Overview

The article underscores the critical importance and diverse applications of high-temperature fans and blowers within the realm of electronics engineering, particularly emphasizing their pivotal role in effective thermal management.

By detailing various manufacturers, advanced technologies, and prevailing market trends, it illustrates how these devices significantly enhance performance and reliability in high-performance electronic systems.

This discussion addresses the urgent need for precise temperature control, which is essential to prevent equipment failures and ensure operational longevity.

Introduction

High-temperature fans and blowers are indispensable tools for electronics engineers, serving a critical function in maintaining optimal thermal conditions within a rapidly evolving technological landscape. As electronic devices grow increasingly powerful and compact, the demand for effective cooling solutions intensifies, presenting engineers with both challenges and opportunities. This article explores the leading high-temperature fans and blowers available, examining their specifications, applications, and the innovative technologies that drive their development.

How can engineers leverage these advanced cooling solutions to enhance performance and reliability in their designs?

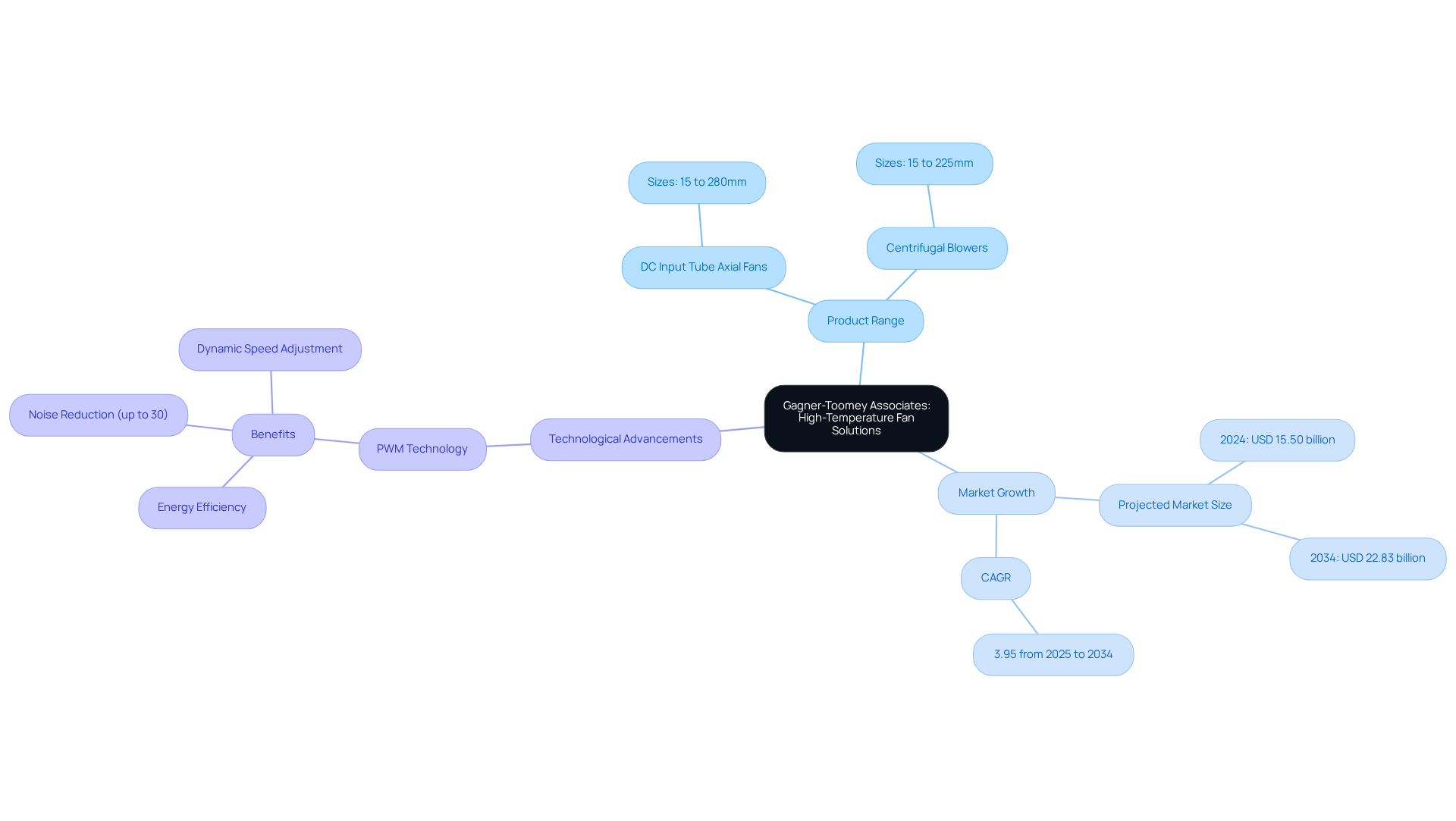

Gagner-Toomey Associates: High-Temperature Fan Solutions for Electronics Engineering

Gagner-Toomey Associates leads the industry in delivering high temperature fans and blowers that are tailored specifically for the electronics engineering sector. As the world’s largest manufacturer of standard and custom air-movers, Gagner-Toomey partners with esteemed manufacturers, including Delta Electronics, to offer cutting-edge temperature control technologies capable of enduring extreme conditions. This commitment ensures optimal functionality and reliability in electronic systems. Their extensive product range features DC input tube axial fans from 15 to 280mm and centrifugal blowers from 15 to 225mm, all optimized for performance, efficiency, and minimal noise, catering to a variety of applications across electronics, automotive, and industrial sectors.

The global temperature regulation fan market is projected to experience significant growth, reaching approximately USD 22.83 billion by 2034, with a compound annual growth rate (CAGR) of 3.95%. High-temperature thermal management technologies, including high temperature fans and blowers, are capturing a notable share of this market due to their essential role in heat management for advanced electronics. Recent developments, such as the incorporation of Pulse Width Modulation (PWM) technology, enhance energy efficiency and can lead to noise level reductions of up to 30% compared to traditional temperature regulation systems. PWM devices dynamically adjust their speeds based on thermal demands, rendering these solutions increasingly attractive.

Gagner-Toomey’s unwavering commitment to exceptional customer service and product representation, combined with their extensive network of local distributors, positions them as a reliable partner for engineers in search of effective and innovative cooling solutions. This is particularly relevant in high-performance applications such as data centers and automotive electronics.

