Overview

This article delves into the crucial distinctions between IP68 and IP69K certifications, which play a vital role in determining the appropriate level of environmental protection for various devices. Understanding these differences is essential for industries that prioritize durability and hygiene.

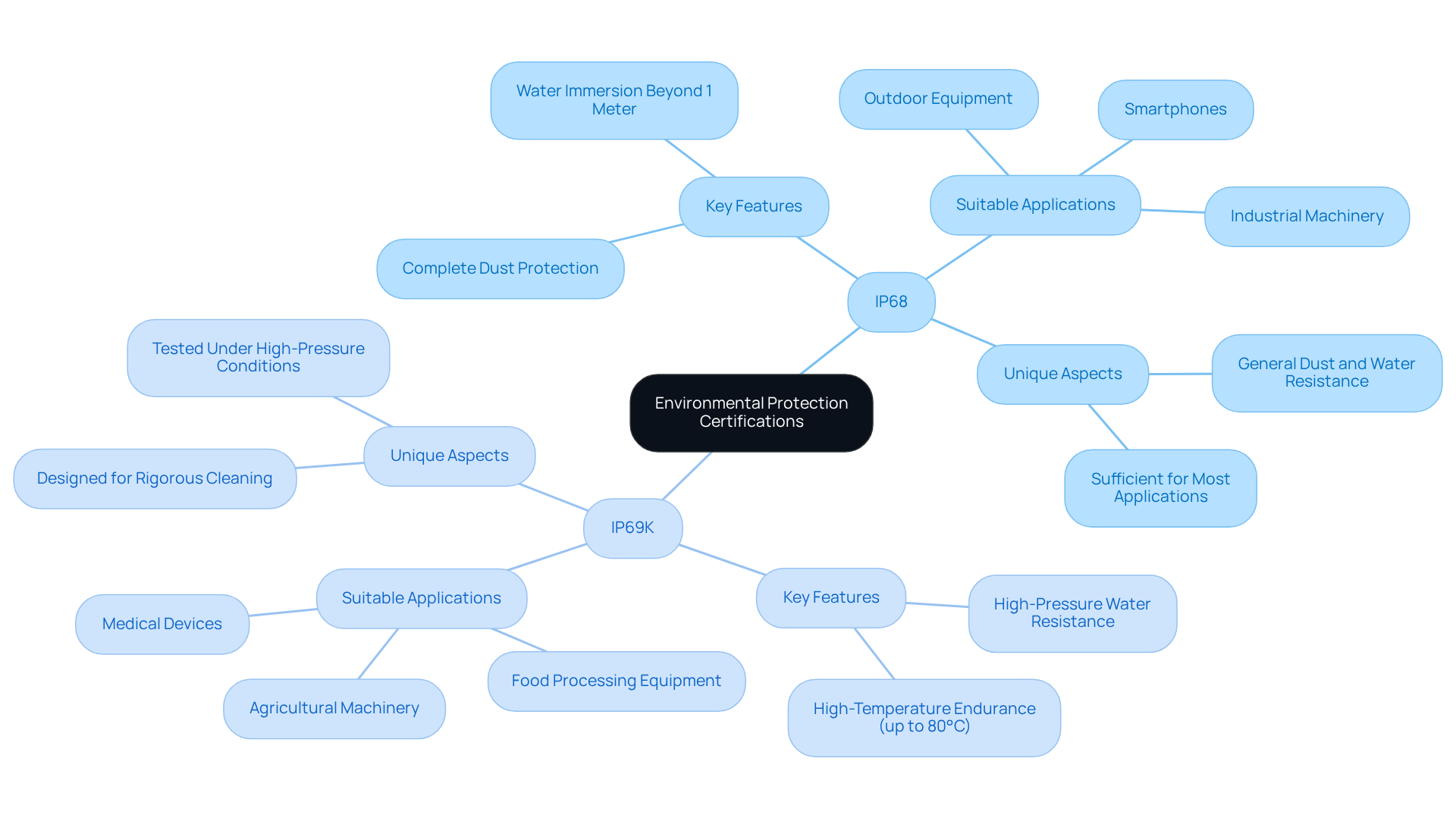

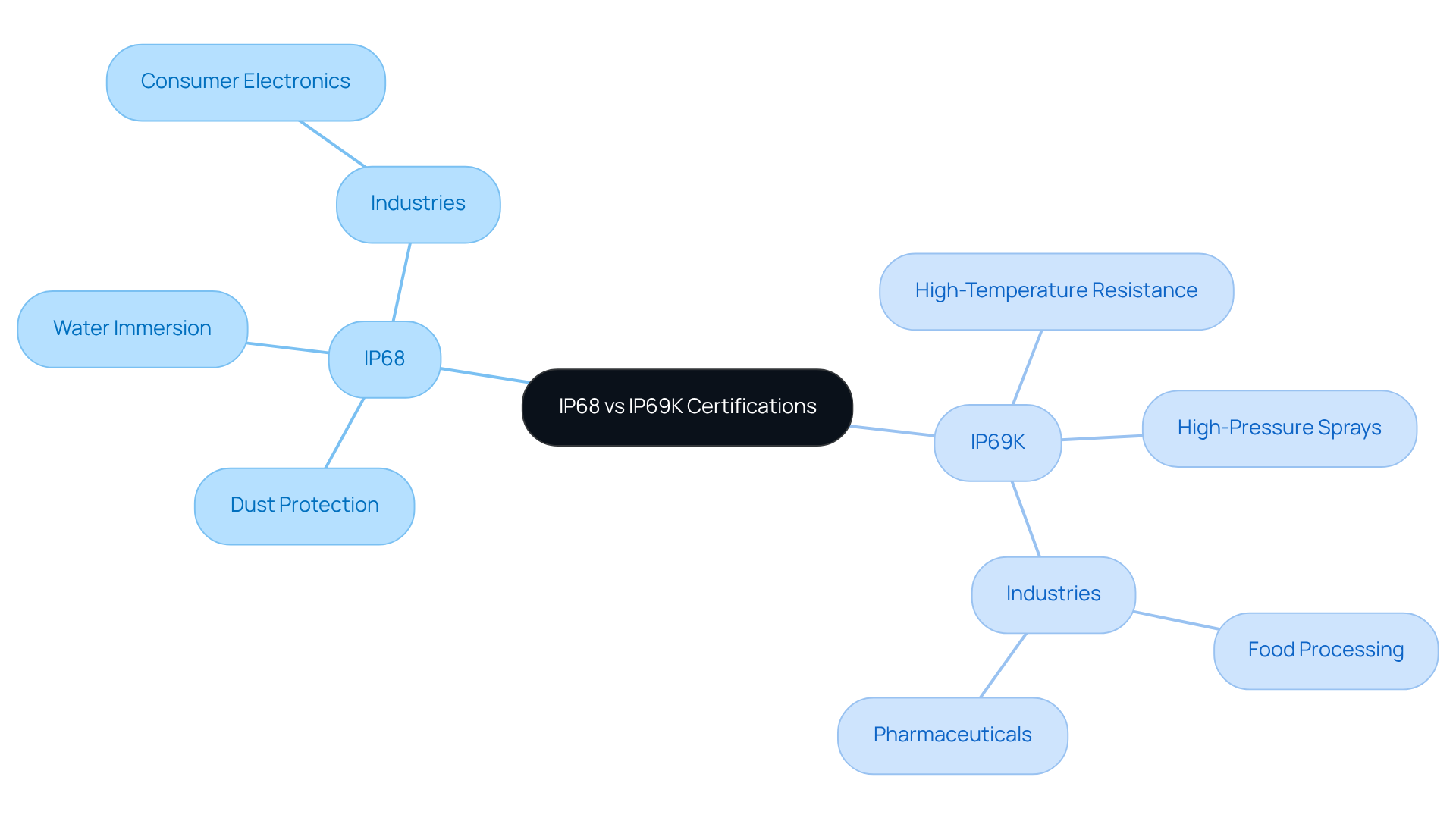

IP68 certification guarantees complete dust protection and the ability to withstand water immersion. This makes it ideal for devices exposed to harsh environments. On the other hand, IP69K is specifically engineered for high-pressure and high-temperature cleaning processes. This feature is particularly significant in sectors such as food processing and pharmaceuticals, where maintaining stringent hygiene standards is paramount.

In summary, while both certifications offer robust protection, the choice between IP68 and IP69K should be guided by the specific environmental challenges faced by the device. Ensuring the right certification not only enhances device longevity but also upholds industry standards for safety and cleanliness.

Introduction

Understanding the nuances between IP68 and IP69K certifications is crucial for engineers and manufacturers who aim to deliver products capable of withstanding the rigors of challenging environments. These two standards represent distinct levels of protection against dust and water, each tailored for specific applications and industries. As the demand for durable and reliable electronics continues to rise, engineers face a pivotal question: how do they determine which certification is best suited for their products?

