Overview

The article examines the critical factors to consider when selecting a DC axial fan for electronics cooling, highlighting essential aspects such as:

- Airflow requirements

- Noise levels

- Energy efficiency

- Customization options

These factors are pivotal for achieving optimal thermal management and performance of electronic components. Their influence extends to the effectiveness, longevity, and sustainability of cooling solutions across various applications, underscoring the necessity for informed decision-making in this domain.

Introduction

Selecting the right DC axial fan is crucial for maintaining optimal cooling in electronic systems, where even minor temperature fluctuations can lead to performance degradation. Engineers must navigate a complex landscape of factors, including:

- Airflow requirements

- Noise levels

to ensure their cooling solutions are effective and efficient. With the market for these fans projected to grow significantly, the challenge extends beyond merely understanding technical specifications; it also involves aligning them with specific application needs. What key considerations can ultimately make or break the cooling performance of electronic devices?

Gagner-Toomey Associates: Expert Guidance on Selecting DC Axial Fans for Optimal Cooling

Gagner-Toomey Associates excels in delivering customized solutions for engineers within the electronics sector, particularly regarding the selection of DC axial fans—crucial components for achieving optimal thermal efficiency across a variety of applications. Their extensive understanding of air movement dynamics and thermal management enables them to navigate the complexities involved in blower selection, ensuring that the chosen units effectively meet specific temperature control requirements.

In their approach, key considerations encompass the evaluation of airflow rates, noise levels, and energy efficiency—elements that are vital for maintaining the performance and longevity of electronic components. With the projected to reach US$ 3.93 billion by 2031, coupled with a growing emphasis on energy-efficient technologies, Gagner-Toomey is strategically positioned to recommend the most effective solutions for any temperature regulation challenge. Their diverse portfolio of manufacturers empowers them to offer tailored recommendations that align with the latest trends in DC axial fans, ensuring clients have access to state-of-the-art cooling solutions.

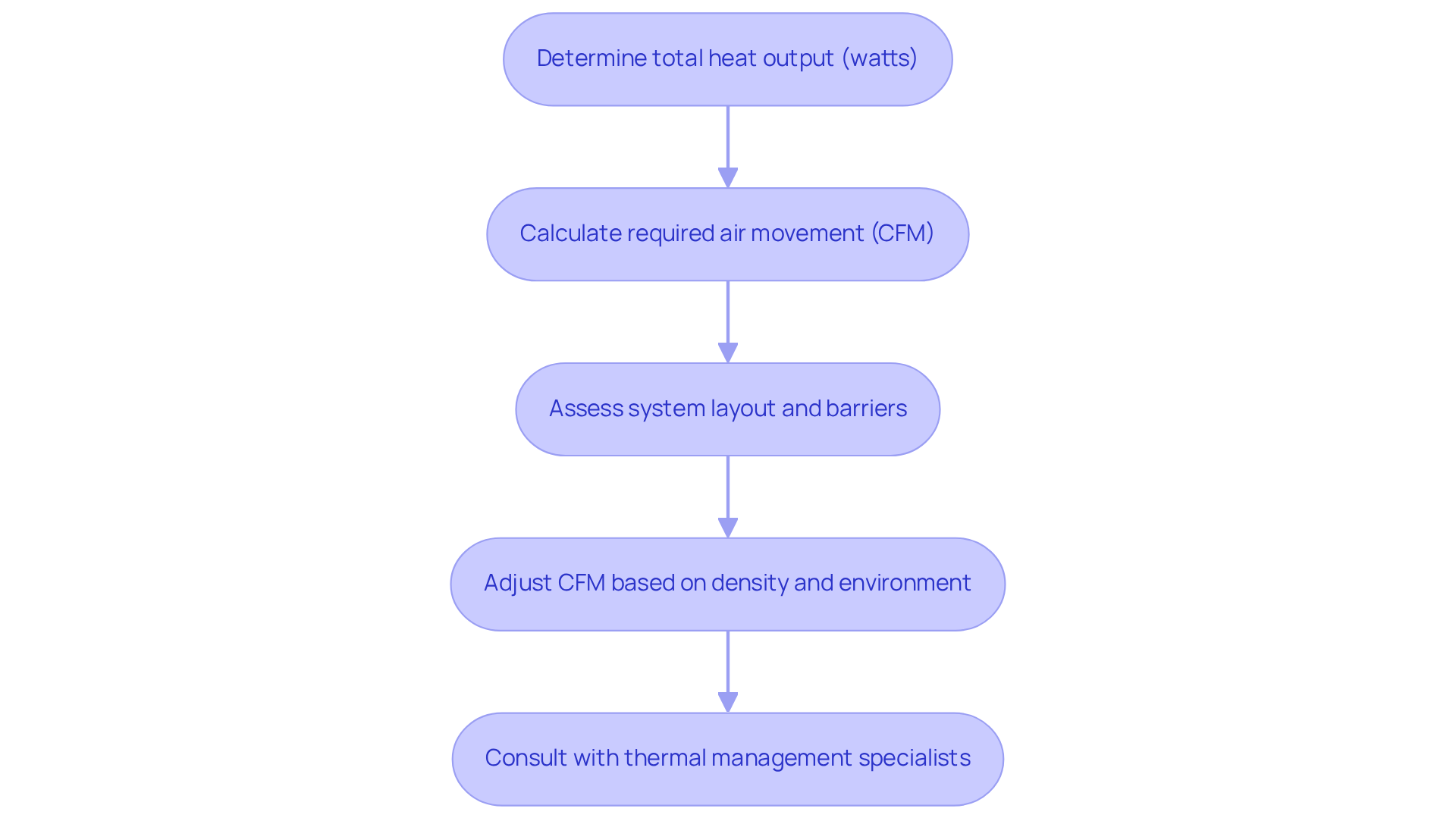

Airflow Requirements: Assessing the Cooling Needs of Your Electronics System

To effectively evaluate the ventilation requirements of your electronics system, begin by determining the total heat output of the components, typically measured in watts (W). The required air movement is quantified in cubic feet per minute (CFM) and must be adequate to dissipate the generated heat. A commonly accepted guideline suggests targeting 1 CFM per watt of heat output; however, this can fluctuate based on the specific application and environmental conditions. Notably, with the introduction of Intel’s Xeon 6 CPUs, which enhance performance by 150% and efficiency by 60% compared to the previous generation, the need for effective thermal management solutions has become increasingly critical in high-performance systems.

