Overview

The article titled “10 Essential Insights on DC Cooling Fans for Engineers” addresses the critical features and benefits of DC cooling fans that engineers must consider when selecting solutions for thermal management in electronics. It asserts that DC cooling fans are not only energy-efficient but also quieter and more reliable than their AC counterparts.

With advancements in technology, these fans offer improved performance and adaptability across various applications, ensuring optimal thermal conditions for electronic components. This knowledge is essential for engineers seeking effective thermal management solutions.

Introduction

The evolution of DC cooling fans is fundamentally reshaping the landscape of thermal management in electronics. Engineers are increasingly turning to these innovative devices, drawn by their efficiency and performance. As technology progresses, the demand for intelligent cooling solutions that minimize energy consumption while maximizing airflow has become paramount. Yet, with a myriad of options and specifications available, how can engineers ensure they select the right fan for their specific applications? This article delves into ten essential insights designed to empower engineers in navigating the complexities of DC cooling fans, thereby enhancing their designs and ultimately driving greater reliability and efficiency in electronic systems.

Gagner-Toomey Associates: Leading Provider of DC Cooling Fan Solutions

Gagner-Toomey Associates stands as a premier provider of , leveraging a diverse portfolio of manufacturers to deliver specifically tailored for the electronics industry. The company excels in tackling , ensuring that its offerings not only meet but surpass the rigorous demands of contemporary applications. For instance, Gagner-Toomey’s , ranging from 15 to 225mm, are meticulously designed for , making them ideal for a variety of electronic systems.

Recent advancements in DC cooling fans technology have ushered in significant enhancements in efficiency and noise reduction. In 2022, several major companies unveiled new lines of brushless DC devices, markedly improving operational quietness and . This trend aligns with the growing demand for intelligent and interconnected , as evidenced by the projected compound annual growth rate (CAGR) of 13.7% for the large fan market from 2025 to 2034.

Industry leaders emphasize the critical role of DC cooling fans in maintaining for electronic components. Effective temperature regulation is vital for preventing material aging and ensuring the longevity of devices. Gagner-Toomey Associates’ unwavering commitment to innovation and excellence, bolstered by endorsements from satisfied clients, positions it as a trusted partner for engineers seeking reliable and effective in the .

Understanding DC Cooling Fans: Key Features and Functionality

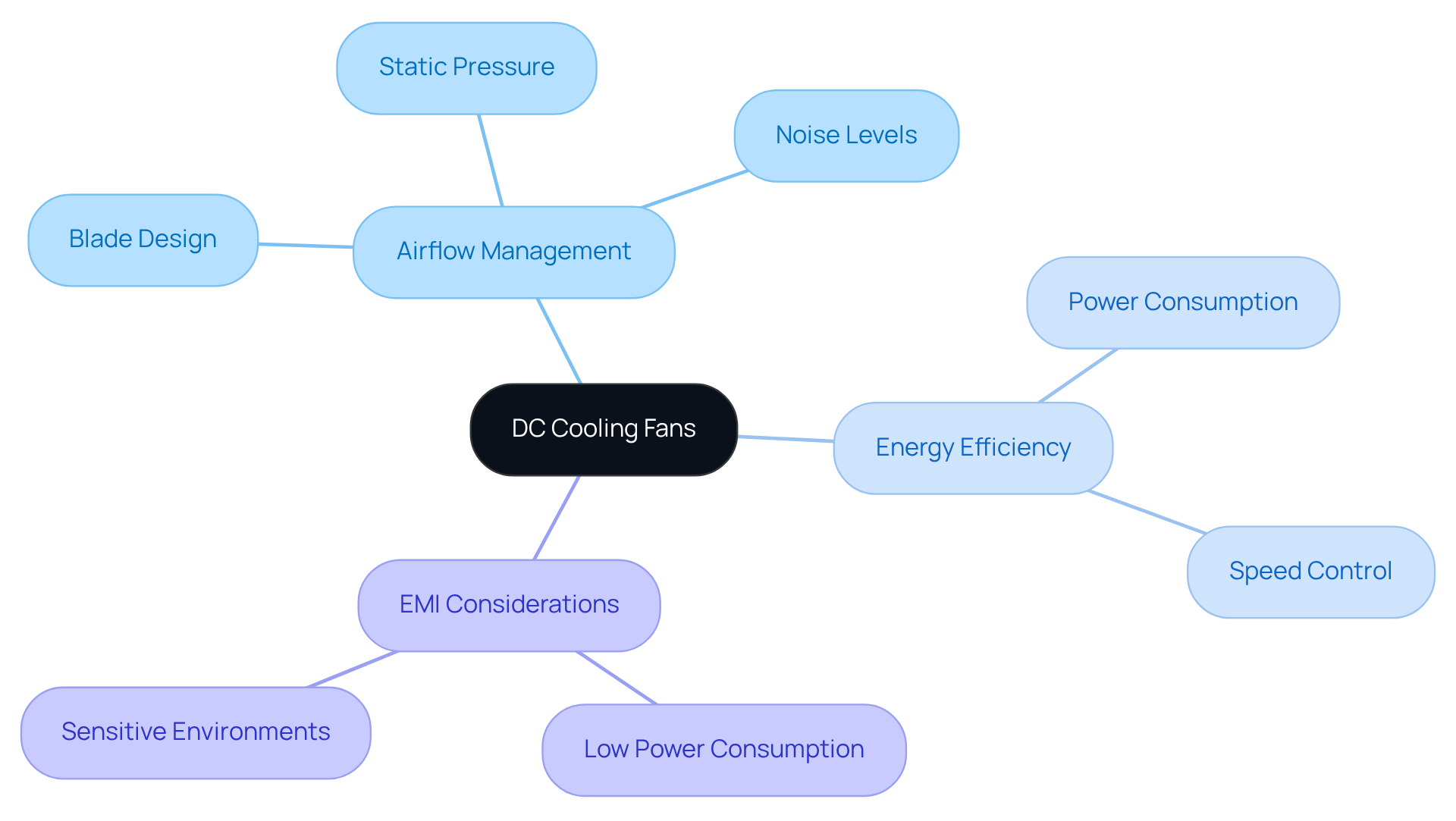

s are essential for managing airflow across electronic components, effectively preventing overheating and ensuring optimal performance. The design of significantly impacts airflow and static pressure; variations in blade shape and angle influence the efficiency of air movement. For instance, devices equipped with curved blades can enhance airflow while simultaneously reducing noise levels, making them ideal for sensitive applications. Furthermore, the type of —such as electronically commutated motors (ECM)—also contributes to the fan’s overall efficiency and quiet operation.

