Overview

The article delineates ten key benefits of axial cooling fans for electronics engineers, asserting their energy efficiency, compact design, low noise operation, and high airflow capabilities. These advantages render axial cooling fans indispensable across diverse applications, as they significantly enhance thermal management, reduce operational costs, and elevate user experience. Ultimately, they play a crucial role in supporting the development of innovative electronic products.

Introduction

Axial cooling fans have emerged as a pivotal component in the realm of electronics engineering, where effective thermal management is crucial for performance and reliability. These innovative devices offer a host of benefits, including energy efficiency and compact design, making them indispensable across various applications. However, as technology continues to evolve, engineers face the challenge of selecting the right cooling solution that balances performance, noise levels, and maintenance needs. The key advantages of axial cooling fans can significantly transform the landscape of electronic design, enhancing both functionality and user experience.

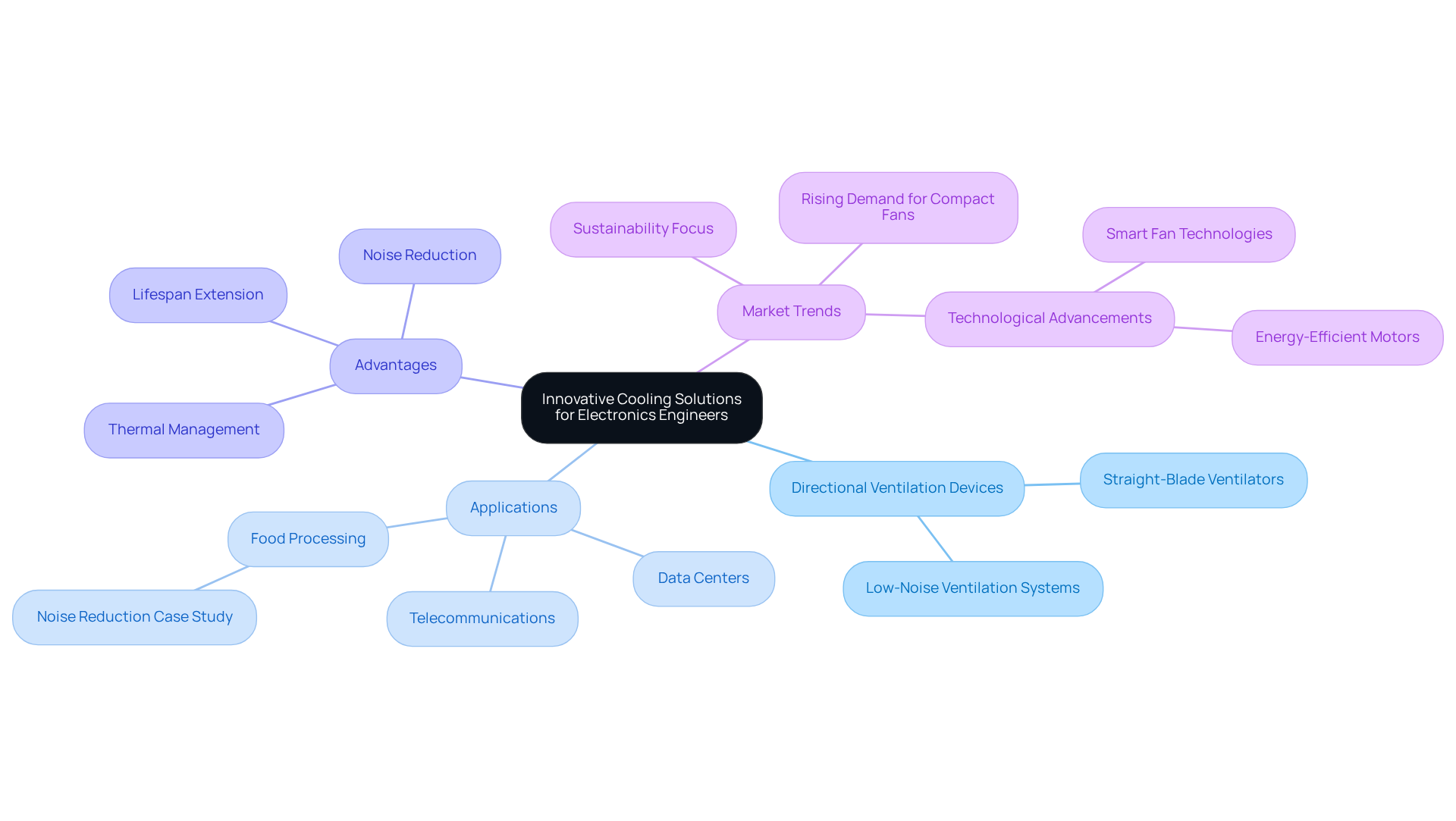

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates stands out as a leader in offering innovative temperature control solutions meticulously tailored for the electronics sector, with a pronounced emphasis on directional ventilation devices. These devices are recognized for their superior efficiency and reduced power consumption, making them ideal for applications that demand precise thermal management. Statistics indicate that straight-blade ventilators dominate the temperature control market, primarily due to their effectiveness in regulating heat within electronics and semiconductors, which remain the foremost applications for these devices.

