Overview

This article emphasizes the critical role of enclosure cooling fans that electronics engineers must consider for effective thermal management. It delineates various cooling solutions, including PWM fans, blowers, and air conditioning units, underscoring their significance in preventing overheating, enhancing system reliability, and prolonging the lifespan of electronic components. The discussion not only highlights the necessity of these solutions but also details their specific advantages, thereby guiding engineers in making informed decisions that directly impact the performance and durability of their systems.

Introduction

Innovative cooling solutions are vital for electronics engineers aiming to enhance performance and reliability in their designs. As technology advances, the demand for sophisticated enclosure cooling fans has escalated, providing engineers with a plethora of options to efficiently manage heat dissipation. Yet, with an abundance of products on the market, how can engineers discern the optimal cooling solutions tailored to their unique requirements?

This article examines ten essential enclosure cooling fans, highlighting their distinctive features and benefits, and steering engineers towards making informed decisions for superior thermal management.

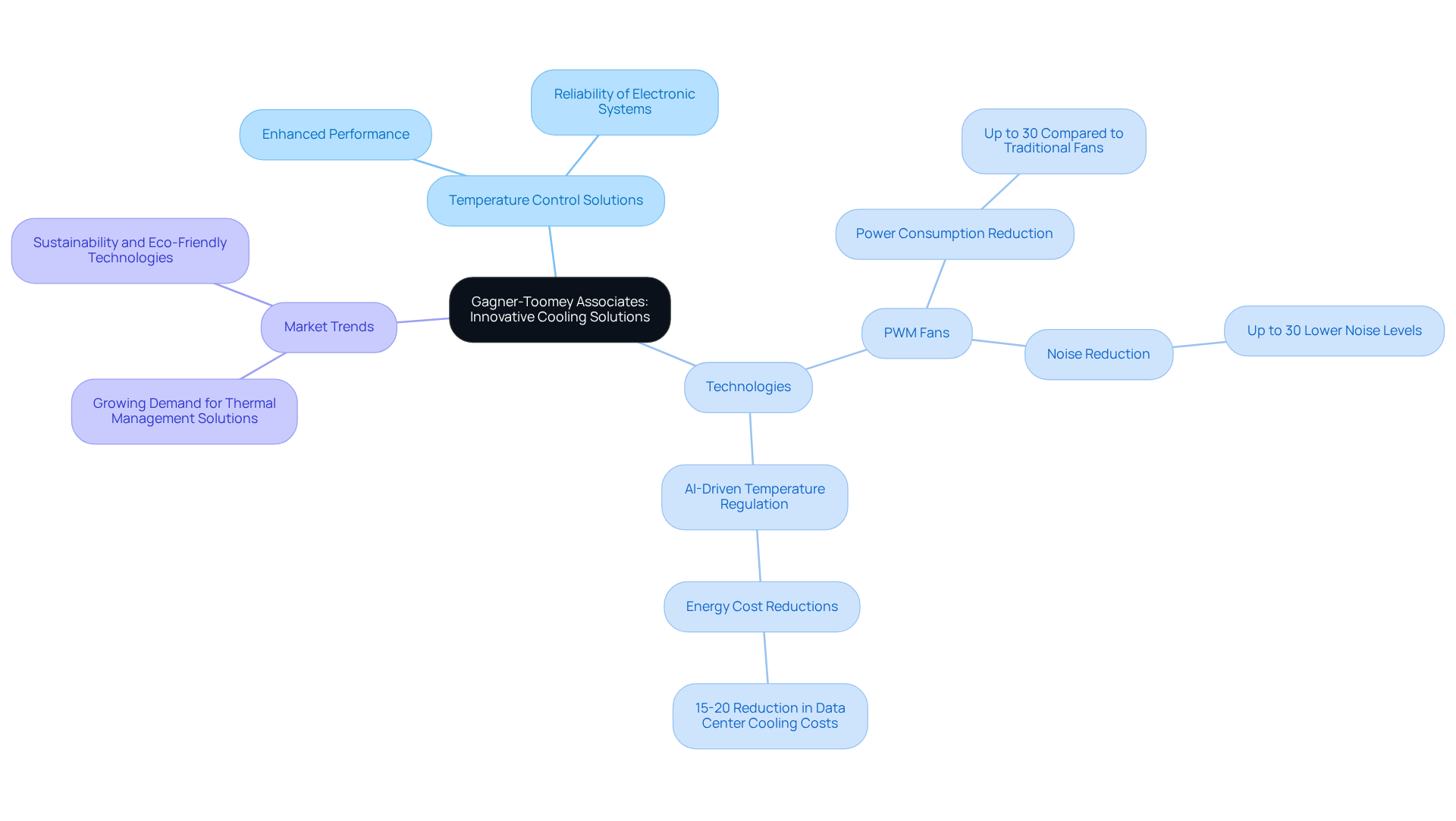

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates excels in delivering innovative temperature control solutions tailored for electronics engineers. By showcasing a diverse range of prominent producers, the company ensures access to cutting-edge temperature regulation technologies that effectively address the complex thermal management challenges faced in the electronics sector. This commitment to excellence not only enhances the performance and reliability of electronic systems but also aligns with the latest trends in temperature management technologies.

