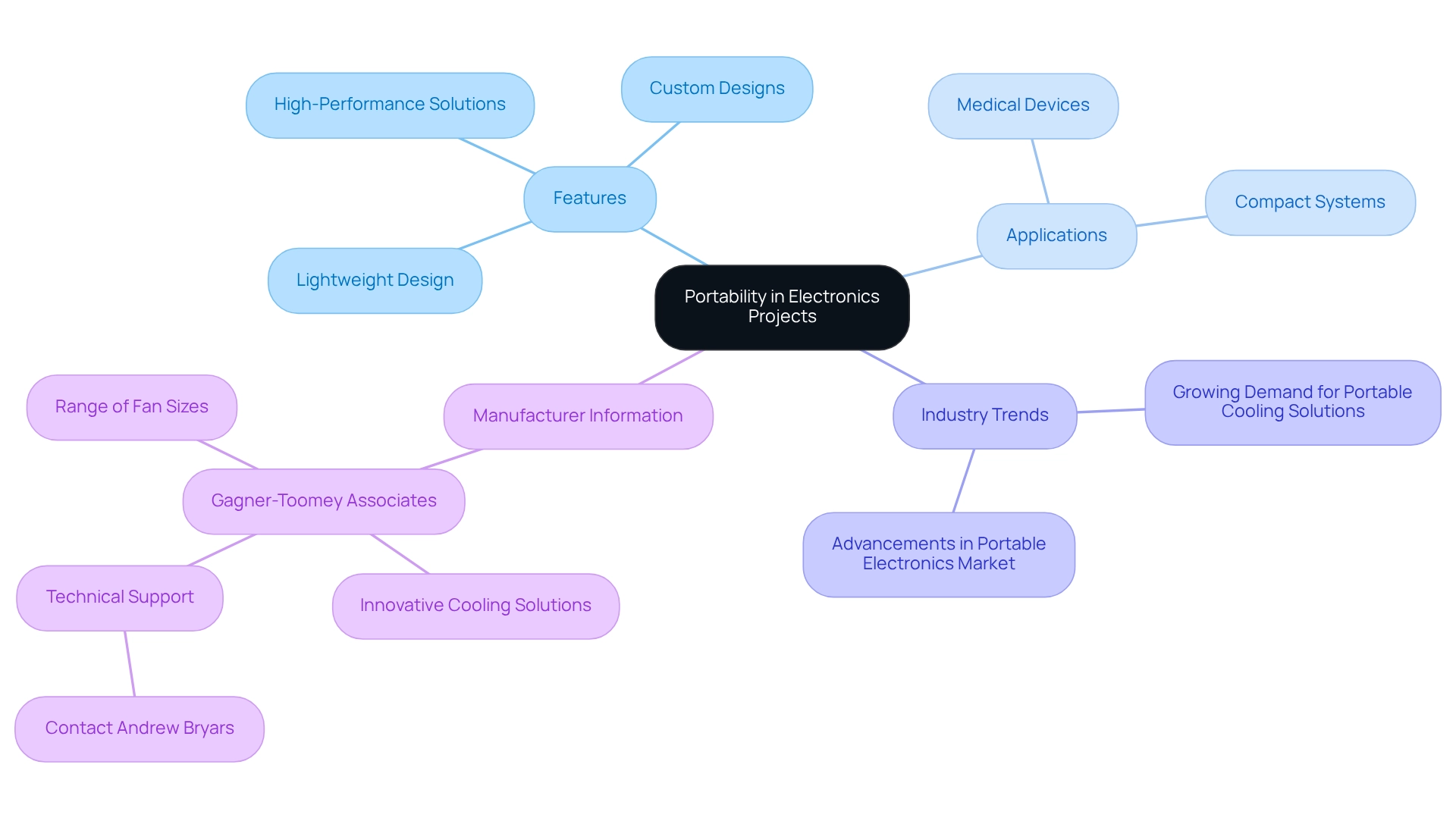

Efficiency: Streamline Maintenance of Electronics with Small Blowers

Compact fans are essential for the maintenance of electronic devices, as they efficiently eliminate dust and debris from sensitive components. This proactive cleaning method addresses the critical issue of overheating, which poses a significant threat to device performance and longevity; excessive heat can detrimentally affect the functionality of electronic equipment.