The effective utilization of directional ventilation devices has been documented across various industries, including data centers and telecommunications, where they significantly enhance airflow and temperature regulation. A notable case involves a food processing plant that achieved a remarkable reduction in noise levels from 88 dB to 72 dB by transitioning to low-noise ventilation systems, exemplifying their dual benefits of efficiency and user comfort.

The advantages of directional ventilation devices for electronics engineers are extensive. They not only enable optimal thermal management but also extend the lifespan of electronic components. Recent advancements in fan technology, such as the incorporation of energy-efficient motors and smart fan systems, facilitate real-time monitoring and control, optimizing airflow according to specific temperature requirements. This capability is particularly vital in high-density applications where space constraints are prevalent.

Experts in the field emphasize that the miniaturization of devices is driving the demand for compact, high-efficiency blowers. As industries increasingly prioritize sustainability and cost-effectiveness, the adoption of axial cooling fans is anticipated to rise. Gagner-Toomey Associates remains at the forefront of these innovations, ensuring that professionals have access to state-of-the-art technologies that align with the evolving requirements of modern electronics applications.

Energy Efficiency: Reduce Power Consumption with Axial Cooling Fans

Axial cooling fans are engineered for optimal energy efficiency, significantly reducing power consumption compared to alternative systems. This efficiency is vital for electronics professionals focused on minimizing operational costs and enhancing the sustainability of their designs. By integrating directional blowers, engineers can achieve improved airflow while consuming less energy, a necessity in today’s environmentally conscious market.