For instance, the increasing adoption of PWM fans can reduce power consumption by up to 30% compared to traditional models. Industry leaders underscore the importance of these advancements, noting that AI-driven temperature regulation can lead to significant reductions in energy costs, thereby amplifying the demand for robust thermal management solutions.

As the market continues to evolve, Gagner-Toomey remains at the forefront, facilitating successful implementations that empower engineers to achieve optimal thermal performance in their designs.

Tripp Lite Enclosure Cooling Fan: High-Performance Airflow Management

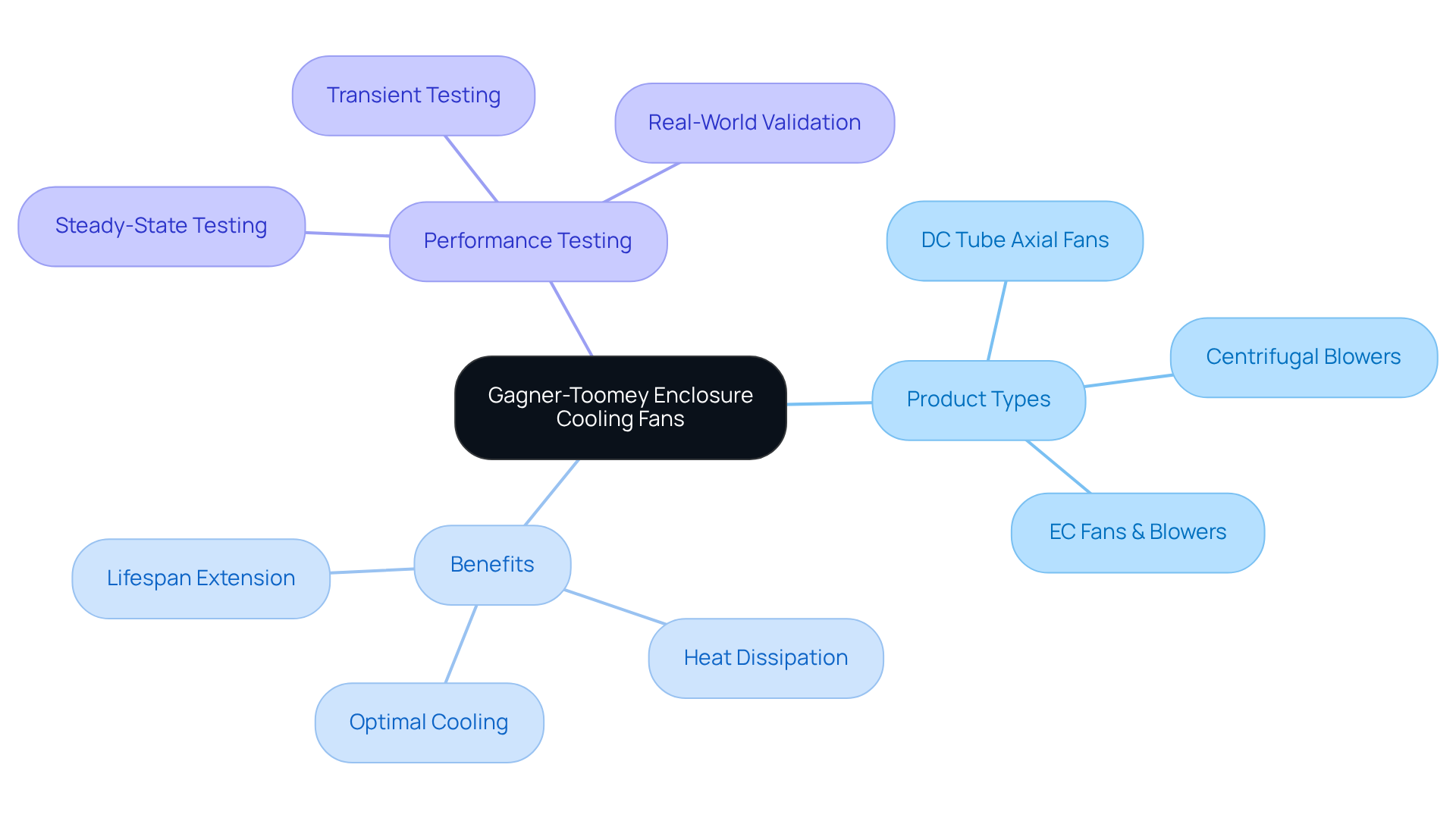

The Gagner-Toomey Associates enclosure cooling fans are a standout solution in high-performance airflow management, making them an essential choice for electronics engineers. With its robust construction and efficient design, this fan provides optimal cooling across diverse applications. The ability to maintain consistent airflow is critical in preventing overheating, thereby extending the lifespan of electronic components. Engineers can rely on enclosure cooling fans for effective heat dissipation within enclosures, ensuring devices operate within safe temperature ranges.

Moreover, Gagner-Toomey offers an extensive product line, including:

- DC input Tube Axial fans ranging from 15 to 280mm

- DC input Centrifugal Blowers from 15 to 225mm

- EC fans and blowers sized from 120 to 910mm

The integration of Gagner-Toomey’s advanced heatsinks and forced-air temperature regulation strategies can significantly enhance thermal management, effectively preventing hotspots in devices. To validate the fan’s performance, rigorous testing protocols that assess both steady-state and transient thermal behavior are essential, ensuring reliable operation in real-world conditions.

Customer reviews consistently highlight its reliability and performance, solidifying its reputation as a trusted solution in the field.

Alpha Enclosure Cooling Fan: Reliable Cooling for Outside Plant Applications

