Overview

The article emphasizes the essential features of DC 12V fans that engineers must consider:

- Variable speed control

- Low noise operation

- Durability

- Airflow efficiency

- System compatibility

- Energy efficiency

- Ease of installation

- Thermal performance

- Warranty support

Each of these features is critical for optimizing performance and reliability in modern electronic applications. The discussion illustrates how these characteristics contribute to effective cooling solutions, energy savings, and user satisfaction across diverse environments. By understanding these factors, engineers can make informed decisions that enhance the functionality and efficiency of their systems.

Introduction

As the demand for efficient cooling solutions intensifies in the realm of modern electronics, the significance of DC 12V fans has surged. These compact devices are not merely accessories; they are critical components that enhance performance, longevity, and user satisfaction across a myriad of applications. This article delves into ten essential features of DC 12V fans, illuminating how engineers can leverage these attributes to optimize their designs. Yet, amidst the plethora of options, one must consider how to ensure that the selected fan meets the specific demands of their unique projects.

Gagner-Toomey Associates: Innovative Solutions for DC 12V Fan Cooling

Gagner-Toomey Associates excels in providing advanced cooling solutions, particularly through the implementation of a DC 12V fan. These devices, measuring 40x40x15 mm, are essential for heat management within electronic systems, significantly enhancing both functionality and component longevity. As electronic devices grow increasingly complex, effective cooling has become paramount; studies indicate that inadequate cooling can lead to a 30% reduction in component lifespan.

As the globe’s foremost producer of standard and custom air-movers, Gagner-Toomey offers engineers access to the latest advancements in ventilation technology. This includes a wide range of DC input Tube Axial units, available in sizes from 15 to 280 mm, and Centrifugal Blowers, ranging from 15 to 225 mm, all optimized for efficiency and low noise. The fans are offered in various airflow and static pressure options, addressing diverse usage requirements. Additionally, most models provide IP protection upon request.

For instance, the San Ace DC 12V fan, which was developed through a comprehensive review of impeller shape, motor characteristics, operating airflow, and expected life, delivers exceptional cooling performance suitable for demanding applications such as servers and ICT equipment. This commitment to excellence ensures that engineers can design reliable systems that meet the rigorous demands of modern electronics. Gagner-Toomey supports this with a comprehensive portfolio of thermal management solutions, including heatsinks, cold plates, and integrated cooling solutions.