This exploration of the key differences between IP68 and IP69K will clarify their unique features and highlight the implications of these choices for product design and market success. By delving into the specifics of each certification, we can better understand how they impact the performance and reliability of electronic devices in various settings.

Ultimately, making informed decisions about these certifications not only enhances product durability but also positions manufacturers for greater success in an increasingly competitive market.

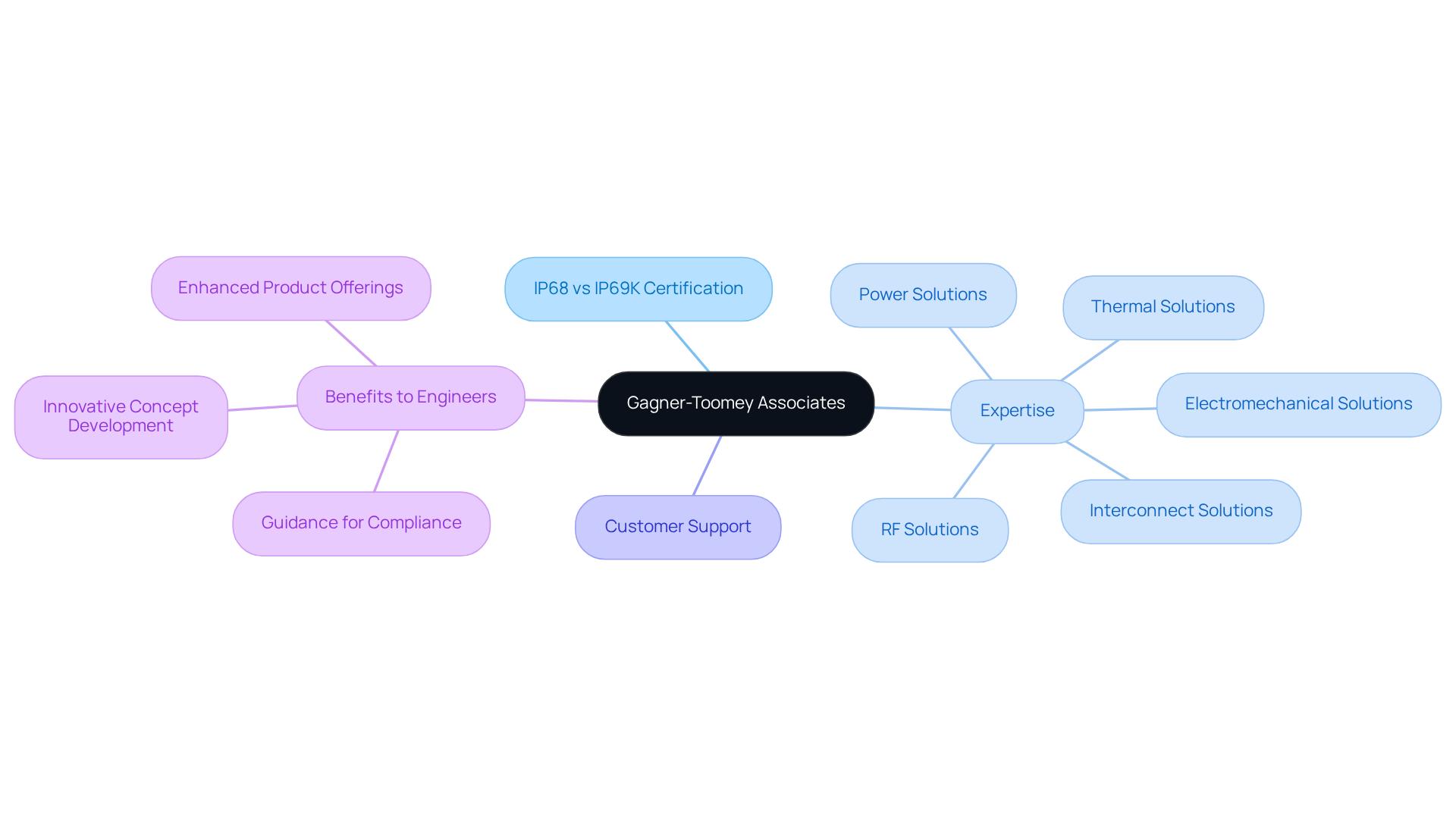

Gagner-Toomey Associates: Your Partner for IP68 and IP69K Certification Solutions

Gagner-Toomey Associates specializes in providing targeted assistance for engineers navigating the complexities of IP68 vs IP69K standards. This focus addresses a critical need in the industry, as compliance with these standards is essential for product success. With a streamlined portfolio that includes thermal, power, RF, interconnect, and electromechanical solutions, the company draws on its extensive expertise to help clients meet these rigorous requirements.

Their commitment to exceptional customer support ensures that engineers receive the guidance necessary to develop robust solutions that adhere to stringent environmental protection standards. This dedication not only aids clients in achieving compliance but also empowers them to bring innovative concepts to market effectively.