In addition to heat output, consider the system layout and any potential barriers to airflow. Effective air circulation management is vital to prevent hotspots and ensure consistent temperature distribution across all components. Recent advancements in thermal management, including smart co-engineering, have led to innovative temperature regulation solutions that capture over 95% of heat from CPUs, significantly boosting efficiency. Thermal management specialists recommend a , taking into account factors such as component density and operational environment.

For example, when assessing ventilation requirements for a densely packed system, it may be necessary to increase the CFM to maintain optimal temperatures. A practical calculation might involve a system with a total heat output of 300 watts, which would necessitate approximately 300 CFM under standard conditions. Engaging with thermal management specialists, including experts from Nexalus who collaborate with Intel on pioneering thermal solutions, can provide valuable insights into specific ventilation needs, ensuring that your cooling strategies are both efficient and sustainable.

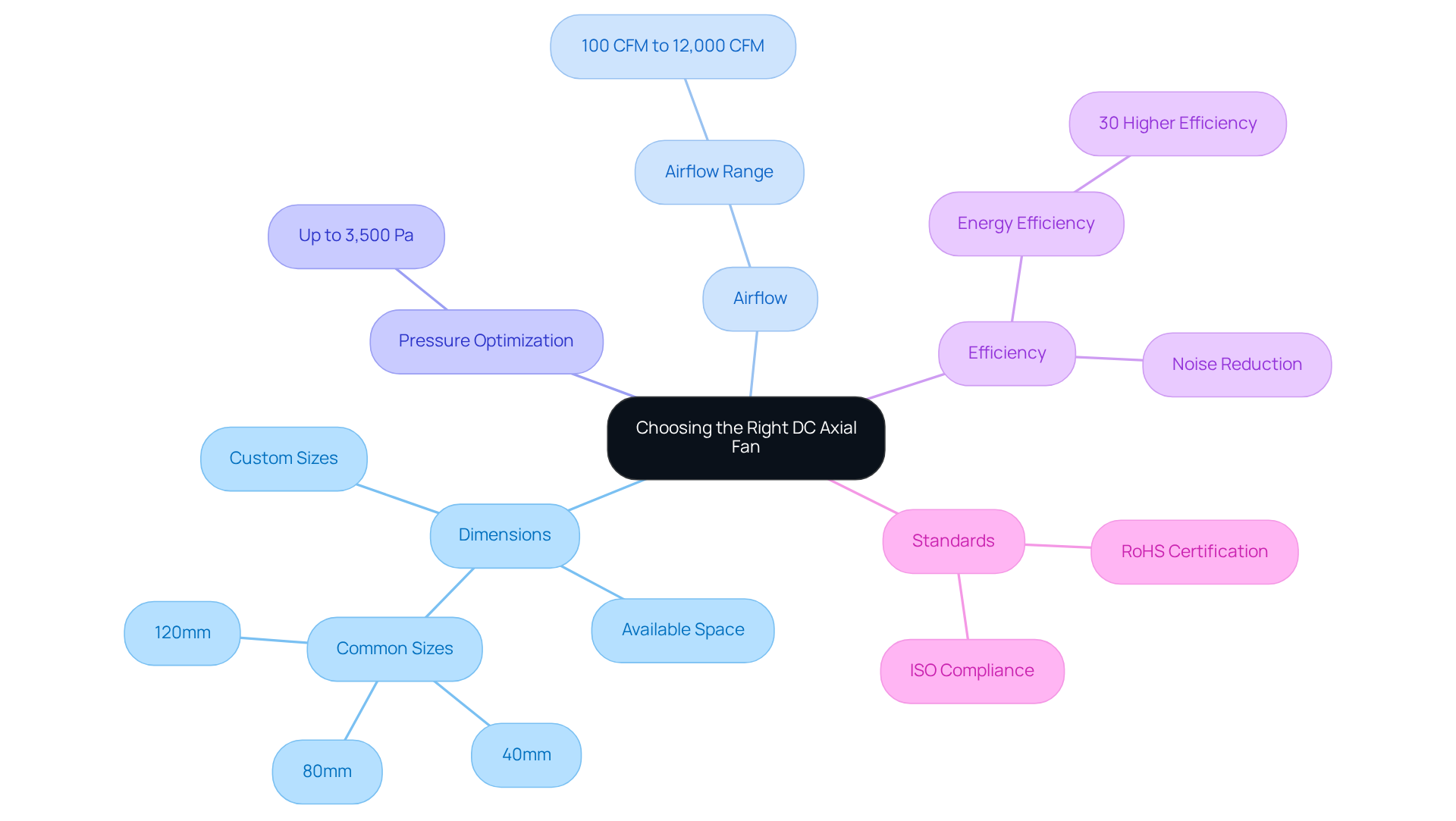

Fan Size and Dimensions: Choosing the Right Fit for Your Application

Selecting the appropriate DC axial fan necessitates meticulous consideration of its physical dimensions to ensure optimal performance in your application. Start by measuring the available space within your enclosure, taking into account height, width, and depth. Common fan sizes include 40mm, 80mm, and 120mm; however, many manufacturers provide custom sizes tailored to specific needs, with airflow adjustments ranging from 100 CFM to 12,000 CFM and pressure optimization up to 3,500 Pa.

The mounting configuration of the fan must align with your system’s design. A properly fitted fan not only enhances airflow efficiency but also reduces noise and vibration, both of which are crucial for ensuring the reliability of electronic systems. Engineers emphasize that the measurements of a blower significantly influence temperature regulation; for example, larger units can move more air at reduced speeds, resulting in quieter operation and improved energy efficiency. Blauberg-motoren’s blowers, for instance, offer 30% greater energy efficiency than traditional models, underscoring the importance of selecting the right blower size.

Statistics indicate that can yield an efficiency boost of up to 30%, making it essential to consider air movement requirements and static pressure when selecting a fan. Additionally, certifications like RoHS and ISO are vital elements to evaluate, ensuring that the devices comply with environmental and quality standards. Custom DC axial fans can be engineered to meet specific cooling needs, guaranteeing that even the most compact electronic devices receive sufficient airflow. By prioritizing the correct dimensions and considering these factors, you can significantly enhance the thermal management of your systems, ultimately extending their lifespan and performance.