The Alpha Enclosure Ventilation Fan is expertly engineered to deliver reliable temperature control in outside plant applications, where environmental challenges such as extreme temperatures and humidity can dramatically impact performance. Designed for resilience, this fan operates effectively even under harsh conditions, significantly minimizing the risk of failure. Its robust construction is essential for preserving the integrity of sensitive equipment exposed to fluctuating weather conditions.

Indeed, studies reveal that inadequate temperature management can result in a staggering 39% failure rate in data centers, with damages surpassing $600,000, as highlighted by industry experts. Moreover, maintaining stable temperatures is crucial, as a mere 10°C increase in temperature can halve the lifespan of electronic components.

By ensuring optimal temperature management, the enclosure cooling fans from Alpha not only safeguard critical components but also extend their operational lifespan, making them an indispensable choice for engineers responsible for protecting outdoor electronics. Routine maintenance of temperature regulation systems is vital to ensure their durability and reliability, further enhancing the performance of the Alpha fan in challenging environments.

Natural Convection Cooling: Passive Solutions for Enclosure Temperature Control

Natural convection serves as a passive technique reliant on the natural movement of air to dissipate heat from enclosures, while enclosure cooling fans enhance this process. This method not only proves to be energy-efficient but also requires no additional power, making it a compelling choice for various applications.

Engineers can strategically design enclosures with appropriately placed vents and openings, along with enclosure cooling fans, to facilitate optimal airflow, allowing hot air to escape while cooler air enters. Such an approach is particularly effective in environments prioritizing energy conservation, significantly reducing operational costs.

By leveraging natural convection, organizations can enhance their sustainability efforts while maintaining operational efficiency.

