Overview

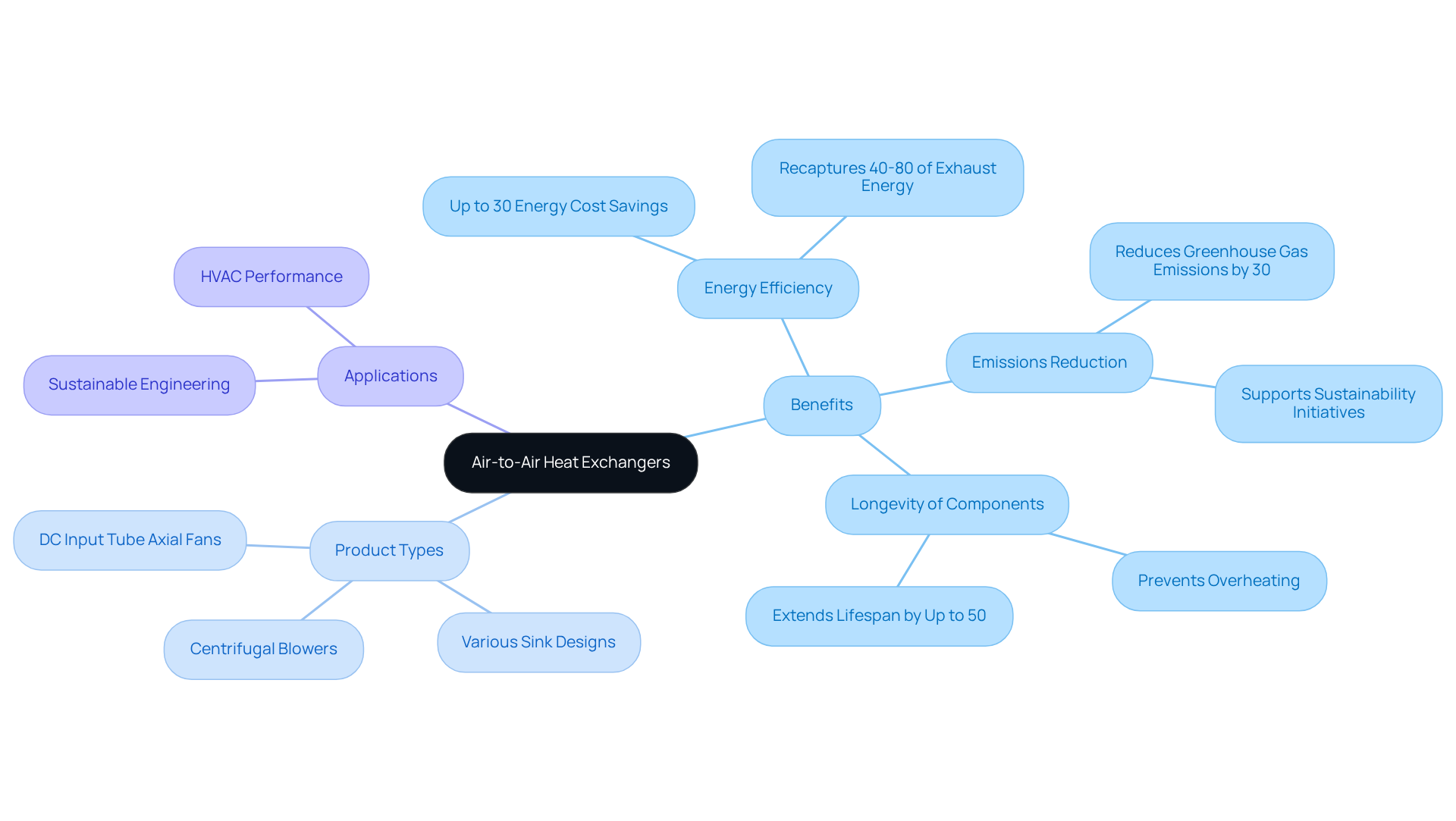

The article highlights the significant advantages of air-to-air heat exchangers, particularly their pivotal role in enhancing energy efficiency, optimizing HVAC performance, and promoting sustainable engineering practices. These systems are capable of achieving energy cost savings of up to 30%, while also extending the lifespan of electronic devices by mitigating overheating. This underscores their critical importance in contemporary engineering applications, making them an essential consideration for professionals in the field.

Introduction

Air-to-air heat exchangers are revolutionizing thermal management within engineering, especially in the electronics sector. These advanced systems not only improve energy efficiency but also play a vital role in sustaining optimal operating conditions for sensitive electronic components. As engineers work to balance performance with sustainability, a pivotal question emerges: how can the integration of air-to-air heat exchangers yield substantial operational savings while ensuring reliability and adherence to environmental standards? This article explores the significant advantages of these thermal devices, examining their influence on:

- Energy recovery

- HVAC performance

- Overall system longevity

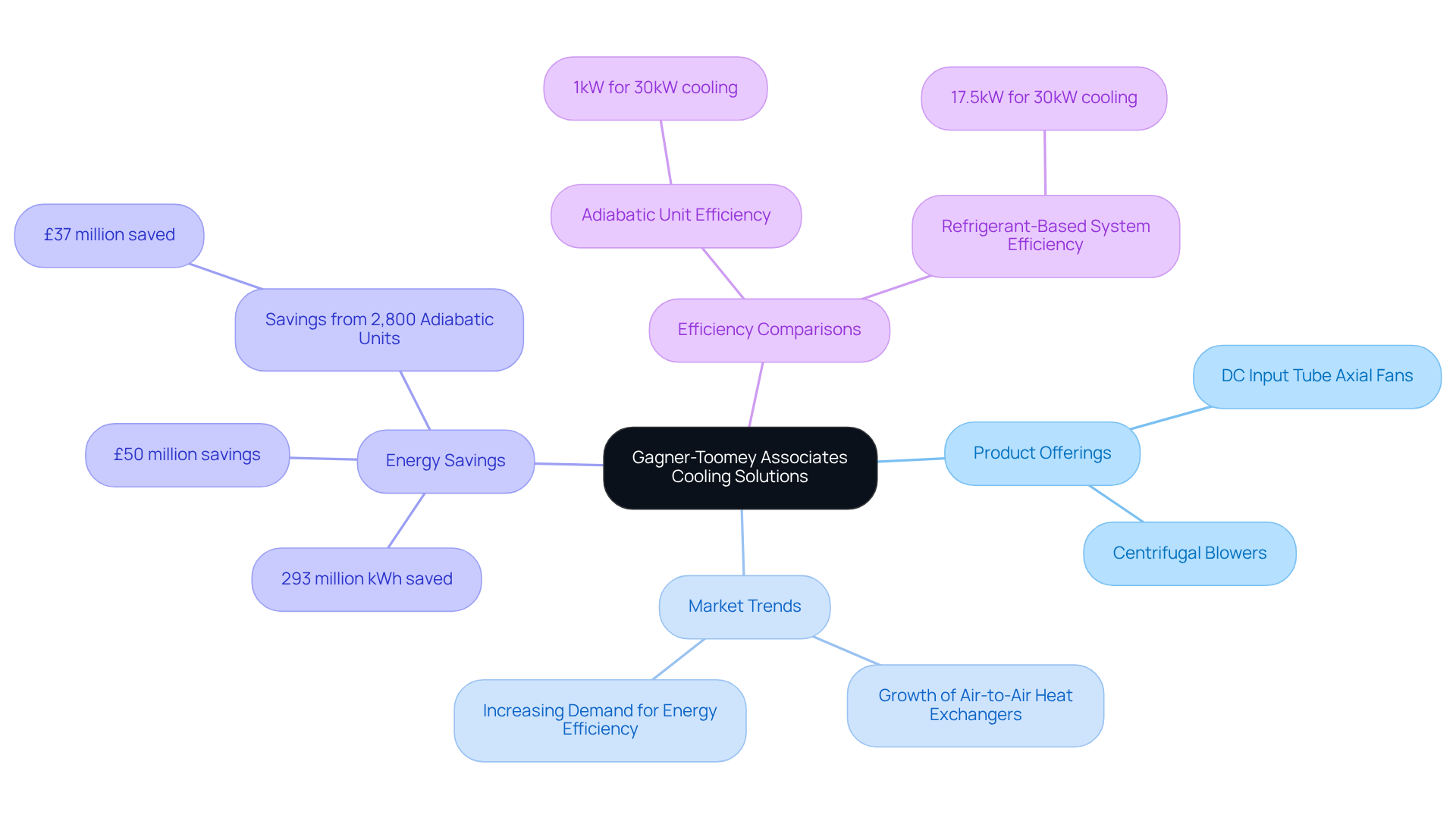

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions tailored specifically for the electronics industry. As the world’s largest producer of both standard and custom air-movers, they empower engineers with access to cutting-edge technologies, offering a comprehensive range of air-to-air thermal devices. These systems are integral to maintaining optimal temperatures for electronic components, which is crucial for ensuring reliability and performance across a variety of applications. Gagner-Toomey provides an extensive product line of DC input tube axial fans and centrifugal blowers, all optimized for performance, efficiency, and low noise, making them exceptionally suited for diverse industrial applications.

Industry projections indicate that the market share of air-to-air heat exchangers will experience significant growth by 2025, driven by their efficiency and effectiveness in cooling. Successful implementations of these systems have yielded remarkable savings; for example, the deployment of 2,800 Adiabatic units has resulted in £37 million saved in utility costs, underscoring their impact on operational expenditures. The case study titled ‘Energy Savings from Adiabatic Units’ reveals that each Adiabatic unit saves 45,000 kWh of energy annually, culminating in a total of 293 million kWh across 6,500 units, which translates to £50 million in annual operational expenditure savings.

Furthermore, industry leaders emphasize the importance of air-to-air thermal devices in electronics cooling, noting their ability to utilize just 1kW of energy to produce 30kW of cooling capacity—significantly more efficient than conventional refrigerant-based systems that require 17.5kW for comparable output. MJ Quinn, the designer of the Adiabatic Cooling Unit, asserts, ‘The solution was the Adiabatic Cooling Unit designed by MJ Quinn,’ reinforcing the efficacy of these systems. Gagner-Toomey’s unwavering commitment to excellence in customer service and product representation solidifies their status as a trusted partner for engineers tackling complex cooling challenges.