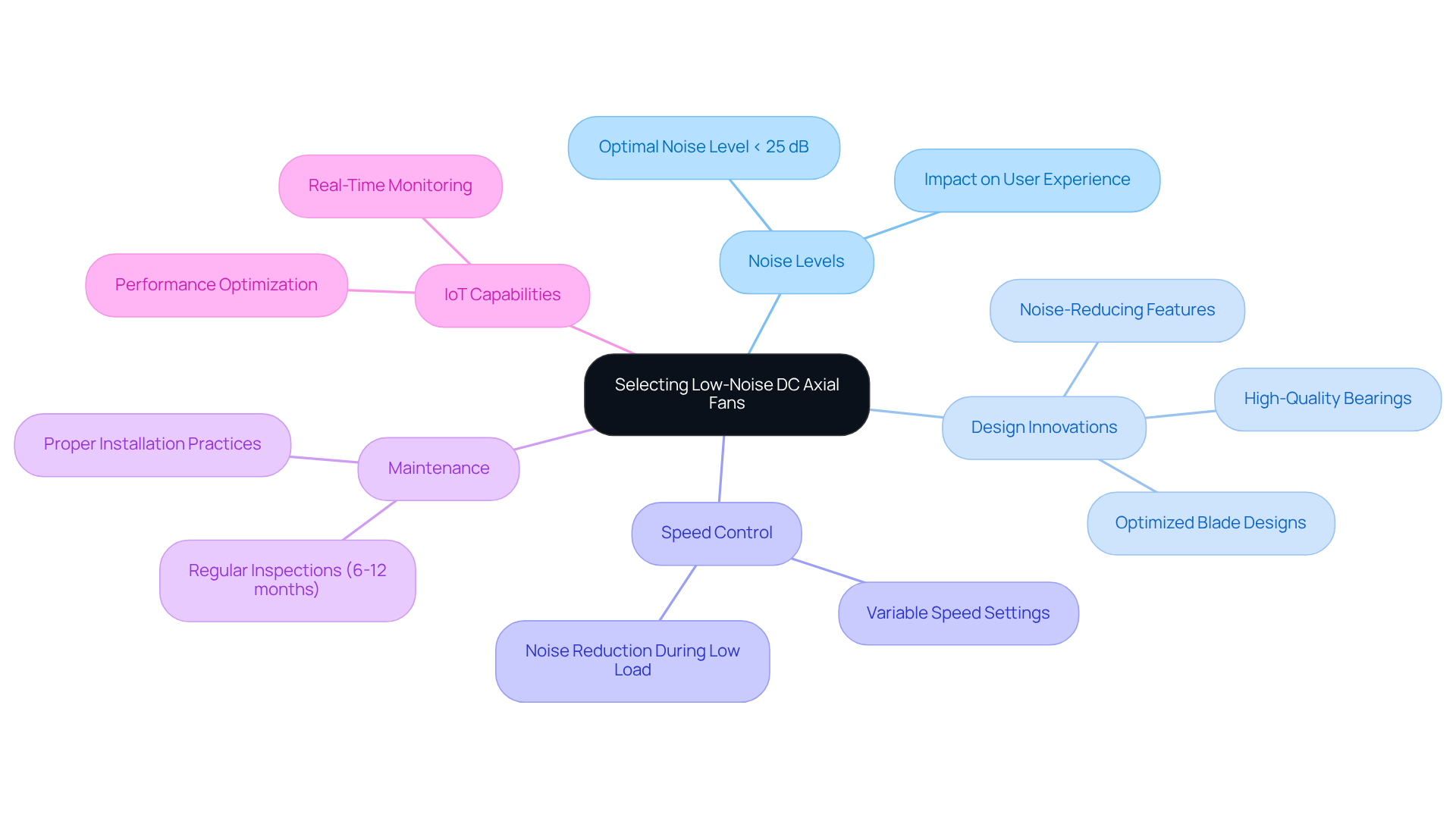

Noise Levels: Selecting Low-Noise Fans for a Quieter Operation

When selecting a dc axial fan, noise levels—typically measured in decibels (dB)—are a critical factor. In environments where noise sensitivity is paramount, a dc axial fan rated below 25 dB is ideal, as it is classified as quiet. Innovations such as optimized blade designs and high-quality bearings play a significant role in minimizing operational noise, thereby enhancing the user experience. The effect of noise levels on fan selection should not be disregarded; it can significantly impact the overall efficiency of temperature control solutions in delicate applications.

Moreover, consider the fan’s speed control capabilities. Fans equipped with variable speed settings can adjust their operation according to temperature requirements, effectively reducing noise during low-load conditions. Recent advancements in quiet fan technology have led to the development of noise-reducing designs, including the dc axial fan with optimized metal blades that maintain high performance while lowering sound levels. These features not only improve the acoustic environment but also contribute to , making them a smart choice for modern electronics cooling applications.

Regular upkeep of axial units is crucial for guaranteeing dependable functioning, with advice indicating inspections every 6-12 months. Furthermore, the incorporation of IoT capabilities in axial devices permits real-time monitoring and control, thereby boosting operational efficiency and performance. Gagner-Toomey Associates excels in providing innovative solutions for dc axial fans specifically designed for the electronics sector, ensuring that engineers have access to the latest advancements in fan technology.