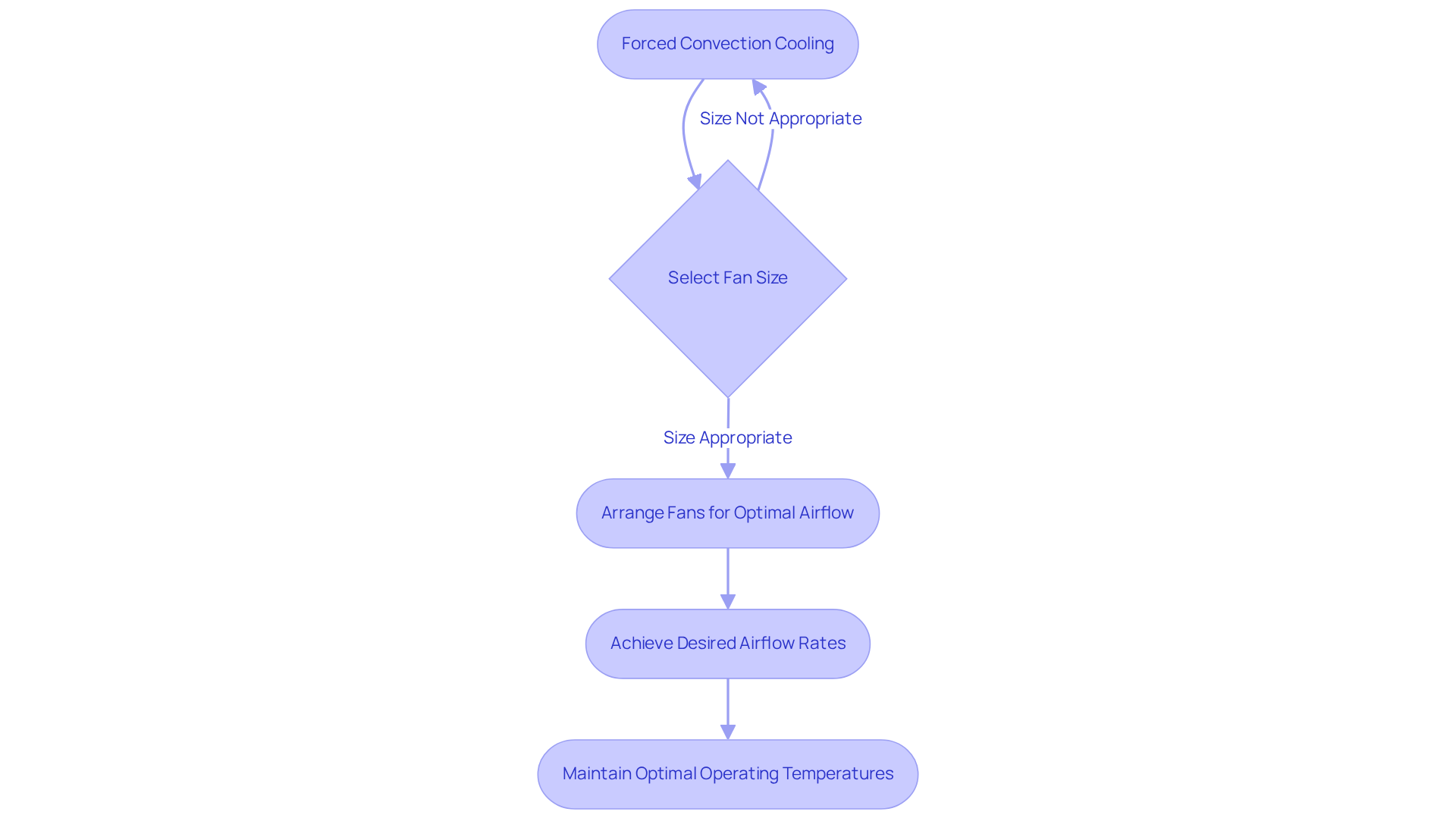

Forced Convection Cooling: Active Methods for Enhanced Airflow

Forced convection ventilation employs enclosure cooling fans or blowers to actively circulate air through an enclosure, significantly enhancing heat dissipation. This method addresses a critical challenge in high-performance applications where electronic components generate substantial heat. By increasing airflow, enclosure cooling fans not only maintain optimal operating temperatures through forced convection ventilation but also prevent thermal throttling and potential damage to sensitive components.

Engineers are empowered to select appropriate fan sizes and arrangements to achieve the desired airflow rates, thereby ensuring effective temperature management in their designs. This strategic approach is essential for optimizing system performance and longevity.

Fan Trays: Essential Components for Optimized Cooling Performance

Fan trays serve as crucial components in electronic systems, integrating multiple enclosure cooling fans to deliver a cohesive solution for enhanced thermal management. By consolidating fans into a singular unit, engineers can streamline installation and maintenance processes while significantly boosting airflow efficiency. These trays are customizable to accommodate various fan sizes and configurations, providing the versatility necessary for diverse temperature management applications. This organization not only enhances cooling efficiency but also bolsters the overall reliability of devices by ensuring consistent airflow throughout all components.

Engineers assert that optimizing airflow with enclosure cooling fans is vital for preventing overheating and sustaining optimal operating conditions. This optimization ultimately contributes to improved system longevity and performance, making fan trays an indispensable element in modern electronic design.

Blowers: Powerful Solutions for Effective Heat Management

Enclosure cooling fans are robust solutions for effective heat management in electronic enclosures. In contrast to traditional fans that primarily provide general ventilation, blowers generate high-pressure airflow, making them ideal for applications requiring directed airflow or the ability to overcome resistance in ductwork.

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers an extensive product line of DC input blowers, available in sizes ranging from 15 to 225mm, optimized for performance, efficiency, and low noise. Their compact design facilitates installation in tight spaces, providing flexibility in network architecture.