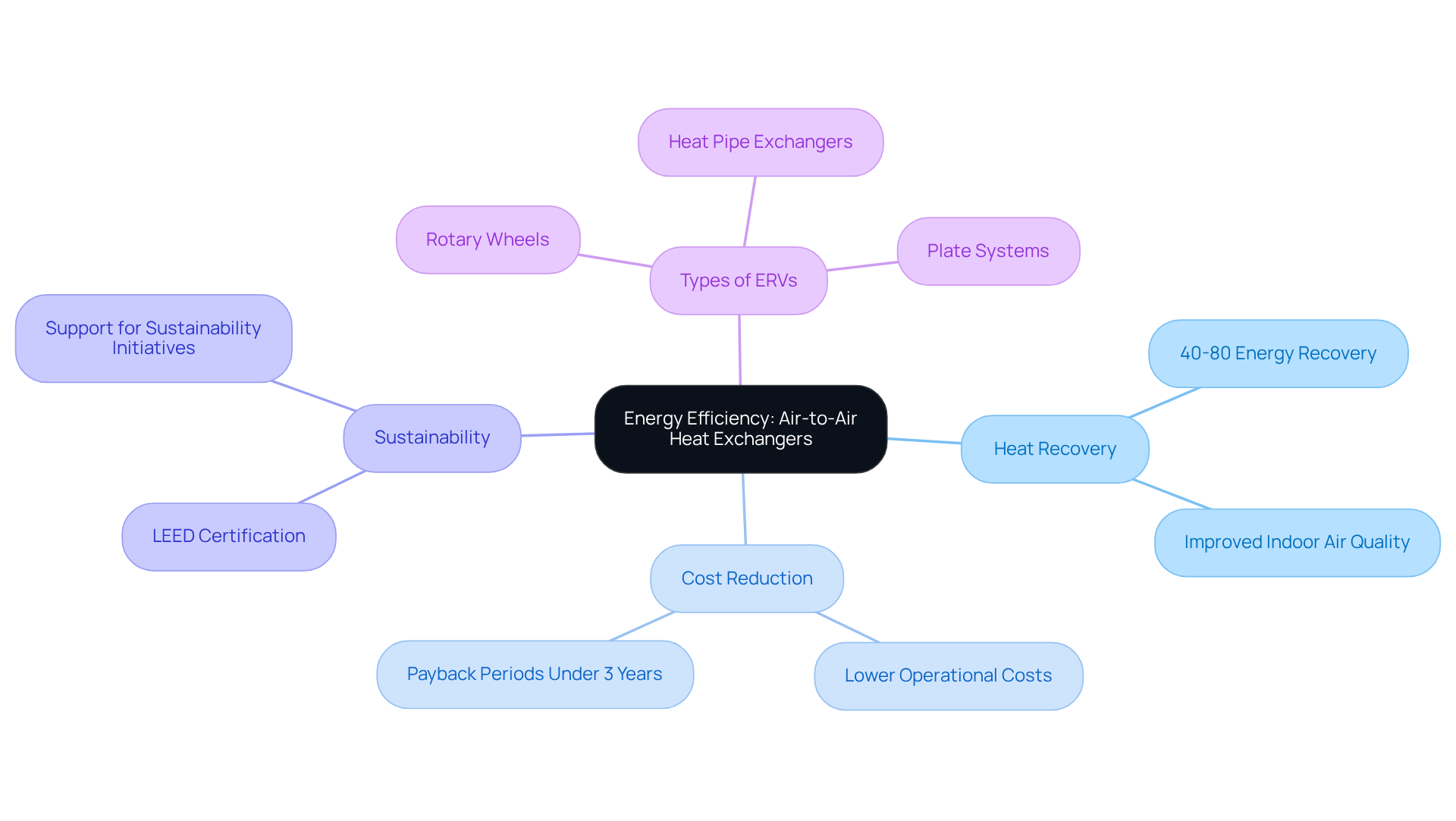

Energy Efficiency: Maximizing Performance with Air-to-Air Heat Exchangers

Engineered to optimize efficiency, air-to-air heat exchangers recover heat from exhaust air and transfer it to the incoming air. This innovative approach significantly reduces the resources needed for heating or cooling, resulting in lower operational costs.

For instance, energy recovery ventilators (ERVs) can reclaim 40-80% of the energy from expelled air, leading to substantial savings and enabling downsizing, with payback periods typically under three years. Furthermore, ERVs can augment ventilation air beyond ASHRAE Standard 62.1 requirements, thereby enhancing compliance and performance metrics.

By integrating these systems, engineers can improve the operational efficiency of electronic devices while actively supporting sustainability initiatives. The ability to recover and reuse energy not only minimizes waste but also aligns with the increasing demand for sustainable engineering solutions.

Recent studies indicate that the incorporation of air-to-air heat exchangers can enhance zone efficiency, facilitating greater throughput in production environments. For example, a project utilizing advanced resource recovery technologies achieved a 15% increase in production following system implementation, illustrating how enhanced zone efficiency translates to increased throughput.

Additionally, understanding the various types of ERVs—such as rotary wheels, thermal pipe devices, and plate systems—can provide valuable insights for engineers assessing diverse applications. The adoption of ERVs can also contribute to achieving LEED certification, making them a crucial consideration for engineers dedicated to sustainability and energy performance.

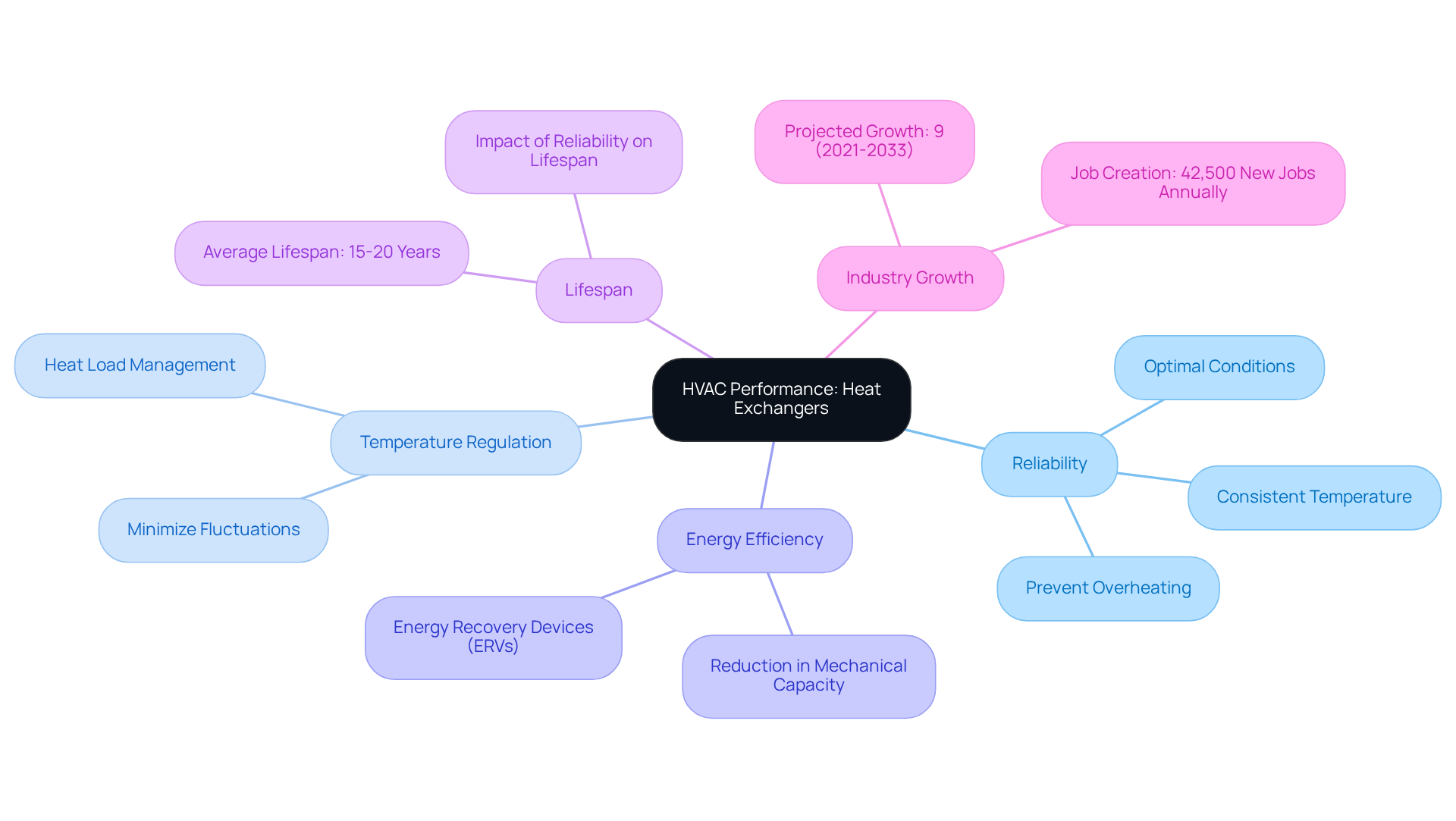

HVAC Performance: Enhancing System Reliability with Heat Exchangers

Incorporating air-to-air exchangers into HVAC units significantly enhances reliability by ensuring consistent temperature regulation. These systems adeptly manage heat loads, preventing overheating and maintaining optimal operating conditions for electronic components. By improving airflow and minimizing temperature fluctuations, engineers can ensure that their systems operate within safe parameters, ultimately extending the lifespan of critical equipment, which averages between 15 to 20 years. This reliability is particularly crucial in environments where electronic devices encounter varying thermal loads.

