Overview

This article provides essential insights into the performance and design of micro fans, underscoring their critical role in thermal management for compact electronic devices. It discusses how advancements in technology, design principles, and energy efficiency are pivotal for optimizing airflow, reducing noise, and ensuring reliable operation. These factors address the unique challenges posed by modern electronics, highlighting the necessity for innovative solutions in this rapidly evolving field.

Introduction

The rapid evolution of electronic devices has significantly intensified the demand for effective thermal management solutions, particularly in the realm of micro fans. These compact cooling systems are essential for maintaining optimal performance and reliability in increasingly powerful gadgets. As engineers navigate the complexities of airflow, pressure, and noise levels, they encounter the challenge of selecting the right micro fan design tailored to specific application needs.

What innovative strategies and insights can guide them in optimizing micro fan performance for the future?

Gagner-Toomey Associates: Innovative Cooling Solutions for Micro Fans

Gagner-Toomey Associates stands at the forefront of tailored for micro fans, effectively addressing the unique challenges posed by compact electronic devices. Their strategic partnerships with leading manufacturers provide engineers with access to cutting-edge technologies that significantly enhance thermal management capabilities. This enhancement is crucial, as efficient temperature regulation solutions lead to improved performance and reliability in electronic systems.

For example, research indicates that proper thermal management can substantially reduce overheating risks, which are increasingly common due to the escalating processing speeds and power consumption of modern devices. By concentrating on power management and interconnect technologies, Gagner-Toomey plays a pivotal role in developing effective thermal management solutions that align with the evolving demands of the electronics industry.

Successful implementations of micro fan technologies have demonstrated their effectiveness in optimizing heat dissipation, thus ensuring the longevity and functionality of compact devices.

Micro Fan Basics: Understanding Operation and Design Principles

Micro devices operate by generating airflow to effectively disperse heat from electronic components. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, specializes in innovative cooling solutions. Their offerings include a comprehensive range of DC input tube axial fans and centrifugal blowers, all optimized for exceptional performance and efficiency. Typically, their arrangement features a rotor and stator, with the rotor rotating to create the necessary airflow. Key design principles focus on optimizing blade shape, size, and motor efficiency to achieve desired airflow rates while minimizing noise levels. Understanding these principles is essential for engineers when selecting the appropriate micro fan, ensuring in compact spaces.

Types of Micro Fans: Exploring Options for Diverse Applications

Micro fans are available in various forms, including axial, centrifugal, and tangential types, each designed for specific applications. , recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input tube axial devices, ranging from 15 to 280mm. These devices are optimized for performance, efficiency, and low noise, with IP protection available in most models upon request.

- Axial blowers are extensively utilized for general cooling purposes due to their high airflow rates.

- Conversely, centrifugal blowers, available in sizes from 15 to 225mm, are ideal for applications requiring higher pressure, particularly in compact electronic devices.

- Furthermore, Gagner-Toomey Associates provides micro fan solutions tailored for consumer applications and tight spaces, with both standard and custom designs commencing from 15x3mm sizes.

- Tangential blowers are frequently employed in environments where space is constrained, ensuring a consistent airflow.

A comprehensive understanding of these types enables engineers to select the most effective fan for their specific application requirements.

Airflow and Pressure: Key Specifications for Micro Fan Performance

Airflow, measured in cubic feet per minute (CFM), signifies the volume of air a fan can move. Pressure, quantified in inches of water gauge (inH2O), reflects the fan’s capacity to overcome system resistance. Achieving a balance between airflow and pressure is crucial for optimal cooling performance, particularly in applications demanding precision thermal management.

Gagner-Toomey Associates, recognized as the globe’s largest producer of standard and custom air-movers, provides an extensive selection of DC input tube axial devices ranging from 15 to 280mm, alongside centrifugal blowers from 15 to 225mm. This diverse offering ensures that engineers can access solutions tailored to meet their specific airflow and pressure requirements across various sectors, including electronics and automotive.

When selecting micro fan devices, engineers must carefully consider these specifications to ensure they align with the of their applications.

Noise Levels: Evaluating Acoustic Performance of Micro Fans

Noise levels in micro fans are measured in decibels (dB), making it essential for engineers to evaluate their acoustic performance, especially in applications where low noise is crucial, such as home appliances and medical devices. The configuration of the fan, including and motor type, significantly influences noise generation. Notably, research indicates that altering blade shape can lead to a noise decrease of up to 3 dB.

Furthermore, integrating control vortex structures and multi-component blades has demonstrated an overall noise reduction of 5.6 dB. Additionally, operational speed plays a crucial role; the rotational speed directly affects the peak frequency of air velocity fluctuation. An increase in airflow can elevate noise levels, with a 40% rise in volume flow correlating to a sound power level increase of over 4 dB.