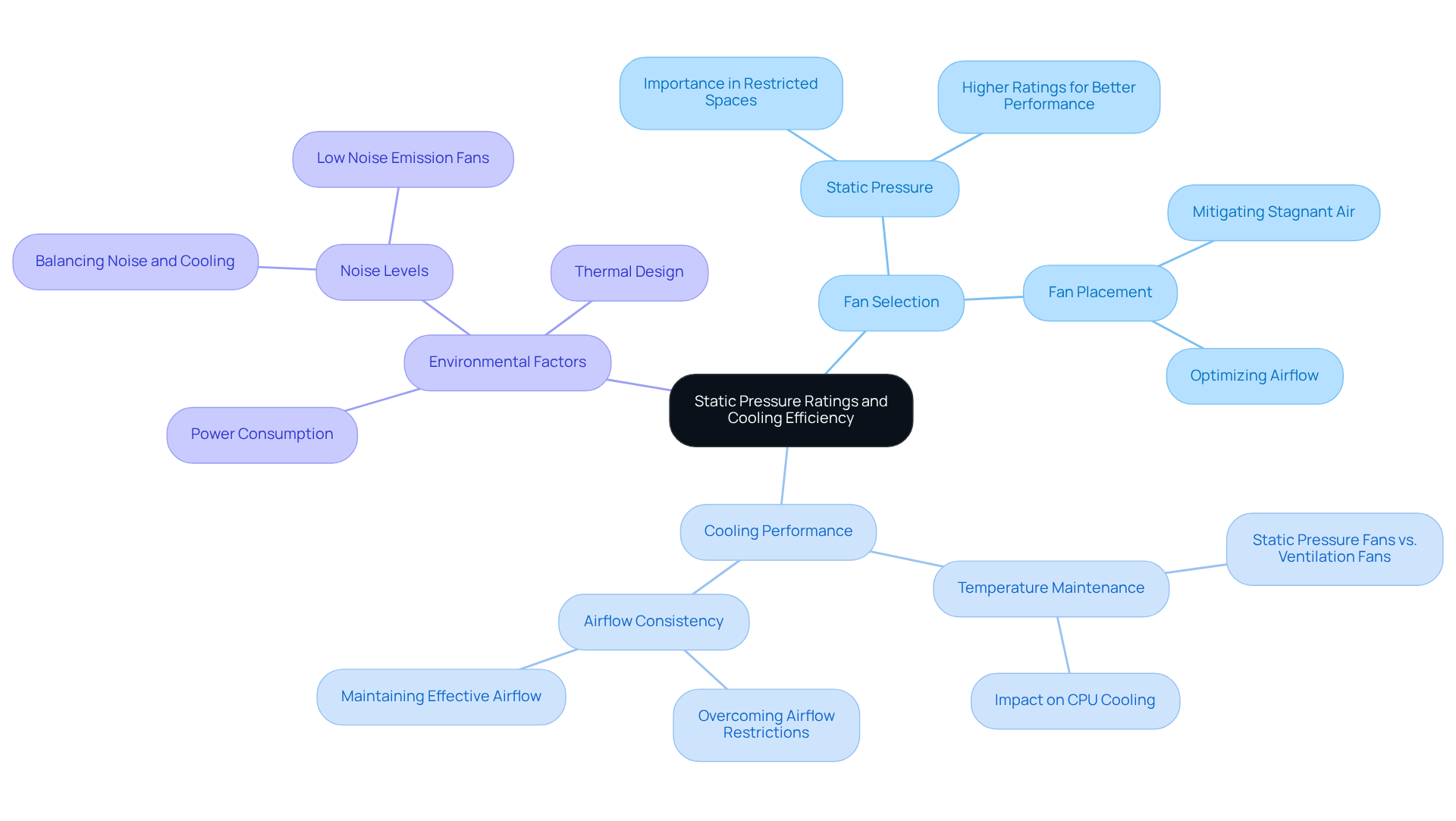

Static Pressure Ratings: Understanding Their Impact on Cooling Efficiency

Static pressure signifies the resistance a fan must surmount to effectively circulate air through enclosures or ductwork, measured in inches of water gauge (inH2O). When choosing a DC axial fan, it is crucial to take into account its , especially in scenarios where air movement could be restricted, like in confined spaces or when filters are involved. A fan with a higher static pressure rating is crucial for ensuring sufficient airflow in these contexts, as it can sustain performance despite obstructions.

Research demonstrates that static pressure plays a significant role in enhancing cooling efficiency in electronics. For example, static pressure fans can maintain CPU temperatures an impressive 3 degrees Celsius cooler than ventilation fans in a radiator setup. Fans designed for high static resistance conditions excel in overcoming barriers, ensuring that airflow remains consistent and effective. Aligning the fan’s performance curve with your system’s specific requirements is vital for achieving optimal cooling. In restricted areas, where resistance to airflow is heightened, selecting a DC axial fan with appropriate static pressure characteristics can prevent overheating and bolster the reliability of electronic devices.

Strategic fan placement is essential for efficient heat dissipation, mitigating the risk of overheating. Furthermore, it is critical to evaluate factors such as power consumption, thermal design, and operating environment when determining airflow requirements. Striking a balance between noise levels and temperature regulation is also a key consideration for effective fan selection. Thoroughly assessing these factors guarantees that the cooling system operates efficiently, ultimately protecting the performance and longevity of essential components.