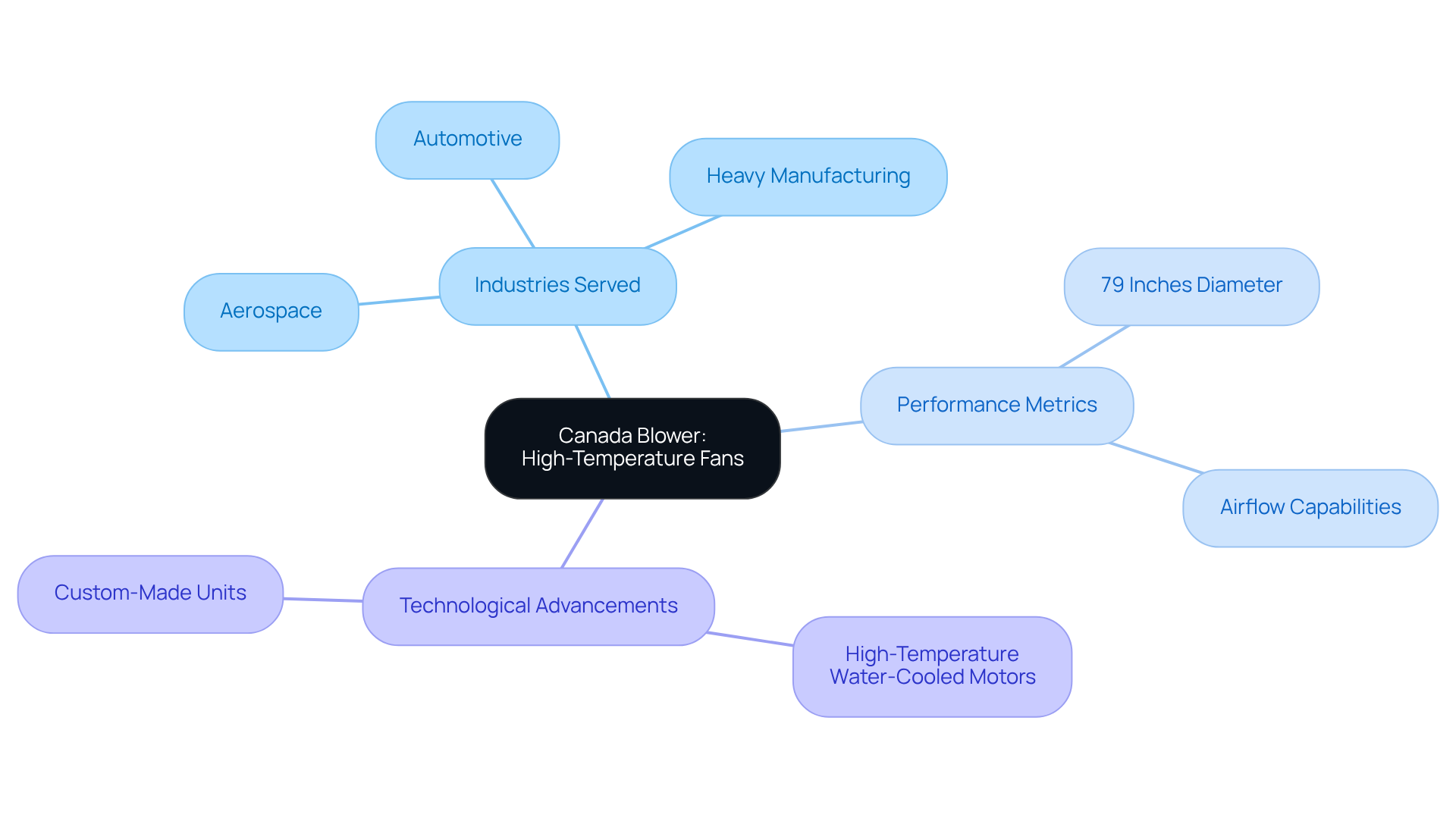

Canada Blower: High-Temperature Fans Operating Up to 2,200°F

Canada Blower specializes in high temperature fans and blowers that function effectively in environments reaching up to 2,200°F. These devices are meticulously engineered for durability and efficiency, making them indispensable in sectors such as aerospace, automotive, and heavy manufacturing. Their robust design, utilizing extremely high-strength stainless steel alloys for the impellers, allows for higher safe speeds at elevated temperatures, ensuring dependable performance even under the most challenging conditions. This reliability is crucial for critical cooling applications, where maintaining optimal ventilation is essential to prevent equipment damage and ensure operational efficiency.

In aerospace and automotive production, high temperature fans and blowers are integral to processes like heat treating and thermal treatment. For example, high temperature fans and blowers are routinely employed in aluminum furnaces and annealing ovens, facilitating efficient airflow and precise temperature control. The ability to withstand extreme temperatures—up to 2,200°F—guarantees that these devices can meet the rigorous demands of industrial applications.

Performance metrics for Canada Blower’s high-temperature units underscore their effectiveness, with certain models achieving efficiencies of up to 79 inches in diameter. These devices are designed to handle substantial amounts of airflow against varying static pressures, making them suitable for diverse operational requirements. Moreover, Canada Blower’s engineers offer expert guidance to assist clients in selecting the appropriate fan for specific applications, ensuring optimal performance and longevity.

Recent advancements in high temperature fans and blowers technology showcase innovations in design and materials, including unique high-temperature water-cooled motors capable of operation up to 2,300°F, which enable even greater operational capabilities. With options for both pre-engineered and custom-made units, Canada Blower remains at the forefront of delivering innovative solutions tailored to the unique needs of the aerospace and automotive sectors.