Regular use of compact fans diminishes the need for extensive maintenance tasks, thereby conserving valuable time and resources. Research indicates that employing small blowers can lead to a reduction in maintenance costs, establishing them as a cost-effective solution for technical professionals.

The North American leaf vacuum market continues to lead, with a projected market size of USD 15.93 billion by 2029, underscoring the increasing recognition of these tools’ importance across various applications, including electronics maintenance. By streamlining maintenance processes, these devices bolster the overall durability and efficiency of electronic equipment, ensuring optimal performance over extended periods.

Furthermore, as the industry shifts towards more sustainable practices—illustrated by STIHL’s commitment to reducing carbon emissions—the adoption of compact devices aligns with innovative solutions that enhance both performance and environmental stewardship.

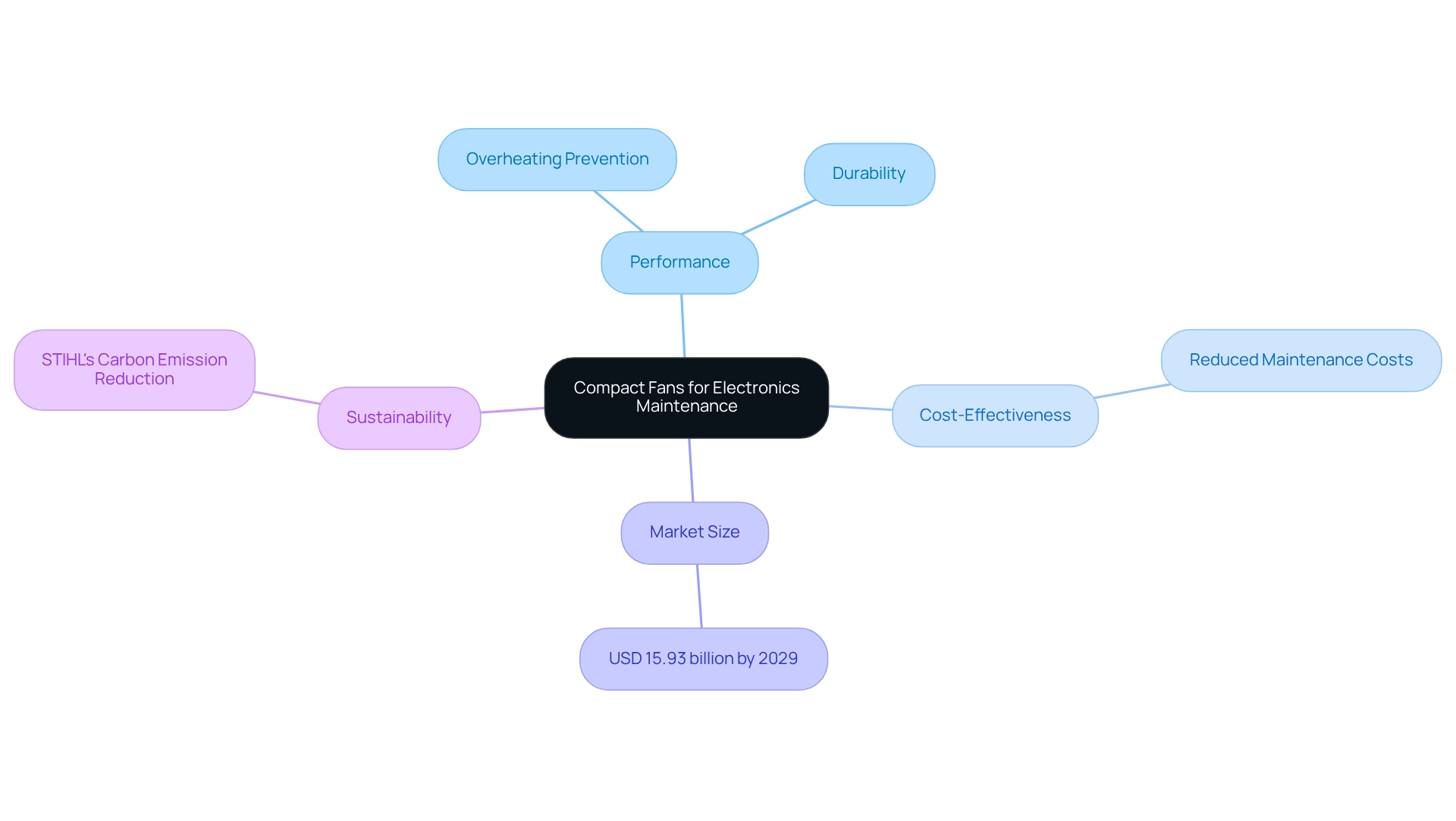

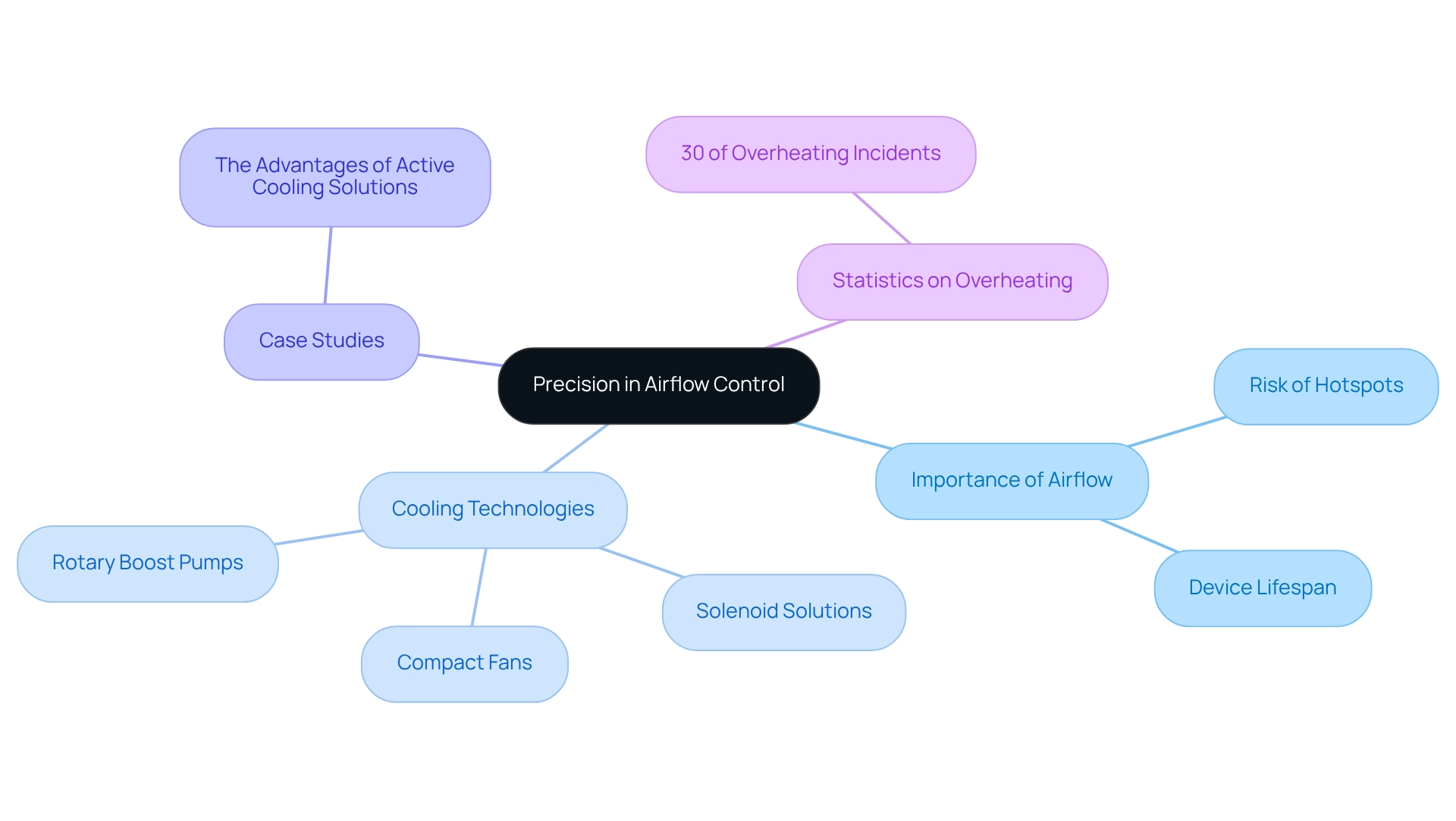

Precision: Achieve Accurate Airflow Control for Sensitive Electronics

Compact fans play a pivotal role in airflow regulation, a critical factor for cooling sensitive electronic components. By meticulously adjusting the fan’s speed and direction, engineers can efficiently channel airflow to essential areas, thereby reducing the risk of hotspots and ensuring that components remain within safe temperature limits. This capability is particularly vital in high-performance applications, such as computing and telecommunications equipment, where overheating can result in significant operational failures.