Choosing fans with lower noise ratings not only enhances user experience but also ensures effective cooling capabilities, as fan noise is closely tied to energy efficiency and operational losses in the system. Examples of low-noise micro fan designs, especially in medical devices, demonstrate the successful integration of advanced acoustic capabilities. For instance, the use of multi-element airfoils enhances lift while reducing noise, ultimately contributing to quieter and more efficient operation.

However, it is important to note that while serrated leading edges can lower sound pressure levels by 1.2 dB, they may also have potential negative effects on aerodynamics, a consideration engineers must take into account.

Thermal Management: The Role of Micro Fans in Electronics

Micro fans play a crucial role in thermal management within electronics, effectively dissipating heat generated by components like CPUs and GPUs. By ensuring optimal operating temperatures, these devices with micro fans prevent overheating, which can significantly degrade performance or lead to component failure.

In compact electronic configurations, where space constraints complicate heat dissipation, efficient thermal management becomes even more critical. Therefore, engineers must integrate micro fans into their designs to ensure the and longevity of electronic devices.

Energy Efficiency: Maximizing Performance with Micro Fans

Enhancing energy efficiency in micro fans is essential for reducing power usage while ensuring high performance. Gagner-Toomey Associates, a leader in innovative cooling solutions, provides advanced features such as:

- Brushless DC motors

- Optimized blade configurations

These features significantly lower energy consumption. Engineers must prioritize energy efficiency not only to minimize operational costs but also to meet sustainability goals in their projects. By integrating energy-efficient micro fans from Gagner-Toomey Associates, users can experience:

- Extended battery life in portable devices

- Reduced energy usage in stationary applications

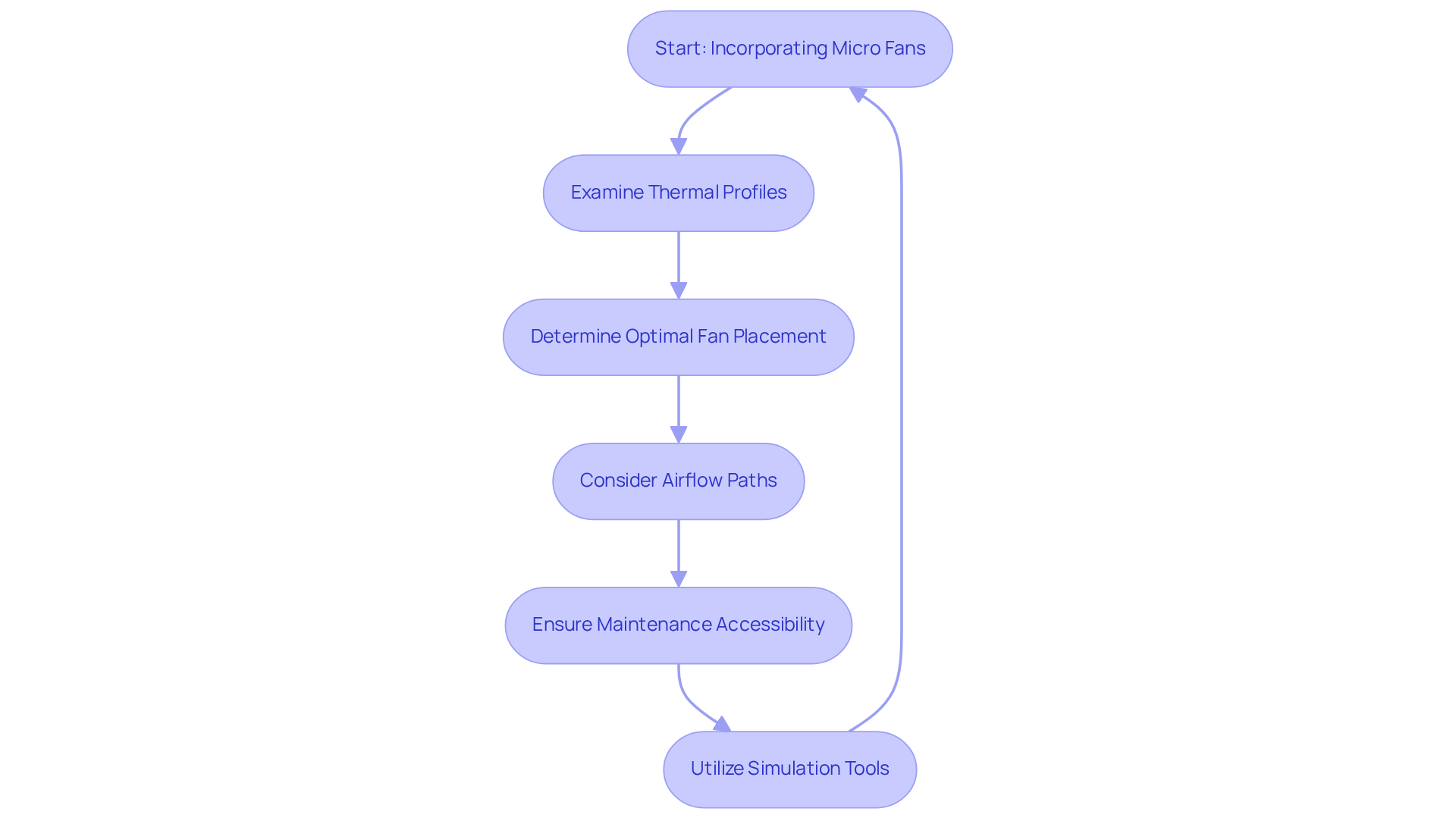

Integration Strategies: Incorporating Micro Fans into Electronic Designs

Incorporating miniature blowers into electronic designs presents a significant challenge that demands a strategic approach to airflow paths, mounting locations, and power supply requirements. Engineers must conduct a thorough examination of their devices’ thermal profiles to identify the optimal fan placement that enhances efficiency.

Research indicates that the arrangement of devices can profoundly influence temperature regulation; ideal positions can mitigate thermal boundary layers and enhance airflow dynamics. For instance, when the fan was removed, the temperature surged to 46C, highlighting the critical role of fan placement in effective thermal management.

Furthermore, ensuring that fans are easily accessible for maintenance not only extends the lifespan and reliability of the system but also minimizes downtime during repairs. Advanced simulation tools can accurately predict airflow patterns, enabling engineers to refine fan placement during the design phase.

This proactive approach is essential for achieving in compact electronic systems, where even a slight reduction in temperature can significantly impact operation and reliability. As one expert noted, ‘Sucking air through the heatsink is more effective than blowing, as it reduces the recycling of heated air and enhances cooling efficiency.’

By adopting these strategies, engineers will be empowered to optimize their designs for superior thermal performance.