Notably, the implementation of recovery devices (ERVs) can reduce the required capacity of mechanical equipment by pre-treating outside air, thereby enhancing efficiency and performance. As the HVAC industry progresses, projected to grow by 9% from 2021 to 2033, the significance of such technologies in achieving energy efficiency and reliability is paramount. HVAC experts emphasize that the dependability of air-to-air heat exchangers is essential for maintaining operational integrity and performance.

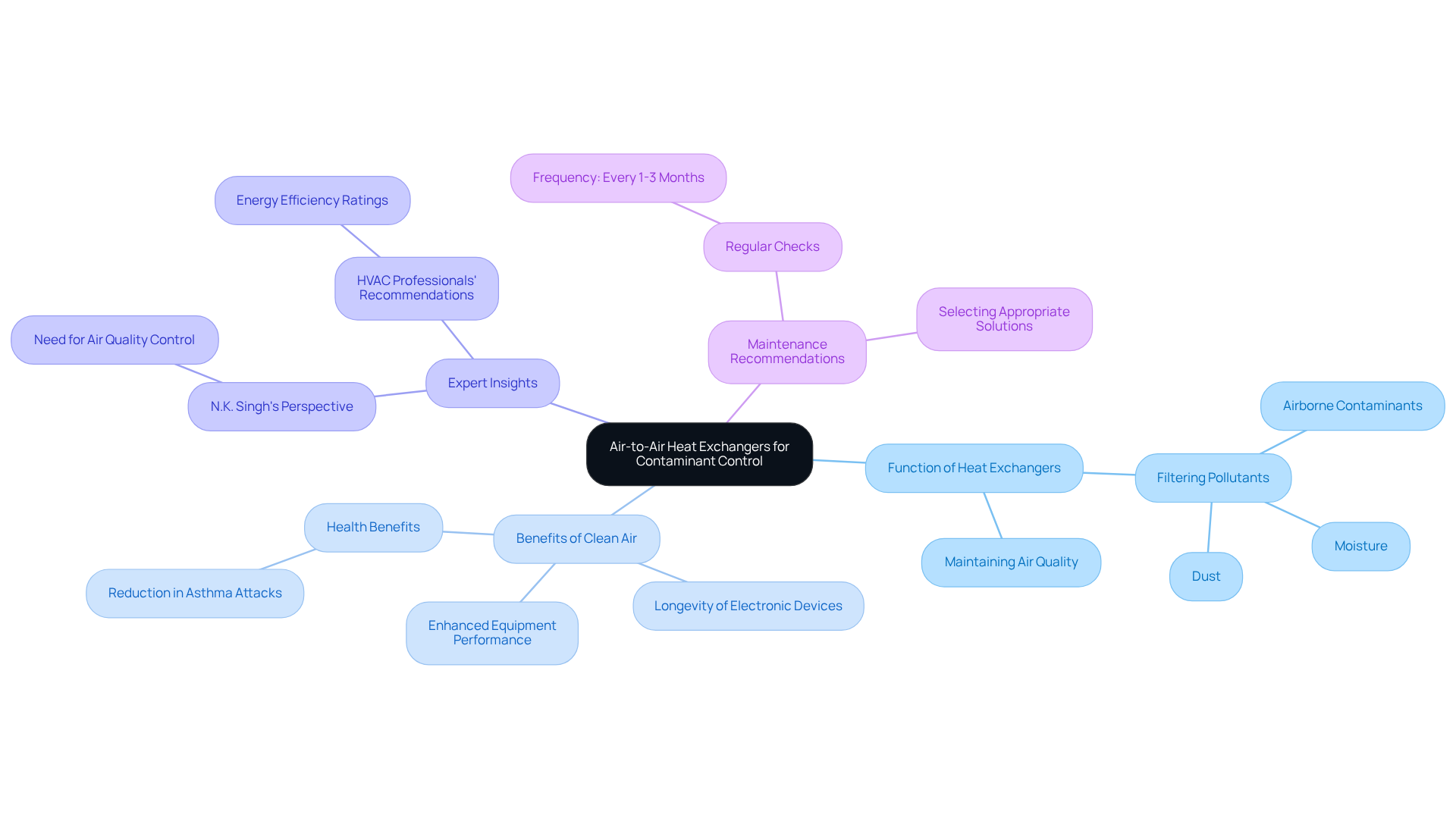

Contaminant Control: Ensuring Clean Air with Heat Exchanger Technology

Air-to-air heat exchangers are essential for contaminant control, effectively filtering incoming air to prevent pollutants from infiltrating sensitive electronic environments. These air-to-air heat exchangers excel at eliminating dust, moisture, and other airborne pollutants, ensuring that only pure air circulates within essential areas. This capability is particularly vital in applications where electronic components are susceptible to damage from particulate matter.

By utilizing air-to-air heat exchangers to maintain excellent air quality, engineers can safeguard their equipment and significantly enhance overall performance. Environmental engineers emphasize that clean air, which can be achieved through air-to-air heat exchangers, is not merely a luxury; it is a fundamental requirement for optimal cooling and the longevity of electronic devices.

As N.K. Singh asserts, “With the rapid increase in urbanization, there is a huge and urgent need of controlling the air quality so that we can breathe freely.” Additionally, a Hamilton family reported a reduction in asthma attacks following the installation of a Heat Recovery Ventilator (HRV), illustrating the tangible benefits of effective air quality management.

To ensure optimal performance, engineers should conduct regular checks on air filter units every 1-3 months and select the appropriate air circulation solution based on specific air quality requirements.