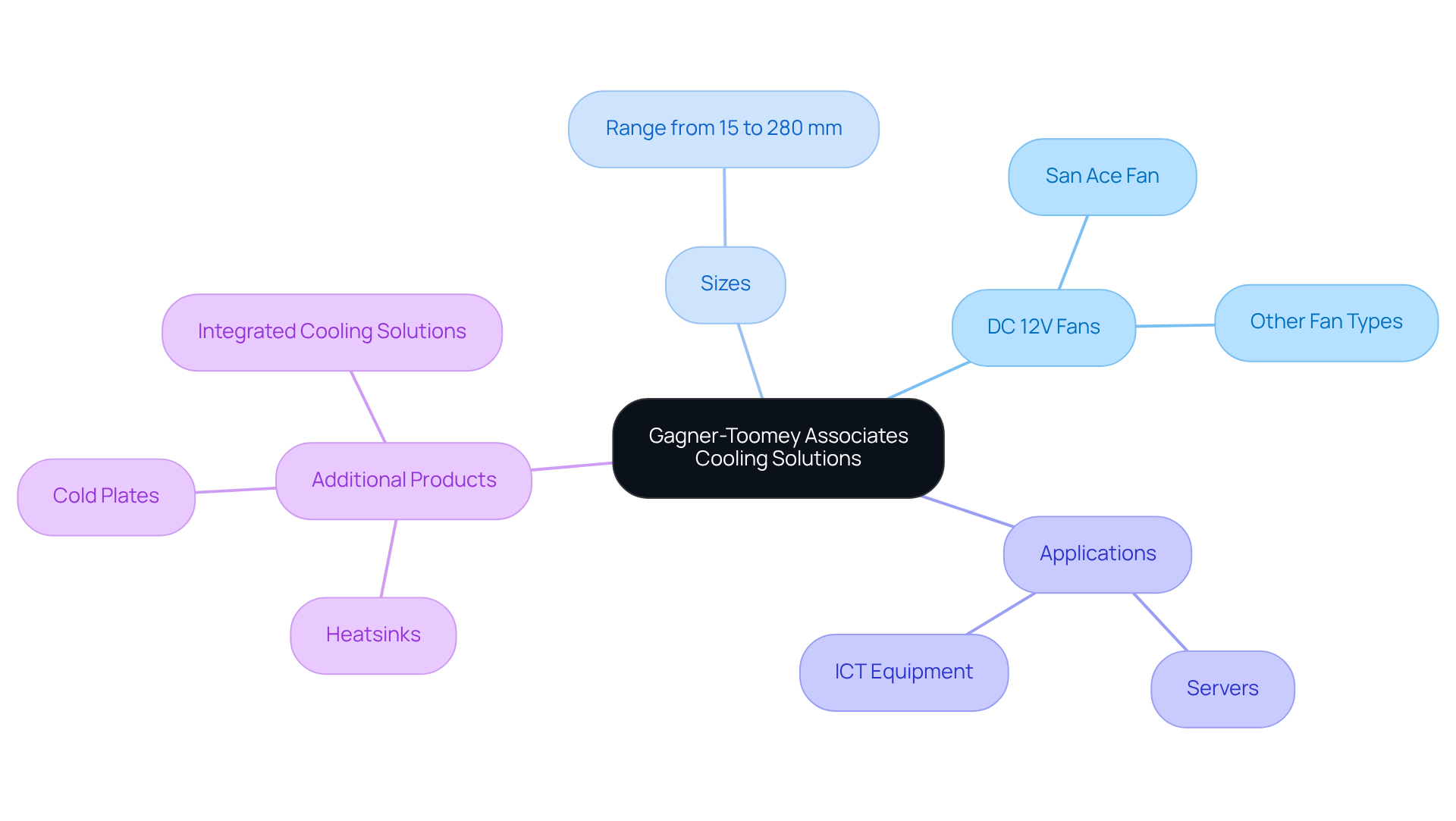

Variable Speed Control: Essential for Performance Optimization

Variable speed control is a pivotal feature in DC 12V fans, allowing engineers to customize the speeds of DC 12V fans according to the thermal load of their systems. This adaptability not only enhances cooling performance but also effectively reduces noise levels and energy consumption. For example, decreasing fan speed by half can result in an energy consumption decrease of one-eighth, illustrating the exponential relationship between speed and power draw, as power consumption varies with the cube of the operating speed.

Furthermore, modern variable speed drives (VSDs) have the potential to cut energy usage by up to 50% for specific motor applications, establishing them as a crucial component in contemporary cooling systems. The implementation of variable speed drives has been shown to yield significant returns, with four ENERGY STAR certified data centers reporting paybacks on investment ranging from 0.54 to 1.7 years.

As noted by P. Pryor, “The fixed speed drives with blowers and pumps are the primary cause of energy waste,” underscoring the importance of variable speed control. By harnessing these capabilities, engineers can ensure their systems operate efficiently under varying conditions, ultimately leading to reduced operational costs and improved system longevity.