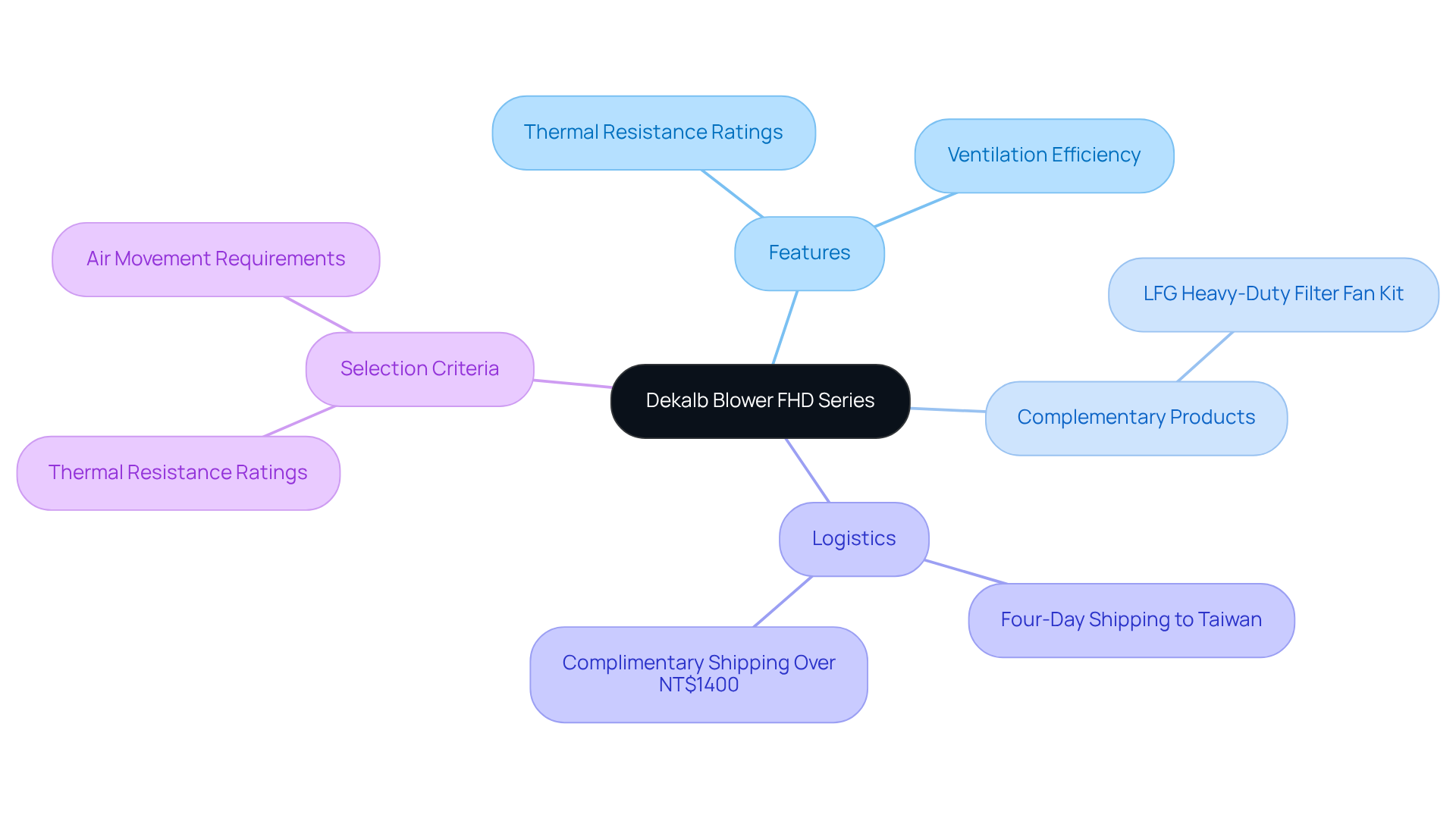

Dekalb Blower: FHD Series High-Temperature Fans for Industrial Use

The Dekalb Blower FHD Series is meticulously engineered for industrial applications that necessitate the use of high temperature fans and blowers. These high temperature fans and blowers utilize advanced materials and innovative design techniques to achieve superior thermal resistance ratings and ventilation efficiency, making them ideal solutions for demanding manufacturing processes.

Effective temperature regulation with high temperature fans and blowers is crucial for maintaining equipment integrity and boosting operational efficiency, especially in environments that challenge conventional temperature management solutions. Moreover, the LFG heavy-duty filter fan kit series complements the FHD Series by safeguarding enclosures from dust, dirt, and moisture, thereby enhancing reliability in harsh conditions.

For electronics engineers contemplating procurement, it is noteworthy that orders to Taiwan typically arrive within four days, with complimentary shipping available on orders exceeding NT$1400. When selecting the appropriate high temperature fans and blowers for specific industrial applications, it is essential to consider thermal resistance ratings and air movement requirements to ensure optimal performance.

Industrial Cooling Fans: Essential Types for Electronics Applications

In the electronics sector, high temperature fans and blowers are vital industrial ventilation devices, which comprise three primary types: axial, centrifugal, and mixed-flow. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, excels in delivering optimized solutions for these applications. Axial blowers are distinguished by their high airflow at low pressure, making them ideal for maintaining electronic components and ensuring ventilation in confined spaces. In data centers, for instance, Gagner-Toomey’s axial devices are preferred for their efficiency in moving substantial volumes of air, which is crucial for sustaining optimal temperatures in high-density computing environments. Notably, over 70% of industrial ventilation installations for temperature regulation utilize axial types, underscoring their dominance in the market.

Gagner-Toomey Associates offers centrifugal blowers that are part of their high temperature fans and blowers, specifically designed for high-pressure applications. These devices are commonly employed in situations where air must traverse ductwork or overcome significant resistance, such as in HVAC systems and various industrial processes. Their robust construction enables them to manage particulate-laden air, rendering them suitable for environments like manufacturing facilities where dust and debris are prevalent. This reliability in high-pressure settings contributes to their substantial market share, which stood at 63.8% in 2024.

Mixed-flow units offer versatility in temperature regulation, utilizing high temperature fans and blowers to generate both radial and axial currents. Gagner-Toomey’s mixed-flow devices excel in applications requiring a balance between airflow volume and pressure, particularly advantageous in automotive cooling systems where space constraints and performance demands are critical.

Market demand illustrates these distinctions, with axial devices leading due to their high efficiency and reduced operational costs. In 2025, axial blowers accounted for a revenue share of 38.42%, driven by their application in data centers and consumer electronics. Engineers frequently stress the importance of selecting the appropriate fan type based on specific application requirements. As one engineer aptly noted, “Choosing the right fan is crucial; axial fans are great for airflow, but when pressure is a concern, centrifugal fans are the way to go.” This insight emphasizes the necessity for engineers to understand the unique characteristics of each fan type to enhance performance in their designs. Furthermore, the fan market is projected to experience significant growth, anticipated to reach USD 29,967.0 million by 2035, reflecting the escalating demand for efficient thermal management solutions across diverse industries.