Notably, statistics indicate that insufficient airflow is responsible for approximately 30% of overheating incidents in devices, underscoring the necessity for effective cooling solutions. Furthermore, innovative solenoid and rotary boost pump solutions from Gagner-Toomey Associates can significantly enhance airflow management in these contexts. Their products, which comply with automotive standards and are certified under quality management IATF 16969, feature low noise operation and precise control via PWM technology.

Case studies, such as ‘The Advantages of Active Cooling Solutions,’ demonstrate that active cooling methods—including small blowers and advanced pump technologies—substantially improve heat dissipation and temperature control, enabling devices to manage substantial heat loads effectively. The significance of precise airflow control cannot be overstated; it not only prolongs the lifespan of electronic devices but also bolsters overall system reliability and performance, ultimately yielding time and cost savings for users.

Versatility: Utilize Small Blowers for Diverse Electronics Applications

Small blowers exhibit remarkable versatility, finding applications across a broad spectrum of electronics projects. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive selection of DC input tube axial fans, available in sizes from 15 to 280mm, alongside centrifugal fans ranging from 15 to 225mm, all optimized for performance and efficiency. Their utility spans from cooling critical computer components to utilizing a small blower for essential ventilation in medical devices, showcasing their adaptability to diverse requirements and environments.

For instance, in the medical sector, small blowers are crucial for ventilating apparatus, ensuring patient safety and comfort. This versatility is further exemplified by the KISS Principle, championed by Kelly Johnson at Lockheed Skunk Works, which underscores the importance of simplicity in design. By prioritizing ease of maintenance, engineers can develop products that are not only effective but also serviceable in challenging conditions.

The elevated maintenance and operating expenses associated with industrial air devices limit their market growth, rendering compact units a more feasible option for numerous applications. Additionally, many models from Gagner-Toomey Associates feature low noise operation and IP protection, further enhancing their suitability for sensitive environments. As engineers continue to innovate, the diverse applications of small blowers, especially those from Gagner-Toomey Associates, will remain a fundamental element in improving performance, solidifying their status as an essential tool in the electronics sector.

Cost-Effectiveness: Save Resources with Affordable Small Blowers

Compact fans stand out for their efficiency and cost-effectiveness, making them an ideal choice for engineers operating within budget constraints. Their affordability facilitates seamless integration into various projects, ensuring that financial limitations do not hinder innovation. Moreover, the energy efficiency of these devices substantially reduces operational costs over time, presenting a compelling case for their use in both small-scale and large-scale electronics initiatives.

For instance, the deployment of compact fans has led to notable energy savings, with data indicating that their implementation can prevent over 3 million metric tons of packaging materials from being utilized, underscoring their broader ecological impact in reducing waste associated with traditional cooling methods. Industry leaders advocate for economical cooling solutions, highlighting the effectiveness of compact fans as a cost-efficient alternative to conventional cooling systems.

Case studies, such as ‘ConnectXperience: The Journey into the World of IoT,’ illustrate their efficacy in educational settings, demonstrating how these devices can enhance project outcomes while ensuring financial viability. Johan Enslin, program director at the U.S. Advanced Research Projects Agency–Energy (ARPA-E), underscores the significance of energy efficiency, stating, ‘With mechanical, it can take up to four or five cycles to clear the fault and that’s so much energy that you have to absorb.’ This perspective reinforces the argument for the operational savings that compact fans can deliver.

Ease of Use: Simplify Your Workflow with User-Friendly Small Blowers

Compact fans are engineered with user-friendliness at their core, featuring intuitive controls and lightweight designs that facilitate effortless operation. This simplicity allows engineers to concentrate on their tasks without the distraction of cumbersome equipment. Whether used for cleaning or cooling, small blowers significantly enhance workflow efficiency and productivity in electronics projects.

