Overview

The article emphasizes the critical features of 3 phase exhaust fans that engineers must consider:

- Energy efficiency

- Noise control

- Durability

- Airflow capacity

- Ease of installation

- Safety features

- Control options

- System compatibility

- Manufacturer support

Each feature is articulated with specific benefits and technological advancements, such as variable frequency drives that contribute to energy savings and sound-dampening technologies aimed at noise reduction. These elements are crucial for optimizing performance and ensuring reliability across various applications.

Understanding these features enables engineers to make informed decisions that enhance operational efficiency and performance. By prioritizing energy efficiency, for instance, engineers can significantly reduce operational costs while maintaining optimal airflow capacity. Noise control technologies not only improve the working environment but also ensure compliance with regulatory standards.

Durability and ease of installation are equally important, as they directly impact maintenance costs and system downtime. Safety features, control options, and system compatibility further enhance the functionality and integration of exhaust fans into existing systems.

In conclusion, the selection of 3 phase exhaust fans should be guided by a comprehensive understanding of these essential features, supported by robust manufacturer assistance. This approach not only maximizes the performance of ventilation systems but also aligns with industry best practices.

Introduction

The evolution of cooling technology has ushered in a new era for engineers, particularly in the realm of 3 phase exhaust fans. These sophisticated systems promise not only enhanced energy efficiency and reduced operational costs but also address critical factors such as noise control, durability, and ease of maintenance. As the market for these fans expands, with projections indicating significant growth in the coming years, the question arises: what essential features must engineers consider to maximize performance and reliability in their designs? This article delves into the ten key attributes of 3 phase exhaust fans, offering insights that empower engineers to make informed decisions in their projects.

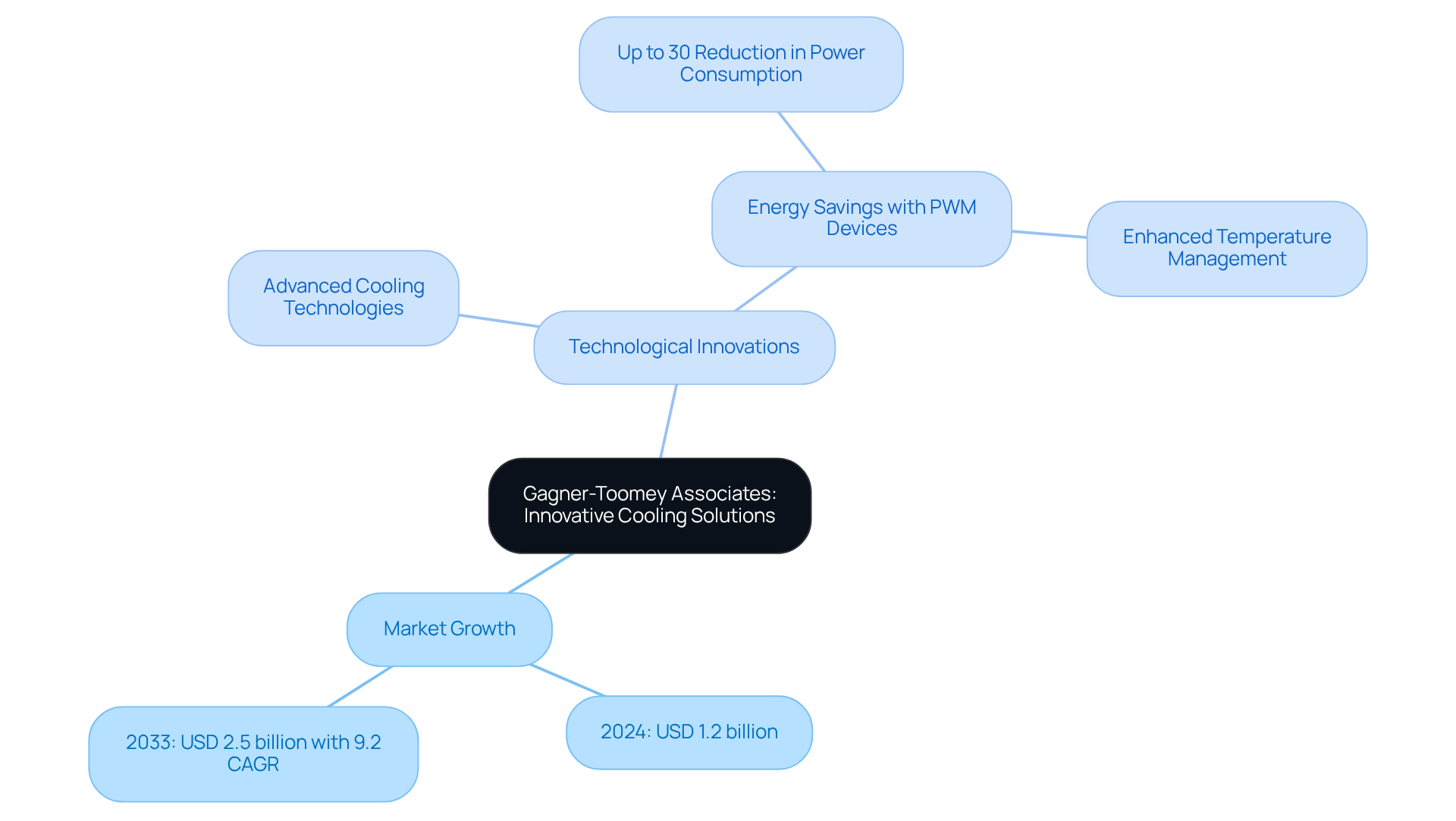

Gagner-Toomey Associates: Innovative Cooling Solutions for 3 Phase Exhaust Fans

Gagner-Toomey Associates stands at the forefront of delivering cutting-edge cooling solutions tailored for 3 phase exhaust fans. Their innovative approach harnesses advanced technologies to significantly enhance performance and energy conservation, ensuring that engineers have access to reliable and effective cooling systems. The adoption of these pioneering cooling technologies is witnessing a notable increase, with the Three Phase Cooling Fans Market projected to expand from USD 1.2 billion in 2024 to USD 2.5 billion by 2033, indicating a compound annual growth rate (CAGR) of 9.2%.