By leveraging Gagner-Toomey Associates’ specialized knowledge, engineers can confidently tackle the challenges posed by the differences between IP68 vs IP69K standards, ultimately enhancing their product offerings and driving success in a competitive landscape.

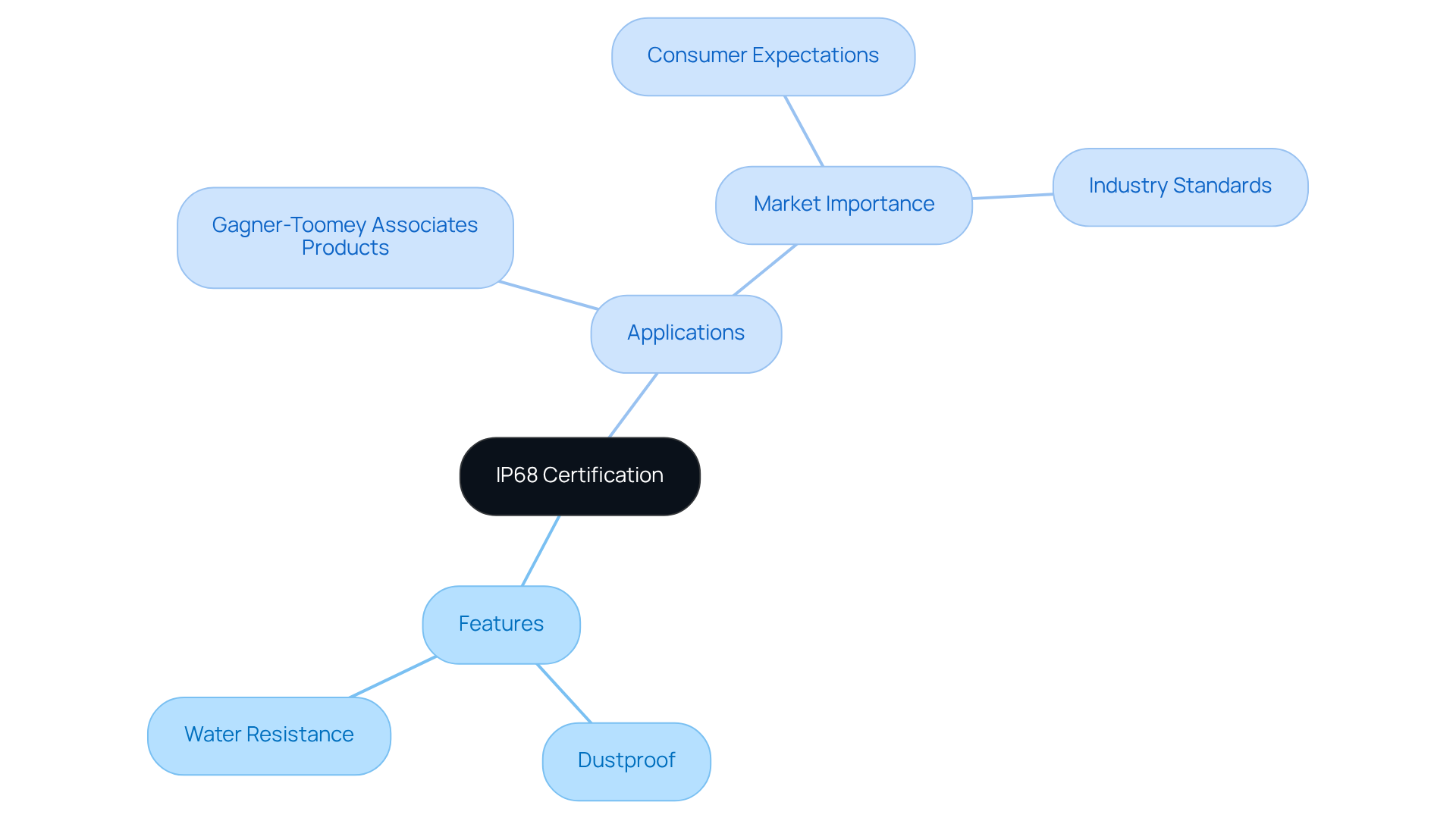

IP68 Certification: Understanding Its Water and Dust Resistance Standards

Certification indicating that an item is entirely dustproof and can endure submersion in water deeper than 1 meter for a designated time is crucial in today’s market. This level of protection is essential for devices used in outdoor or industrial settings, where exposure to dust and moisture is prevalent. Engineers must consider these standards when creating items to ensure they operate effectively in challenging environments, thereby enhancing longevity and reliability.

For instance, Gagner-Toomey Associates provides cutting-edge fiber assembly solutions, including patchcords, jumpers, and unique breakout cables, designed to comply with IP67 standards. These assemblies utilize robust materials and advanced sealing technologies that guarantee durability and performance in harsh conditions. Current industry standards necessitate thorough testing for waterproof and dustproof compliance, emphasizing the need for manufacturers to validate their products’ durability and reliability.

Adherence to the standards of IP68 vs IP69K is equally essential, ensuring that devices can withstand extreme conditions. This compliance not only instills confidence in consumers but also meets the growing demand for resilient electronics. Manufacturers must prioritize these standards to enhance their product offerings and maintain a competitive edge in the market.

