Overview

The article provides essential insights into axial fans, specifically targeting electronics engineers by emphasizing their functionality, applications, advantages, and considerations for selection. It elaborates on the operational characteristics of axial fans, highlighting their efficiency across various industries and examining emerging trends that underscore their significance in modern electronic cooling solutions.

Introduction

In the rapidly evolving landscape of technology, axial fans have emerged as vital components across a multitude of industries, particularly in the electronics sector. Gagner-Toomey Associates stands at the forefront of this innovation, delivering tailored cooling solutions that significantly enhance performance and efficiency. By leveraging their extensive expertise and unwavering commitment to customer service, they empower engineers to effectively tackle unique challenges in thermal management.

As the demand for energy-efficient systems continues to grow, understanding the functionality, applications, and advantages of axial fans becomes essential for engineers aiming to optimize their designs. This article delves into the intricacies of axial fan technology, exploring their critical role in various industries, the differences between axial and centrifugal fans, and the future trends shaping this crucial market.

Gagner-Toomey Associates: Innovative Solutions for Axial Fan Applications

Gagner-Toomey Associates excels in providing innovative solutions for axial fans specifically designed for the electronics sector. This expertise is underscored by a sales staff with an average tenure of over 20 years, equipping engineers with energy-efficient cooling technologies that significantly enhance performance and efficiency. Their unwavering commitment to exceptional customer service guarantees that engineers receive customized support to address the unique challenges of their projects.

Serving a diverse array of markets—including Telecom, IoT, Automotive, and Medical—Gagner-Toomey Associates enhances its ability to deliver specialized solutions in thermal management. The company supports customers throughout Northern California and Nevada, acting as the exclusive sales and marketing team for the manufacturers they represent.

As the demand for innovative cooling solutions, particularly axial fans, continues to escalate, Gagner-Toomey Associates stands as a pivotal ally for engineers striving to develop state-of-the-art electronic systems.

Understanding Axial Fans: Definition and Functionality

A propeller fan, commonly referred to as a fan, is engineered to move air parallel to its rotational axis. This fan is characterized by blades that rotate around a central shaft, creating a pressure differential that draws air in and expels it in a linear direction. Such a design excels in environments that demand high airflow rates at low pressure, making axial fans particularly suitable for cooling electronic components and enhancing ventilation systems across diverse sectors, including:

- Automotive

- Telecom

- Energy

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers an extensive range of DC input tube fans, varying from 15 to 280mm. These fans are tailored for performance, efficiency, and low noise, with IP protection available in most models upon request. It is crucial to select the appropriate fan type based on specific airflow and pressure requirements to ensure optimal performance across various applications. The aerodynamic efficiency and energy-saving attributes of these fans are highlighted by case studies that demonstrate the benefits of using FRP axial fans, which outperform traditional metallic units in terms of weight reduction and power consumption. For instance, one case study revealed a 20% decrease in energy usage when employing FRP devices compared to their metallic counterparts. As Bill Cory notes, ‘Axial devices adhere closely to classical theory and require less ‘know-how’ than centrifugal units,’ highlighting their user-friendly design.

Consequently, ducted blowers not only facilitate efficient cooling strategies but also promote sustainability in electronic applications.

Key Applications of Axial Fans in Various Industries

Axial fans are pivotal across various industries, leveraging their ability to efficiently move substantial volumes of air. Their key applications encompass:

- Electronics: Vital for cooling components in computers and servers, axial fans help sustain optimal temperatures, thereby boosting performance and extending longevity.

- In heating, ventilation, and air conditioning systems, axial fans are essential for effective air circulation, which enhances energy efficiency and comfort in both residential and commercial environments.

- In the automotive sector, axial fans play a crucial role in engine cooling and climate control, ensuring that vehicles function smoothly under diverse conditions.

- In manufacturing processes, axial fans are essential for ventilation and exhaust applications, helping to maintain safe and efficient working conditions.

The directional fan market is projected to experience significant growth, with forecasts indicating a considerable increase in market size from 2025 to 2033. This expansion is fueled by a rising demand for energy-efficient technologies and substantial investments in advanced materials and manufacturing methodologies. Furthermore, the market is undergoing a transition towards sustainable practices, underscoring the importance of ventilators in facilitating these trends. As noted by a representative from a global consulting firm, “Our organization has been collaborating with for several years now and we are very pleased with the quality of the reports supplied by the company,” which highlights the reliability of insights pertaining to axial devices.