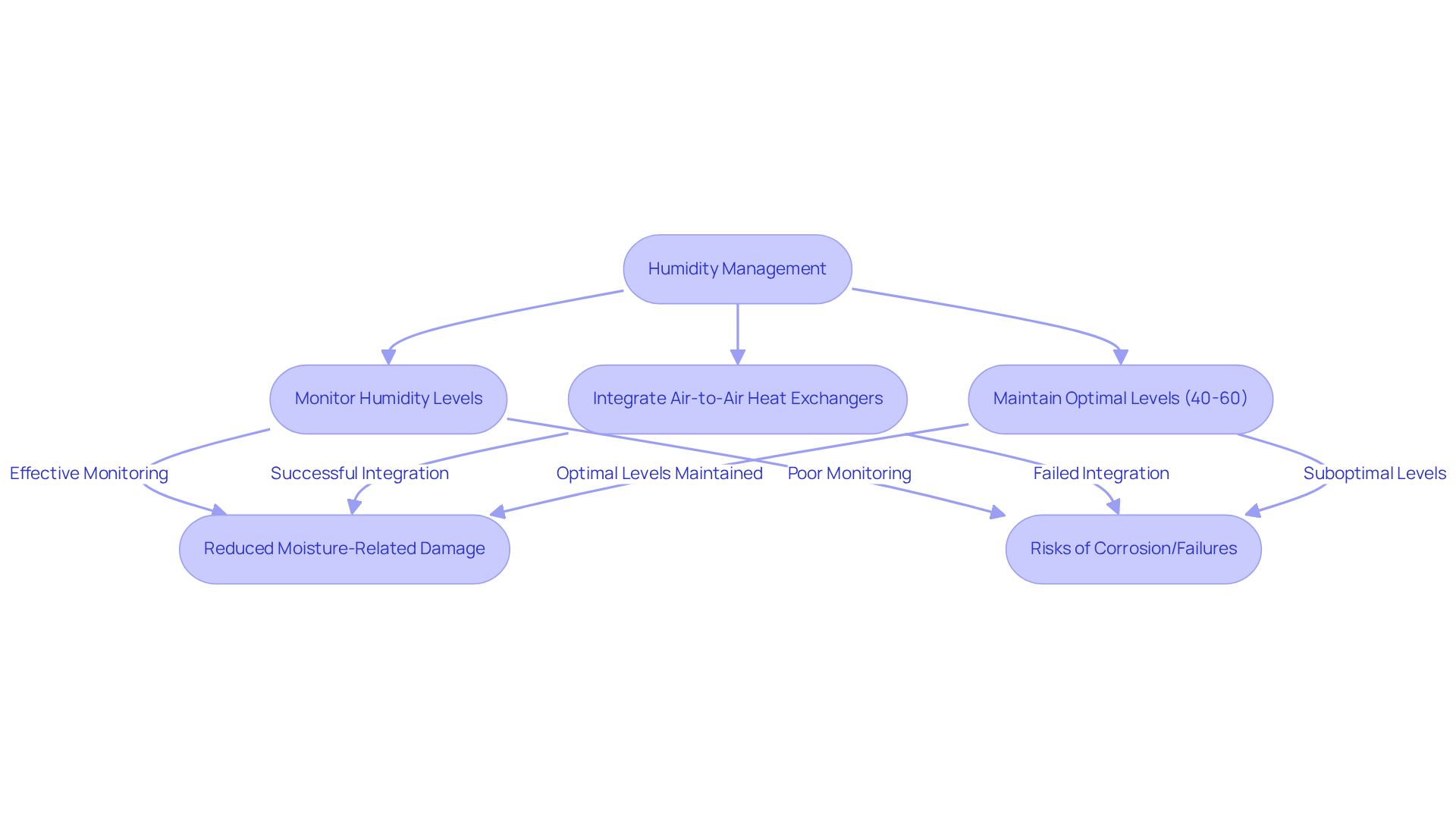

Humidity Management: Protecting Electronics with Effective Heat Exchange

Effective humidity management is essential for protecting electronic components from moisture-related damage. Air-to-air heat exchangers play a pivotal role in this process by facilitating the transfer of moisture between incoming and outgoing air flows. This capability is particularly beneficial in environments where humidity fluctuations can result in condensation and corrosion of sensitive electronics.

Maintaining optimal humidity levels, ideally between 40-60%, significantly reduces failure rates linked to moisture, a leading cause of electronic component degradation. For example, MSL 3 components may be exposed to 30% relative humidity for a maximum of 168 hours, underscoring the critical need for humidity control.

Engineers have noted that the integration of air-to-air heat exchangers not only enhances the reliability of the setup but also extends the lifespan of vital components. By ensuring a controlled environment, these systems mitigate risks such as delamination and solder joint failures, which can arise from excessive humidity.

A case study examining the effects of high humidity on electronics illustrates how uncontrolled moisture can lead to corrosion and short circuits, further reinforcing the necessity for effective humidity control. As we approach 2025, the importance of precise humidity regulation in electronics production continues to escalate, highlighting the demand for innovative solutions like thermal devices to combat moisture-related challenges.