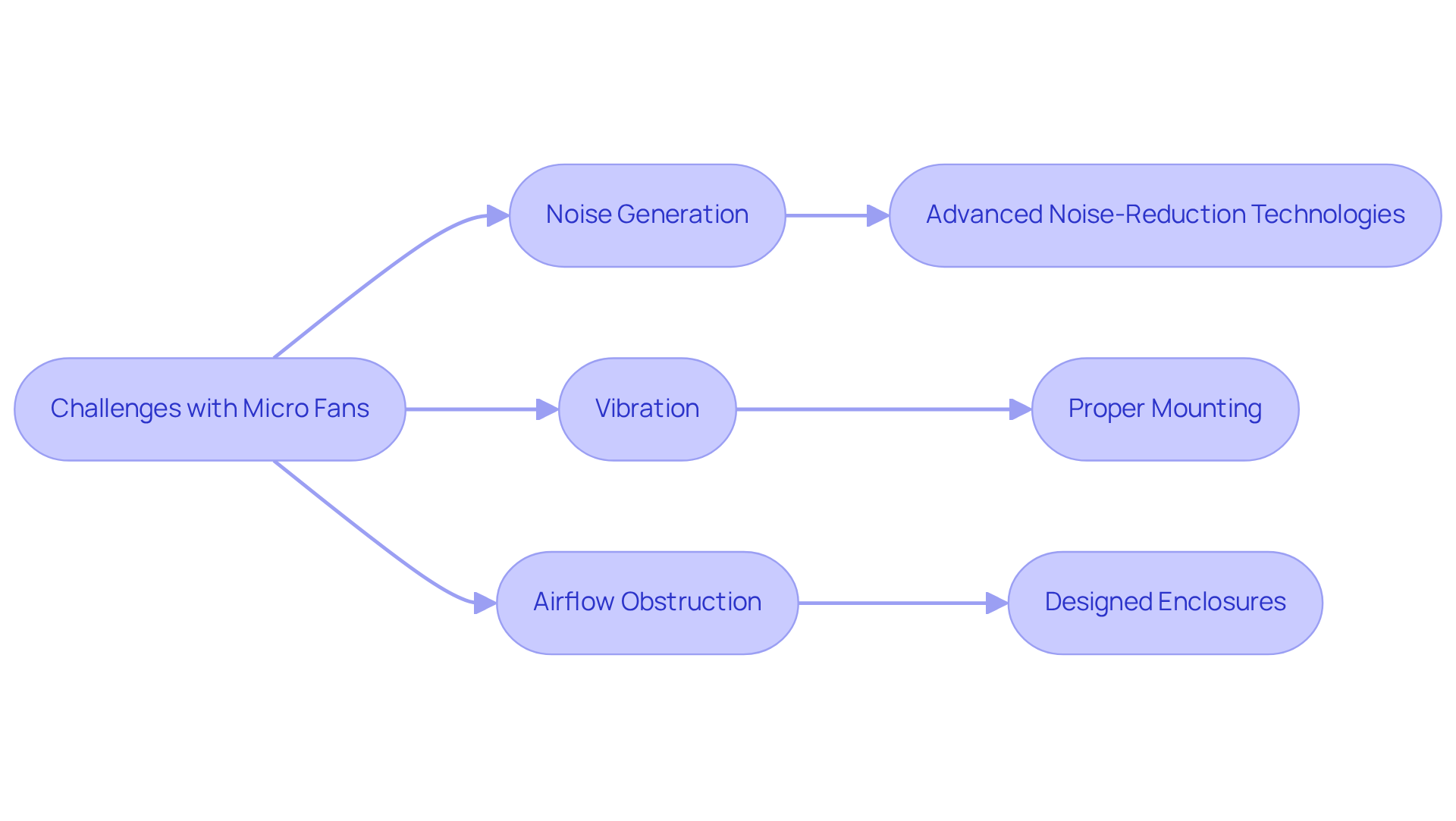

Challenges and Solutions: Overcoming Issues with Micro Fans

Common challenges with small motors encompass noise generation, vibration, and airflow obstruction. Engineers face these issues head-on by selecting fans equipped with advanced noise-reduction technologies, ensuring proper mounting to minimize vibration, and designing enclosures that facilitate unobstructed airflow.

Routine upkeep and vigilant observation play a critical role in before they compromise efficiency. By proactively addressing these challenges, engineers significantly enhance the reliability and efficiency of their cooling solutions.