Axial vs. Centrifugal Fans: Key Differences and Considerations

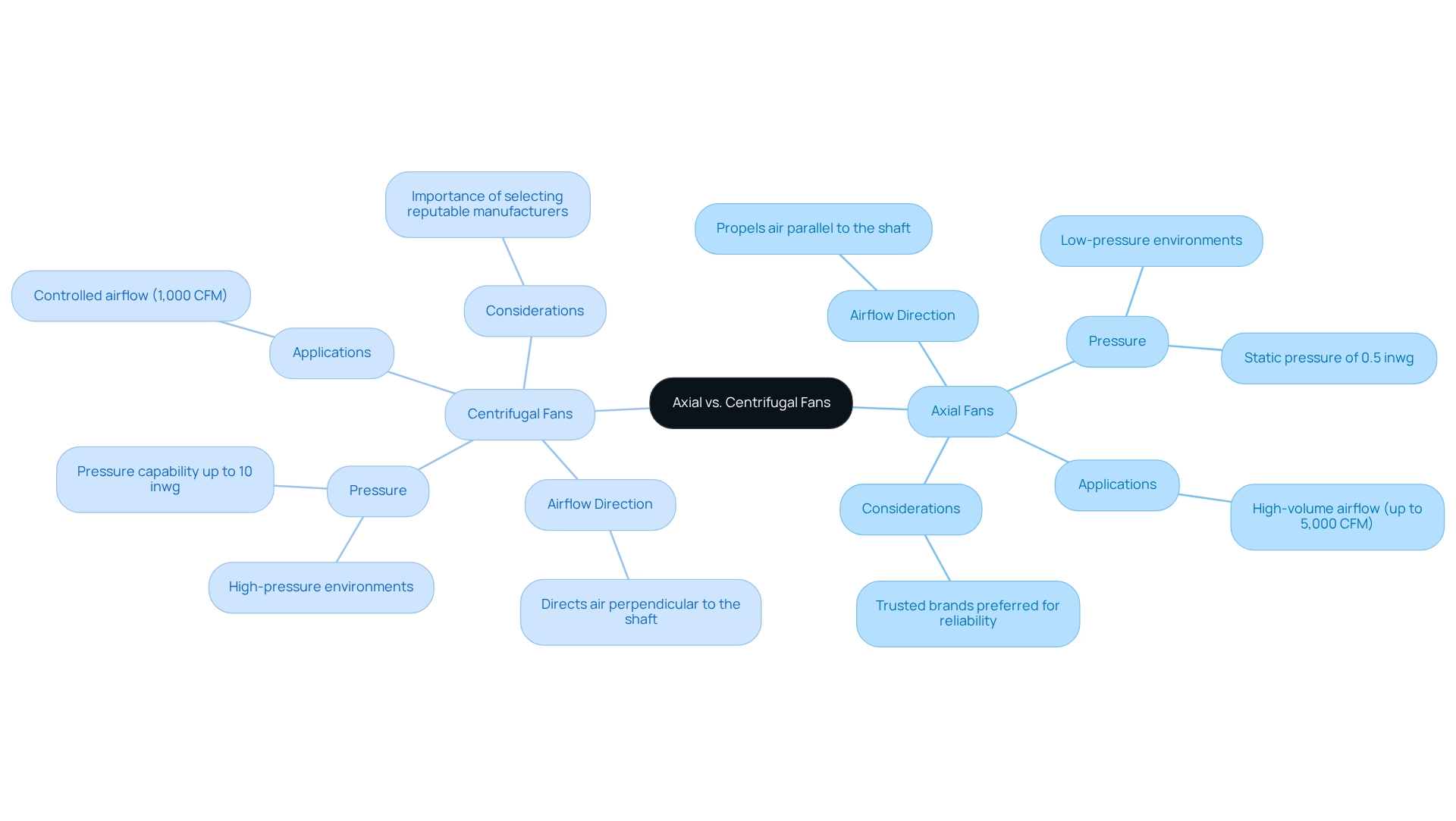

Axial fans and centrifugal blowers are engineered to meet distinct operational requirements, each offering unique advantages that are critical for specific applications:

- Airflow Direction: Axial fans propel air parallel to the shaft, making them ideal for scenarios that demand high airflow rates. Conversely, centrifugal blowers direct air perpendicular to the shaft, enabling them to generate higher pressures. While axial fans typically excel in low-pressure environments, centrifugal blowers perform optimally in high-pressure conditions, capable of producing pressures up to 10 inches of water gauge (inwg). This characteristic renders centrifugal blowers suitable for applications requiring robust airflow against resistance, while axial fans are generally more effective for high-volume, low-pressure applications, moving up to 5,000 cubic feet of air per minute (CFM) with a static pressure of 0.5 inwg. In contrast, centrifugal fans are better equipped for scenarios necessitating higher pressure and more controlled airflow, achieving a volumetric airflow of approximately 1,000 CFM. As noted by Dug, understanding how to evaluate fan performance is crucial for making informed decisions in fan selection.

- Real-World Applications: A case study from ProcessBarron underscores the importance of selecting the appropriate fan type. Their industrial fan repair services illustrate how timely maintenance and upgrades can enhance plant efficiency and lower carbon emissions. This case study emphasizes the tangible impacts of choosing the right propellers, particularly in distinguishing between axial fans and centrifugal types based on operational needs.