When selecting a fan for specific applications, engineers must consider these features carefully. A well-designed DC cooling fan can consume up to 70% less while delivering equivalent airflow; specifically, a 25-watt DC cooling fan provides the same performance as a 100-watt AC fan, making DC cooling fans a cost-effective choice for commercial use. Additionally, DC cooling fans provide various speed control functions to meet specific airflow targets, enabling precise —an essential factor in effective thermal management scenarios.

As emphasized by industry specialists, the functionality of DC cooling fans transcends mere airflow; they are vital in ensuring the reliability of sensitive electronic devices. In environments where minimizing is critical, such as in medical instruments and telecom switches, DC cooling fans are preferred because of their . This characteristic renders them particularly suitable for applications in , as illustrated in case studies that underscore their advantages in minimizing electromagnetic interference.

In conclusion, understanding the impact of blade design and motor type on DC fan performance is imperative for engineers aiming to . By selecting the appropriate fan, they can ensure efficient temperature regulation while extending the lifespan and dependability of electronic components.

Benefits of DC Cooling Fans: Efficiency and Performance Advantages

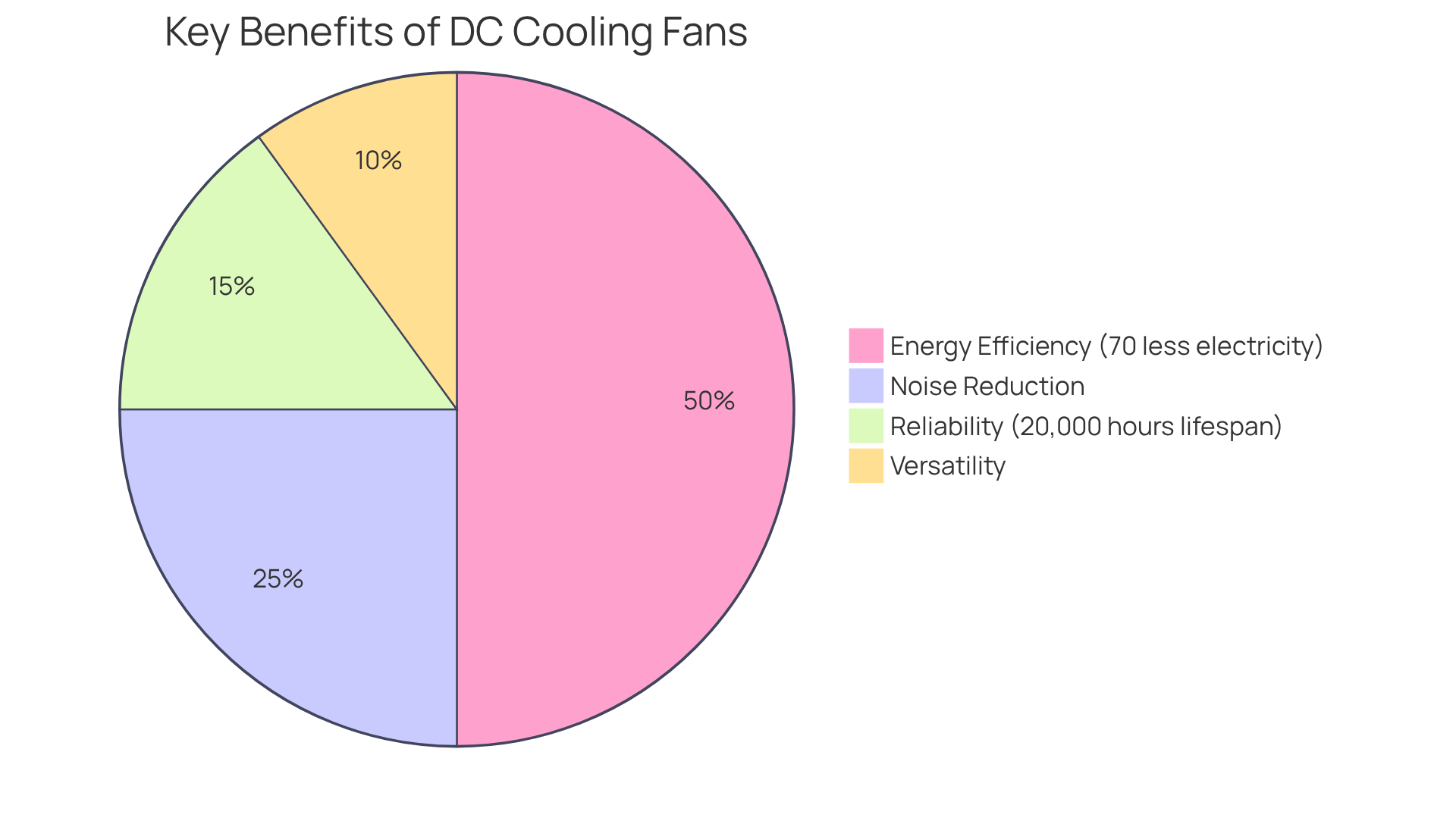

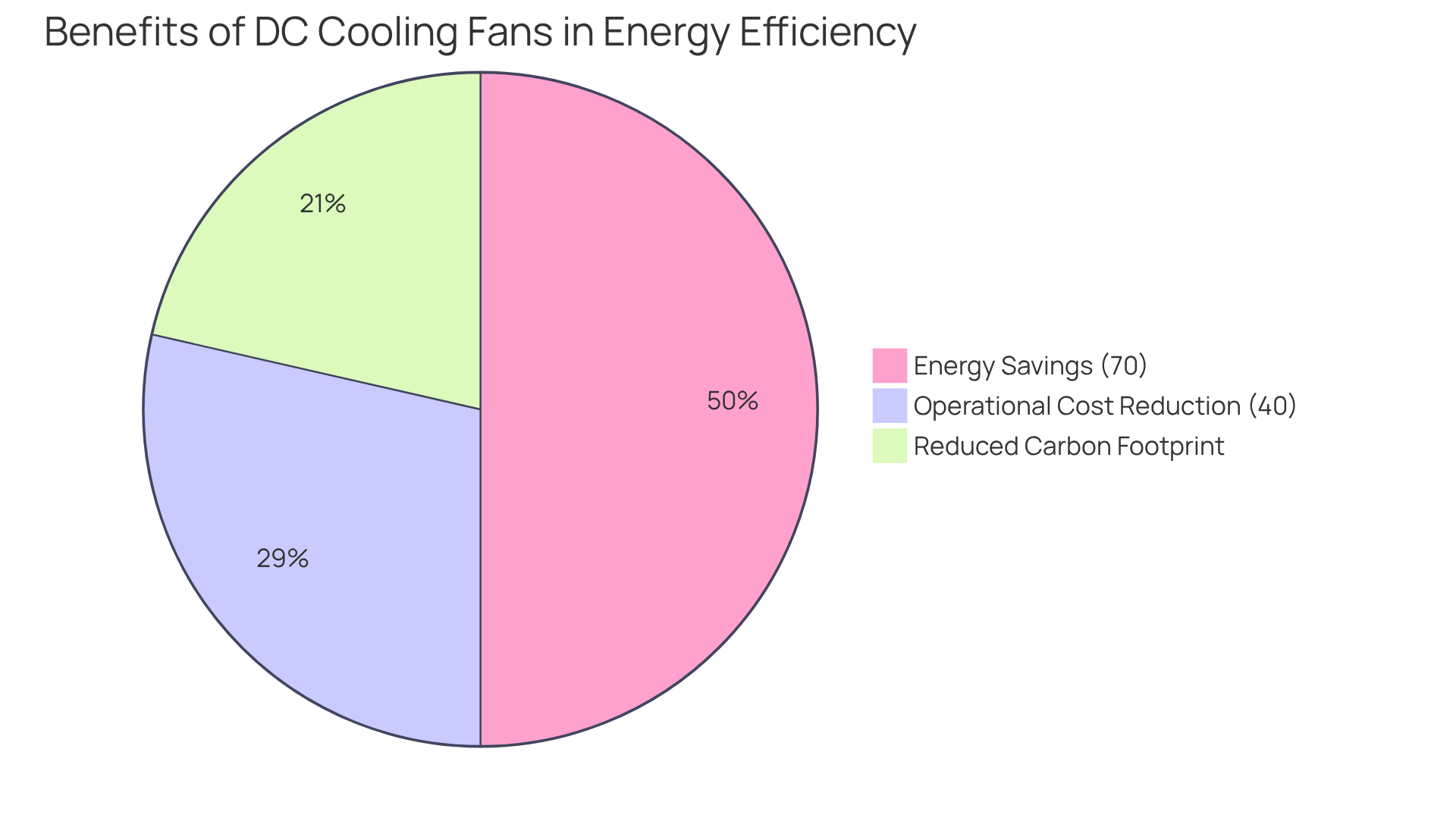