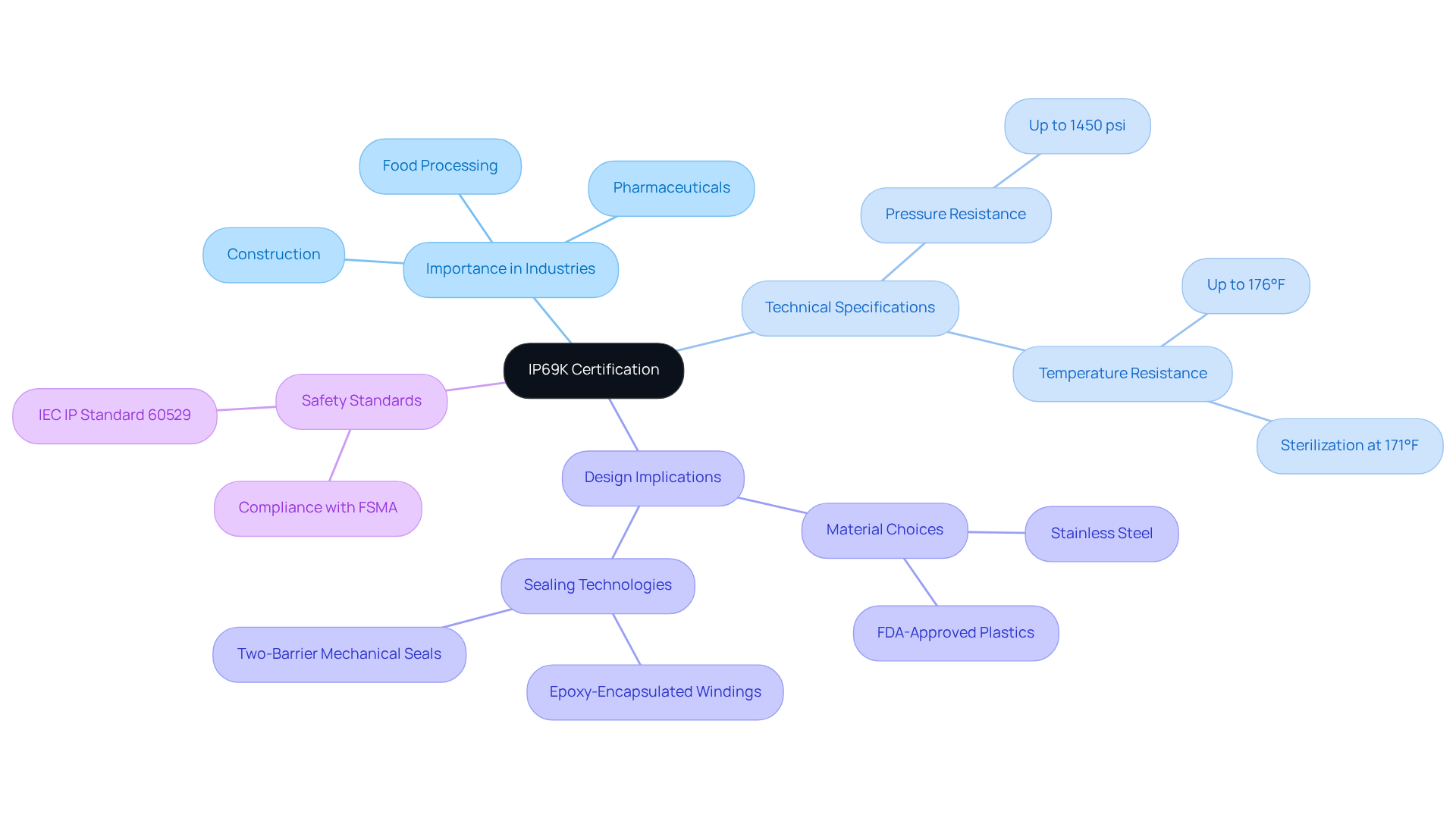

IP69K Certification: High-Pressure and High-Temperature Protection Explained

IP69K approval signifies that an item can withstand high-pressure and high-temperature water jets, making it essential for environments with stringent cleaning protocols. This certification is particularly crucial in sectors like food processing and pharmaceuticals, where hygiene is paramount. For example, IP69K-rated washdown electric motors are engineered to endure frequent cleanings with high-pressure jets and caustic chemicals, ensuring compliance with rigorous food safety regulations such as the Food Safety Modernization Act (FSMA), enacted in 2011.

Industry professionals stress that the ability to endure these cleaning processes is vital for maintaining operational integrity and preventing contamination. As the market increasingly demands IP69K-certified products, engineers must integrate these specifications into their designs to guarantee durability and functionality under extreme cleaning conditions. This focus on cleanliness and reliability not only enhances product safety but also aligns with evolving industry standards and consumer expectations.

Significantly, this classification represents the highest level of ingress protection as defined by the IEC IP standard 60529, underscoring its critical role in ensuring product reliability. Furthermore, IP69K-rated products can withstand water jets at temperatures up to 176°F and pressures of up to 1450 psi, demonstrating their robustness in challenging environments.

Comparing Environmental Protection: IP68 vs. IP69K

When comparing IP68 vs IP69K certifications, both offer robust protection against environmental factors, yet they serve distinct purposes. IP68 is designed for complete dust protection and the capacity to endure prolonged water immersion, making it particularly suitable for devices frequently exposed to moisture and particulate matter, such as smartphones and industrial machinery. Conversely, IP69K is tailored for high-pressure and high-temperature environments, ensuring that devices can withstand rigorous cleaning processes essential in industries like food processing and pharmaceuticals. This certification is crucial for equipment that must endure high-pressure water jets and steam cleaning, which are vital for upholding hygiene standards. The assessment involves rotating the device while being sprayed with water heated to 80°C and pressurized to 80-100 bar, underscoring its suitability for extreme cleaning conditions.

Understanding these distinctions, particularly the differences in IP68 vs IP69K, is vital for engineers when determining which certification aligns best with their needs. While the standard IP68 rating is generally sufficient for various applications, including outdoor use, a higher level of protection is necessary in environments that require thorough cleaning and sterilization. Data suggests that inadequate IP ratings can result in product failures, highlighting the importance of carefully evaluating environmental conditions and cleaning requirements. As electronics engineer Fabien BIBI notes, “In the vast majority of situations, this level of protection is more than adequate, but IP69K approval has been created for extreme scenarios.” By selecting the appropriate certification, engineers can enhance the durability and reliability of their devices, ensuring optimal performance in their intended applications.