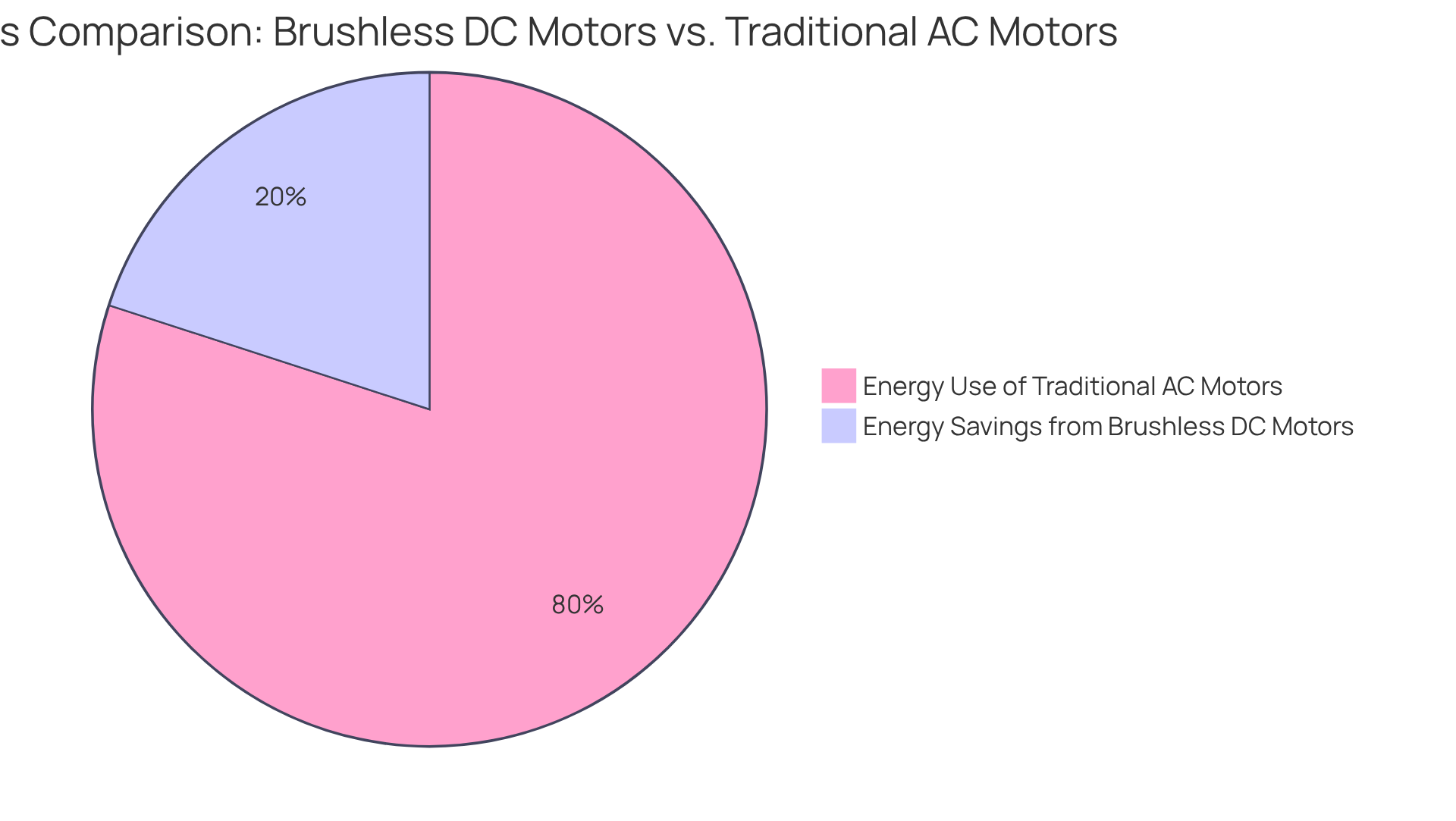

Energy Efficiency: Choosing Fans That Minimize Power Consumption

When selecting a DC axial fan, prioritizing is paramount. Devices featuring brushless DC motors stand out for their exceptional efficiency and significantly reduced power usage compared to conventional AC motors. These motors can achieve energy savings of up to 20%, as evidenced by case studies demonstrating a 20% reduction in energy consumption when utilizing FRP axial devices instead of traditional metallic units. This positions them as a compelling choice for engineers who prioritize sustainability, particularly when using a DC axial fan. Furthermore, devices equipped with variable speed regulation can adjust their energy consumption in accordance with cooling requirements, thereby maximizing effectiveness and enhancing overall efficiency.

By prioritizing energy-efficient devices like a DC axial fan, you not only reduce operational expenses but also make a substantial contribution to promoting a sustainable environment by minimizing your total energy use. As sustainability experts highlight, every small action contributes to a larger impact, making informed choices in fan selection essential for both economic and ecological benefits. For example, Gro Harlem Brundtland stated, “Sustainable development is the development that meets the needs of the present without compromising the ability of future generations to meet their own needs,” underscoring the importance of making informed decisions in fan selection.

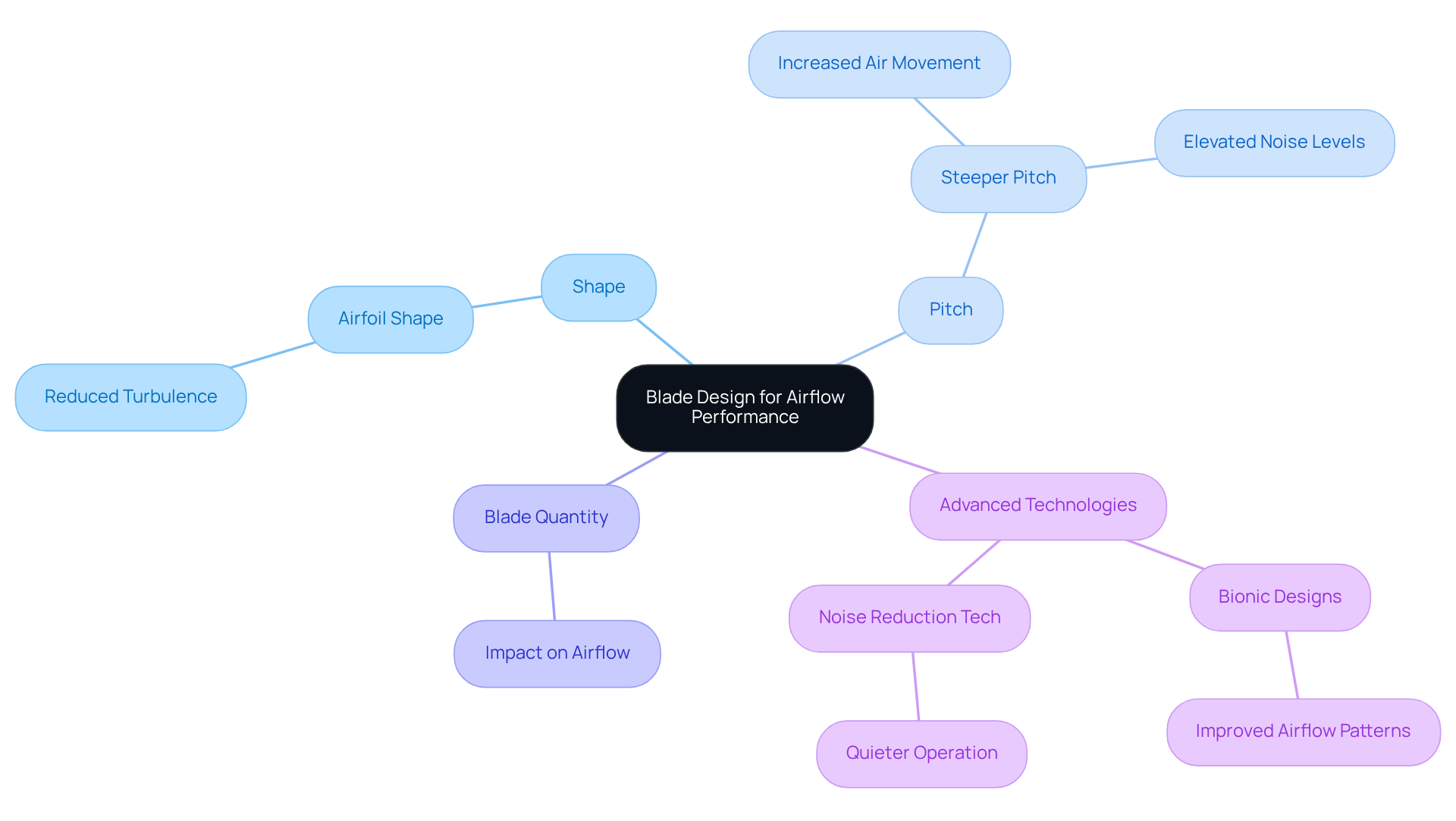

Blade Design: Evaluating Features That Enhance Airflow Performance

Blade design plays a pivotal role in determining the performance of the DC axial fan, with characteristics such as shape, pitch, and blade quantity significantly influencing air movement and efficiency. For example, blades engineered with an airfoil shape are specifically designed to reduce turbulence and enhance air flow, whereas a steeper blade pitch can increase air movement but may also elevate noise levels. Modern DC axial fans incorporate aerodynamic blade designs and lightweight materials, which further optimize air movement patterns and enhance overall efficiency.