- Key Differences: When deciding between axial fans and centrifugal types, it is essential to consider the specific requirements of your application. Buyers often prefer trusted brands known for reliability and safety, especially in high-stakes environments where performance is paramount. This highlights the necessity of selecting a fan that not only meets operational demands but also comes from a reputable manufacturer.

Understanding these distinctions is vital for engineers aiming to optimize performance in their designs and applications.

Advantages of Axial Fans: Why Choose Them?

Axial fans offer numerous advantages, establishing themselves as a preferred choice across various applications:

- High Airflow: These fans excel in moving substantial volumes of air, which is essential for effective cooling in electronic systems.

- Compact Design: Their streamlined size facilitates integration into confined spaces, providing versatile installation options.

- Energy Efficiency: Axial units generally consume less power than their centrifugal counterparts, resulting in decreased operational expenses. This efficiency is particularly pronounced in scenarios where energy savings are crucial.

- Cost-Effectiveness: With lower initial purchase prices and reduced maintenance costs, these ventilation devices present a budget-friendly solution for diverse cooling needs.

- Performance Insights: Research indicates that specific designs, such as the +10° staggered blade arrangement, can enhance total pressure rise, leading to improved performance. This insight guides engineers in selecting optimal fan designs for their cooling solutions. A study on total pressure distribution reveals that this configuration achieves a higher total pressure rise compared to others, contributing to superior performance.

- Aerodynamic Considerations: It is vital to acknowledge that these fans exhibit an aerodynamically unstable operating range near their optimal performance. This characteristic can impact operating safety if system pressure fluctuates, making it essential for engineers to consider these factors in their designs.

- Expert Insights: Industry specialists emphasize the importance of accurately understanding performance levels, stating, “You also need to correctly interpret the indicated performance levels,” thus ensuring that engineers can maximize the advantages of rotary blowers in their applications.

- Real-World Savings: Case studies highlight significant energy savings achieved through the use of directed airflow devices, underscoring their critical role in cooling scenarios.

Collectively, these elements highlight why axial fans are a preferred choice among engineers in the electronics industry, especially for cooling applications where efficiency and performance are crucial.