Common Applications of IP68 Certification in Electronics

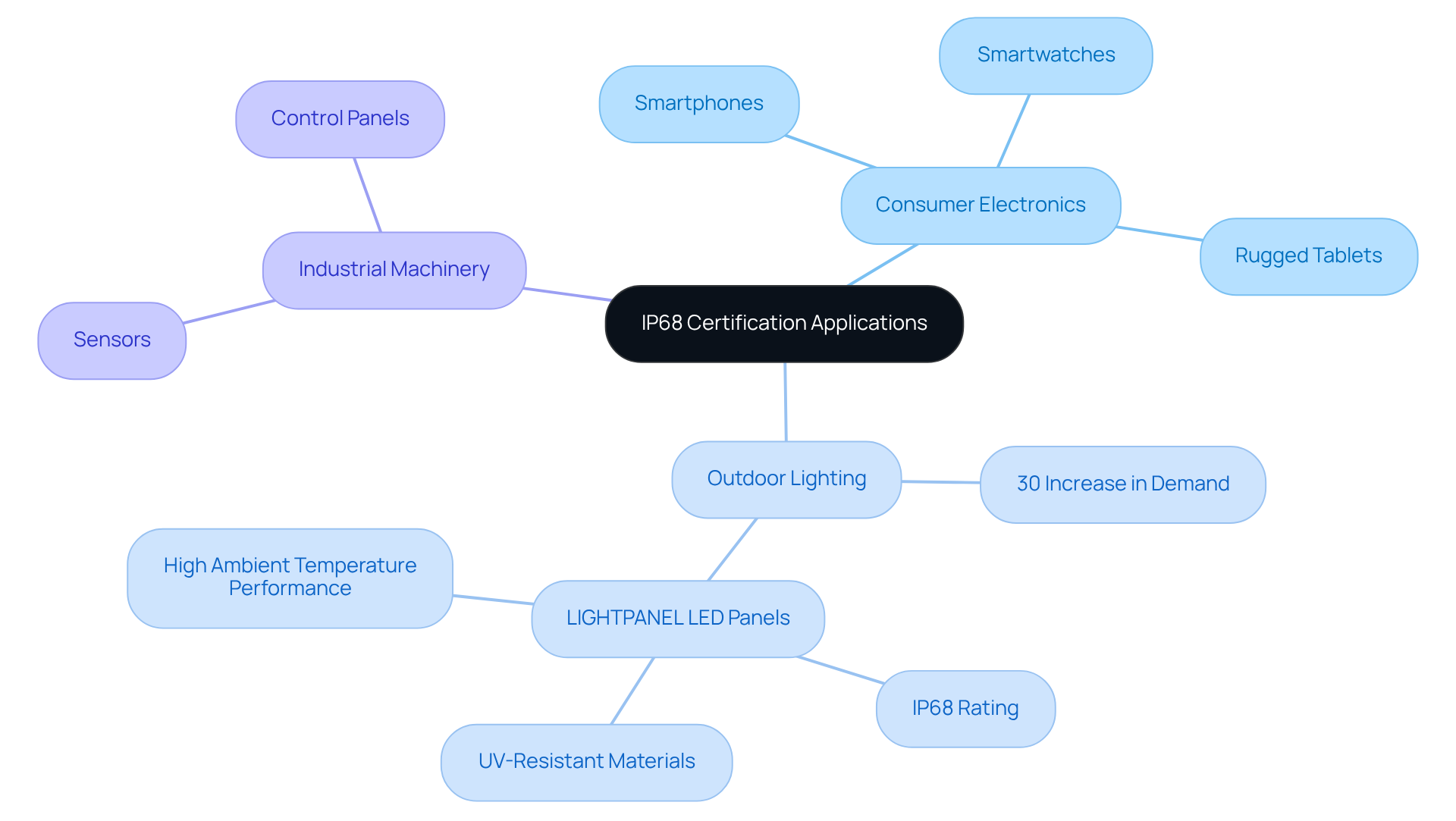

The comparison of IP68 vs IP69K standards serves as a crucial benchmark in consumer electronics, outdoor lighting, and industrial machinery. This rating is commonly found in devices like smartphones, smartwatches, and rugged tablets, all engineered to endure water and dust exposure, thereby ensuring longevity and reliability. In industrial environments, high-level protection standards are vital for devices such as sensors and control panels, which must operate effectively under challenging conditions, safeguarding performance against moisture and particle infiltration.

The demand for waterproof standards in outdoor lighting has surged significantly. Recent statistics reveal a 30% increase in rated items over the past year, underscoring the need for resilient solutions capable of withstanding diverse environmental challenges. This trend not only highlights the importance of the IP68 standard but also emphasizes the comparison of IP68 vs IP69K in enhancing product durability and fostering user trust across various applications.

As Andreas Weyer from LIGHTPANEL notes, “The new panels excel in performance and can withstand challenging environments while maintaining superior light output.” This statement underscores the critical role of IP68 vs IP69K in driving innovations in outdoor lighting, highlighting the significance of these standards in the industry.

Key Applications of IP69K Certification in Harsh Conditions

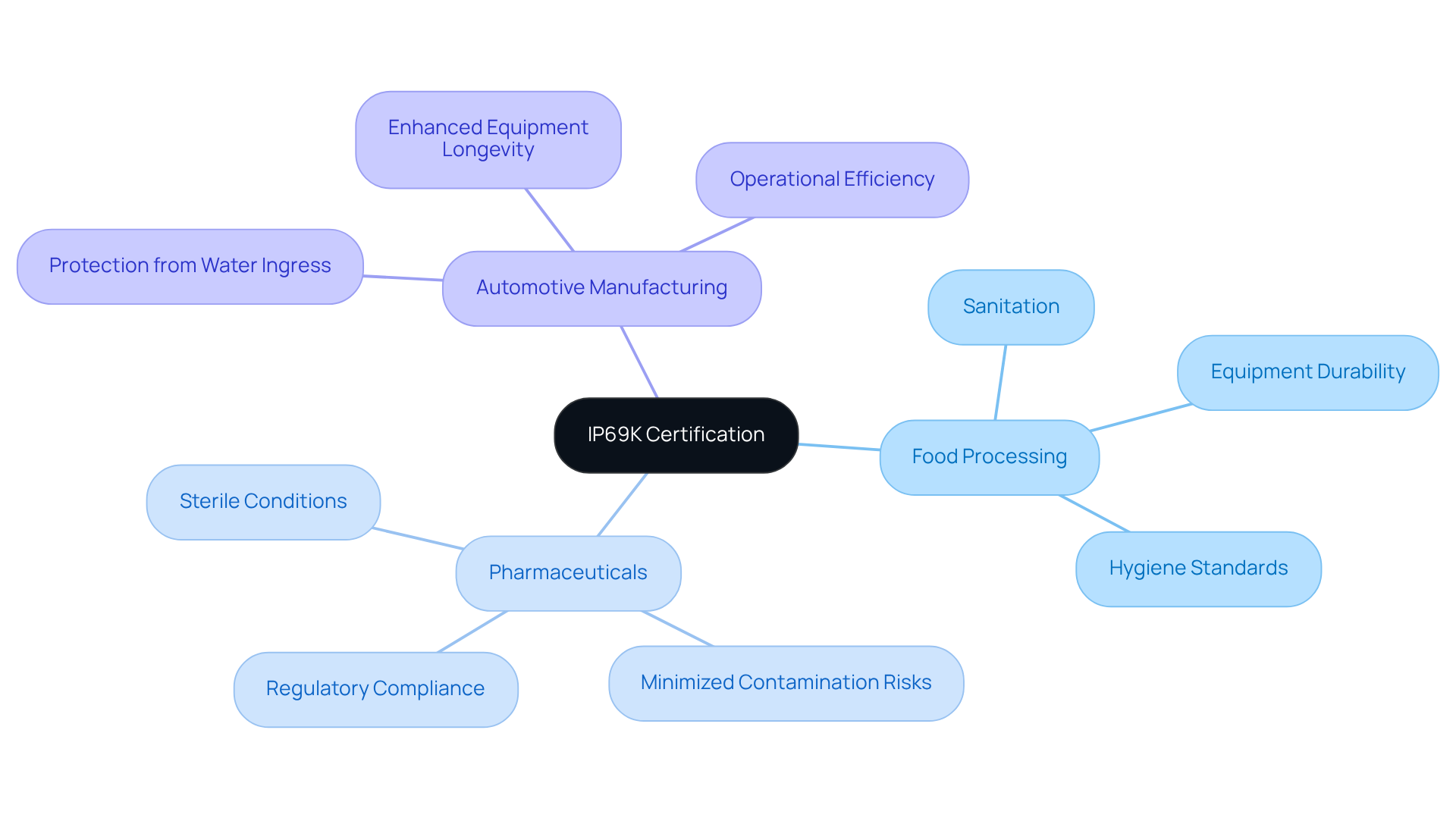

In industries such as food processing, pharmaceuticals, and automotive manufacturing, the comparison of IP68 vs IP69K standards is crucial, as machinery must endure rigorous cleaning procedures involving high-pressure water jets. This accreditation guarantees that equipment can withstand these demanding conditions while upholding operational integrity and hygiene standards. Machinery that benefits from this standard includes conveyor systems, packaging machines, and automotive parts, all of which require regular cleaning to prevent contamination.