offer a multitude of advantages, particularly in , , and reliability. Notably, DC cooling fans consume approximately 70% less electricity than their AC counterparts of similar size and speed, leading to over time. This energy efficiency is vital in scenarios requiring prolonged operation, as it results in lower operational costs and diminished environmental impact. Moreover, centrifugal and axial blowers equipped with AC motors account for 40-50% of total energy consumption, underscoring the superior efficiency of DC cooling fans when compared to traditional alternatives.

Additionally, the sound levels of DC cooling fans are significantly lower, making them ideal for . Research indicates that DC cooling fans operate more quietly than AC units, which are known to produce disruptive sound levels. This quiet operation is attributed to the absence of brushes in DC motors, leading to smoother performance and reduced mechanical noise.

The reliability of DC cooling fans is further highlighted by their , which is essential for maintaining optimal temperatures in electronic systems. can enhance product reliability by up to 30%, demonstrating the crucial role of DC cooling fans in . Furthermore, the versatility of DC cooling fans allows for their application across various scenarios, enhancing their adaptability in diverse environments.

Engineers can capitalize on these benefits to design more resilient electronic systems, ensuring components remain within optimal temperature ranges while minimizing noise and energy consumption. As the demand for efficient temperature regulation solutions continues to escalate, the adoption of DC cooling fans is anticipated to rise, with the market projected to reach USD 3.2 billion by 2033. This growth is driven by their superior performance and the increasing focus on .