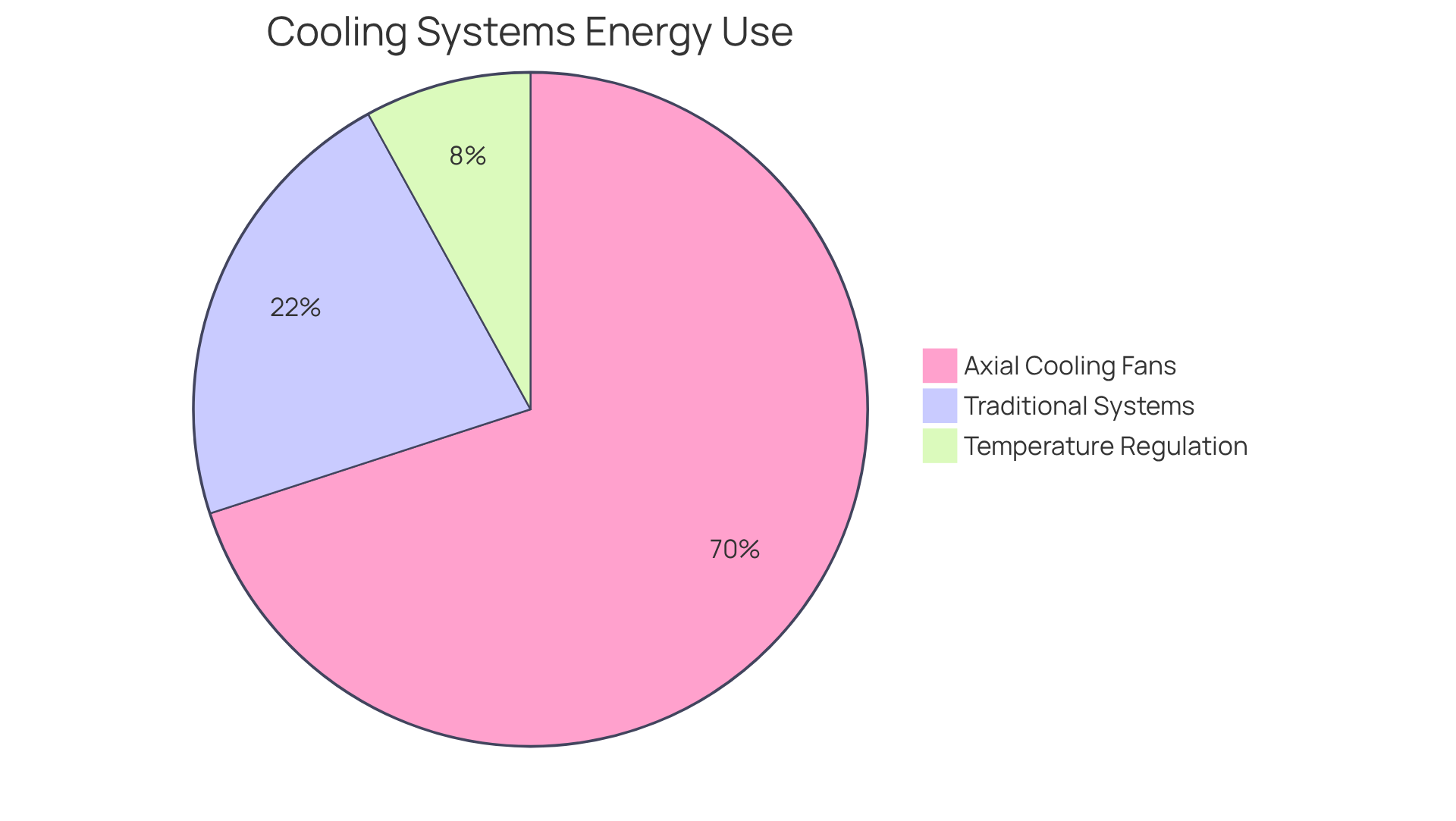

For instance, organizations utilizing compact directional blowers have documented up to a 70% reduction in power usage relative to traditional air conditioning systems, leading to considerable cost savings and a smaller carbon footprint. Furthermore, temperature regulation accounts for 22% of a data center’s total energy consumption, underscoring the critical role of ventilators in boosting energy efficiency.

Advances in ducted blower technology, particularly the incorporation of electronically commutated (EC) motors, empower devices to adjust their speed in response to real-time temperature demands, thereby enhancing efficiency. As Pete Bartolik notes, EC motors facilitate precise operation at the necessary speed, further optimizing energy consumption.

As the demand for energy-efficient solutions escalates, the role of axial cooling fans in electronics design will increasingly become indispensable, aligning with the industry’s shift towards more sustainable technological solutions. Additionally, the market for small ventilation devices is expected to grow from $3,061.57 million in 2025 to $4,381.46 million by 2032, highlighting the rising significance of these innovations.

Moreover, with Active PFC technology, Total Harmonic Distortion (THD) can be minimized to as low as 2%, which is crucial for preserving power quality in sensitive electronic applications.