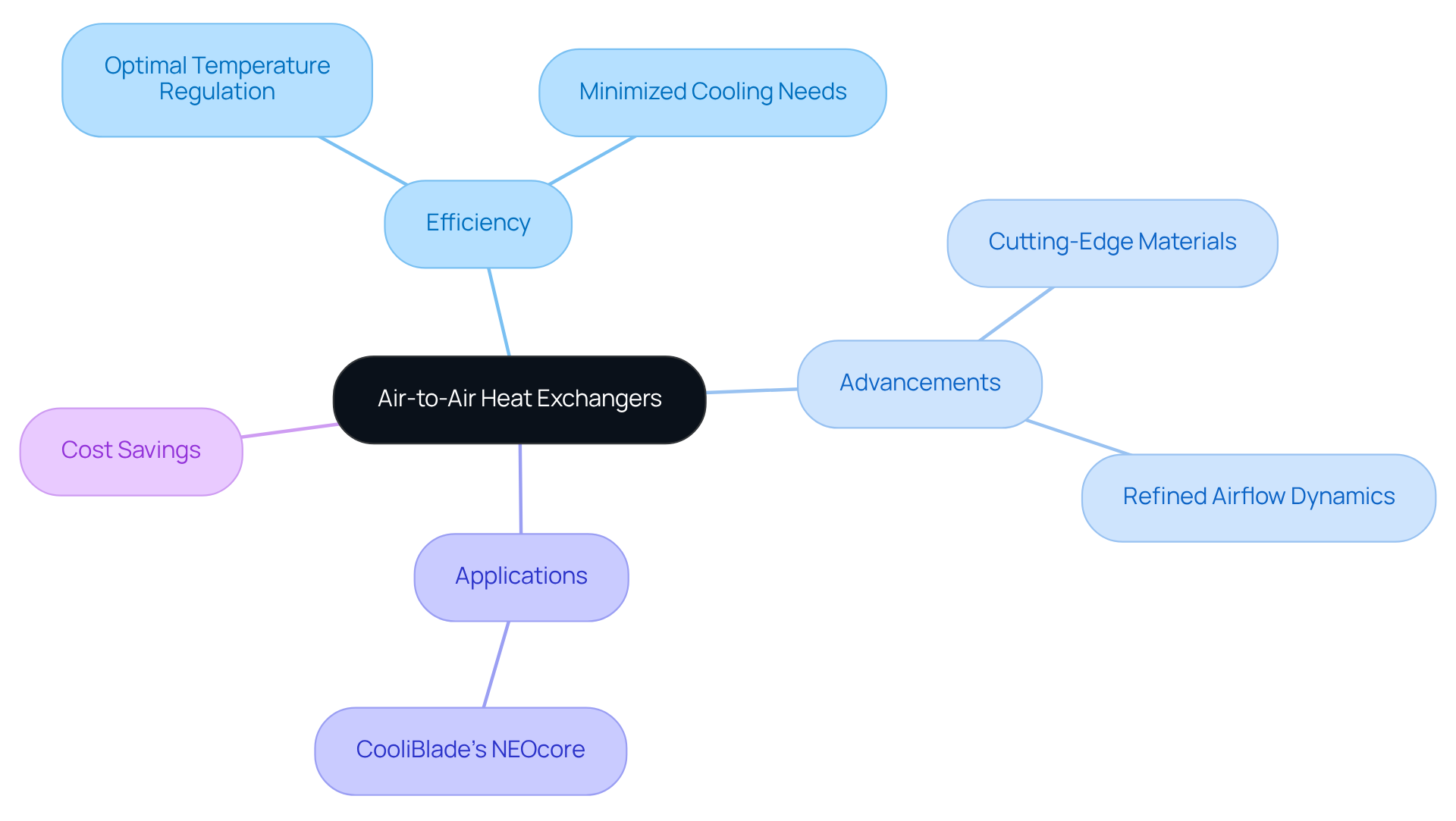

Thermal Management: Relying on Air-to-Air Heat Exchangers for Efficiency

Air-to-air heat exchangers are indispensable for achieving efficient temperature regulation in electronic devices. These systems facilitate the transfer of heat between air streams, thereby maintaining optimal operating temperatures for sensitive components. This efficiency not only enhances performance but also minimizes the need for supplementary cooling solutions, resulting in significant cost savings.

Engineers rely on these setups to manage thermal loads effectively, ensuring compliance with stringent performance standards. Recent advancements in thermal management, including the utilization of cutting-edge materials and refined airflow dynamics, have notably improved the efficiency of these systems. For instance, the thermal conductivity of thermal conduits can exceed 1000W/m.K., providing a quantitative measure of their effectiveness.

Moreover, practical applications, such as CooliBlade’s NEOcore thermal management solution, exemplify the deployment of air-to-air heat exchangers across various electronic apparatus, guaranteeing adherence to rigorous performance criteria while boosting energy efficiency. As the demand for effective thermal regulation solutions continues to rise, particularly in relation to electric vehicles, air-to-air heat exchangers remain a pivotal component in the design and operation of contemporary electronic systems.