When selecting a fan, it is imperative to evaluate the of your application, including environmental conditions, and to choose a blade design that aligns with those needs. Recent advancements in blade technology, such as bionic designs, have been developed to improve airflow patterns and efficiency. These innovative designs not only enhance performance metrics but also contribute to quieter operation through the integration of noise reduction technologies, making them suitable for a wide range of applications within the electronics industry. Furthermore, considering the need for waterproof or dust-resistant devices is crucial for ensuring reliability in challenging environments.

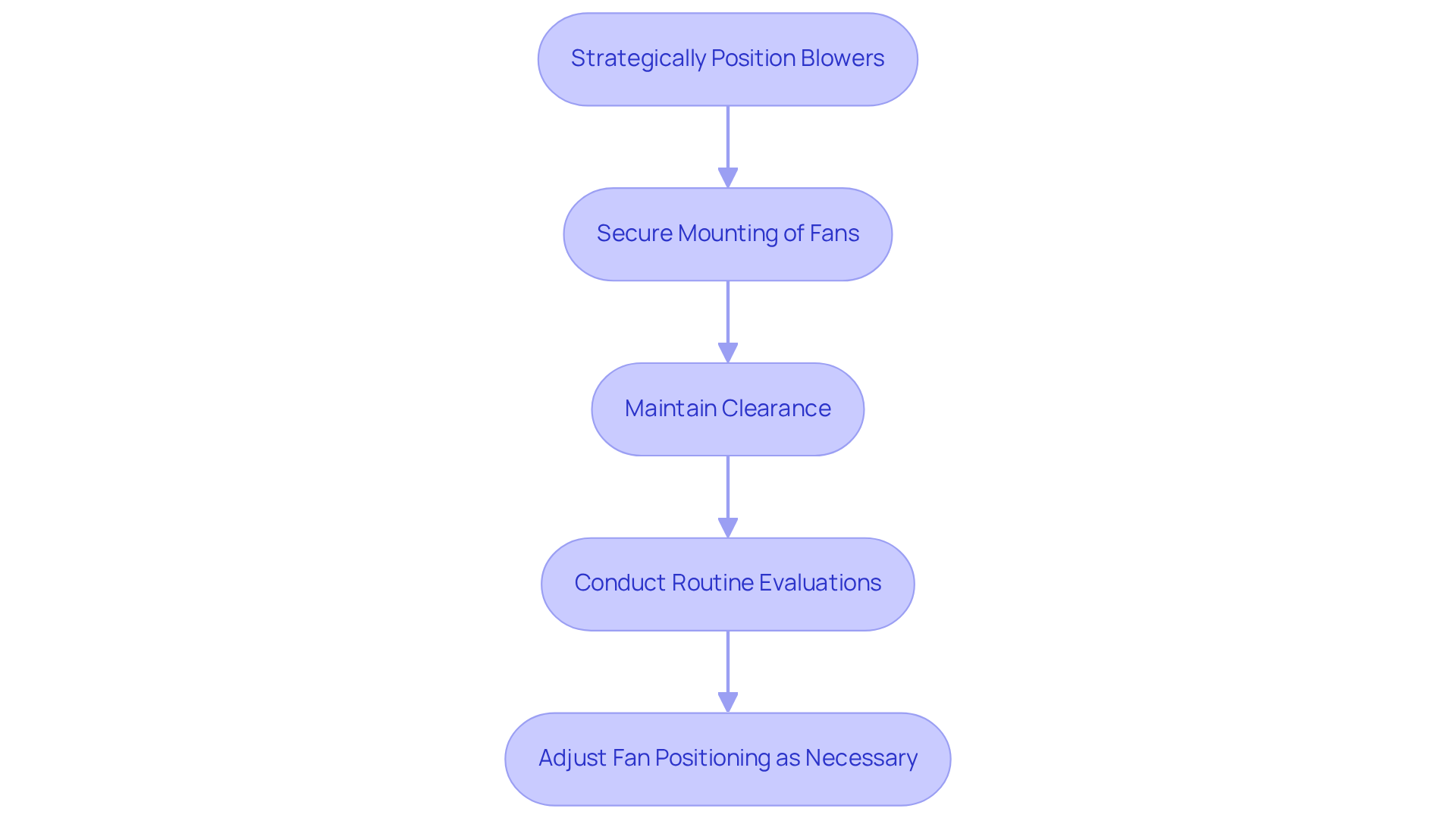

Space Limitations: Optimizing Fan Placement for Effective Cooling

In space-constrained applications, optimizing fan placement is essential for achieving effective temperature regulation. Strategically position the blowers to ensure unobstructed airflow to and from the components being cooled. Utilizing several smaller devices rather than a single large unit can , ensuring that all areas of the system receive adequate temperature control.

- Secure mounting of fans is critical, along with maintaining sufficient clearance around them to prevent airflow restrictions.

- Conduct routine evaluations of temperature regulation, allowing for adjustments in fan positioning as necessary to uphold ideal operating temperatures.

- Thermal engineers emphasize that a thoughtful fan arrangement can significantly influence system reliability and efficiency, particularly in compact designs where every inch counts.