In the food processing sector, IP69K-rated equipment is essential for ensuring sanitation and hygiene, as it can withstand repeated washdowns without compromising performance. This is particularly significant given the stringent regulations surrounding food safety, where any oversight can lead to substantial financial losses and harm to brand reputation. Industry leaders stress that using IP69K-certified components not only boosts productivity but also reduces the risk of contamination, thereby protecting public health. As noted by Joyce/Dayton, “Companies need reliable equipment that complies with strict industry cleanliness standards.”

Similarly, in automotive production, this standard holds great importance. Equipment utilized in car washes and cleaning processes must prevent water and cleaning agents from penetrating sensitive internal components. The durability and reliability of IP69K-rated devices ensure that vehicles remain safeguarded during maintenance, ultimately prolonging their lifespan and enhancing operational efficiency.

Data shows that the differences between IP68 vs IP69K accreditation play a significant role in upholding hygiene standards across these sectors. By ensuring that equipment can endure high-pressure washdowns at pressures ranging from 1,160 to 1,450 psi and temperatures of 176°F, companies can mitigate the risk of contamination and associated recalls, which can be detrimental to both finances and reputation. Therefore, adopting IP69K-rated equipment is not merely a choice but a necessity for businesses dedicated to excellence in hygiene and operational safety.

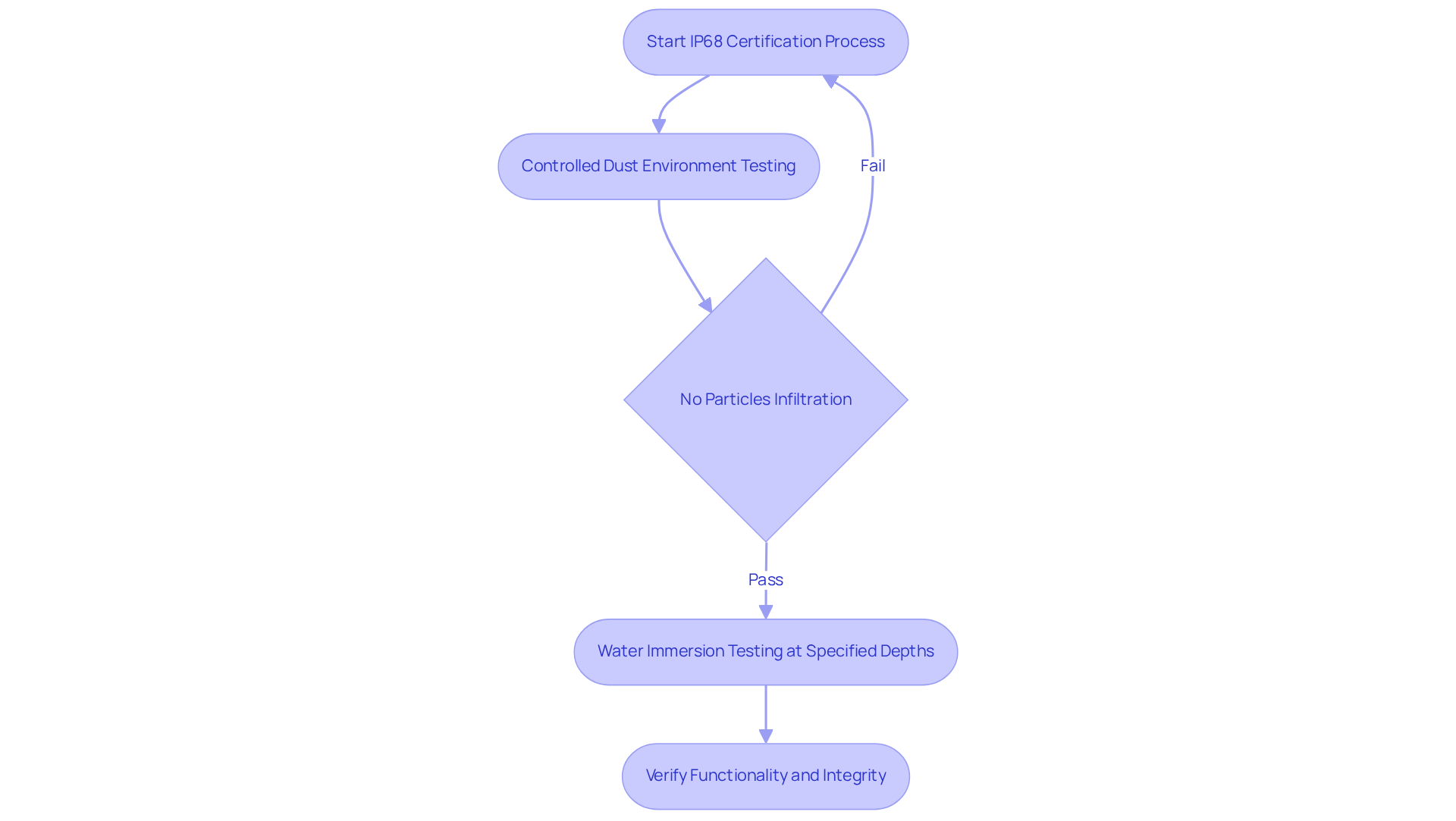

Testing Methods for IP68 Certification: Ensuring Compliance

Obtaining IP68 certification, especially when comparing IP68 vs IP69K, is crucial for ensuring that products can withstand harsh environments. This certification process begins with rigorous testing that evaluates an item’s resistance to dust and water. Initially, the item is placed in a controlled dust environment, where it must prove that no particles can infiltrate its enclosure. Following this, the item undergoes immersion in water at specified depths and durations, as dictated by the standard. This prolonged immersion is vital; it verifies that the item maintains its functionality and integrity under challenging conditions.

Engineers must meticulously design their products to endure these tests. Compliance with IP68 vs IP69K is essential not just for market acceptance, but also for guaranteeing long-term reliability. Products that successfully pass these stringent tests include a wide range of consumer electronics, such as smartphones and smartwatches, as well as industrial control panels and outdoor equipment like marine radios and underwater cameras. These items benefit significantly from enhanced protection against dust and water exposure.

According to various case studies, products that compare IP68 vs IP69K standards provide users with confidence in their operational stability and safety, particularly in environments susceptible to dust and prolonged water submersion. This assurance ultimately boosts consumer trust in their performance, making IP68 certification a key factor in product design and marketing.