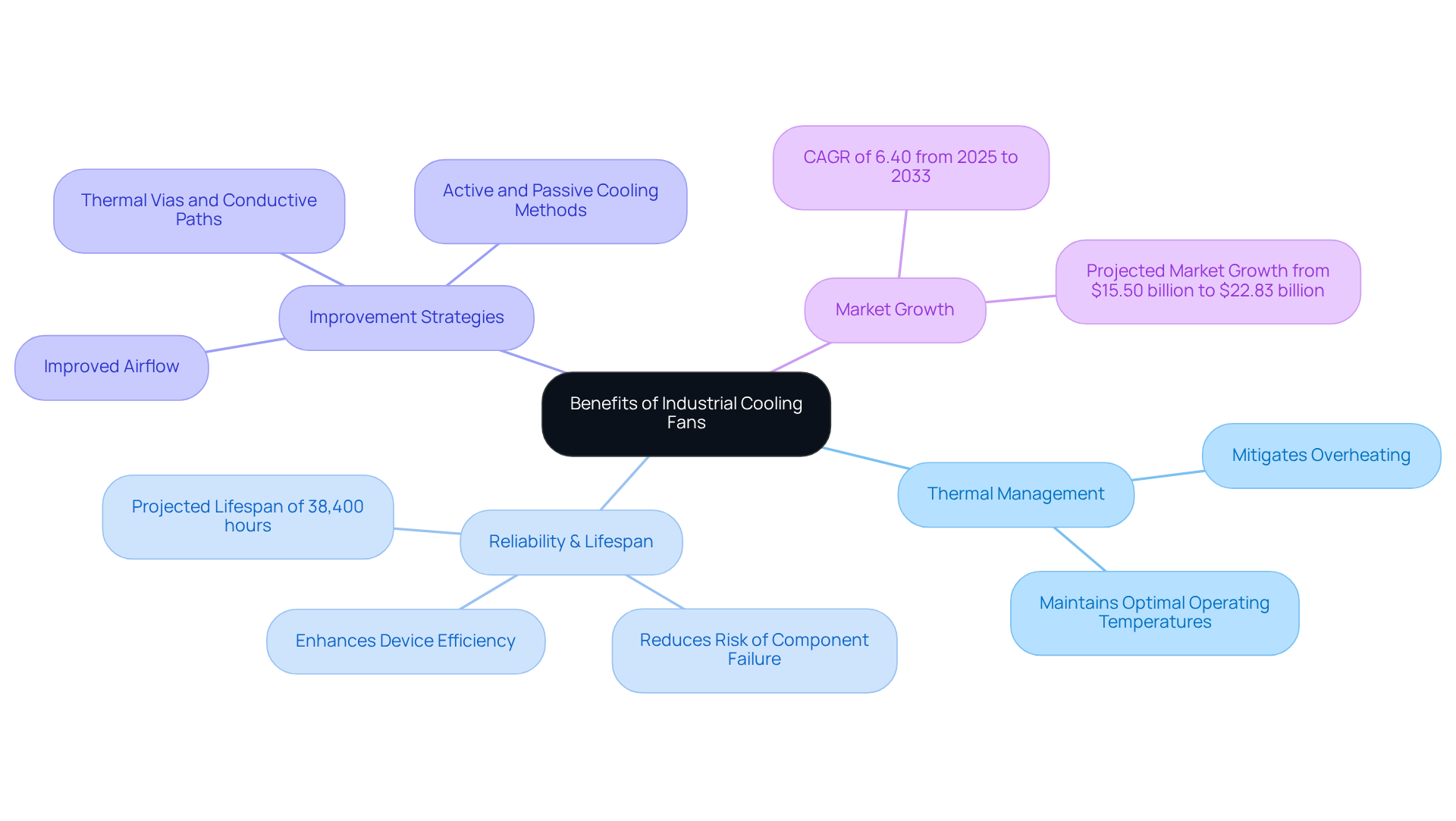

Benefits of Industrial Cooling Fans for Electronics Engineers

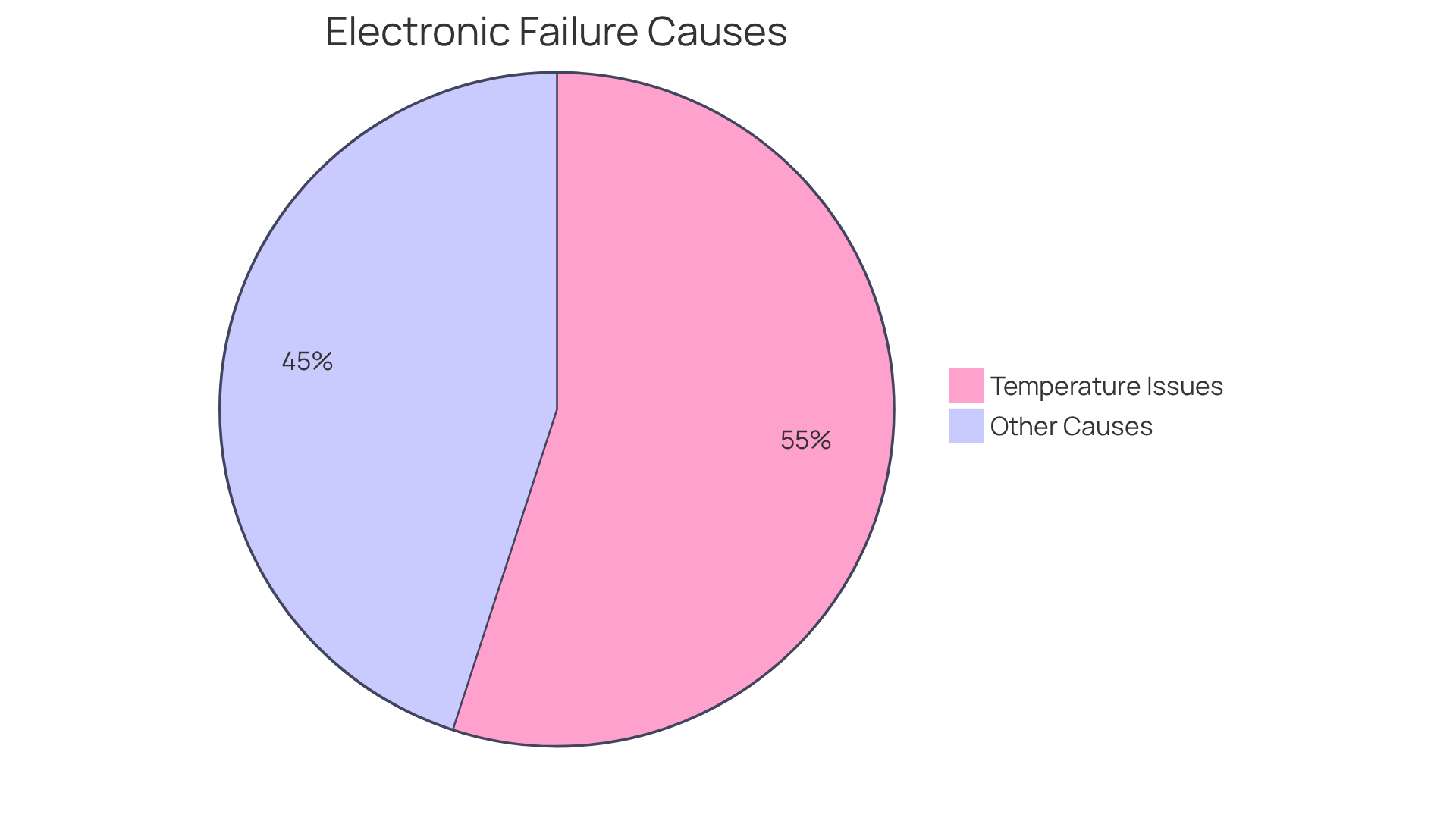

High temperature fans and blowers are essential industrial ventilation devices for optimizing thermal management in electronics engineering, which significantly enhances the reliability and lifespan of components. By maintaining optimal operating temperatures, these fans mitigate the risk of overheating, which accounts for approximately 55% of electronic equipment failures. Effective thermal management, utilizing high temperature fans and blowers, is crucial in preventing these failures and ensuring devices operate at peak efficiency.

For example, components that utilize advanced temperature regulation technologies are projected to exceed 38,400 hours of operational lifespan by 2025, particularly as the average operating temperature stabilizes around 40°C. Moreover, case studies illustrate that implementing strategies such as improved airflow and thermal vias can lead to substantial reliability enhancements, ensuring that electronic devices remain functional even in harsh environments.

As the demand for high-performance computing and energy-efficient technologies escalates, understanding the advantages of industrial fans becomes imperative for engineers aiming to enhance the durability and performance of their designs. As Gennex states, “Effective thermal management prevents overheating and mitigates the risk of component failure, ensuring devices operate at peak efficiency.”

Furthermore, the semiconductor fan market is anticipated to grow at a CAGR of around 6.40% from 2025 to 2033, underscoring the increasing importance of efficient temperature regulation solutions in the industry.

Choosing the Right Industrial Cooling Fan for Your Electronics Needs

Selecting the appropriate industrial ventilation fan, such as high temperature fans and blowers, for your electronics needs requires a comprehensive evaluation of several key factors:

- Airflow requirements

- Static pressure

- Noise levels

- Environmental conditions

In premium rack systems, for instance, engineers often allocate over 25% of the overall power budget to cooling devices, underscoring the importance of effective selection. High-Volume Low-Speed (HVLS) devices, which utilize minimal energy compared to conventional HVAC systems, provide optimal temperature control, further emphasizing the necessity for energy-efficient alternatives.

To achieve optimal performance, it is crucial to match the specific demands of the application to the specifications of high temperature fans and blowers. Centrifugal blowers, as noted by Johann Tang, a product specialist, are ideal for high static pressure applications, stating that “centrifugal blowers are best for applications requiring higher pressure, such as ducted systems or where air must overcome resistance.” In contrast, axial blowers are commonly used for general-purpose cooling due to their ability to generate substantial airflow.

Assessing energy efficiency ratings is also vital; energy-saving devices can significantly reduce operational costs and minimize environmental impact. Engineers should consider the long-term advantages of energy-efficient models, which can lead to considerable savings over time. Furthermore, maintenance accessibility is a critical aspect; ensuring that air circulators are easily reachable for routine inspections and repairs can enhance system reliability.

Environmental conditions, including heat, dampness, and corrosive chemicals, must also be factored in when selecting high temperature fans and blowers to ensure they can withstand specific challenges. As one engineer remarked, “Understanding airflow requirements is crucial for selecting industrial fans, ensuring effective air circulation and comfortable working conditions.” By prioritizing these factors, engineers can bolster system reliability and contribute to a more sustainable operational environment.