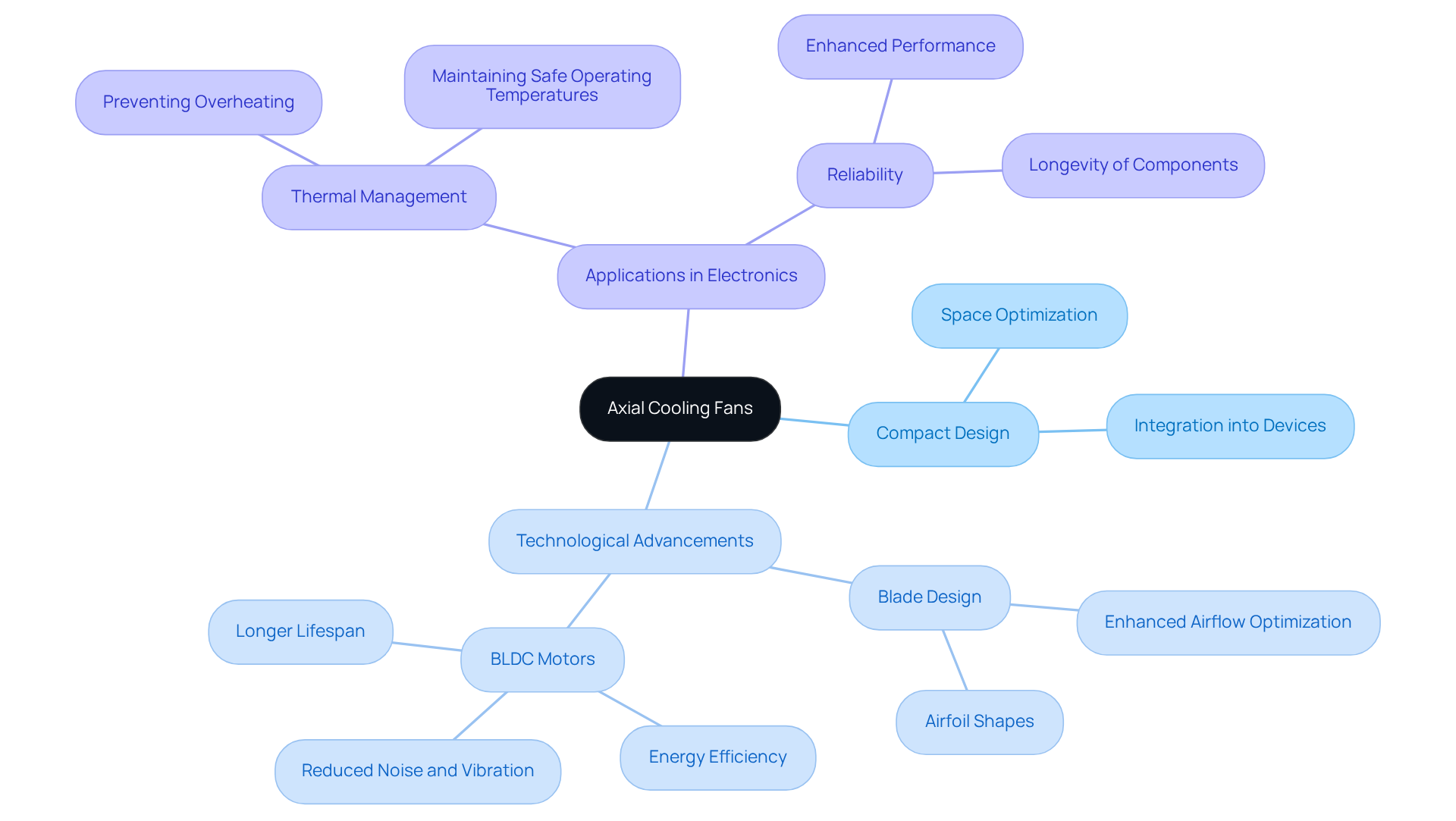

Compact Design: Optimize Space with Axial Cooling Fans

Axial ventilation units are distinguished by their compact design, making them particularly suitable for applications in restricted spaces. Their streamlined structure allows for seamless integration into various electronic devices, ensuring that performance remains uncompromised. This compactness empowers engineers to optimize layouts effectively, facilitating efficient cooling even in tight environments.

Recent advancements in blade design, including enhanced airflow optimization technologies and improved airfoil shapes, have further elevated their efficiency, promoting superior thermal management without expanding the footprint of electronic systems. For instance, Brushless DC (BLDC) motors, increasingly prevalent in these devices, demonstrate greater energy efficiency compared to conventional AC motors due to their direct conversion of electrical power into rotational motion. Consequently, critical components can function within safe temperature ranges, significantly bolstering reliability and longevity.

The effective application of these devices in electronics, as highlighted in multiple case studies, underscores their vital role in space optimization, rendering them indispensable for contemporary engineering solutions.

As Jack Funkhouser, Vice President of Sofasco, asserts, ‘With more than 23 years of experience in the industrial sector, he is committed to propelling SOFASCO to new heights and making it a preferred option for industrial refrigeration solutions.