Applications of DC Cooling Fans: Where They Excel in Electronics

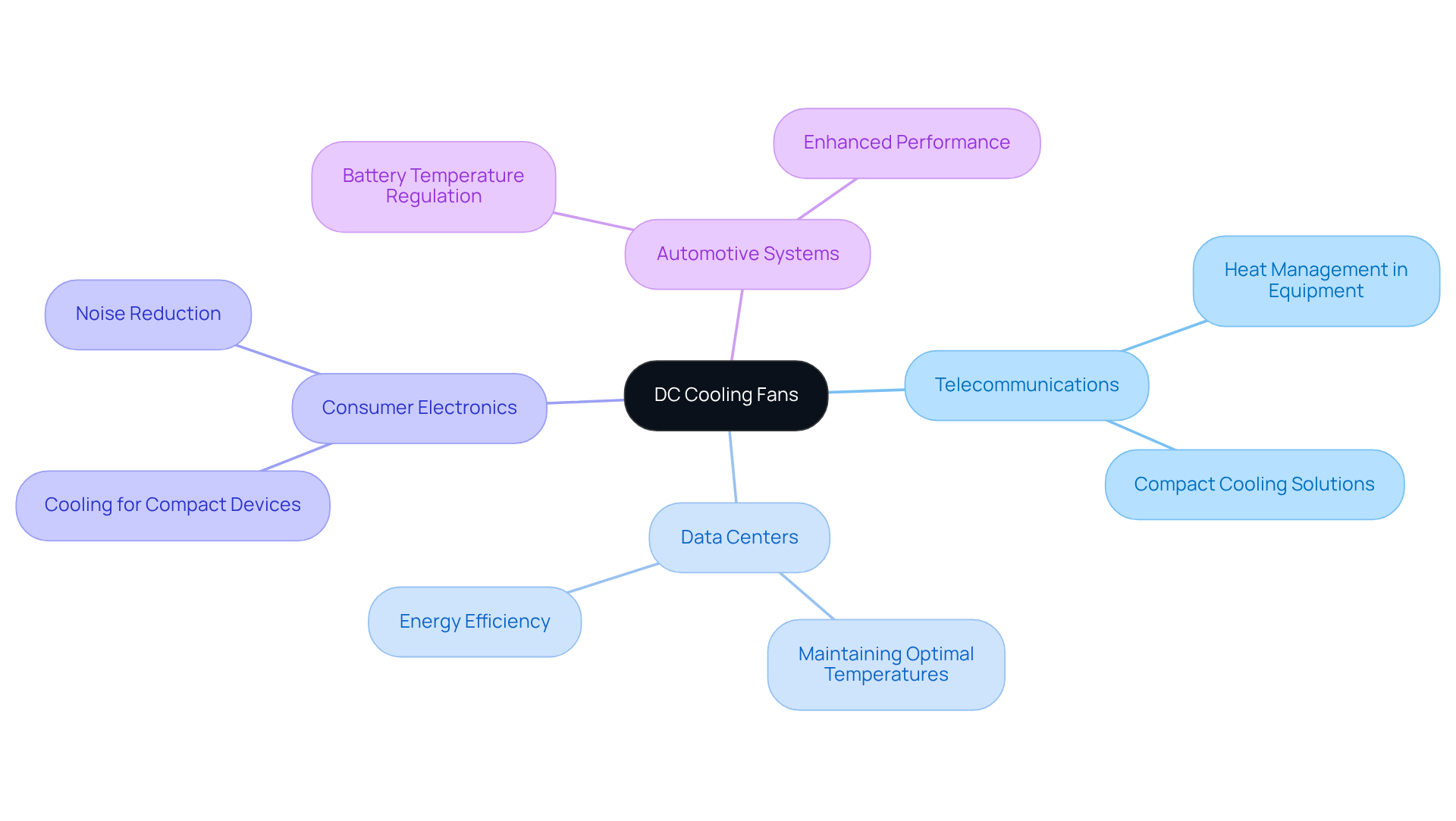

play a , such as telecommunications, data centers, consumer electronics, and automotive systems. Their capability to in DC cooling fans indispensable in where is paramount. Understanding these applications empowers engineers to for their projects.

Energy Efficiency of DC Cooling Fans: Reducing Power Consumption

, such as those offered by Gagner-Toomey Associates, are engineered for optimal power efficiency while providing substantial airflow. By utilizing advanced motor technologies, including , these devices can achieve energy savings of up to 70% compared to conventional AC solutions. For example, a 25-watt DC fan can deliver the same airflow as a 100-watt AC fan, showcasing a significant reduction in . This efficiency not only but also minimizes the carbon footprint associated with temperature regulation systems.

Real-world applications demonstrate the effectiveness of DC units across various environments. In commercial settings, such as restaurants, the implementation of DC ventilation systems has led to estimated of approximately 40%. Engineers have noted that DC cooling fans, with their ability to dynamically adjust speed based on ambient temperature, provide on-demand cooling, further enhancing energy efficiency.

Furthermore, the design of DC units, often featuring optimized blade configurations, contributes to their . , spanning from 15 to 280mm, as well as DC input Centrifugal Blowers, ranging from 15 to 225mm, ensuring tailored solutions for various applications. Insights from engineers indicate that aiming to reduce power consumption while maintaining effective cooling solutions. Additionally, these devices come equipped with options for IP protection and custom designs, further broadening their applicability.

It is crucial to acknowledge that DC enthusiasts typically face a , estimated to be 20-50% more than AC counterparts, which should be factored into any assessment of overall cost-effectiveness. Moreover, DC devices produce less electromagnetic interference than their AC equivalents, reinforcing their advantages. As the industry continues to evolve, the adoption of these advanced technologies will be pivotal in fostering sustainable energy practices.

Controlling DC Cooling Fans: Mechanisms for Speed and Performance

Regulating the speed of is essential for enhancing in electronic systems. Two primary mechanisms for achieving this are Pulse Width Modulation (PWM) and .

- PWM operates by rapidly switching the power supply on and off, allowing for based on thermal requirements. This method not only enhances energy efficiency but also significantly reduces noise levels, making it a preferred choice in modern applications. For instance, when the is set to 50%, the average voltage supplied to the fan is 2.5V, demonstrating how varying the duty cycle directly influences fan performance.

- In contrast, voltage regulation adjusts the voltage supplied to the fan, which can lead to less smooth operation at lower speeds and may shorten the fan’s lifespan due to increased motor stress. Voltage-regulated devices are becoming less common compared to , which provide better performance and adaptability. Studies indicate that voltage-regulated devices are less prevalent in modern systems, highlighting the shift towards .

Real-world applications demonstrate the effectiveness of these control strategies. For instance, in a dual-fan system, staggering the startup sequence can reduce the total startup current requirement to 12.25 A for 500 milliseconds, allowing one fan to reach full speed before the other starts. This approach minimizes the initial power demand, which is critical in systems where power supply ratings are a concern.

Performance metrics further illustrate the advantages of PWM. PWM fans can run at reduced speeds while maintaining effective temperature control, thus extending their lifespan and improving overall system reliability. Engineers have observed that utilizing PWM can result in a more reactive temperature regulation system, automatically modifying fan speeds according to CPU temperature variations.

As the industry evolves in 2025, the integration of PWM and voltage regulation continues to be a focal point for . The choice between these methods often depends on specific application requirements, with PWM emerging as the leading technology for efficient and effective control of DC cooling fans. As Annie Chan, an account manager in the field, states, “The purpose of this article is to share knowledge related to DC devices for optimizing your thermal solutions.