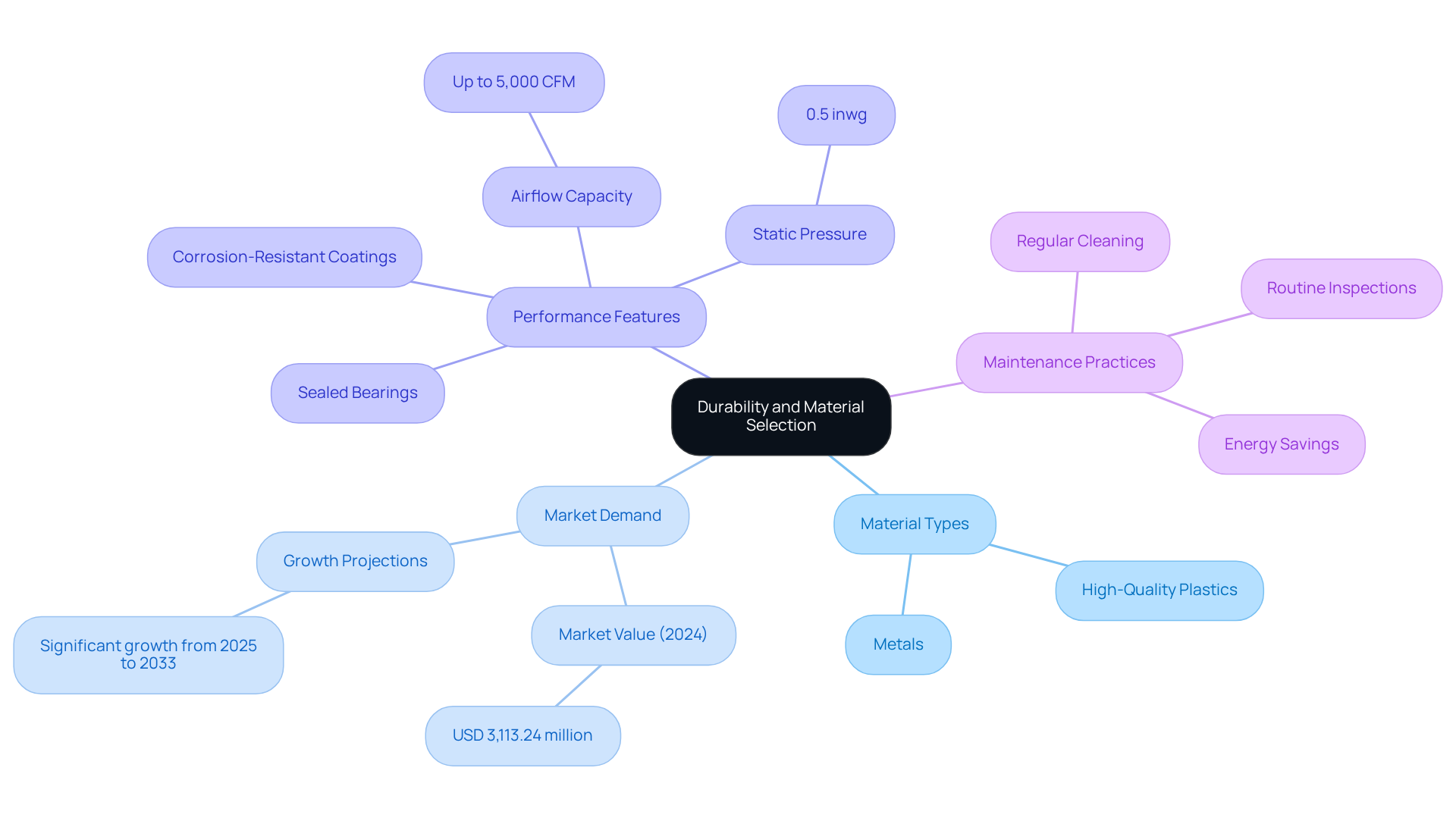

Durability and Material Selection: Ensuring Long-Lasting Fan Performance

Selecting a DC axial fan necessitates careful consideration of materials, as this choice is crucial for ensuring the durability and longevity of the fan. Fans made from high-quality plastics or metals demonstrate superior resistance to wear and tear, significantly extending their lifespan. Essential features such as sealed bearings and corrosion-resistant coatings are particularly important in demanding environments where moisture or contaminants are prevalent.

The DC axial fan market, valued at USD 3,113.24 million in 2024, underscores the increasing demand for durable cooling solutions. These fans can (CFM) with a static pressure of 0.5 inches of water gauge (inwg), showcasing their impressive efficiency even under challenging conditions. Regular maintenance practices, including thorough cleaning and routine inspections, are vital for prolonging fan life and ensuring optimal performance. Case studies have demonstrated that effective maintenance can yield significant energy savings, further highlighting the importance of quality materials and upkeep strategies. By prioritizing material quality and implementing effective maintenance strategies, engineers can guarantee that their cooling solutions remain both reliable and efficient over time.