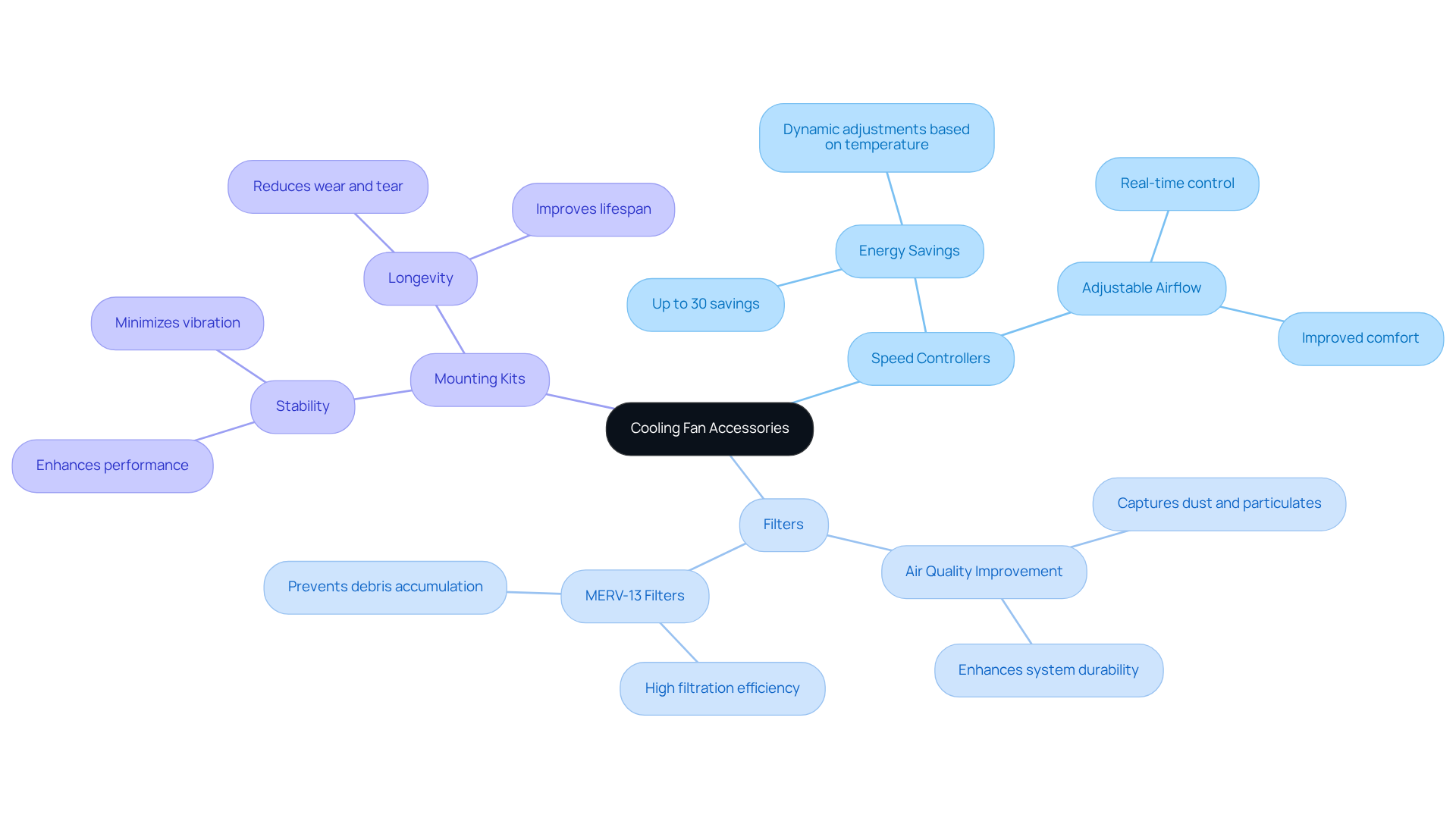

Cooling Fan Accessories: Enhancements for Optimal Performance

Cooling fan components—such as speed controllers, filters, and mounting kits—are essential for maximizing fan functionality across various applications. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a comprehensive array of temperature management solutions that significantly enhance the efficiency of these accessories.

- Speed controllers utilize advanced sensors and algorithms to adjust speeds in accordance with environmental conditions, thereby facilitating adjustable airflow. This capability is particularly beneficial in environments where temperature requirements fluctuate.

- Research demonstrates that the implementation of automatic fan speed controllers can yield energy savings of up to 30% by dynamically adjusting fan speeds based on real-time temperature and humidity data.

- Filters, especially MERV-13 filters, contribute to improved air quality by capturing dust and particulates, while simultaneously enhancing system durability by preventing debris accumulation.

- Moreover, properly designed mounting kits ensure fan stability and minimize vibration, which can detrimentally impact performance and lifespan.

By integrating these accessories with Gagner-Toomey’s cutting-edge thermal management solutions—including a diverse range of DC input Tube Axial fans and Centrifugal Blowers from 15 to 280mm—engineers can markedly improve the efficiency and longevity of their systems. This integration is particularly vital in high-temperature environments where high temperature fans and blowers are crucial for reliable temperature regulation.

Targeted Cooling Solutions: Blowers for Precision Cooling in Electronics

High temperature fans and blowers are crucial for achieving efficient thermal control within high-performance electronics, directing ventilation exactly where needed to maintain optimal temperatures for critical components. These devices excel at reducing temperatures of high-performance CPUs, power supplies, and other heat-sensitive components, thereby ensuring reliability and functionality in demanding applications.

In high-density environments, where heat generation is significant, high temperature fans and blowers enhance temperature regulation by delivering directed airflow, which is essential for preventing overheating and extending the lifespan of electronic systems. Engineers acknowledge that the incorporation of blowers not only enhances thermal performance but also bolsters the overall stability and functionality of advanced electronic devices.

A study reveals that temperature-related issues account for approximately 55% of electronic equipment failures, underscoring the importance of effective temperature management solutions. Furthermore, the micro blower market is projected to grow at a CAGR of 5-8% from 2025 to 2032, reflecting the increasing demand for efficient temperature management technologies within the electronics sector.