Engineers can leverage enclosure cooling fans, such as Gagner-Toomey blowers, to enhance temperature regulation in critical areas, ensuring efficient heat removal from sensitive components. This capability significantly improves overall system reliability, particularly in high-density environments such as data centers and automotive thermal management systems that utilize enclosure cooling fans.

With advancements in electric blower technology, including smart sensors and IoT integration, these devices can adapt to varying thermal conditions, further enhancing their effectiveness in maintaining optimal operating temperatures. For instance, electric blower fans from Gagner-Toomey can deliver up to 5,000 CFM with an efficiency of 50%, underscoring their capability in high-performance applications.

Furthermore, Gagner-Toomey provides IP protection in most models upon request, along with a comprehensive portfolio of thermal management solutions, including heatsinks, liquid temperature regulation options, and integrated custom temperature management solutions. Gagner-Toomey Associates underscores the importance of these technologies in enhancing temperature control solutions, equipping engineers with the resources necessary for efficient thermal management.

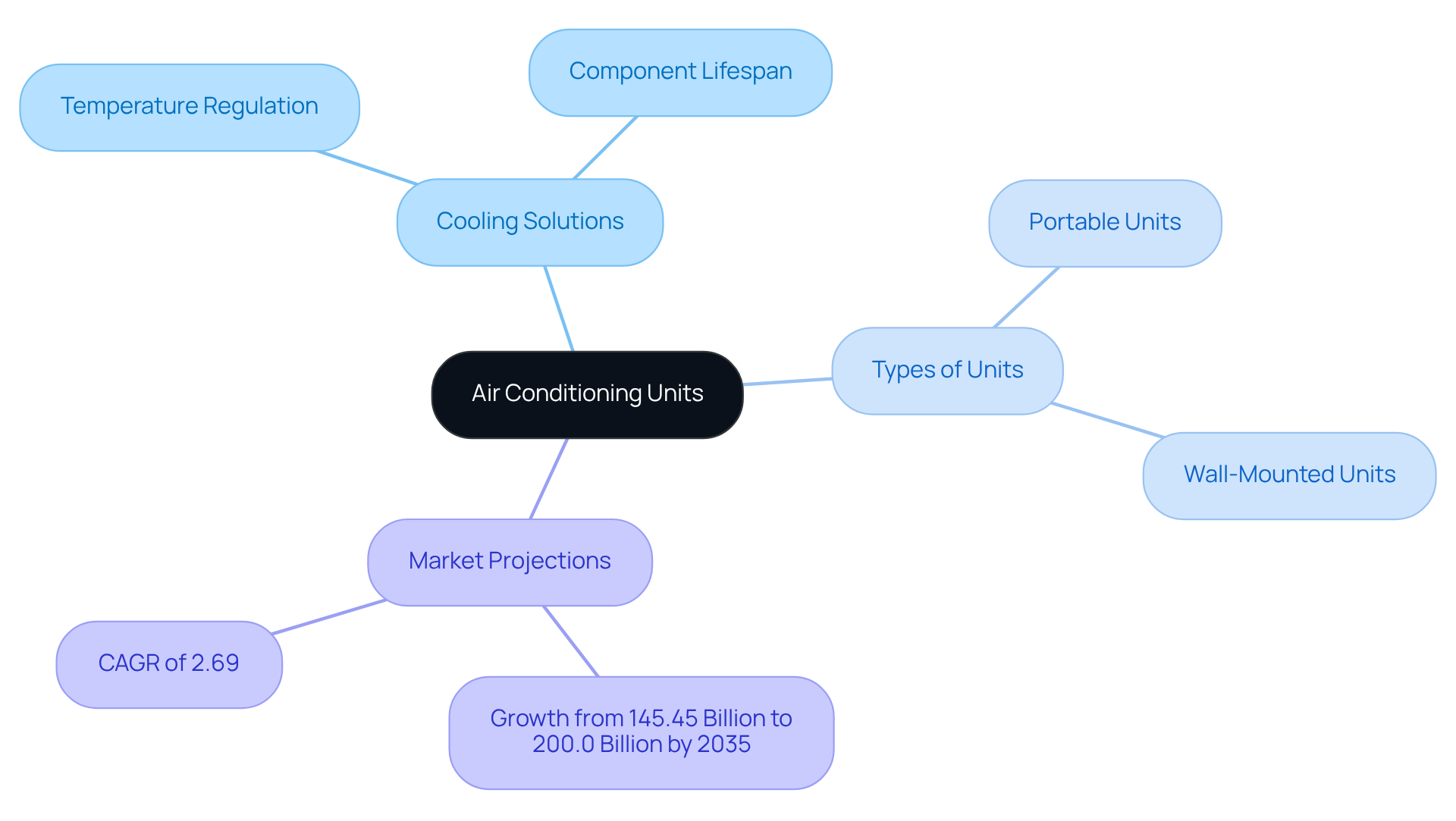

Air Conditioning Units: Comprehensive Cooling Solutions for Electronics

Air conditioning units play a pivotal role in delivering comprehensive cooling solutions for larger electronic setups that produce substantial heat. These systems are meticulously designed to maintain precise temperature regulation, which is vital for ensuring optimal operating conditions for sensitive equipment. Engineers have access to a diverse array of air conditioning options, including portable and wall-mounted units, tailored to fulfill specific project requirements.

By integrating air conditioning into their designs, engineers can effectively manage thermal conditions, keeping equipment within safe temperature thresholds. This not only enhances performance but also extends the lifespan of components, ultimately leading to more reliable and efficient operations.

According to industry reports, the Air Conditioning Equipment Market is projected to expand from 145.45 USD Billion in 2023 to 200.0 USD Billion by 2035, with a CAGR of 2.69% from 2025 to 2035. As urban development continues, the demand for effective temperature regulation methods is expected to rise significantly. Garvit Vyas notes that manufacturers focusing on sustainable practices can leverage this trend, underscoring the critical role of air conditioning in modern technological systems.