Low Noise Operation: Enhance User Experience with Quiet Axial Fans

Axial cooling fans stand out due to their quiet operation, a design feature meticulously crafted to minimize sound levels while ensuring effective airflow. This capability significantly enhances the overall user experience, particularly in consumer electronics, where noise can negatively impact user satisfaction. Notably, low noise directional blowers are often 10-15 dB quieter than conventional models, making them an essential choice for applications where sound sensitivity is paramount. By opting for low noise directional blowers, designers can guarantee that their products operate silently, thereby increasing their appeal to consumers.

The advantages of reduced noise extend beyond mere comfort; as highlighted, “A quieter fan can enhance user comfort, improve productivity, and promote longer usage sessions.” This trend underscores a broader movement towards elevating user experience through innovative design.

Furthermore, engineers must consider the specific application context when deciding between low noise ducted units and axial cooling fans. It is equally important to evaluate thermal performance and airflow requirements to ensure optimal temperature regulation solutions.

High Airflow: Ensure Effective Cooling with Axial Fans

Axial ventilation units are distinguished by their exceptional ability to circulate substantial volumes of air efficiently, an essential factor in maintaining optimal temperatures within electronic devices. Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive array of DC input tube fans, ranging from 15 to 280mm, all optimized for performance, efficiency, and low noise. This high airflow capacity is crucial for preventing overheating, which can jeopardize both performance and reliability.

In 2025, the significance of airflow in electronics cooling is paramount, as engineers increasingly depend on directional blowers to deliver the necessary cooling power across diverse applications, from data centers to consumer electronics. Airflow rates for inline blowers in electronics applications typically range from 500 CFM for smaller units to over 100,000 CFM for industrial setups, underscoring their versatility.

Furthermore, Gagner-Toomey’s directional blowers are acclaimed for their energy efficiency, consuming less power while delivering superior airflow, which contributes to cost-effectiveness and sustainability. With a typical lifespan of 10 to 15 years, these devices ensure long-term reliability when properly maintained. Additionally, their quiet operation renders them suitable for environments where noise levels are a concern.

By facilitating efficient temperature regulation, axial cooling fans extend the lifespan and enhance the performance of electronic components, making them an indispensable choice for engineers seeking reliable temperature management solutions.

Versatile Applications: Utilize Axial Fans Across Multiple Industries

Axial cooling fans are essential components utilized across multiple sectors, including telecommunications, automotive, and industrial machinery. Their design facilitates efficient airflow with axial cooling fans, making them ideal for temperature regulation in diverse environments. In telecommunications, axial cooling fans play a critical role in maintaining optimal temperatures within equipment racks, thereby ensuring reliable performance. In the automotive industry, axial cooling fans are essential for cooling engine compartments and electronic systems, significantly enhancing vehicle reliability. Furthermore, in industrial machinery, axial cooling fans are utilized to cool motors and control panels, preventing overheating and promoting operational efficiency.

The adaptability of axial cooling fans empowers engineers to customize airflow solutions for specific applications, whether in HVAC systems or electronic enclosures, establishing them as a preferred choice for effective thermal management. Additionally, understanding the performance enhancement opportunities within compressed air systems, as outlined in the sourcebook ‘Improving Compressed Air System Performance,’ can provide valuable insights into optimizing temperature regulation strategies in industrial settings. This relationship underscores the importance of axial devices in maintaining system efficiency and addressing potential issues such as leaks and pressure drops.

Easy Maintenance: Simplify Upkeep with Axial Cooling Fans

Axial cooling devices are designed for effortless maintenance, allowing technicians to keep their systems running efficiently with minimal effort. Routine cleaning and inspections are straightforward tasks that can significantly extend the lifespan of these devices. This ease of maintenance not only reduces downtime but also lowers long-term operational costs, establishing axial devices as a reliable choice for professionals focused on efficiency and dependability.

Durability: Rely on Long-Lasting Performance of Axial Fans

Axial ventilation devices are engineered for exceptional durability, featuring robust designs that withstand the rigors of continuous operation. This inherent durability ensures that engineers can rely on these devices for sustained performance, significantly reducing the need for frequent replacements. Such reliability is paramount in critical applications where consistent temperature regulation is vital for optimal device functionality.