Disadvantages of Axial Fans: Potential Drawbacks to Consider

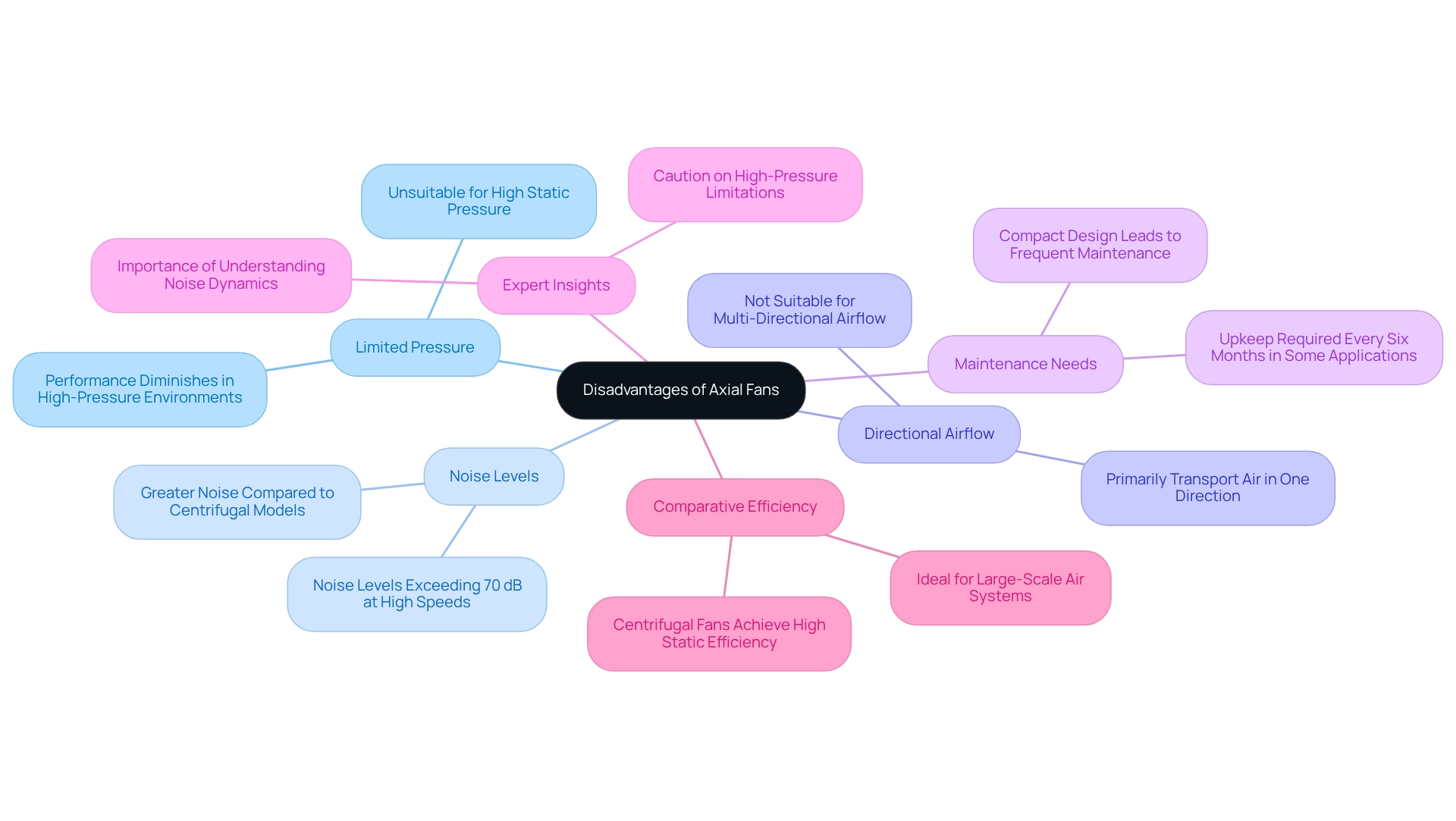

While axial fans present numerous advantages, they also exhibit several notable drawbacks that engineers must consider:

- Limited Pressure: Axial fans are not designed for applications requiring high static pressure. Their performance diminishes in high-pressure environments, rendering them unsuitable for specific industrial applications.

- Noise Levels: These devices can generate greater noise levels compared to centrifugal models, particularly at increased speeds. Research indicates that certain types of blowers can produce noise levels exceeding 70 dB during high-speed operations, which is a critical factor in environments where sound management is essential, such as in residential or sensitive electronic settings.

- Directional Airflow: Directional airflow is achieved by axial fans, which primarily transport air in a single direction and may not be suitable for every application. This limitation can hinder their effectiveness in systems that demand multi-directional airflow.

- Maintenance Needs: Although these ventilators are generally easy to maintain, their compact design may lead to more frequent maintenance requirements, especially in applications like evaporative cooling towers, where they are favored for their energy efficiency. A case study highlights that while certain blowers perform effectively in these environments, they may necessitate upkeep every six months, unlike centrifugal units that can operate for extended periods without maintenance.

- Expert Insights: Industry specialists caution that while axial fans are effective for temperature regulation, their limitations in high-pressure environments and potential noise concerns must not be overlooked when selecting the appropriate device for specific electronic applications. As R. Legendre observed, “A mathematical treatment is presented for a new way of studying noise generated aerodynamically in a jet,” underscoring the importance of understanding noise dynamics in fan selection.

- Comparative Efficiency: It is also noteworthy that centrifugal blowers achieve high static efficiency, making them ideal for large-scale air systems. This comparison emphasizes the relative drawbacks of using axial fans in high-pressure applications.