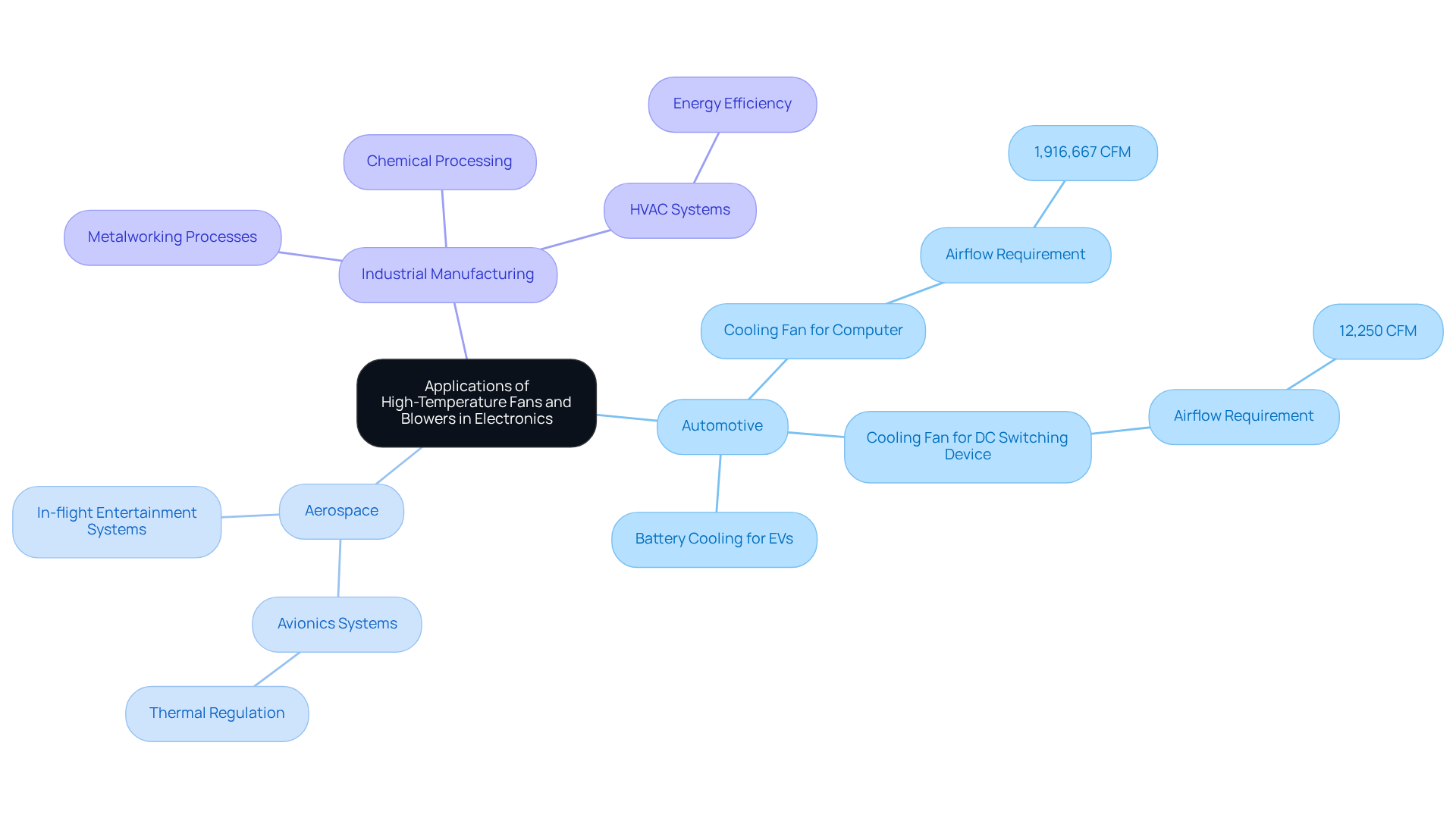

Applications of High-Temperature Fans and Blowers in Electronics

High temperature fans and blowers play a pivotal role across various industries within electronics, including automotive, aerospace, and industrial manufacturing. Gagner-Toomey Associates, recognized as the globe’s largest producer of standard and custom air-movers, provides advanced temperature regulation solutions designed for effectiveness, efficiency, and minimal noise.

In the automotive sector, these devices are crucial for regulating the temperature of engine components and electronic control units, thereby preventing overheating and ensuring optimal performance. For example:

- A computer necessitates a cooling fan with an airflow of 1,916,667 CFM.

- A DC switching device requires a cooling fan with an airflow of 12,250 CFM.

In aerospace applications, high temperature fans and blowers are utilized to manage heat in avionics systems, where reliable thermal regulation is essential for safety and functionality. The implementation of effective thermal performance monitoring has led to significant enhancements in system reliability and longevity, underscoring the importance of these devices.

Within industrial production, high temperature fans and blowers are essential for regulating temperature in processes that involve extreme heat, such as metalworking and chemical processing. Gagner-Toomey’s extensive product range of DC input tube axial devices and centrifugal blowers, varying from 15 to 910mm, not only improves equipment efficiency but also contributes to workplace safety by ensuring optimal operating conditions.

As the demand for sophisticated temperature regulation solutions continues to rise, the market for high temperature fans and blowers is projected to expand significantly, driven by advancements in materials and design that enhance thermal management capabilities across various applications.