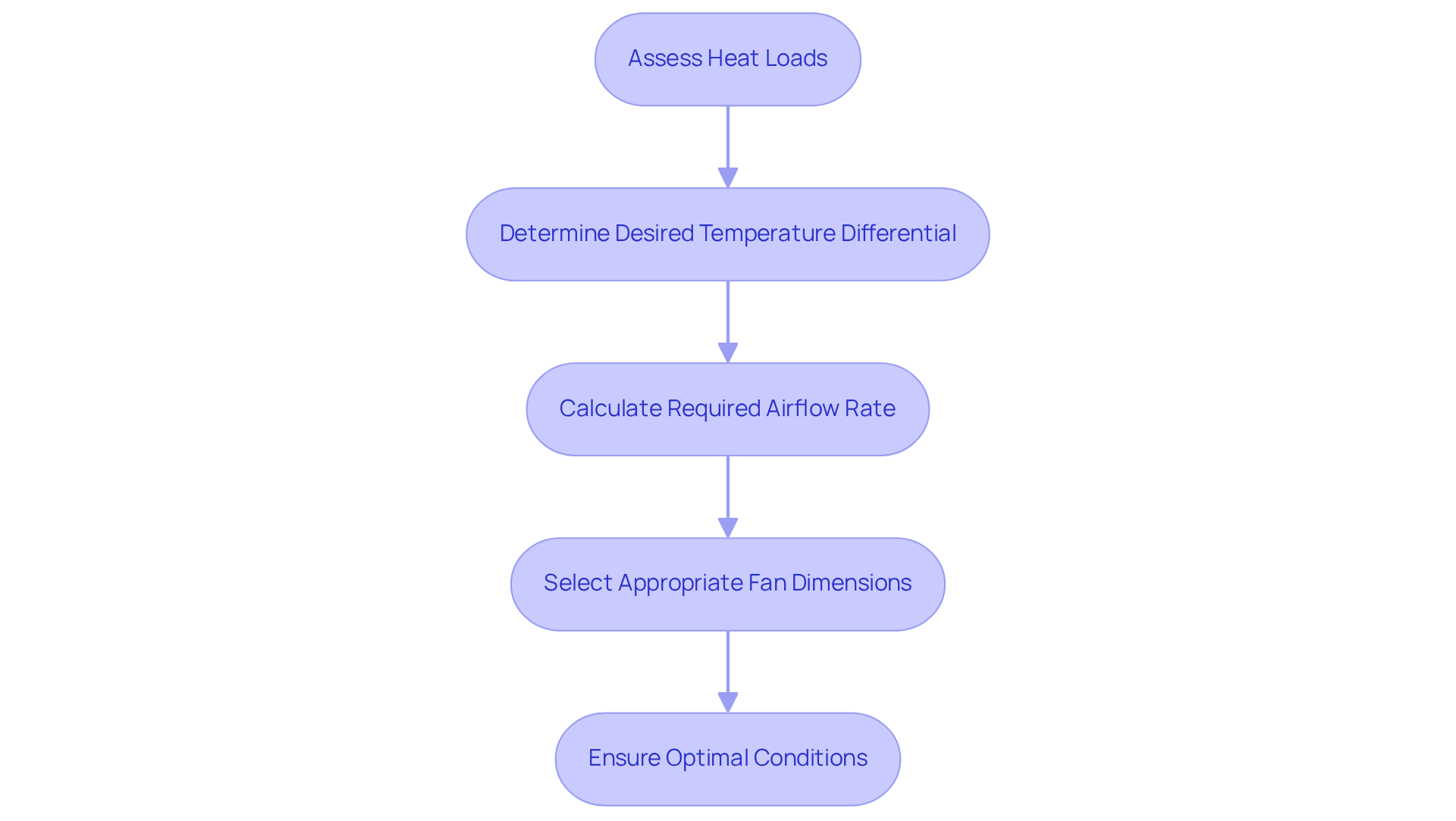

Basic Airflow Calculations: Key Considerations for Effective Cooling Design

Fundamental airflow assessments are crucial for effective temperature management in device enclosures, which often utilize enclosure cooling fans. Engineers face the challenge of managing heat loads generated by components while using enclosure cooling fans to achieve the desired temperature differential and airflow rate necessary for optimal conditions.

By applying established formulas and guidelines, engineers can determine the appropriate fan dimensions and configurations required to ensure sufficient temperature regulation. This proactive approach not only mitigates the risk of overheating but also guarantees that electronic devices operate reliably and efficiently.