Noise Considerations for DC Cooling Fans: Managing Acoustic Impact

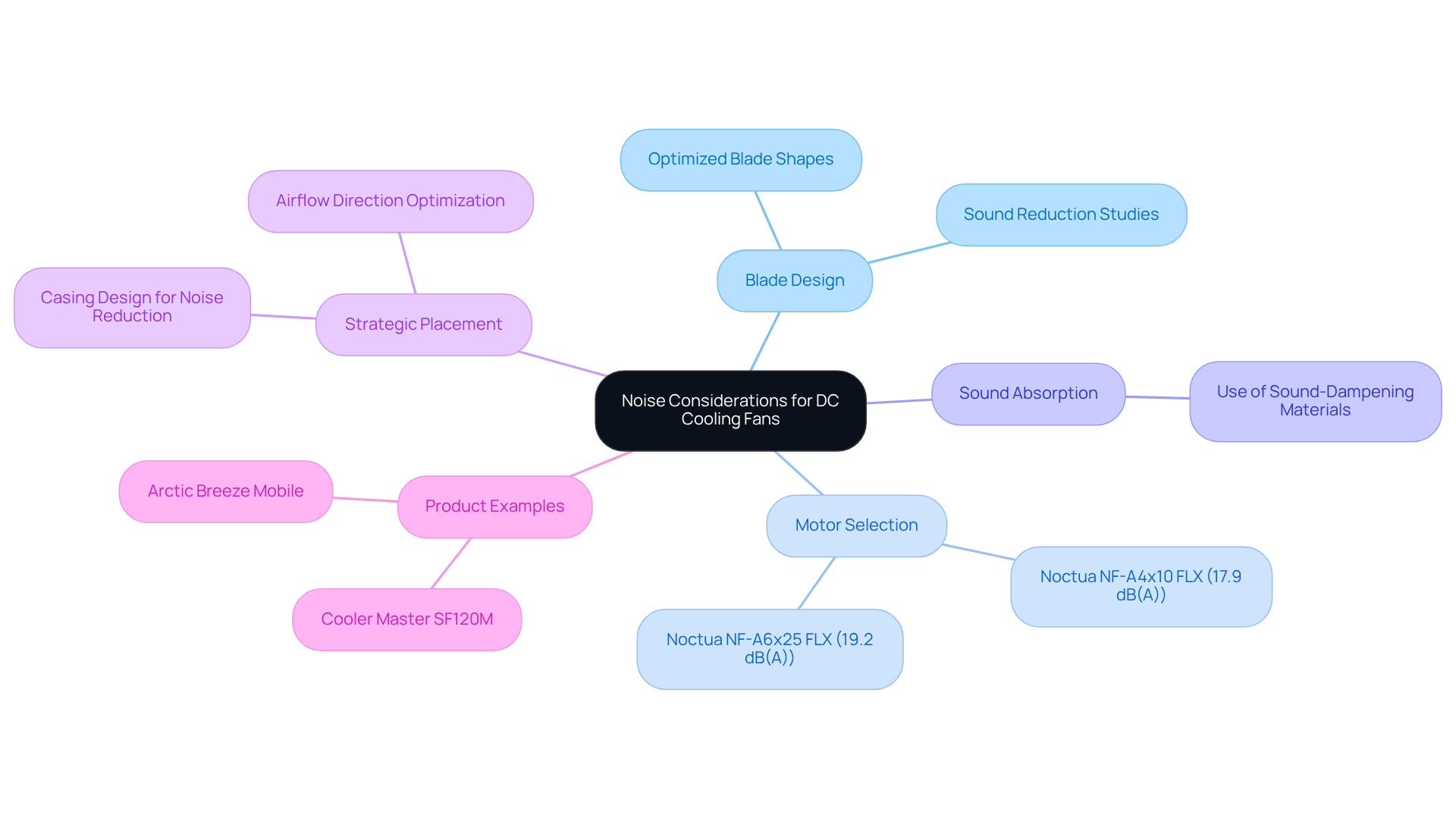

The presents a significant challenge, especially in consumer electronics and sensitive environments. acoustic impact by selecting fans with optimized blade designs that minimize turbulence and sound. Advanced blade shapes, for instance, can considerably reduce , with studies indicating that a well-engineered fan can achieve sound reductions of up to 15%.

In addition to blade design, employing is essential. Fans like the Noctua NF-A4x10 FLX operate at an exceptionally low sound level of 17.9 dB(A), making them ideal for scenarios where sound is a concern. Comparatively, the Noctua NF-A6x25 FLX operates at a sound level of 19.2 dB(A), showcasing the variety of quiet options available to engineers. Furthermore, incorporating sound-absorbing materials within the fan housing can effectively dampen vibrations and reduce overall .

Strategic fan placement plays a crucial role in . Positioning fans to direct airflow efficiently while minimizing sound transmission can enhance user experience. For example, a casing design that allows airflow to circulate between the sides can aid in reducing sound levels for standalone chargers.

Real-world examples of low-noise include the Cooler Master SF120M, which features an that optimizes airflow performance while minimizing operational sound. Engineers increasingly prioritize both functionality and design when selecting , ensuring that sound levels are controlled without compromising performance.

As the demand for quieter temperature control solutions escalates, understanding and implementing effective will be vital for engineers in 2025 and beyond. It is also important to note that the typical sound pressure level from a 40 kW AC/DC converter can reach 73.6 dB(A) from the air intake side, highlighting the urgent need for efficient sound management strategies in environments with multiple refrigeration systems. A 10% reduction in RPM can result in a 27% decrease in brake horsepower (BHP), further illustrating the correlation between fan speed and noise levels.