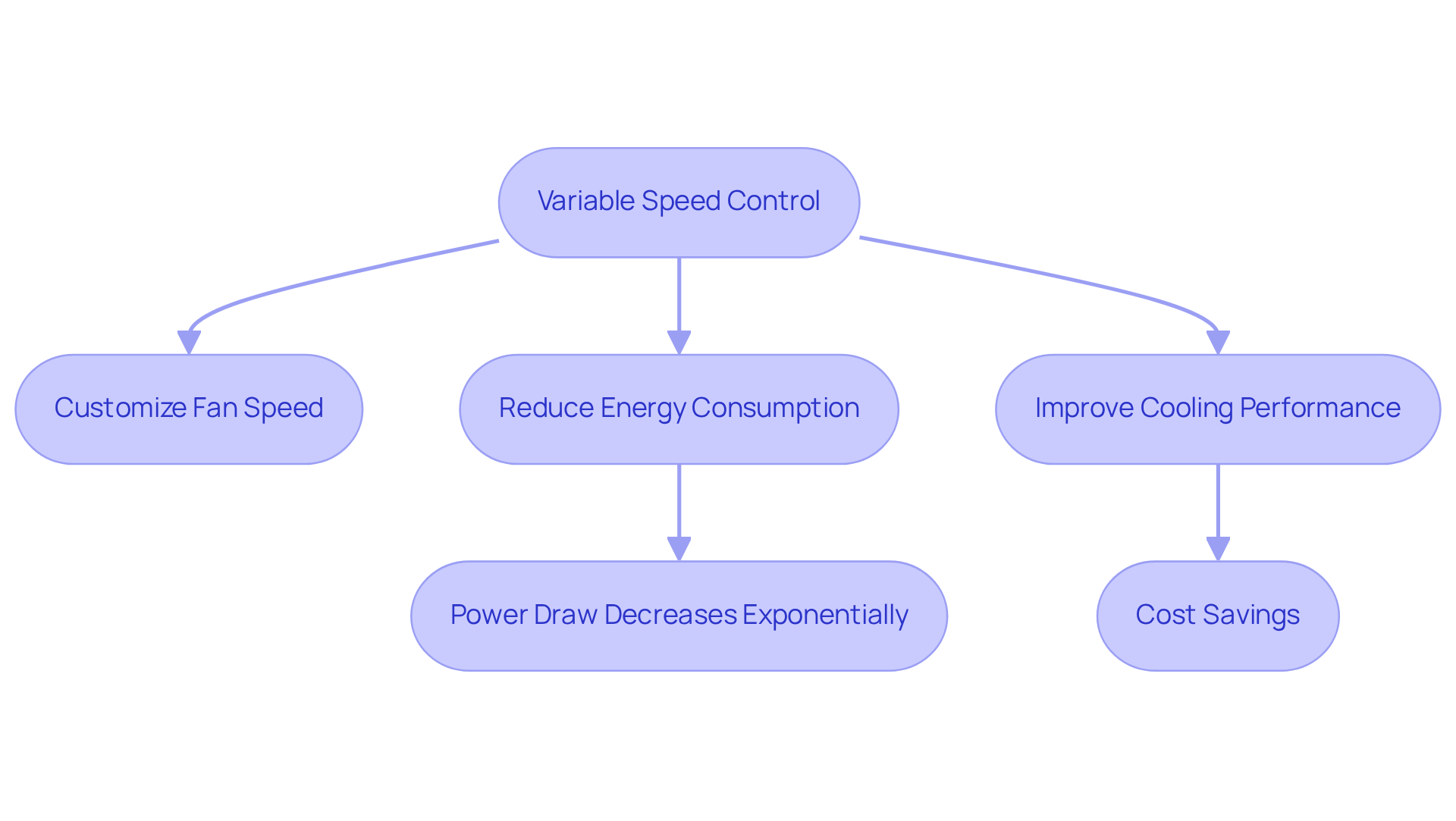

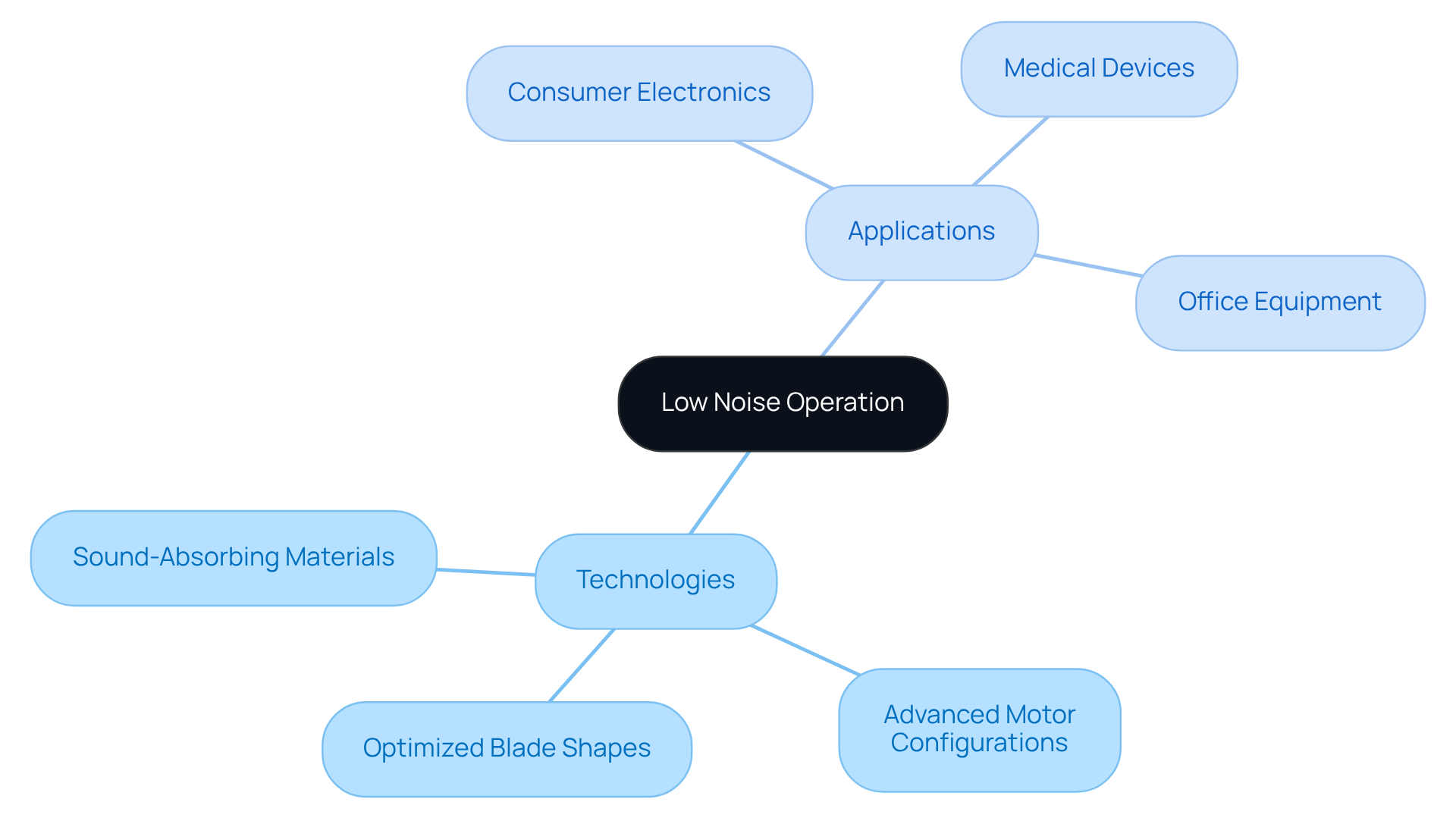

Low Noise Operation: A Key Feature for User Comfort

Low noise operation is paramount for a dc 12v fan, particularly in applications where user comfort is essential. Fans equipped with noise reduction technologies—such as optimized blade shapes and advanced motor configurations—achieve quiet operation while delivering effective cooling performance. This capability is especially vital in consumer electronics, medical devices, and office equipment, where excessive noise can disrupt both productivity and patient care.

For instance, the integration of sound-absorbing materials and innovative fan designs significantly lowers operational noise levels, thereby enhancing the overall user experience. In medical environments, quieter cooling devices contribute to a more supportive atmosphere, decreasing stress for both patients and healthcare providers.

As the demand for silent operation continues to grow, manufacturers are increasingly focusing on these technologies to meet the needs of sensitive applications.

Durability and Build Quality: Ensuring Long-Term Reliability

Durability and construction quality are paramount in the DC 12V fan, especially when operating under demanding conditions. Gagner-Toomey Associates excels in producing devices crafted from premium materials, such as reinforced plastics and corrosion-resistant metals, designed to withstand extreme temperatures and vibrations. These materials not only enhance the longevity of the fans but also significantly improve their overall performance.

For example, in industrial settings, Gagner-Toomey’s DC 12V fan devices are used to cool machinery and prevent overheating, thereby demonstrating their reliability in challenging applications. Engineers must prioritize devices that adhere to rigorous testing standards, ensuring dependable functionality under adverse conditions.

The selection of materials plays a crucial role in influencing the fan’s efficiency, noise levels, and lifespan, underscoring the necessity of choosing products that exemplify superior craftsmanship and robust design. Furthermore, the compact dimensions and transportability of these devices make them suitable for a wide range of applications, including automotive systems and electronics, further emphasizing their versatility.