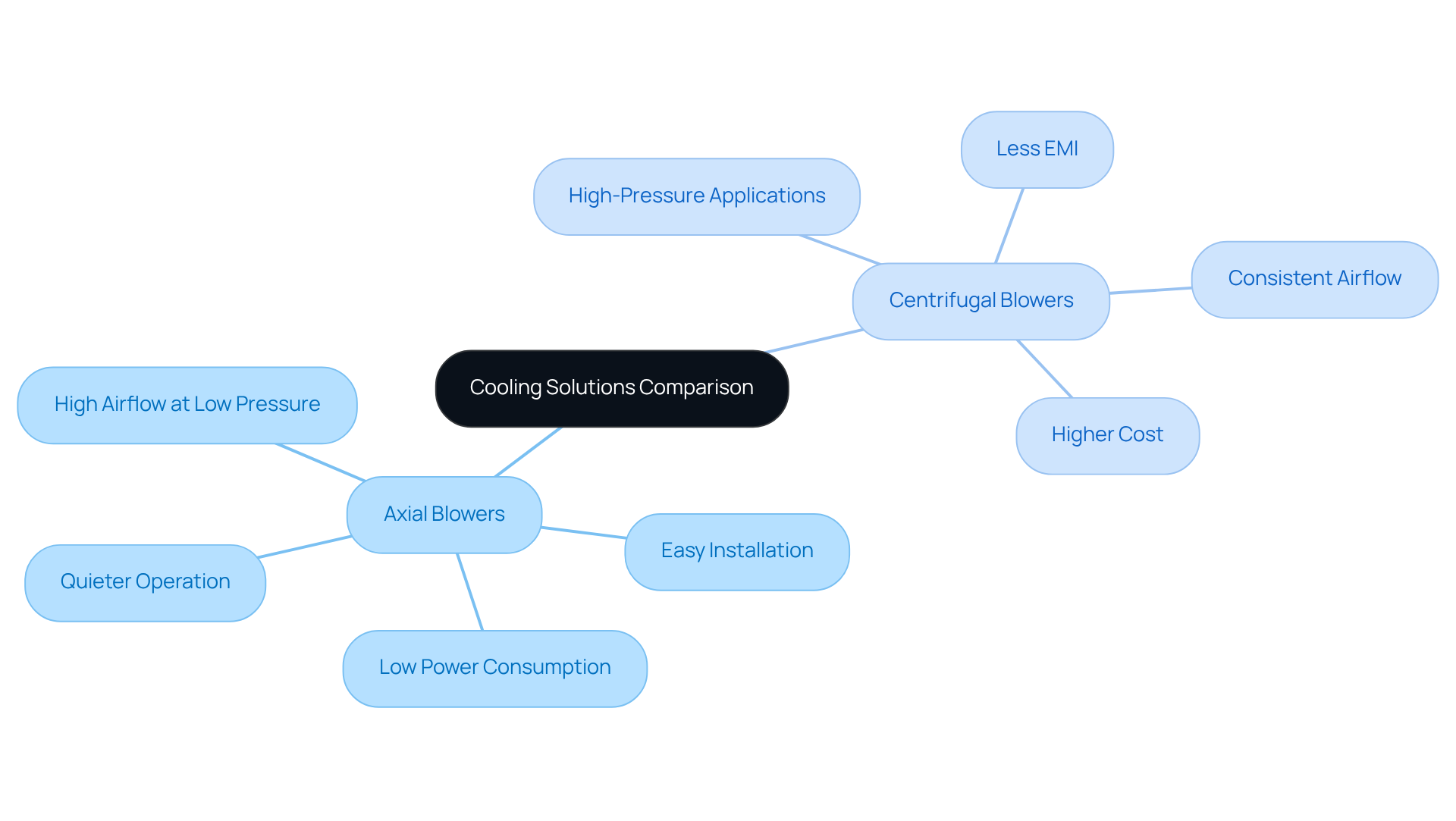

Comparison with Other Fan Types: Choose the Right Cooling Solution

When selecting a temperature regulation option, it is essential to compare axial blowers with other types, such as centrifugal models. Axial blowers, which trace their origins to Persian windmills in A.D. 500, excel in applications that require high airflow at low pressure, making them ideal for temperature regulation in electronics. Their straightforward design facilitates easy installation and maintenance, while their low power consumption and quieter operation present significant advantages in noise-sensitive environments. Notably, increased CFM typically results in higher noise levels from blowers, a critical consideration for designers.