Gagner-Toomey Associates plays a pivotal role in this process by connecting engineers with local distribution partners, ensuring a stable supply of components when and where they are needed. The Jindal BOPP Slitter Rewinder case study exemplifies how the integration of user-friendly air systems has led to substantial improvements in operational efficiency, thereby boosting production capabilities.

The design of these devices not only simplifies usage but also fosters a more organized and effective work environment, enabling engineers to achieve their objectives with greater ease and speed. As Rita Lazar-Tippe, Chief Digital Officer, remarked, ‘Our requirements were too custom for typical tools, but user-friendly systems can meet those standards while allowing us to work more efficiently.

Low Noise: Maintain a Quiet Workspace with Small Blowers

Compact fans stand out due to their quiet operation, a vital feature that distinguishes them from conventional cooling devices. Designed for silent functioning, these devices prove especially advantageous in environments where noise reduction is paramount, such as laboratories and offices. In these settings, fostering a tranquil atmosphere is essential for enhancing concentration and productivity. Research underscores that excessive noise can severely impede workplace efficiency, with findings indicating that quieter environments significantly boost focus and overall output.

For instance, the implementation of compact fans in tech laboratories has led to a marked improvement in operational comfort. Engineers have observed that the diminished noise levels facilitate uninterrupted work, creating a more conducive environment for innovation. Moreover, case studies highlight the effectiveness of low-noise cooling options, illustrating how miniature fans operate at sound levels considerably lower than their conventional counterparts, thus minimizing distractions. Notably, the advancement of Liquid Cooling Plates exemplifies how quieter operation can enhance performance in high-demand scenarios, providing improved heat transfer efficiency while sustaining a serene workspace.

The advantages of quiet cooling solutions, which often incorporate a small blower, extend beyond simple comfort; they also play a crucial role in prolonging the lifespan of electronic components by ensuring effective thermal management without the disruptive noise typically associated with larger cooling systems. As Vince McLeod, a senior industrial hygienist, asserts, “Noise reduction is crucial in industrial settings to maintain productivity and worker comfort.”

As the demand for sophisticated devices continues to escalate, the role of small blowers in preserving a quiet work environment becomes increasingly vital, empowering engineers to focus on developing innovative technologies without the interference of unwanted noise. Furthermore, statistics indicate that air cooling systems lack the efficiency of liquid cooling systems in high-performance scenarios, further bolstering the case for integrating small blowers into electronics projects.

Safety: Protect Equipment and Users with Small Blower Features

Compact fans from Gagner-Toomey Associates are equipped with essential safety features that protect both users and equipment. A notable enhancement is thermal overload protection, which prevents overheating, thereby prolonging the lifespan of the fan and improving operational safety. Additionally, integrated safety guards minimize the risk of injury during operation, ensuring that engineers can work confidently with these advanced cooling solutions.

In a recent rehabilitation initiative by Habitat for Humanity in Ravenna, Ohio, the utilization of compact fans with enhanced safety features from Gagner-Toomey Associates played a vital role in managing air quality and energy efficiency. This initiative effectively minimized air leakage considerably, illustrating how powerful fan technology can aid in both safety and performance in demanding settings. Scott Craven, Construction Manager for Habitat for Humanity of Portage County, remarked, “I like to operate my air door during foam applications, pushing air into the house (pressurization) and expelling the fumes from the house,” emphasizing the practical advantages of utilizing compact fans in specific applications.

Statistics indicate that it costs less to be safe every day than to make one careless mistake along the way. This principle underscores the significance of including dependable safety measures in compact fans, enabling engineers to focus on their tasks without the interruption of potential dangers. Expert insights affirm that these safety attributes not only safeguard users but also enhance the overall dependability of electronic systems, making a small blower from Gagner-Toomey Associates an essential tool in the tech sector. The product line includes a variety of sizes and types, ranging from 15mm to 225mm, ensuring that engineers have access to the right solution for their specific needs.

Environmental Benefits: Promote Sustainability with Small Blowers

Compact fans are pivotal in promoting sustainability within technology projects. Many models are designed for energy efficiency, significantly reducing power consumption and minimizing their environmental footprint. For instance, electric fans, unlike gas-powered alternatives, produce fewer emissions, contributing to a cleaner and healthier environment. This transition not only aligns with eco-friendly practices but also addresses the increasing demand for sustainable solutions in the industry. As Barack Obama asserted, “Climate change is no longer some far-off problem; it is happening here, it is happening now,” underscoring the urgency of adopting sustainable technologies.