Maintenance Tips for Ensuring Optimal Performance of Axial Fans

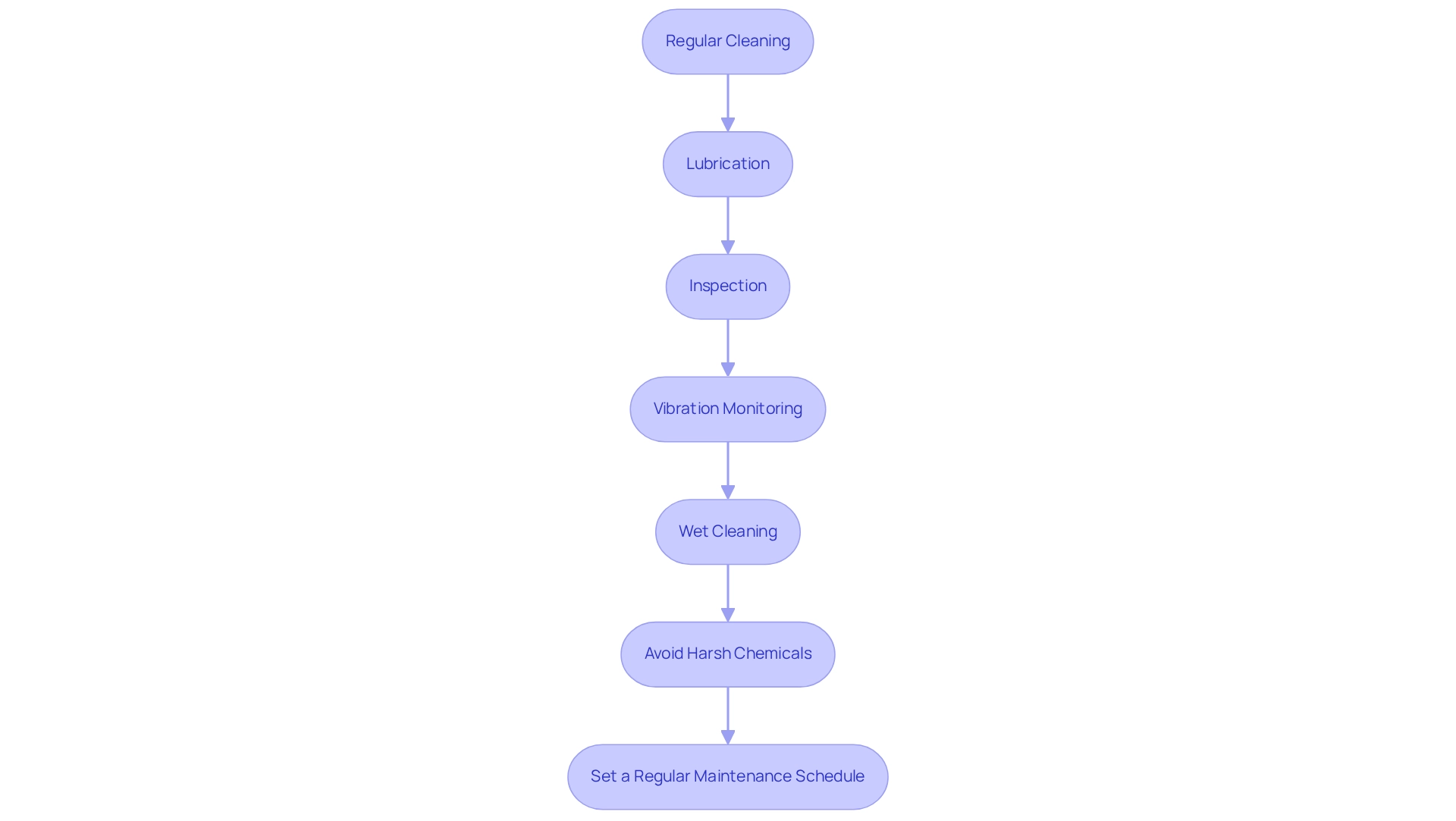

To ensure optimal performance of shaft blowers, it is essential to implement the following maintenance strategies:

- Regular Cleaning: Periodically remove dust and debris from the blades to prevent airflow obstruction, which can significantly impact cooling efficiency.

- Lubrication: Adhere to manufacturer guidelines for lubricating moving parts. Proper lubrication minimizes friction and wear, extending the lifespan of the fan.

- Inspection: Conduct routine inspections for signs of wear or damage. This proactive approach ensures that all components are functioning correctly and helps identify potential issues before they escalate.

- Vibration Monitoring: Monitor vibration levels consistently, as excessive vibrations can indicate underlying mechanical problems that require immediate attention. This practice is crucial for maintaining the fan’s operational integrity and preventing costly failures.

- Wet Cleaning: For a thorough cleaning, consider using a low-pressure water jet while protecting electrical components and bearings. This method not only improves the fan’s performance but also extends its lifespan by preventing oxidation in the motor through effective condensation evaporation. Ensure to cover condensate drain holes during this process to avoid water accumulation. This technique exemplifies Gagner-Toomey’s commitment to excellence in product representation and customer service by promoting effective maintenance practices.

- Avoid Harsh Chemicals: When cleaning, steer clear of aggressive cleaning agents that could damage the fan. Opt for gentle solutions that maintain the integrity of the fan components.

- Set a Regular Maintenance Schedule: To further enhance reliability and performance, establish a regular maintenance schedule that includes all the above strategies. This proactive method guarantees that ventilation systems function at optimal effectiveness and lifespan.

By adhering to these upkeep suggestions, engineers can greatly improve the dependability and performance of ventilation systems in electronic cooling applications.