Gagner-Toomey’s extensive product lineup, which includes DC 12V fan Tube Axial units and Centrifugal Blowers, coupled with advanced thermal management solutions, reflects their commitment to providing high-performance cooling options across various applications.

Airflow Efficiency: Maximizing Cooling Performance

Airflow efficiency is crucial in devices with a DC 12V fan, as it directly influences their ability to circulate air effectively within a system. Engineers must prioritize devices that deliver high airflow rates while minimizing power consumption. Aerodynamic blade structures, such as those found in a DC 12V fan, significantly enhance airflow by reducing drag, thereby facilitating smoother air movement. For instance, the Same Sky’s CFM-6025V-131-167 model achieves an impressive 16 CFM of airflow with no back pressure and a static pressure of 0.1 inH O, underscoring the impact of optimized design on performance.

Moreover, features like brushless motor technology play a vital role in enhancing airflow efficiency by reducing friction and energy loss, which is essential in high-performance settings. The relationship between fan speed and airflow is governed by fan affinity laws; increasing the speed can exponentially elevate both airflow and pressure. Notably, tripling the fan speed results in nine times the pressure, while the power required escalates dramatically, highlighting the necessity for careful selection based on specific application requirements.

Integrating elements such as Pulse Width Modulation (PWM) control allows for precise adjustments to fan speed, improving efficiency in response to real-time thermal demands. This adaptability is critical in dynamic cooling environments, ensuring that electronic components operate within safe temperature limits. Furthermore, PWM and 0-10V speed control provide flexibility for managing varying heat load conditions, thereby enhancing overall system efficiency. Ultimately, understanding these design components and their effects on airflow efficiency is essential for engineers aiming to optimize cooling performance in their projects.

System Compatibility: Ensuring Versatile Integration

System compatibility serves as a fundamental characteristic of DC 12V fan devices, which is essential for engineers managing diverse applications and configurations. These devices must be meticulously designed to accommodate standard mounting options and electrical connections, thereby facilitating seamless integration into existing systems.

Moreover, compatibility with various control systems and protocols significantly enhances their versatility, rendering them ideal for a broad spectrum of applications. For instance, devices engineered with modular features can effortlessly adapt to various setups, ensuring efficient operation across multiple environments.

This adaptability not only streamlines installation but also supports the evolving demands of modern electronic systems, underscoring the critical role of thoughtful design in achieving optimal performance.

As illustrated in case studies, the incorporation of intelligent controllers with conventional ventilation systems exemplifies how a DC 12V fan can be effectively utilized in contemporary contexts, ensuring both functionality and user satisfaction.

Energy Efficiency: Minimizing Power Consumption

Energy efficiency stands as a pivotal concern for the DC 12V fan, particularly in contexts where power consumption is critical. The integration of advanced motor technologies and innovative structures in fans can lead to a substantial reduction in energy usage, all while maintaining optimal performance levels. Engineers must prioritize the development of energy-saving devices, not only to lower operational costs but also to support sustainability initiatives in their designs.

Ease of Installation: Simplifying User Experience

The ease of installation stands as a pivotal feature of the dc 12v fan, effectively streamlining the integration process for both engineers and end-users. Fans that integrate user-friendly mounting options, clear wiring instructions, and plug-and-play capabilities significantly reduce installation time and complexity.

For instance, configurations that allow for rapid attachment without the need for specialized tools or extensive technical knowledge enhance user satisfaction and operational efficiency. This focus on user-friendly designs is particularly vital in consumer products, where a seamless user experience can substantially influence purchasing decisions and foster brand loyalty.

By prioritizing these design elements, manufacturers can ensure their products not only fulfill technical specifications but also address the practical needs of users, ultimately culminating in a more favorable overall experience.

Thermal Performance: Maintaining Optimal Operating Conditions

Thermal performance is paramount for devices that utilize a dc 12v fan, as it profoundly affects the operating conditions of electronic components. These dc 12v fans are specifically engineered to maintain optimal temperatures across diverse loads and environmental conditions, which is essential for preventing overheating—a primary contributor to electronic failures.

Research indicates that overheating incidents are responsible for approximately 30% of electronic device failures, highlighting the necessity for effective cooling solutions. As Gary Masessa aptly poses, “If your design allows for either 12V or 48V, which should you choose?” This question underscores the importance of evaluating the specific requirements of your project when selecting a fan.