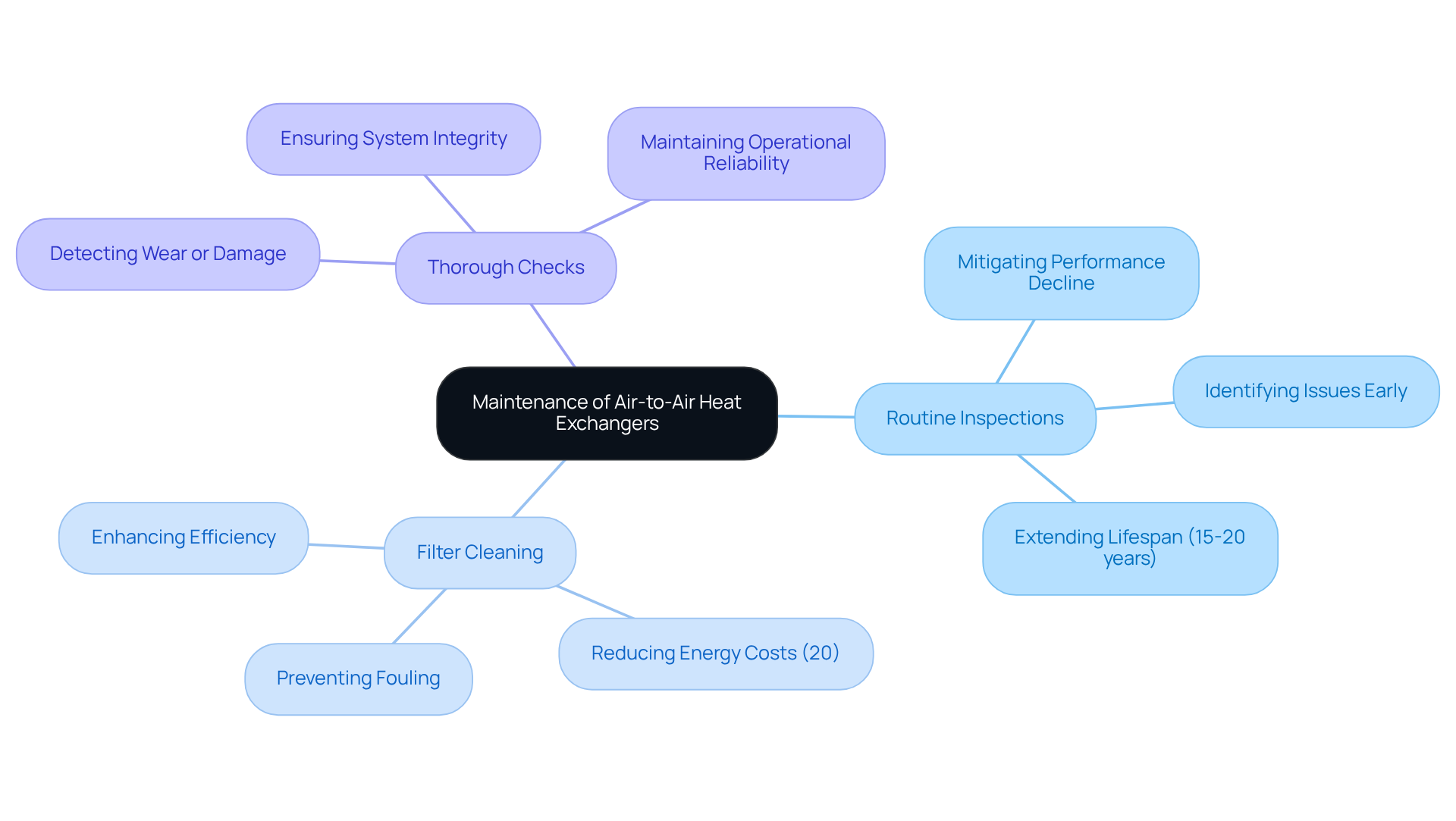

Maintenance: Ensuring Longevity of Air-to-Air Heat Exchangers

Routine upkeep is essential for guaranteeing the durability and effectiveness of air-to-air heat exchangers. This encompasses:

- Routine inspections

- Filter cleaning

- Thorough checks for signs of wear or damage

By adhering to a systematic upkeep timetable, engineers can significantly mitigate performance decline and extend the operational lifespan of thermal devices such as air-to-air heat exchangers. Maintenance of air-to-air heat exchangers not only enhances efficiency but also diminishes the likelihood of unforeseen failures, ensuring that operations remain dependable under diverse conditions.

Specialists in the field emphasize that air-to-air heat exchangers, when properly maintained, can achieve an average lifespan of 15 to 20 years, provided that routine inspections and cleaning are consistently performed. For example, implementing a preventative maintenance schedule can lead to a 20% reduction in energy costs while enhancing overall system reliability.

Furthermore, case studies reveal that organizations prioritizing regular upkeep have reported substantial improvements in thermal system longevity, with some experiencing up to a 30% increase in operational lifespan. This proactive approach is crucial for maintaining optimal performance of air-to-air heat exchangers and safeguarding investments in industrial applications.

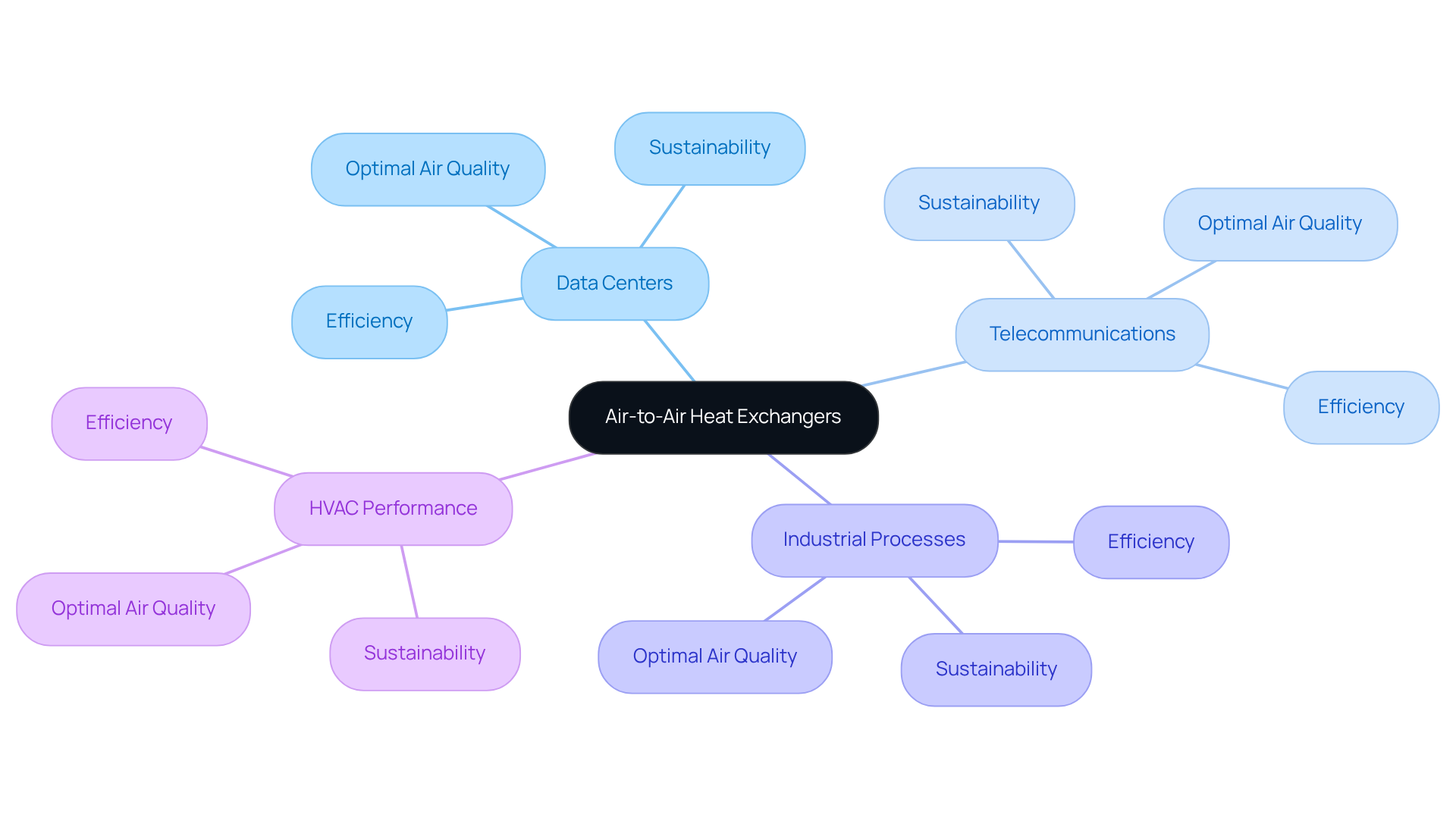

Versatility: Applications of Air-to-Air Heat Exchangers in Engineering

Air-to-air heat exchangers are pivotal components in numerous engineering applications, especially in data centers, telecommunications, and industrial processes. Their design promotes efficient thermal transfer while ensuring optimal air quality, rendering them ideal for environments where precise temperature regulation is essential. For instance, in data centers, these devices play a critical role in cooling electronic enclosures, significantly enhancing operational efficiency.