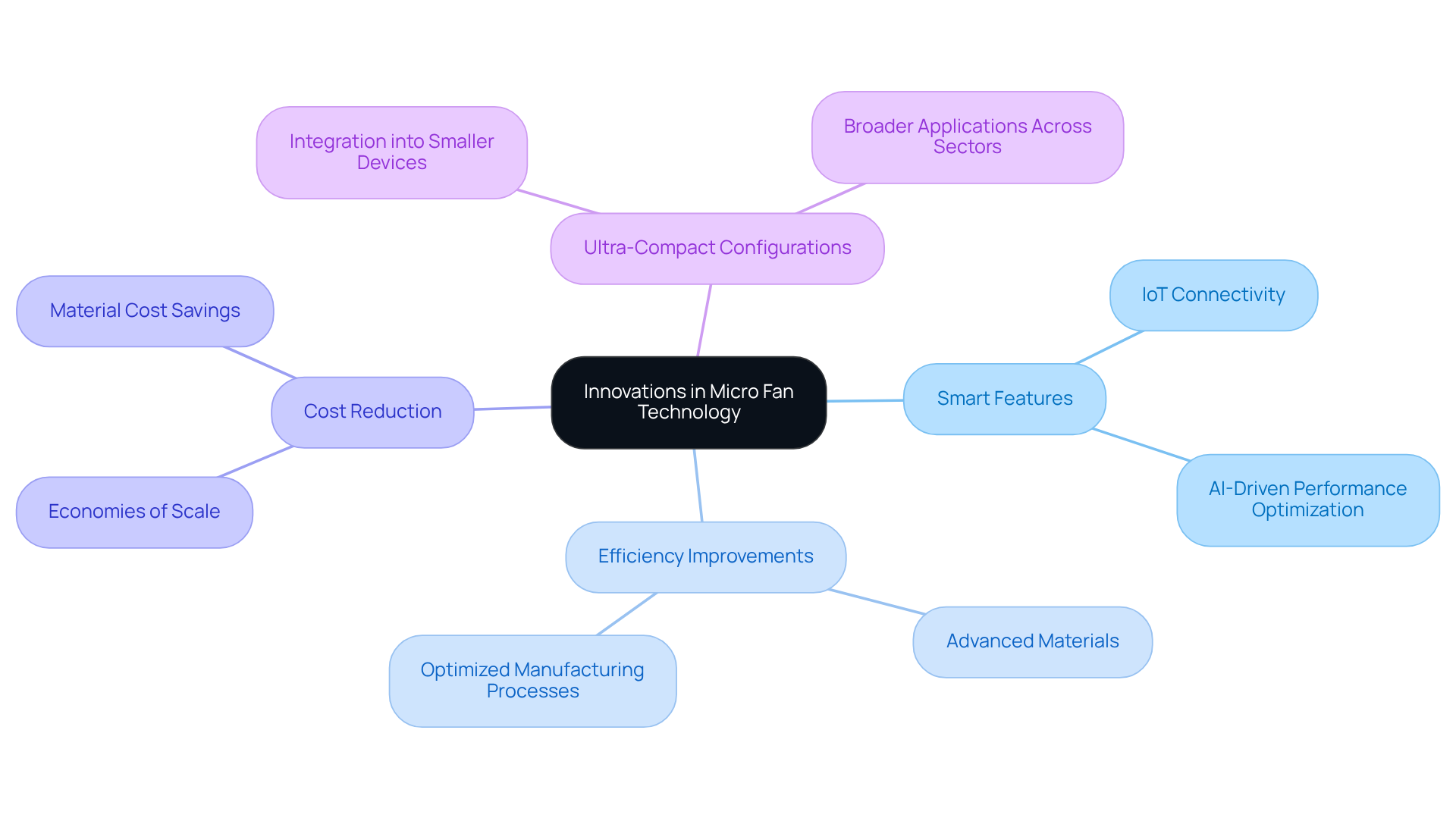

Future Trends: Innovations in Micro Fan Technology

The future of micro fan technology is poised for significant advancements, especially with the integration of smart features like IoT connectivity and AI-driven performance optimization. These are anticipated to enhance efficiency while simultaneously reducing costs. Moreover, the evolution of ultra-compact configurations will enable the integration of micro fans into even smaller devices, thereby broadening their applications across diverse sectors. Engineers must remain vigilant regarding these trends to effectively leverage new technologies in their designs and sustain a competitive edge.

Conclusion

Micro fans serve as indispensable components in the domain of thermal management, particularly within compact electronic devices. Their capacity to efficiently dissipate heat not only enhances device performance but also ensures longevity and reliability. This article emphasizes the critical need for a comprehensive understanding of micro fan operation, design principles, and their essential role across various applications.

The discussions presented highlight the diversity of micro fan types, such as:

- Axial fans

- Centrifugal fans

- Tangential fans

Each meticulously designed to meet specific performance requirements. The equilibrium between airflow and pressure, alongside considerations for noise levels and energy efficiency, emerges as a pivotal factor for engineers in selecting the most appropriate micro fan. Moreover, strategic integration and the resolution of common challenges are vital for maximizing the effectiveness of these cooling solutions.

As technology advances, remaining informed about the latest innovations in micro fan design and performance becomes increasingly crucial. Engineers are urged to adopt these advancements, ensuring their designs not only satisfy current demands but also anticipate future trends. By prioritizing effective thermal management through the implementation of micro fans, the reliability and efficiency of electronic devices can be significantly enhanced, paving the way for more sustainable and high-performing technologies.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for its innovative thermal management solutions specifically designed for micro fans, addressing the unique challenges of compact electronic devices.

How do Gagner-Toomey Associates’ partnerships benefit engineers?

Their strategic partnerships with leading manufacturers provide engineers access to cutting-edge technologies that enhance thermal management capabilities, which is crucial for improving performance and reliability in electronic systems.

Why is thermal management important for modern electronic devices?

Proper thermal management is important because it can significantly reduce overheating risks, which are common due to increasing processing speeds and power consumption in modern devices.

What are the key components of micro fan technology?

Micro fan technology typically includes a rotor and stator, with the rotor rotating to create airflow. Key design principles focus on optimizing blade shape, size, and motor efficiency to achieve desired airflow rates while minimizing noise.

What types of micro fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers various types of micro fans, including axial, centrifugal, and tangential fans, each designed for specific applications.

What are the characteristics of axial blowers?

Axial blowers are widely used for general cooling purposes due to their high airflow rates.

When are centrifugal blowers preferred over axial blowers?

Centrifugal blowers are preferred in applications requiring higher pressure, particularly in compact electronic devices.

What size range do Gagner-Toomey Associates’ micro fans cover?

Their micro fans range in size from 15 to 280mm, with options for both standard and custom designs starting from 15x3mm sizes.

What is the purpose of tangential blowers?

Tangential blowers are used in environments with constrained space, providing a consistent airflow.

How can engineers select the most effective fan for their applications?

A comprehensive understanding of the different types of micro fans allows engineers to choose the most effective fan based on specific application requirements.