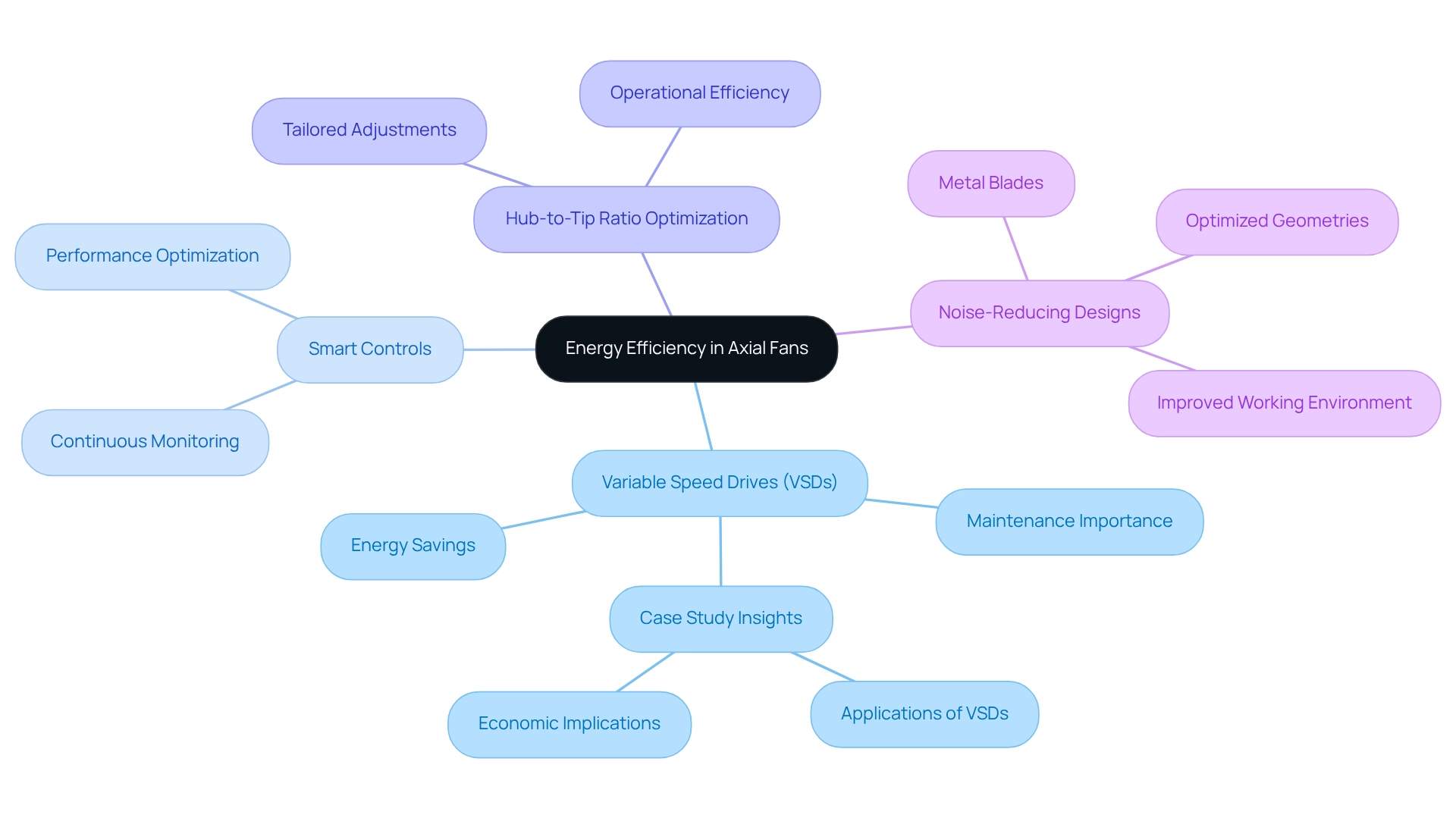

Energy Efficiency in Axial Fans: Maximizing Performance and Savings

Enhancing energy effectiveness in axial fans can lead to substantial cost reductions and improved operational performance. To achieve these benefits, consider the following key strategies:

- Variable Speed Drives (VSDs): Implementing VSDs facilitates the adjustment of fan speed based on real-time cooling requirements. This not only reduces energy consumption but also enhances overall system performance. A case study titled ‘Applications of Variable Speed Drive (VSD) in Electrical Motors Energy Savings’ underscores their efficiency in optimizing energy consumption across various applications, including blowers, while exploring the financial benefits and productivity improvements associated with VSDs. Regular maintenance is crucial for ensuring that axial fans operate at peak performance. Routine inspections and servicing can significantly reduce energy waste, extend equipment lifespan, and sustain optimal performance levels.

- Smart Controls: The integration of smart technology allows for continuous monitoring and optimization of fan performance. By adapting to changing environmental conditions, smart controls can enhance performance and minimize unnecessary energy usage.

- Hub-to-Tip Ratio Optimization: Adjusting the hub-to-tip ratio to meet specific operational requirements can improve performance. This adjustment is vital for achieving optimal efficiency in diverse operational contexts.

- Noise-Reducing Designs: Employing metal blades with optimized geometries can result in lower noise levels while maintaining high performance. Recent reports indicate that such designs can significantly improve the working environment and contribute to energy conservation.

José López, an analyst, emphasizes that these blowers are commonly used in applications such as filter chamber extraction, where the air may contain dust particles and is less pure than in scenarios involving forward curved blades. By adopting these strategies, engineers can markedly enhance the energy efficiency of rotating devices, yielding both economic and ecological benefits.