Energy-efficient small blowers can lead to substantial reductions in energy consumption, which is a critical factor as the electronics industry increasingly prioritizes sustainability. Research indicates that employing energy-efficient blowers can decrease energy usage by up to 30%, significantly impacting overall efficiency. By incorporating these devices into their designs, engineers can enhance project efficiency while actively engaging in environmental conservation efforts.

Case studies, such as Kirsten Schatz’s Clean Air Initiatives, demonstrate the broader implications of sustainable practices in technology. Schatz’s advocacy for clean air and sustainable transportation emphasizes the necessity of community involvement in environmental initiatives, a principle that can be mirrored in the electronics sector through the integration of energy-efficient technologies. Similar initiatives could be adopted within the industry, promoting the use of compact devices to achieve cleaner air and reduced emissions.

Ultimately, by selecting small blowers, engineers optimize their project outcomes while also contributing to a more sustainable future, aligning their efforts with the principles of environmental stewardship and innovation. The transparency surrounding data collection and usage in the industry further highlights the significance of sustainability practices, ensuring that the advantages of these technologies are communicated effectively.

Conclusion

The transformative impact of small blowers in the electronics industry is profound and cannot be overstated. Their versatility, cost-effectiveness, and energy efficiency render them essential tools for engineers who strive to innovate within the constraints of modern design. By enabling seamless integration into various applications—from healthcare to automotive—small blowers enhance performance, reliability, and user experience.

Moreover, the environmental benefits of adopting small blowers align with the industry’s growing emphasis on sustainability. By significantly reducing energy consumption and emissions, these devices contribute to a cleaner and more efficient future. As industries face increasing pressure to adopt environmentally responsible practices, the role of small blowers in promoting sustainability becomes ever more critical.

In summary, small blowers are not merely components; they are integral to the evolution of electronic systems. Their ability to streamline maintenance, provide precise airflow control, and ensure safety positions them as indispensable assets in the development of innovative technologies. As engineers embrace these solutions, they not only enhance their projects but also contribute to a sustainable and efficient electronics landscape, paving the way for a brighter technological future.

Frequently Asked Questions

What solutions does Gagner-Toomey Associates provide for the technology sector?

Gagner-Toomey Associates delivers innovative solutions tailored for the technology sector by representing a diverse portfolio of manufacturers in cooling, power management, timing, RF, and interconnect technologies, empowering engineers to tackle complex challenges.

How does Gagner-Toomey Associates support engineers?

They provide engineers with access to cutting-edge products and outstanding customer support, enhancing the performance and efficiency of electronic systems.

What role does miniaturization play in technology according to Gagner-Toomey?

Miniaturization facilitates the integration of more features into single components, enabling new applications in space-constrained sectors like healthcare and automotive, where efficiency and reliability are crucial.

What is the projected growth of the wearable medical devices market?

The wearable medical devices market is projected to grow at a CAGR of 25.9% from 2025 to 2034, reaching around USD 427.05 billion.

What is the significance of the quote by Warren Bennis in relation to Gagner-Toomey’s mission?

The quote emphasizes that innovation requires trials and patience, which resonates with Gagner-Toomey’s commitment to fostering innovation in technology.

What are the key features of compact fans offered by Gagner-Toomey Associates?

Key features include a lightweight and compact design for easy integration, high-performance power solutions for critical applications, and custom designs available to meet specific project requirements.

How do compact fans enhance the performance of portable medical devices?

The integration of compact fans in devices like surgical robots improves performance by providing high-efficiency power solutions, thereby enhancing healthcare accuracy and patient safety.

What benefits do compact fans provide in terms of maintenance for electronic devices?

Compact fans efficiently eliminate dust and debris, reducing the risk of overheating and the need for extensive maintenance, which conserves time and resources while lowering maintenance costs.

How does the North American leaf vacuum market relate to the importance of compact fans?

The North American leaf vacuum market, projected to reach USD 15.93 billion by 2029, highlights the increasing recognition of compact fans’ importance across various applications, including electronics maintenance.

What trend is occurring in the industry regarding sustainability and compact devices?

The industry is shifting towards more sustainable practices, and the adoption of compact devices aligns with innovative solutions that enhance performance while promoting environmental stewardship.