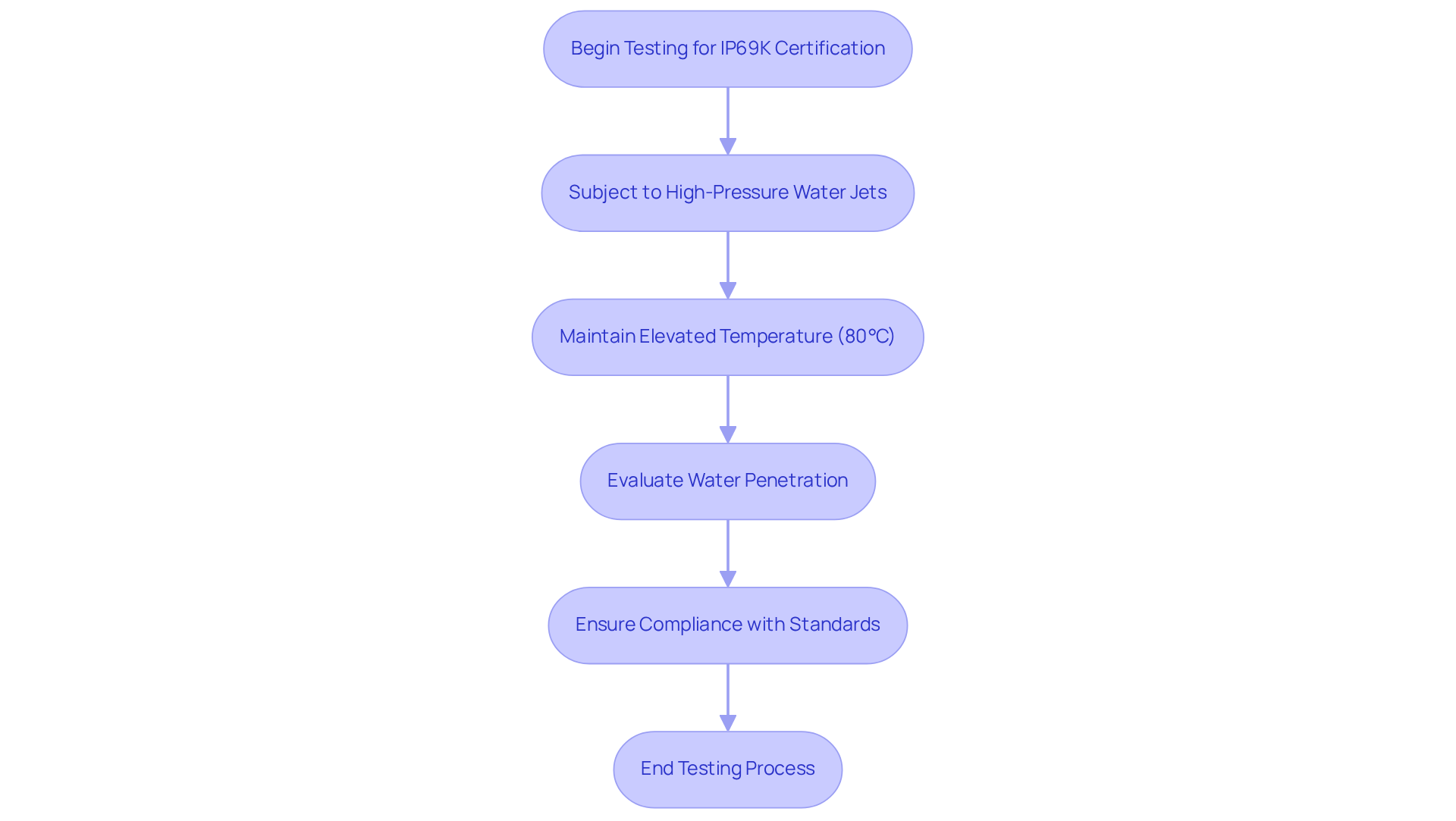

Testing Procedures for IP69K Certification: What Engineers Should Know

Testing for this level of approval requires subjecting the item to high-pressure water jets at elevated temperatures, typically around 80°C. This rigorous evaluation must consider multiple perspectives to ensure comprehensive protection against water penetration. Engineers must be well-versed in these testing standards to design products that effectively meet the necessary criteria, thereby ensuring their suitability for demanding applications.

Understanding the implications of these tests is crucial. By adhering to established protocols, engineers can guarantee that their products not only withstand rigorous conditions but also maintain reliability over time. This commitment to quality is essential in industries where performance is non-negotiable.

In conclusion, recognizing and implementing these testing standards is not just a regulatory requirement; it is a strategic advantage. Engineers who prioritize these practices will enhance their product’s marketability and reliability, ultimately leading to greater customer satisfaction and trust.