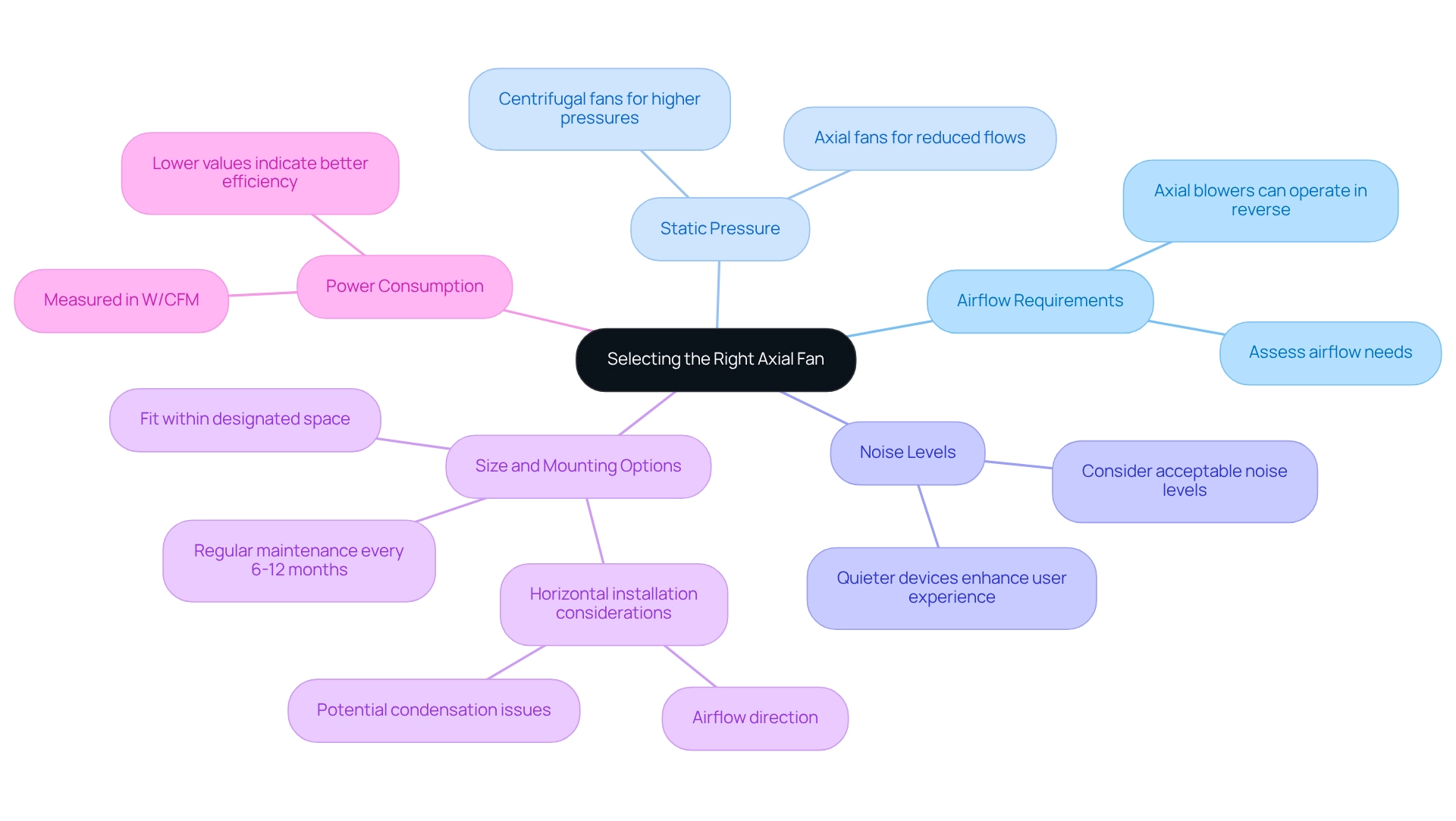

Selecting the Right Axial Fan: Factors to Consider

Choosing the appropriate fan necessitates a thoughtful evaluation of several essential factors.

- Airflow Requirements: Precisely assess the airflow necessary for efficient cooling in your specific application. This assessment is critical for maintaining optimal operating temperatures and ensuring system reliability. Notably, axial blowers can function in reverse to expel air, providing additional versatility in cooling solutions.

- Static Pressure: Evaluate the static pressure requirements of your setup. Axial blowers typically excel in scenarios requiring reduced flows and increased pressures, while centrifugal blowers are preferred for applications demanding higher pressures.

- Noise Levels: Consider the acceptable noise levels for your environment. In sensitive applications, quieter cooling devices can significantly enhance user experience and operational efficiency.

- Size and Mounting Options: Confirm that the cooling device fits within the designated space and can be securely mounted. Proper installation is vital; when installing axial fans horizontally, careful attention must be paid to airflow direction and potential condensation issues. Regular maintenance every 6-12 months is advisable to ensure longevity and reliable operation, as both installation and maintenance are fundamental to achieving these outcomes.