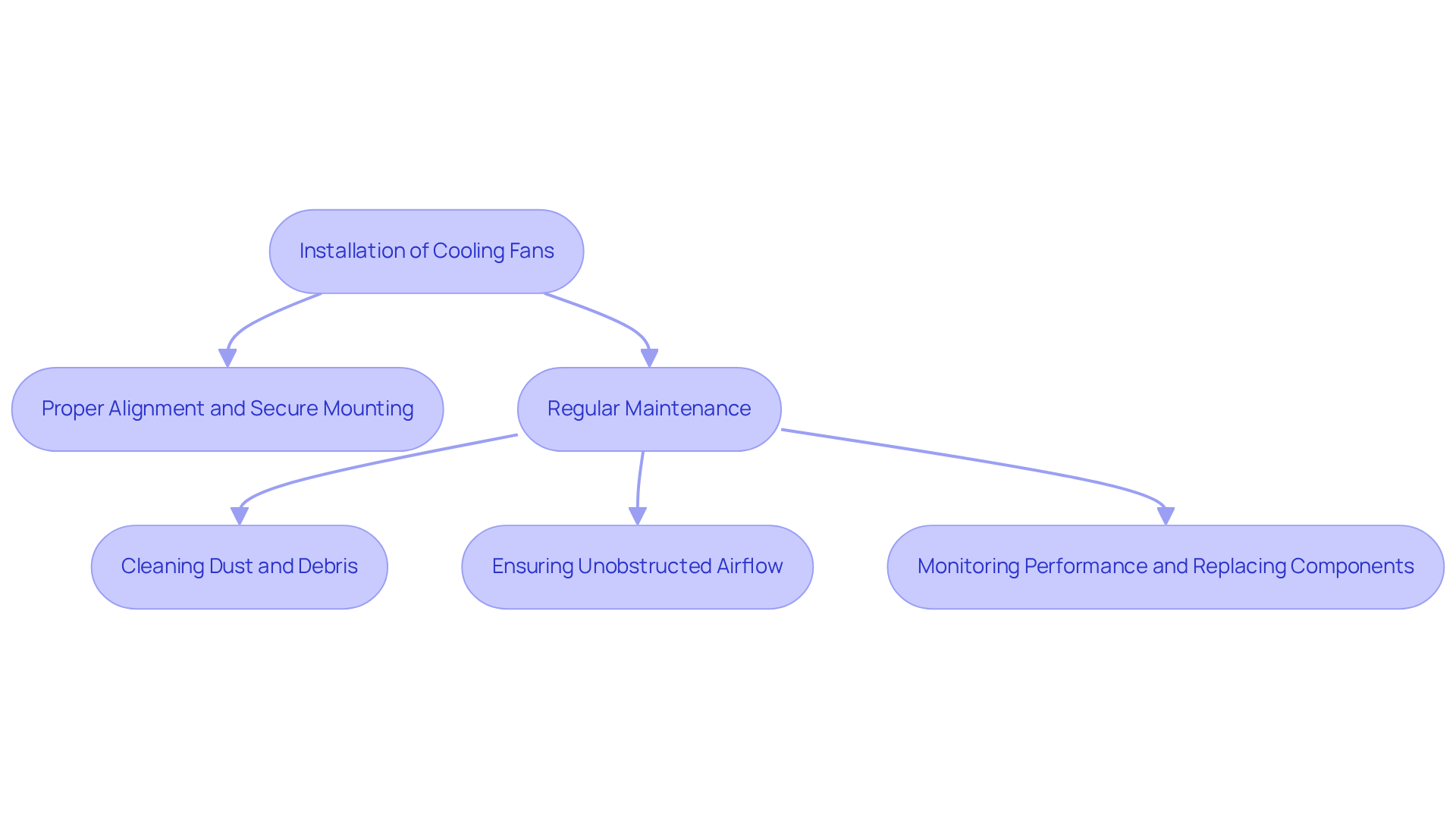

Best Practices for Installing and Maintaining Enclosure Cooling Fans

Implementing best practices for installing and maintaining enclosure cooling fans is crucial for maximizing their performance and longevity. Engineers must prioritize:

- Proper alignment and secure mounting during installation to mitigate vibration and noise, which can adversely affect fan operation.

- Regular maintenance, which is not merely recommended; it is essential. This includes:

- Diligently cleaning dust and debris from fan blades.

- Ensuring unobstructed airflow, both of which are vital for maintaining optimal efficiency.

- Actively monitoring fan performance and promptly replacing worn-out components to significantly prevent system failures.

By adhering to these best practices, engineers can ensure that their cooling solutions operate effectively and reliably over time.

Conclusion

Innovative cooling solutions are essential for electronics engineers, ensuring optimal performance and longevity of electronic systems. This article underscores the critical role of enclosure cooling fans, showcasing a range of advanced technologies and products designed to tackle the thermal management challenges prevalent in the electronics industry. By leveraging these innovative cooling methods, engineers can proficiently manage heat dissipation, thereby enhancing the reliability and efficiency of their designs.

Key insights from this discussion highlight the importance of selecting the appropriate type of cooling fan, such as:

- PWM fans for energy efficiency

- Blowers for directed airflow in high-density environments

Furthermore, the integration of natural and forced convection methods, alongside best practices for installation and maintenance, is pivotal in achieving effective temperature regulation. Emphasizing routine maintenance and proper installation ensures that cooling solutions operate at peak performance, significantly extending the lifespan of sensitive components.

As the demand for effective temperature management solutions continues to escalate, engineers are urged to explore the diverse range of enclosure cooling fans and associated technologies available. By adopting these innovative cooling strategies, professionals in the electronics field can safeguard their equipment while contributing to more sustainable and efficient operational practices. Embracing advanced cooling solutions is not merely advantageous; it is essential for maintaining competitiveness in an ever-evolving technological landscape.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates excels in delivering innovative temperature control solutions tailored for electronics engineers, offering access to cutting-edge technologies that address thermal management challenges in the electronics sector.