Maintenance of DC Cooling Fans: Ensuring Longevity and Reliability

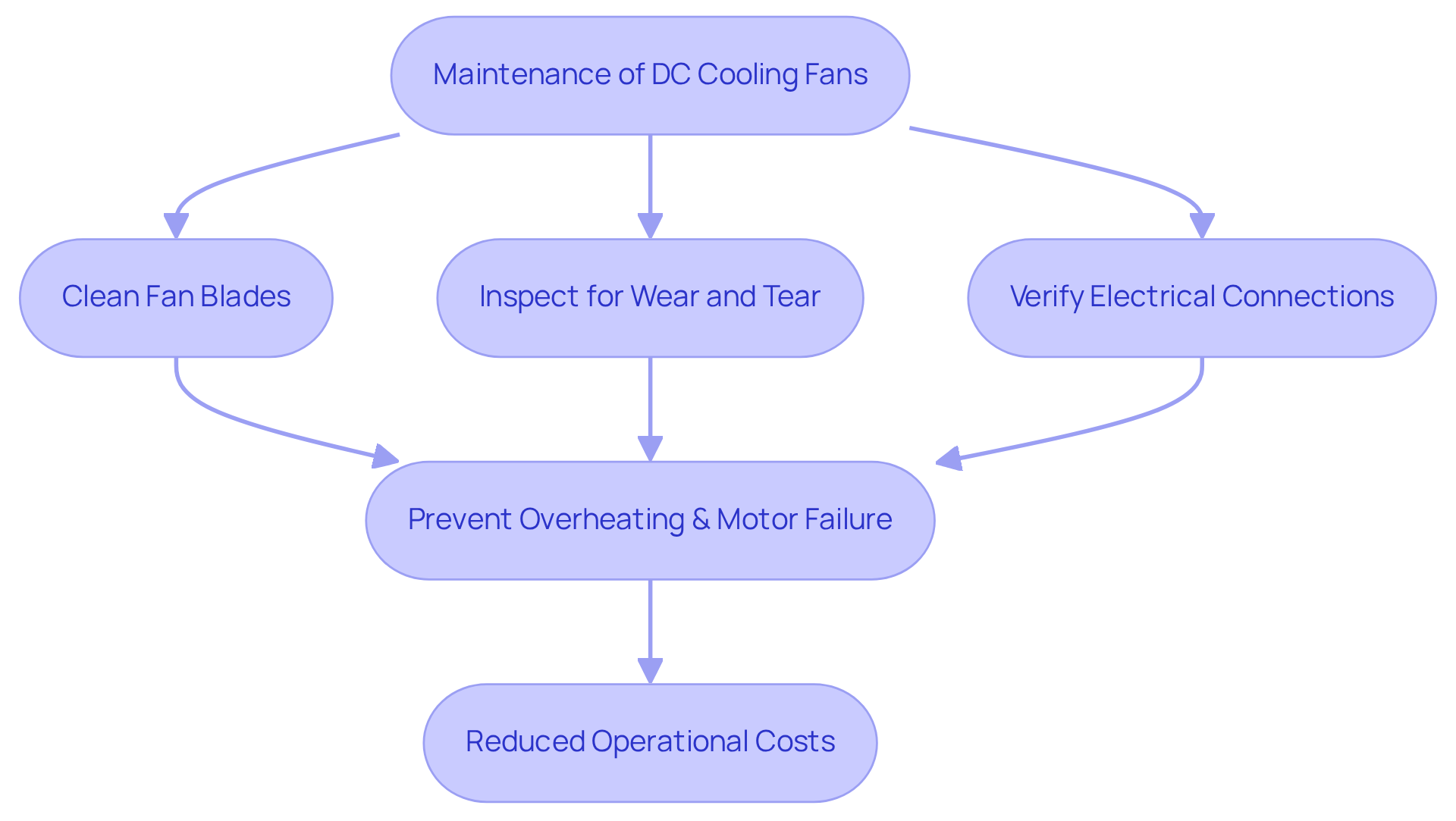

To ensure the longevity and reliability of , is essential. This maintenance involves:

- Cleaning dust and debris from fan blades

- Verifying proper electrical connections

A well-structured maintenance schedule can significantly reduce failure rates; studies indicate that nearly 80 percent of electric motor failures are preventable with appropriate upkeep. Moreover, upkeep constitutes 75% of the unit’s overall cost of ownership (TCO), underscoring the .

Engineers emphasize that consistent cleaning and checks are vital. Neglecting these tasks can lead to overheating and eventual motor failure, which may double operational costs due to premature replacements of DC cooling fans. Additionally, is crucial for scheduling and identifying potential issues early.

By focusing on upkeep, engineers can guarantee in electronic systems, ultimately of their uses.