- Power Consumption: Assess the specific power consumption measured in watts per cubic foot per minute (W/CFM). Lower values indicate improved performance, which is essential for energy-conscious designs. Emphasizing this aspect underscores the importance of efficiency in the selection process.

By taking these factors into account, engineers can make informed decisions that enhance the performance and reliability of their cooling solutions.

Future Trends in Axial Fan Technology: What Engineers Should Know

The future of axial fans technology is poised for transformative advancements that will significantly enhance performance and application. Key trends include:

- Smart Technology Integration: Axial fans are increasingly being equipped with IoT capabilities, enabling real-time monitoring and control. This integration enhances operational effectiveness and adaptability across diverse environments.

- Advanced Materials: The rise of lightweight and durable materials is leading to improved performance and reduced energy consumption. These materials not only extend the longevity of the fans but also contribute to overall system efficiency.

- Aerodynamic Improvements: Innovations in blade design are optimizing airflow while minimizing noise levels. Enhanced aerodynamics are crucial for applications requiring quiet operation, particularly in residential and office settings.

- Sustainability Focus: There is an increasing emphasis on energy-efficient designs that mitigate environmental impact. With the fan market valued at USD 3,113.24 million in 2024, this figure underscores the growing importance of sustainable solutions, especially within the context of smart homes and energy-efficient structures. Environmental impact factors are influencing the demand for specific ventilators, positioning sustainability as a key motivator in the sector.

- Future Trends Statistics: Recent advancements, such as FläktGroup’s new fan, which boasts a 15% improvement in air movement capacity, exemplify the ongoing innovation within this sector.

- Practical Uses: Axial fans are finding various applications beyond traditional uses, including home ventilation and electronics cooling, which together account for approximately 20% of the market. The shift towards intelligent technology in these sectors is driving demand and highlighting the importance of directional devices in contemporary applications. As noted by a Global Consulting Firm, “Our company has been working with for some years now and we are very happy with the quality of the reports provided by the company. I, on behalf of my organization, would like to thank you for offering professional reports.”

These developments underscore the pivotal role that axial fans will play in the evolving landscape of electronics and energy efficiency, making them essential components for engineers to incorporate into their designs.

Conclusion

Axial fans are integral to the efficient operation of cooling systems across various industries, particularly in the electronics sector. Their ability to move large volumes of air at low pressure makes them essential for applications ranging from HVAC systems to automotive cooling. Gagner-Toomey Associates stands out as a leader in providing tailored axial fan solutions, leveraging extensive industry expertise to meet the unique thermal management needs of engineers.

Understanding the differences between axial and centrifugal fans is crucial for selecting the appropriate technology for specific applications. While axial fans excel in high airflow scenarios, they do have limitations in pressure capabilities and noise levels. Engineers must carefully evaluate factors such as airflow requirements, noise constraints, and maintenance needs to optimize their designs effectively.

Looking ahead, the axial fan market is poised for growth, driven by advancements in smart technology, sustainable materials, and aerodynamic enhancements. These trends promise improved performance and align with the increasing demand for energy-efficient solutions. By embracing these innovations, engineers can contribute to the development of more effective and environmentally friendly cooling systems.

In summary, axial fans represent a vital component in modern engineering, offering significant advantages in efficiency and performance. As the landscape continues to evolve, staying informed about the latest technologies and trends will empower engineers to make informed decisions, ensuring optimal thermal management in their projects.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates excels in providing innovative solutions for axial fans specifically designed for the electronics sector, backed by a sales staff with an average tenure of over 20 years.

What types of markets does Gagner-Toomey Associates serve?

Gagner-Toomey Associates serves a diverse array of markets, including Telecom, IoT, Automotive, and Medical.

What is the role of axial fans in cooling electronic components?

Axial fans are engineered to move air parallel to their rotational axis, making them ideal for cooling electronic components by providing high airflow rates at low pressure.

What are the advantages of using axial fans?

Axial fans offer aerodynamic efficiency, energy-saving attributes, and are user-friendly. They can significantly reduce energy usage, as demonstrated by case studies showing a 20% decrease in energy usage when using FRP axial fans compared to metallic units.

What applications do axial fans have across different industries?

Axial fans are used in various applications, including: – Cooling components in electronics like computers and servers. – Air circulation in heating, ventilation, and air conditioning systems. – Engine cooling and climate control in the automotive sector. – Ventilation and exhaust applications in manufacturing processes.

What is the projected growth of the axial fan market?

The directional fan market is expected to experience significant growth from 2025 to 2033, driven by rising demand for energy-efficient technologies and investments in advanced materials and manufacturing methodologies.

Why are axial fans considered sustainable?

Axial fans promote sustainability in electronic applications by facilitating efficient cooling strategies, which align with the transition towards sustainable practices in various industries.