How do PWM fans contribute to energy efficiency?

PWM fans can reduce power consumption by up to 30% compared to traditional models, making them an important advancement in temperature management technologies.

What role does AI play in temperature regulation according to industry leaders?

AI-driven temperature regulation can lead to significant reductions in energy costs, amplifying the demand for robust thermal management solutions.

What types of enclosure cooling fans does Gagner-Toomey offer?

Gagner-Toomey offers a range of enclosure cooling fans, including DC input Tube Axial fans (15 to 280mm), DC input Centrifugal Blowers (15 to 225mm), and EC fans and blowers (120 to 910mm).

Why is maintaining consistent airflow important in electronic systems?

Maintaining consistent airflow is critical in preventing overheating, which extends the lifespan of electronic components and ensures devices operate within safe temperature ranges.

What is the significance of rigorous testing for cooling fans?

Rigorous testing protocols that assess both steady-state and transient thermal behavior are essential to validate fan performance and ensure reliable operation in real-world conditions.

What makes the Alpha Enclosure Ventilation Fan suitable for outside plant applications?

The Alpha Enclosure Ventilation Fan is designed to operate effectively under harsh environmental conditions, such as extreme temperatures and humidity, minimizing the risk of failure for sensitive equipment.

What are the consequences of inadequate temperature management in data centers?

Inadequate temperature management can lead to a 39% failure rate in data centers, with damages exceeding $600,000, highlighting the importance of effective thermal management.

How does temperature increase affect the lifespan of electronic components?

A mere 10°C increase in temperature can halve the lifespan of electronic components, making stable temperature management crucial.

Why is routine maintenance important for temperature regulation systems?

Routine maintenance is vital to ensure the durability and reliability of temperature regulation systems, enhancing the performance of cooling fans like the Alpha fan in challenging environments.