Innovations in DC Cooling Fans: Emerging Technologies and Trends

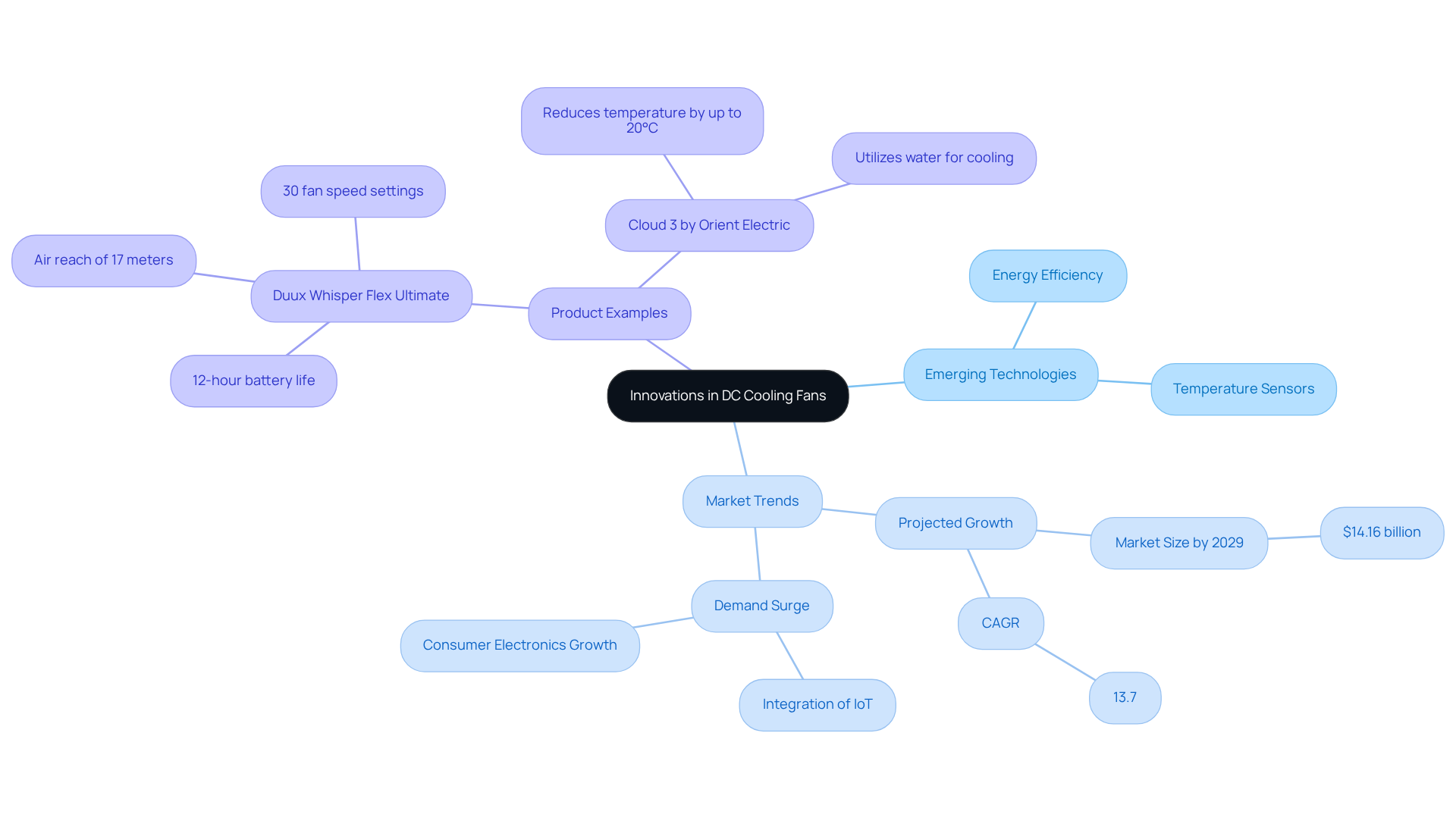

Recent advancements in DC ventilation devices underscore the emergence of intelligent units equipped with their speed based on current thermal conditions. This innovative technology enhances temperature regulation efficiency and contributes to , establishing these devices as a compelling choice for a variety of applications. For example, the Duux Whisper Flex Ultimate Fan epitomizes this trend, boasting a 12-hour battery life and the capability to project air distances of up to 17 meters, all while operating at an impressively quiet 13 dBa.

Market trends indicate a pronounced shift towards , with projections suggesting continued expansion as engineers increasingly prioritize and noise reduction in their designs. By 2025, the demand for these advanced is anticipated to surge, driven by the growing integration of IoT technologies within consumer electronics and industrial applications. The is expected to reach $14.16 billion by 2029, with a CAGR of 13.7%, highlighting the significance of these innovations.

Real-world examples of featuring thermal sensors include the Cloud 3 model by Orient Electric, which utilizes cutting-edge technology to lower room temperatures by as much as 20 degrees Celsius. Such advancements not only enhance user comfort but also align with the industry’s commitment to sustainable and energy-efficient solutions. Furthermore, the Duux Globe Desk Fan stands out for its energy efficiency, consuming merely 2W at the lowest speed setting, showcasing the diverse range of smart fans available.

Insights from engineers emphasize the importance of staying informed about these to optimize performance and ensure that designs meet the evolving market demands. As Aarti Bagekari, a research associate, remarked, ‘The market for DC cooling fans is witnessing significant growth in the near future.’ Incorporating smart technologies will be essential for engineers striving to deliver cutting-edge products. To effectively integrate these advancements, engineers should evaluate their current designs and explore how smart fan technologies can enhance both performance and energy efficiency.