Engineers must assess ventilators based on their thermal efficiency metrics, ensuring they can effectively dissipate heat in critical applications. By employing a dc 12v fan, which is recognized for its energy efficiency and low noise levels, engineers can significantly enhance the reliability and longevity of their systems, ultimately resulting in improved performance and reduced maintenance costs.

Furthermore, considering the versatility of DC units across various contexts, such as computers and vehicles, can further guide their selection for optimal thermal management.

Warranty and Customer Support: Ensuring Peace of Mind

When selecting devices like a DC 12V fan, the importance of warranty and customer assistance cannot be overstated. A strong warranty not only reflects a manufacturer’s confidence in the quality and performance of their product but also offers engineers essential protection against potential defects.

For example, the Arctic P12 Pro A-RGB units provide a six-year warranty and achieve a static pressure of 6.9 mm H₂O, which highlights their reliability in high-performance applications. Moreover, responsive customer support is vital for engineers, facilitating troubleshooting and resolution of issues that may arise during installation or operation.

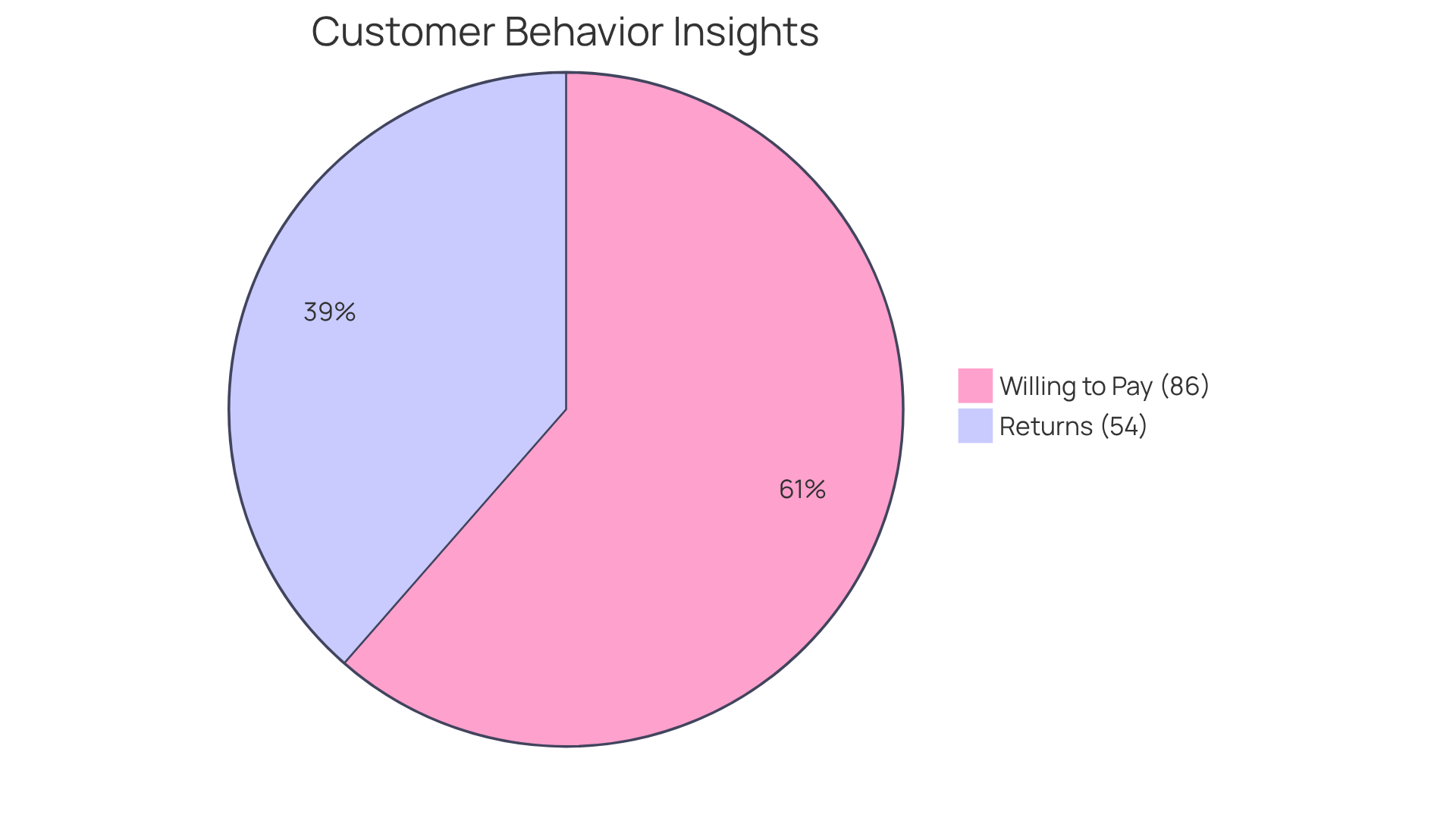

Notably, 54% of customers return products if the installation process proves complicated, underscoring the necessity of effective support. Companies that prioritize customer service frequently witness a significant increase in customer satisfaction and loyalty, with 86% of consumers willing to pay more for superior service.

This assurance is invaluable for engineers who rely on these components to ensure the success of their designs, making the choice of fans with robust warranties and exceptional support a strategic decision.

Conclusion

The exploration of essential features of DC 12V fans underscores their critical role in modern engineering, particularly in enhancing thermal management and ensuring the longevity of electronic components. These fans transcend mere mechanical devices; they embody a sophisticated fusion of technology and design that meets the escalating demands of electronic systems across diverse applications.

Key arguments throughout this article emphasize the significance of features such as:

- Variable speed control

- Low noise operation

- Durability

- Airflow efficiency

- System compatibility

- Energy efficiency

- Ease of installation

- Thermal performance

- Robust warranty options

Each characteristic plays a vital role in optimizing cooling performance, reducing energy consumption, and improving user experience, ultimately leading to more reliable and efficient electronic systems.