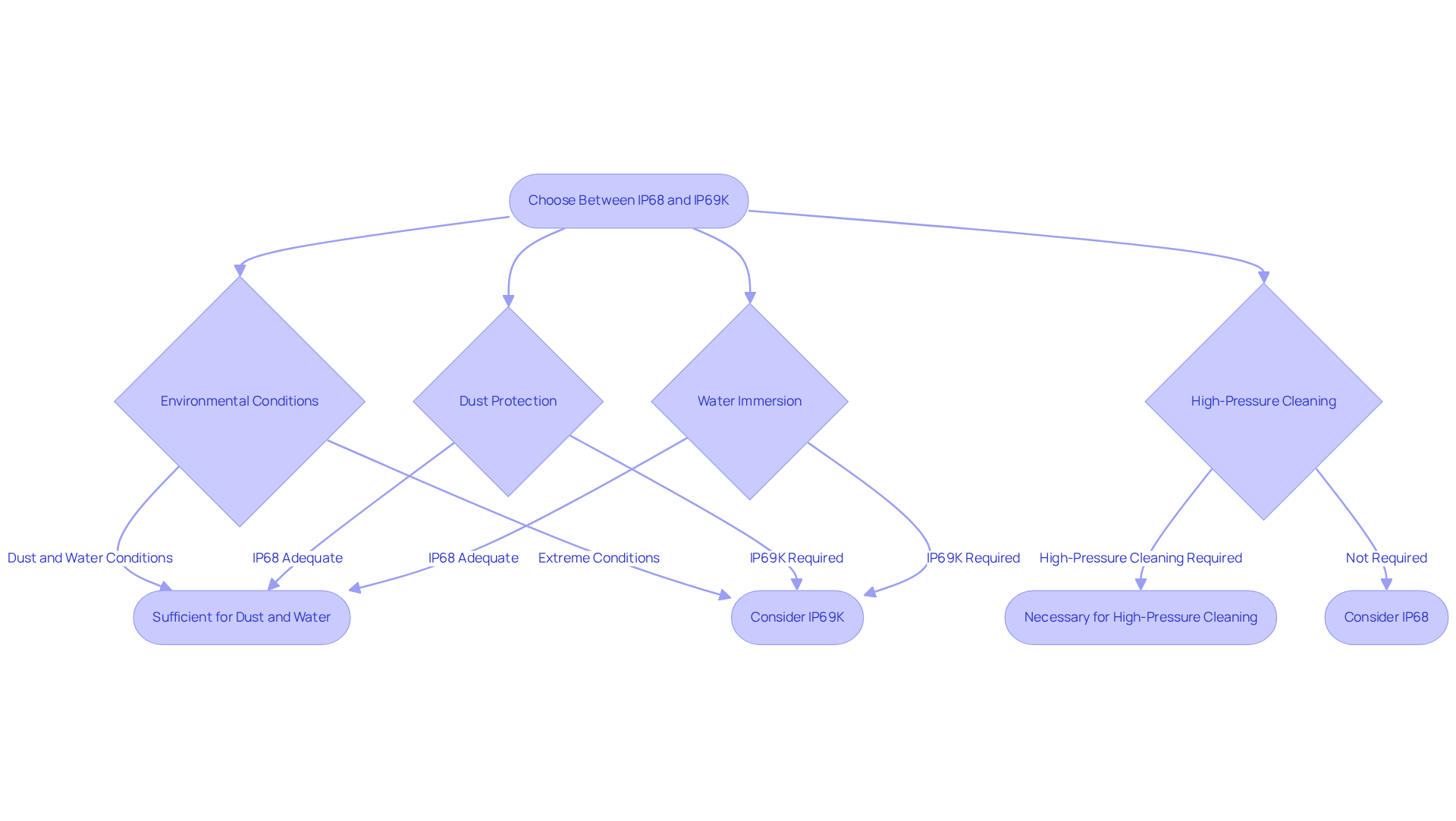

Choosing Between IP68 and IP69K: Implications for Product Design

When engineers face the decision of selecting between two certifications, they must carefully consider the specific environmental conditions their devices will encounter. For instance, if a device is likely to be exposed to dust and water immersion, an IP68 rating may suffice when considering IP68 vs IP69K, as it guarantees total dust protection and immersion beyond 1 meter for durations ranging from 30 minutes to 1 hour. However, in scenarios that demand high-pressure cleaning—where devices endure water jets at pressures up to 1450 psi—or extreme temperature exposure, opting for a higher level of ingress protection becomes essential.

This choice not only influences product design but also affects manufacturing processes and market positioning. As noted by Fabien BIBI, an electronic engineer, ‘If you intend to deploy electronic sensors in an environment where they will frequently need to undergo high-pressure cleaning, then it is crucial to consider the differences between IP68 vs IP69K approval.’ Engineers must understand that selecting a higher qualification can significantly enhance durability and reliability, which are vital for maintaining a competitive edge in demanding industries.

The ramifications of these certification choices extend beyond mere compliance; they can ultimately determine a product’s success in the marketplace, particularly in sectors where cleanliness and durability are paramount. By making informed decisions regarding ingress protection ratings, engineers can ensure their products not only meet industry standards but also excel in performance and reliability.

Key Takeaways: Distinguishing IP68 from IP69K Certifications

IP68 approval provides exceptional protection against dust and allows for extended immersion in water, making it particularly suitable for consumer electronics and outdoor applications. Conversely, this specific standard is designed to withstand high-pressure and high-temperature water sprays, which is essential for industries requiring stringent cleaning processes, such as food processing and pharmaceuticals.

Understanding these distinctions is vital for engineers. Choosing the right certification ensures that products can endure their intended environments and operational challenges. Recent consumer trends reveal a growing preference for devices with high durability ratings, reflecting an increased awareness of the importance of sturdiness and reliability in harsh conditions. For example, a survey indicated that 75% of consumers prioritize the comparison of IP68 vs IP69K ratings when purchasing outdoor electronics.

As industries continue to evolve, the significance of these qualifications will only increase, underscoring the necessity for engineers to be well-versed in their implications. Sectors like automotive and healthcare particularly benefit from a thorough understanding of these ratings, as they frequently operate in environments where exposure to dust and water is common. Furthermore, experts stress that selecting the appropriate certification can avert costly product failures, reinforcing the critical nature of this knowledge for engineers.

Conclusion

Understanding the differences between IP68 and IP69K certifications is essential for engineers and manufacturers who aim to develop products capable of withstanding harsh environmental conditions. Both certifications offer significant protection against dust and water, yet they cater to distinct operational needs.

IP68 is particularly suited for devices that require complete dust protection and can endure prolonged water immersion, making it ideal for consumer electronics and outdoor applications. Conversely, IP69K is specifically designed for high-pressure and high-temperature environments, ensuring that products meet stringent hygiene standards in industries such as food processing and pharmaceuticals.

This article highlights key aspects of each certification, detailing their applications and the critical importance of rigorous testing to achieve compliance. Engineers must carefully evaluate the specific requirements of their products to select the appropriate certification. With a growing consumer preference for durable electronics, understanding the distinctions between IP68 and IP69K is increasingly vital. This knowledge not only aids in product design but also enhances marketability and consumer trust.

As industries evolve and the demand for resilient products rises, engineers are encouraged to prioritize these certifications in their designs. By doing so, they can ensure their products not only meet industry standards but also excel in performance and reliability. Investing time in understanding IP68 and IP69K certifications will ultimately lead to better product outcomes and a stronger competitive edge in the marketplace.

Frequently Asked Questions

What is the focus of Gagner-Toomey Associates?

Gagner-Toomey Associates specializes in assisting engineers with IP68 and IP69K certification solutions, addressing the complexities of these standards to ensure product success.

Why is compliance with IP68 and IP69K standards important?

Compliance with IP68 and IP69K standards is essential for product success, as it ensures devices can withstand challenging environmental conditions, enhancing their longevity and reliability.

What types of solutions does Gagner-Toomey Associates offer?

The company offers a streamlined portfolio that includes thermal, power, RF, interconnect, and electromechanical solutions designed to meet rigorous environmental protection standards.

What does IP68 certification signify?

IP68 certification indicates that an item is entirely dustproof and can endure submersion in water deeper than 1 meter for a designated time, making it crucial for devices used in outdoor or industrial settings.

What types of products does Gagner-Toomey Associates provide that comply with IP67 standards?

Gagner-Toomey Associates provides fiber assembly solutions, including patchcords, jumpers, and unique breakout cables, designed to comply with IP67 standards.

What does IP69K certification entail?

IP69K certification signifies that an item can withstand high-pressure and high-temperature water jets, making it essential for environments with stringent cleaning protocols, such as food processing and pharmaceuticals.

Why is IP69K certification critical in certain industries?

IP69K certification is crucial in sectors like food processing and pharmaceuticals for maintaining hygiene and compliance with food safety regulations, ensuring that products can endure frequent cleanings with high-pressure jets and caustic chemicals.

What are the capabilities of IP69K-rated products?

IP69K-rated products can withstand water jets at temperatures up to 176°F and pressures of up to 1450 psi, demonstrating their robustness in challenging environments.

How do IP68 and IP69K standards impact product development?

Engineers must integrate IP68 and IP69K specifications into their designs to ensure durability and functionality under extreme conditions, ultimately enhancing product safety and reliability in the market.