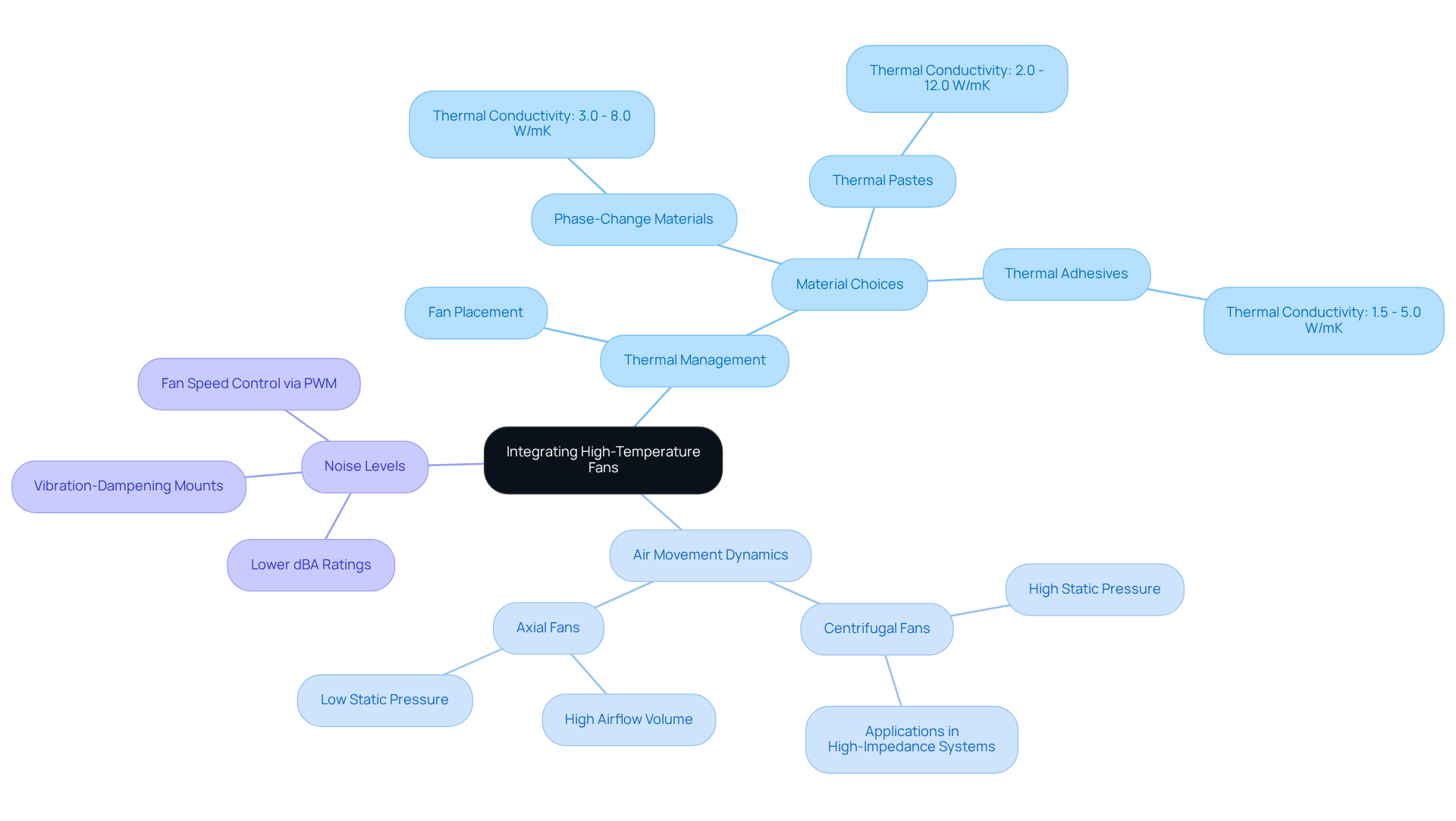

Key Considerations for Integrating High-Temperature Fans in Electronics Design

Incorporating high temperature fans and blowers into electronic designs presents a critical challenge: effective thermal management, air movement dynamics, and noise levels must be meticulously considered. Engineers are tasked with ensuring that high temperature fans and blowers meet the system’s thermal requirements; failure to do so can result in excessive temperatures, leading to component failure and a diminished lifespan of the device.

Proper fan placement emerges as a vital strategy for optimizing airflow—strategic positioning can avert hot air stagnation and guarantee effective cooling across densely packed components. Furthermore, minimizing noise is essential for enhancing user experience, particularly in consumer electronics. Selecting devices with lower dBA ratings and employing vibration-dampening mounts represent effective strategies to achieve this objective.

By addressing these factors, engineers can significantly elevate the performance and reliability of their designs, particularly when incorporating high temperature fans and blowers. For instance, the integration of advanced materials such as phase-change materials, with a thermal conductivity range of 3.0 – 8.0 W/mK, alongside the use of centrifugal fans in high-impedance systems, exemplifies how thoughtful design choices can yield superior thermal management outcomes.

The xMEMS XMC-2400 chip, capable of moving up to 39 cubic centimeters of air per second, showcases cutting-edge fan technology that enhances cooling efficiency. Ultimately, adopting a holistic approach to fan integration not only boosts thermal performance but also contributes to the longevity and safety of electronic devices.

Conclusion

High-temperature fans and blowers serve as critical components that significantly enhance the performance and reliability of electronic systems. Their capability to maintain optimal operating temperatures is essential in preventing overheating, which is responsible for a substantial percentage of electronic equipment failures. As the demand for advanced thermal management solutions escalates, comprehending the diverse options available and their specific applications becomes increasingly vital for electronics engineers.

Throughout this discussion, notable manufacturers such as Gagner-Toomey Associates, Canada Blower, and Dekalb Blower have been highlighted for their innovative high-temperature fan solutions. Key features include:

- The utilization of advanced materials

- Energy-efficient technologies such as Pulse Width Modulation (PWM)

- The significance of selecting the appropriate fan type based on airflow and pressure requirements

Furthermore, the role of cooling fan accessories in optimizing performance has been underscored, illustrating how these enhancements can yield considerable energy savings and improve system longevity.

In conclusion, the incorporation of high-temperature fans and blowers into electronic designs is not merely a technical consideration; it is a vital strategy for ensuring device reliability and efficiency. Engineers are encouraged to adopt a holistic approach when selecting and integrating these components, taking into account factors such as environmental conditions, maintenance accessibility, and specific application needs. As the market for high-temperature cooling solutions continues to expand, remaining informed about the latest advancements and best practices will empower engineers to develop robust and efficient electronic systems capable of thriving in demanding environments.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in high-temperature fans and blowers tailored for the electronics engineering sector, offering both standard and custom air-movers.

What are the key features of Gagner-Toomey’s products?

Their products include DC input tube axial fans ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, optimized for performance, efficiency, and minimal noise.

What is the projected growth of the global temperature regulation fan market?

The global temperature regulation fan market is projected to reach approximately USD 22.83 billion by 2034, with a compound annual growth rate (CAGR) of 3.95%.

How does Pulse Width Modulation (PWM) technology enhance high-temperature fans?

PWM technology enhances energy efficiency and can reduce noise levels by up to 30% compared to traditional systems by dynamically adjusting speeds based on thermal demands.

What industries benefit from Canada Blower’s high-temperature fans?

Canada Blower’s high-temperature fans are utilized in industries such as aerospace, automotive, and heavy manufacturing, particularly for processes like heat treating and thermal treatment.

What is the maximum temperature Canada Blower’s fans can operate at?

Canada Blower’s fans can operate effectively in environments reaching up to 2,200°F.

What materials are used in Canada Blower’s high-temperature fans?

Canada Blower’s fans are constructed using extremely high-strength stainless steel alloys for the impellers, ensuring durability and efficiency at elevated temperatures.

What performance metrics are highlighted for Canada Blower’s high-temperature units?

Certain models achieve efficiencies of up to 79 inches in diameter and are designed to handle substantial airflow against varying static pressures.

What is the purpose of the Dekalb Blower FHD Series?

The Dekalb Blower FHD Series is engineered for industrial applications requiring high-temperature fans and blowers, focusing on superior thermal resistance and ventilation efficiency.

What additional product complements the FHD Series?

The LFG heavy-duty filter fan kit series complements the FHD Series by protecting enclosures from dust, dirt, and moisture, enhancing reliability in harsh conditions.

How quickly can orders to Taiwan from Dekalb Blower be expected to arrive?

Orders to Taiwan typically arrive within four days, with complimentary shipping available on orders exceeding NT$1400.

What should be considered when selecting high-temperature fans for industrial applications?

When selecting high-temperature fans, it is essential to consider thermal resistance ratings and air movement requirements to ensure optimal performance.