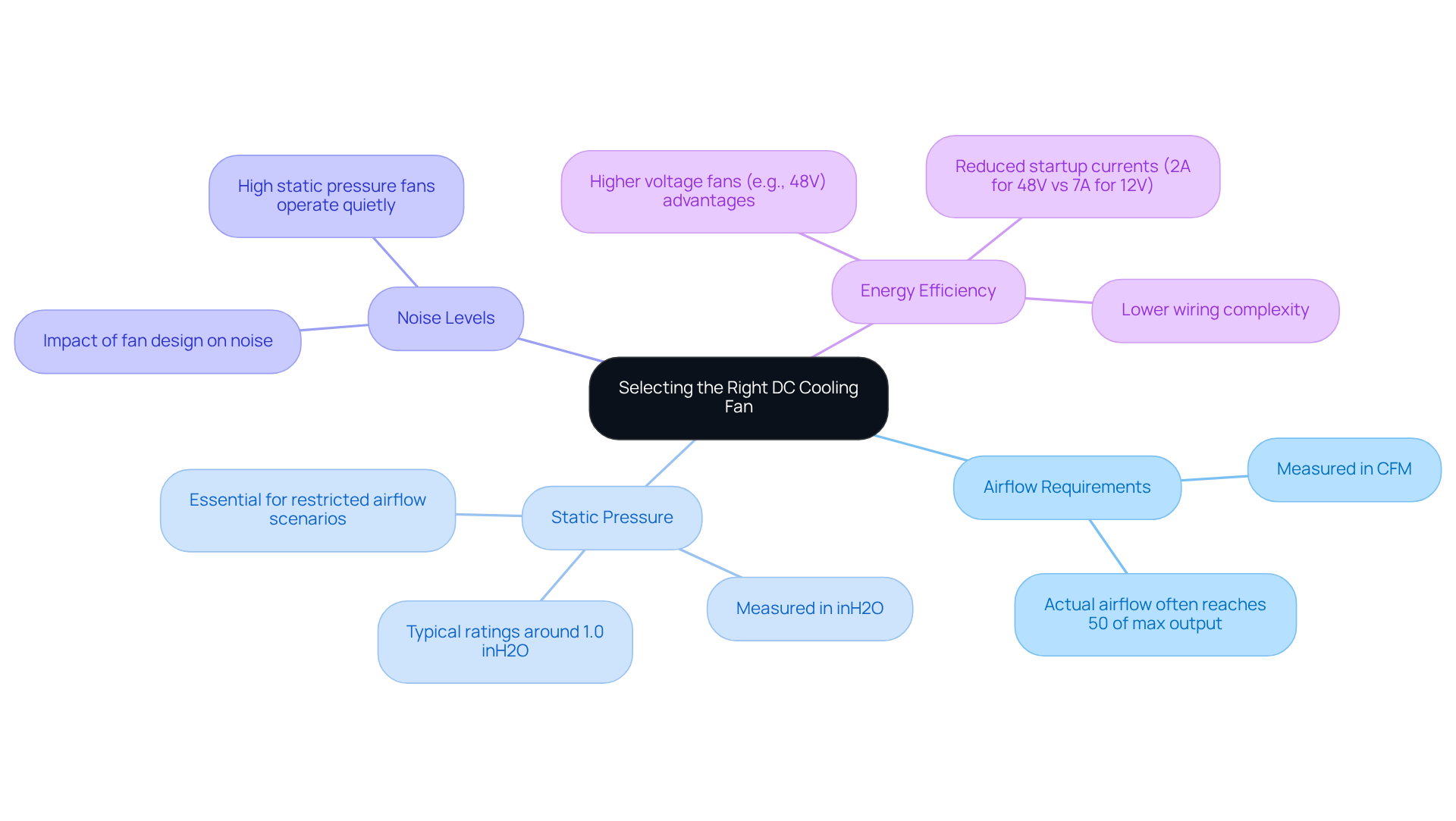

Selecting the Right DC Cooling Fan: Key Considerations for Engineers

Selecting the right DC fan necessitates a comprehensive evaluation of several critical factors that significantly impact system performance. Engineers must assess , typically measured in cubic feet per minute (CFM), as it is vital for . In most forced air cooling applications, actual airflow often reaches approximately half of the fan’s maximum output, making this a crucial consideration for engineers.

Additionally, is an essential metric, particularly in scenarios with restricted airflow, as it indicates the fan’s ability to move air against resistance, measured in inches of water column (inH2O). For airflow devices, static pressure ratings generally hover around 1.0 inH2O, providing a benchmark for evaluating performance across various applications. Moreover, noise levels are a significant factor; devices designed for high static pressure tend to operate more quietly under load, rendering them suitable for environments where noise reduction is paramount.

has become increasingly critical, particularly with the rising demand for sustainable solutions. , such as 48V models, present advantages like reduced startup currents (2A for 48V compared to 7A for 12V) and lower wiring complexity, which can enhance overall system efficiency. As Gary Masessa noted, [higher voltage DC ventilators](https://coolingfans.blog/benefits-of-choosing-a-higher-voltage-dc-cooling-fan) deliver substantial benefits in applications requiring high power efficiency, making them ideal for telecom, data centers, and industrial systems.

Real-world instances underscore these considerations: engineers have reported and following upgrades to fans that effectively balance airflow and static pressure.

As one engineer remarked, understanding the specific and the interplay between airflow and static pressure is crucial for selecting the appropriate fan type. This thorough approach ensures that the chosen fan not only fulfills immediate cooling demands but also contributes to the of electronic components.

Conclusion

Understanding the essential role of DC cooling fans is crucial for engineers dedicated to optimizing thermal management in electronic systems. These devices not only enhance performance but also contribute significantly to energy efficiency and noise reduction, rendering them indispensable across various applications. As the demand for innovative and effective cooling solutions continues to escalate, the insights provided in this article serve as a valuable resource for making informed decisions.

Key points discussed include:

- The substantial advantages of DC cooling fans over traditional AC fans, particularly their impressive energy savings and lower noise levels.

- Advancements in technology, including brushless motors and optimized blade designs, have led to enhanced performance and efficiency.

- The importance of selecting the right fan based on airflow requirements, static pressure, and noise considerations has been emphasized, ensuring that engineers can effectively meet specific project needs.

As the landscape of electronic cooling evolves, staying abreast of innovations and trends in DC cooling fans will be vital. Engineers are encouraged to explore the latest technologies and consider how these advancements can enhance their designs. By prioritizing energy efficiency and effective thermal management, the integration of DC cooling fans will not only improve product reliability but also contribute to a more sustainable future in the electronics industry.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a leading provider of DC cooling fans, specializing in high-performance solutions for the electronics industry and addressing complex engineering challenges.

What types of DC cooling fans does Gagner-Toomey offer?

Gagner-Toomey offers centrifugal blowers ranging from 15 to 225mm, designed for optimal performance and minimal sound, suitable for various electronic systems.

What recent advancements have been made in DC cooling fan technology?

Recent advancements include the introduction of new lines of brushless DC devices that significantly improve operational quietness and energy efficiency.

Why are DC cooling fans important for electronic components?

DC cooling fans are crucial for maintaining optimal thermal conditions, preventing material aging, and ensuring the longevity of electronic devices.

What are the key features of DC cooling fans?

Key features include blade design that affects airflow and static pressure, the use of electronically commutated motors (ECM) for efficiency, and various speed control functions for precise airflow management.

How do DC cooling fans compare to AC fans in terms of energy consumption?

DC cooling fans consume up to 70% less energy than AC fans while delivering equivalent airflow, making them a cost-effective choice.

What are the benefits of using DC cooling fans in sensitive environments?

DC cooling fans have low power consumption and reduced electromagnetic interference (EMI), making them suitable for applications like medical instruments and telecom switches.

What advantages do DC cooling fans offer in terms of noise levels?

DC cooling fans operate significantly quieter than AC units due to the absence of brushes in DC motors, making them ideal for environments requiring minimal noise.

What is the expected lifespan of DC cooling fans?

DC cooling fans often exceed a lifespan of 20,000 hours, contributing to the reliability of electronic systems.

What is the projected market growth for DC cooling fans?

The market for DC cooling fans is projected to reach USD 3.2 billion by 2033, driven by their superior performance and increasing demand for energy-efficient technologies.