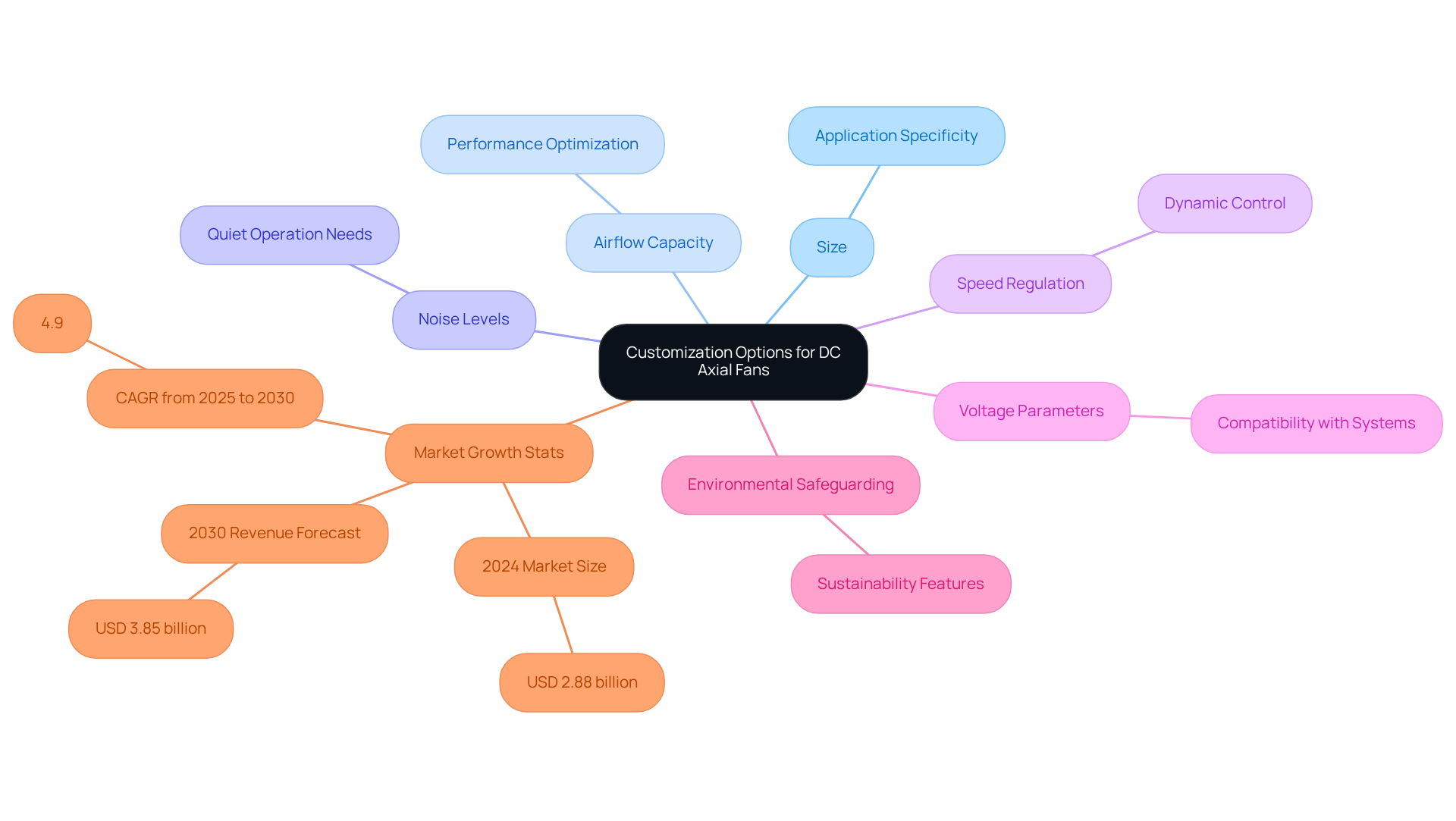

Customization Options: Tailoring DC Axial Fans to Meet Specific Requirements

Manufacturers increasingly recognize the critical need for customization in DC axial fan devices, empowering engineers to adjust key characteristics such as size, airflow capacity, and noise levels to suit specific applications. This customization encompasses vital elements like speed regulation, voltage parameters, and , ensuring that the devices meet the unique requirements of various settings.

Communicating your specific requirements effectively to the manufacturer is essential for achieving optimal results. By adopting a tailored approach, you can significantly enhance the performance and efficiency of your temperature control solutions. As the market for DC axial fans is projected to grow from USD 2.88 billion in 2024 to USD 3.85 billion by 2030, the trend toward customized solutions is increasingly relevant, particularly in the electronics sector where precision cooling is paramount. The average lead time for these customized solutions varies; however, manufacturers are often well-equipped to deliver tailored products efficiently, aligning with the fast-paced demands of the industry. Furthermore, the presence of major companies like Omron Corporation and Delta Fan in the competitive landscape underscores the importance of innovation and responsiveness in meeting engineers’ needs. The Asia-Pacific region’s dominance in the DC axial fan market further highlights the growing demand for customized solutions across diverse applications.

Conclusion

Selecting the right DC axial fan is a critical decision that ensures optimal cooling in electronic systems. This choice not only impacts thermal efficiency but also contributes to the longevity and performance of sensitive components. By understanding the various factors involved—such as airflow requirements, fan size, noise levels, static pressure ratings, energy efficiency, blade design, and customization options—engineers can make informed decisions that align with their specific cooling needs.

Key insights highlighted throughout the article include:

- The importance of accurately assessing airflow needs based on heat output.

- The significance of selecting appropriately sized fans for effective airflow.

- The necessity of considering noise levels in sensitive environments.

The discussion on static pressure ratings emphasizes how overcoming airflow resistance is essential for maintaining optimal cooling efficiency. Furthermore, the growing trend towards energy-efficient and customizable solutions illustrates the need for engineers to stay informed about advancements in fan technology.

Ultimately, the choice of DC axial fans significantly influences the reliability and efficiency of electronic systems. By prioritizing these factors and leveraging expert guidance, engineers can enhance their cooling strategies, ensuring that their systems operate effectively while contributing to sustainability efforts. As the demand for high-performance cooling solutions continues to rise, making well-informed selections becomes increasingly vital for success in the electronics industry.

Frequently Asked Questions

What services does Gagner-Toomey Associates provide?

Gagner-Toomey Associates offers expert guidance on selecting DC axial fans for optimal cooling in the electronics sector, focusing on customized solutions for engineers.

Why are DC axial fans important for electronic components?

DC axial fans are crucial for achieving optimal thermal efficiency, helping to maintain performance and longevity by effectively managing air movement and thermal management.

What key factors should be considered when selecting DC axial fans?

Key considerations include airflow rates, noise levels, and energy efficiency, all of which are vital for effective temperature control.

What is the projected market growth for axial ventilation?

The axial ventilation market is projected to reach US$ 3.93 billion by 2031, highlighting the increasing emphasis on energy-efficient technologies.

How do you assess the airflow requirements for an electronics system?

To assess airflow requirements, determine the total heat output of the components in watts (W) and aim for approximately 1 CFM (cubic feet per minute) per watt of heat output, adjusting based on specific applications and environmental conditions.

What recent advancements have impacted thermal management solutions?

Recent advancements include smart co-engineering solutions that capture over 95% of heat from CPUs, significantly enhancing efficiency in high-performance systems.

How does system layout affect airflow management?

The system layout and potential barriers to airflow must be considered to ensure effective air circulation, preventing hotspots and ensuring consistent temperature distribution.

What should you consider when choosing the size of a DC axial fan?

Consider the available space within your enclosure, including height, width, and depth, as well as the fan’s mounting configuration to ensure optimal performance and airflow efficiency.

What are common sizes for DC axial fans?

Common fan sizes include 40mm, 80mm, and 120mm, with many manufacturers offering custom sizes tailored to specific needs.

How can optimizing fan size affect performance?

Optimizing fan size can yield an efficiency boost of up to 30%, enhancing airflow and reducing noise and vibration, which are crucial for the reliability of electronic systems.

What certifications should be evaluated when selecting a fan?

Certifications like RoHS and ISO are important to ensure compliance with environmental and quality standards.

How can custom DC axial fans benefit electronic devices?

Custom DC axial fans can be engineered to meet specific cooling needs, ensuring that even compact electronic devices receive sufficient airflow for effective thermal management.