Conversely, centrifugal blowers are more suitable for high-pressure applications, generating a consistent, high-pressure airflow that is optimal for systems requiring directed cooling, such as air conditioning and industrial ventilation. Furthermore, DC-powered ventilators produce less electromagnetic interference (EMI) than their AC-powered counterparts, an important factor for electronics specialists concerned about EMI in their applications.

Axial cooling fans are generally more cost-effective than centrifugal types, which have a more complex design that can complicate installation and maintenance. By understanding these distinctions, professionals can make informed decisions tailored to their specific temperature management needs, ensuring optimal performance and efficiency in their electronic systems.

Comprehensive Benefits: Why Axial Cooling Fans Are Essential for Electronics Engineers

Axial cooling fans are essential for electronics professionals, offering a multitude of advantages that cannot be overlooked. These devices excel in energy efficiency, compact design, low noise operation, and high airflow, making them versatile solutions for a wide range of applications. Their durability and ease of maintenance further enhance their appeal, ensuring that professionals can rely on them for sustained performance over time. By integrating axial fans into their projects, engineers not only optimize their designs but also play a pivotal role in advancing innovative electronic products.

Conclusion

Axial cooling fans stand as essential instruments for electronics engineers, delivering a multitude of benefits that significantly enhance performance and efficiency in thermal management. Their energy efficiency, compact design, low noise operation, and high airflow capabilities render them ideal for diverse applications across various industries. By incorporating these fans into their designs, engineers can achieve optimal temperature regulation, extend the lifespan of electronic components, and foster sustainable practices within the industry.

The article underscores several pivotal advantages of axial cooling fans, notably their remarkable reduction in power consumption, which translates to considerable cost savings. The compact form factor of these devices facilitates seamless integration into confined spaces, while their low noise levels elevate user comfort and satisfaction. Additionally, the durability and ease of maintenance associated with axial fans guarantee long-lasting performance, establishing them as a trustworthy choice for professionals committed to efficiency and reliability.

As industries continue to evolve and emphasize energy efficiency and sustainability, the significance of axial cooling fans will only intensify. Adopting these innovative cooling solutions empowers electronics engineers to refine their designs, bolster product reliability, and ultimately propel advancements in technology. The role of axial cooling fans in engineering is paramount; they not only address current demands but also lay the groundwork for future innovations in the electronics sector.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leader in providing innovative temperature control solutions specifically tailored for the electronics sector, focusing on directional ventilation devices that enhance thermal management efficiency.

What are the benefits of directional ventilation devices?

Directional ventilation devices offer superior efficiency, reduced power consumption, optimal thermal management, and extended lifespan for electronic components. They also improve airflow and temperature regulation in various applications, such as data centers and telecommunications.

How do axial cooling fans contribute to energy efficiency?

Axial cooling fans are designed for optimal energy efficiency, significantly reducing power consumption compared to traditional systems. They can lead to up to a 70% reduction in power usage, helping organizations minimize operational costs and their carbon footprint.

What advancements have been made in fan technology?

Recent advancements include the incorporation of energy-efficient motors, smart fan systems for real-time monitoring and control, and electronically commutated (EC) motors that adjust speed based on temperature demands, enhancing overall efficiency.

Why is compact design important for axial cooling fans?

The compact design of axial ventilation units allows for seamless integration into restricted spaces, enabling engineers to optimize layouts for efficient cooling in tight environments without compromising performance.

What role do axial cooling fans play in sustainability?

Axial cooling fans are increasingly vital as industries prioritize sustainability. Their energy-efficient design aligns with the shift towards environmentally conscious technologies, making them essential in modern electronics applications.

What is the projected market growth for small ventilation devices?

The market for small ventilation devices is expected to grow from $3,061.57 million in 2025 to $4,381.46 million by 2032, indicating a rising significance of innovations in this area.

How do advancements in blade design enhance fan efficiency?

Recent advancements in blade design, including improved airflow optimization technologies and airfoil shapes, have elevated fan efficiency, promoting superior thermal management while maintaining a compact footprint.