In conclusion, engineers are urged to prioritize these features when selecting DC 12V fans for their projects. By emphasizing innovation and quality in design, not only can system performance be enhanced, but alignment with sustainability goals is also achieved. Through informed choices regarding fan specifications and the integration of advanced cooling solutions, engineers can significantly influence the reliability and efficiency of their designs, paving the way for future advancements in technology.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for providing advanced cooling solutions, particularly through the implementation of DC 12V fans, which are essential for heat management within electronic systems.

What are the dimensions of the DC 12V fans offered by Gagner-Toomey?

The DC 12V fans offered by Gagner-Toomey measure 40x40x15 mm.

Why is effective cooling important in electronic devices?

Effective cooling is important because inadequate cooling can lead to a 30% reduction in component lifespan, as electronic devices become increasingly complex.

What types of fans does Gagner-Toomey provide?

Gagner-Toomey provides a wide range of air-movers, including DC input Tube Axial units (sizes from 15 to 280 mm) and Centrifugal Blowers (sizes from 15 to 225 mm), optimized for efficiency and low noise.

What features do the DC 12V fans offer?

The DC 12V fans are available in various airflow and static pressure options and can provide IP protection upon request.

Can you give an example of a specific DC 12V fan and its application?

The San Ace DC 12V fan is an example that delivers exceptional cooling performance suitable for demanding applications such as servers and ICT equipment.

What is the significance of variable speed control in DC 12V fans?

Variable speed control allows engineers to customize fan speeds according to the thermal load, enhancing cooling performance while reducing noise levels and energy consumption.

How does reducing fan speed affect energy consumption?

Decreasing fan speed by half can result in a reduction of energy consumption by one-eighth, illustrating the exponential relationship between speed and power draw.

What benefits do modern variable speed drives (VSDs) provide?

Modern VSDs can cut energy usage by up to 50% for specific motor applications, making them a crucial component in cooling systems.

Why is low noise operation important for DC 12V fans?

Low noise operation is essential in applications where user comfort is important, such as consumer electronics, medical devices, and office equipment, as excessive noise can disrupt productivity and patient care.

What technologies are used to achieve low noise operation in DC 12V fans?

Technologies such as optimized blade shapes, advanced motor configurations, and sound-absorbing materials are used to achieve quiet operation while delivering effective cooling performance.

How are manufacturers responding to the demand for silent operation in cooling devices?

Manufacturers are increasingly focusing on noise reduction technologies to meet the needs of sensitive applications where silent operation is crucial.