The market for air-to-air heat exchangers is projected to experience substantial growth by 2025, driven by the increasing demand for energy-efficient cooling solutions in high-density computing environments. Moreover, their versatility extends to enhancing HVAC performance in commercial buildings, demonstrating their adaptability across diverse sectors.

Engineers recognize the importance of these systems, as they not only optimize resource consumption but also support sustainability initiatives by reducing reliance on traditional cooling methods. This multifaceted functionality underscores the vital role of air-to-air heat exchangers in advancing contemporary engineering solutions.

Energy Recovery: Leveraging Heat Exchangers for Sustainable Engineering

Air-to-air heat exchangers are essential for heat recovery, as they efficiently capture waste heat from exhaust air and repurpose it to precondition incoming air. This innovative method not only limits power usage but also significantly decreases the carbon footprint associated with engineering activities.

By incorporating these systems into their designs, engineers can champion sustainable practices while simultaneously enhancing project efficiency. The recovery and reuse of power are increasingly essential in today’s eco-conscious engineering environment, aligning with the urgent call for greener solutions.

As Henrik Tikkanen emphasizes, ‘Because we don’t think about future generations, they will never forget us.’ This perspective underscores the importance of adopting technologies like heat exchangers to minimize environmental impact.

Furthermore, with the anticipated growth in electricity dependence expected to climb from 10% of total consumption in 2019 to 25% by 2070, the incorporation of power recovery solutions becomes increasingly critical. Recent advancements in power recovery technologies for 2025 are poised to redefine efficiency benchmarks, making it imperative for engineers to remain knowledgeable and proactive in applying these sustainable solutions.

Comprehensive Benefits: The Essential Role of Air-to-Air Heat Exchangers

Air-to-air heat exchangers are essential in the electronics sector, delivering significant benefits that enhance energy efficiency and optimize HVAC performance. These systems not only guarantee clean air and effective humidity management but also play a pivotal role in sustaining optimal operating conditions for electronic components.

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers for cooling, offers a comprehensive range of thermal management solutions, including:

- DC input tube axial fans

- Centrifugal blowers

- Various sink designs

Their innovative products facilitate seamless integration into diverse applications, promoting resource recovery and significantly supporting sustainable engineering practices. For instance, organizations utilizing air-to-air thermal devices can achieve energy cost savings of up to 30%, while also decreasing greenhouse gas emissions by as much as 30%.

Furthermore, recent research indicates that these setups can extend the lifespan of electronic devices by preventing overheating, which can reduce component durability by up to 50%. Industry leaders emphasize the importance of thermal devices in electronics, highlighting their critical role in enhancing reliability and performance.

By leveraging the advantages of air-to-air heat exchangers, engineers can develop systems that are not only more effective and reliable but also environmentally friendly, aligning with the growing demand for sustainable engineering solutions. Additionally, the modular design of these thermal devices simplifies installation and reduces labor and time, further enhancing their appeal.

Case studies reveal that the efficacy of air-to-air heat exchangers in energy recovery is highlighted by their ability to recapture 40-80% of the energy from exhausted building air. In summary, the integration of these systems into engineering practices is vital for optimizing performance and sustainability.

Conclusion

Air-to-air heat exchangers are pivotal in modern engineering, especially in the electronics sector, delivering numerous benefits that enhance energy efficiency and operational reliability. These systems optimize HVAC performance and ensure clean air and effective humidity management, which are essential for preserving the integrity and longevity of sensitive electronic components.

The article underscores several key advantages of air-to-air heat exchangers, particularly their capacity to recover and reuse energy, which significantly reduces operational costs and environmental impact. Innovations such as energy recovery ventilators (ERVs) reclaim a substantial portion of energy from exhaust air, resulting in notable savings and improved compliance with performance standards. Furthermore, integrating these systems into HVAC units bolsters reliability by maintaining consistent temperature regulation, thereby extending the lifespan of critical equipment.

As the demand for sustainable engineering solutions escalates, the importance of air-to-air heat exchangers becomes increasingly pronounced. By leveraging these technologies, engineers can enhance the performance and efficiency of their systems while contributing to broader sustainability initiatives. The proactive adoption of air-to-air heat exchangers will be instrumental in shaping the future of engineering practices, ensuring alignment with both operational excellence and environmental stewardship.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for being the world’s largest producer of standard and custom air-movers, providing innovative cooling solutions specifically tailored for the electronics industry.

What types of products does Gagner-Toomey offer?

Gagner-Toomey offers a comprehensive range of air-to-air thermal devices, including DC input tube axial fans and centrifugal blowers, all optimized for performance, efficiency, and low noise.

Why are air-to-air thermal devices important for electronics?

Air-to-air thermal devices are crucial for maintaining optimal temperatures for electronic components, which ensures their reliability and performance across various applications.

What are the projected trends for air-to-air heat exchangers by 2025?

The market share of air-to-air heat exchangers is expected to experience significant growth by 2025, driven by their efficiency and effectiveness in cooling.

Can you provide an example of cost savings from using Adiabatic units?

The deployment of 2,800 Adiabatic units has resulted in £37 million saved in utility costs, with each unit saving 45,000 kWh of energy annually, leading to a total of £50 million in annual operational expenditure savings across 6,500 units.

How do air-to-air thermal devices compare to conventional refrigerant-based systems?

Air-to-air thermal devices can utilize just 1kW of energy to produce 30kW of cooling capacity, whereas conventional refrigerant-based systems require 17.5kW for comparable output, making air-to-air devices significantly more efficient.

What role do energy recovery ventilators (ERVs) play in energy efficiency?

ERVs can reclaim 40-80% of the energy from expelled air, significantly reducing heating or cooling resource needs, leading to lower operational costs and enabling downsizing.

How can incorporating air-to-air heat exchangers benefit production environments?

The incorporation of air-to-air heat exchangers can enhance zone efficiency, facilitating greater throughput in production environments, as demonstrated by a project that achieved a 15% increase in production following system implementation.

What types of ERVs are available for engineers to consider?

Engineers can consider various types of ERVs, including rotary wheels, thermal pipe devices, and plate systems, depending on their specific applications.

How do air-to-air exchangers enhance HVAC system reliability?

Air-to-air exchangers improve reliability by ensuring consistent temperature regulation, managing heat loads, preventing overheating, and maintaining optimal operating conditions for electronic components.

What is the projected growth for the HVAC industry from 2021 to 2033?

The HVAC industry is projected to grow by 9% from 2021 to 2033, highlighting the importance of air-to-air heat exchangers in achieving energy efficiency and reliability.