By collaborating with a diverse array of manufacturers, Gagner-Toomey plays a crucial role in developing products that meet the stringent demands of the electronics industry, especially in cooling applications. Successful implementations of advanced cooling technologies have demonstrated substantial energy savings, with PWM devices reducing power consumption by up to 30% compared to conventional models. This commitment to innovation not only enhances operational performance but also aligns with the industry’s growing emphasis on sustainability and energy conservation.

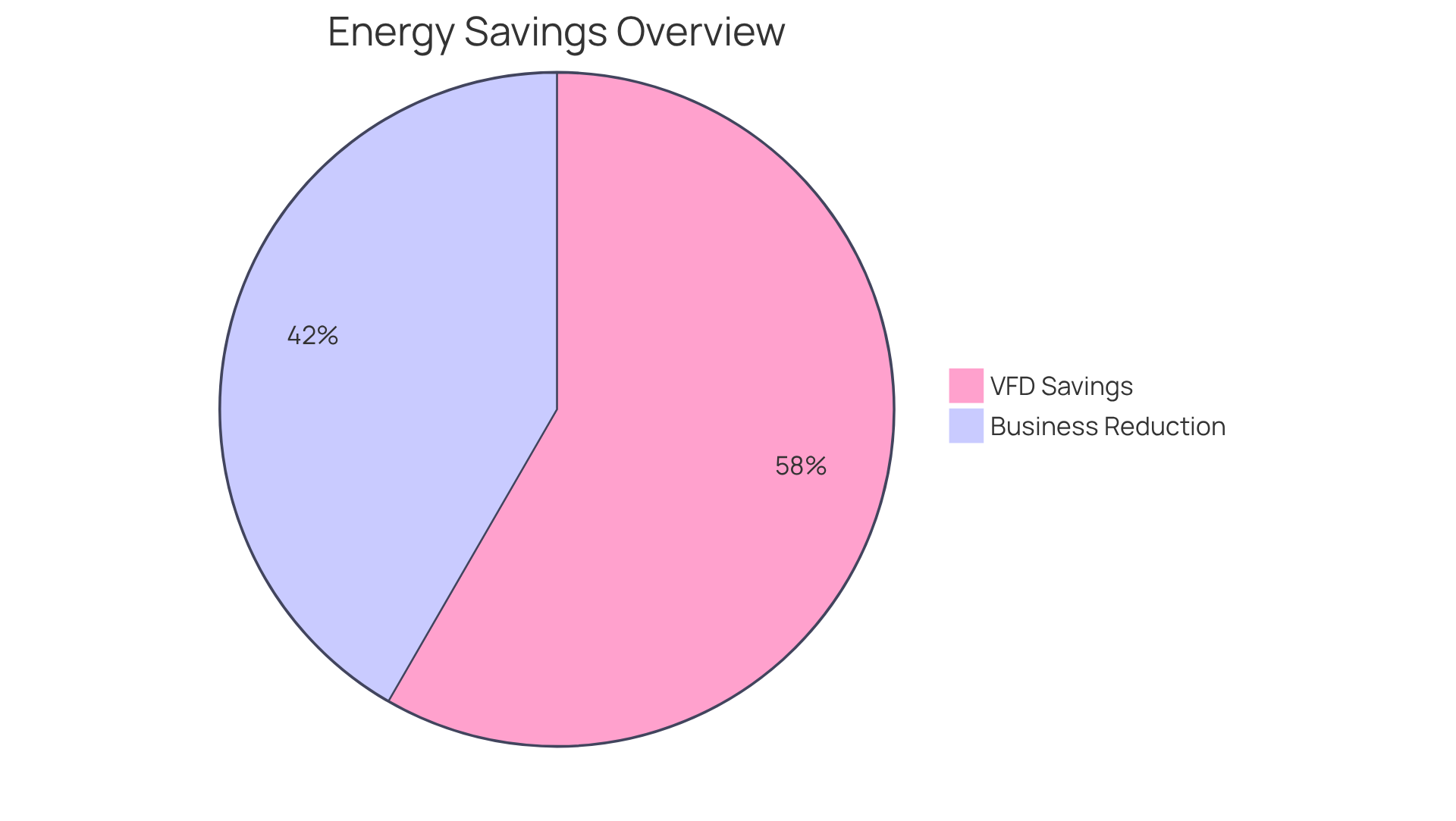

Energy Efficiency: Essential for Cost-Effective Operation

Energy conservation is crucial in the operation of 3 phase exhaust fans, as these systems are meticulously engineered to minimize energy consumption while maximizing airflow. The integration of variable frequency drives (VFDs) is instrumental in achieving this objective, allowing for precise regulation of fan speed. This capability empowers users to customize performance according to specific operational requirements, leading to a significant reduction in energy waste. For example, VFDs can facilitate energy savings of up to 70% in fan applications, with businesses experiencing a decrease in energy usage by as much as 50%, which translates to substantial reductions in electricity costs.

Moreover, the implementation of VFDs not only enhances operational flexibility but also prolongs equipment lifespan by reducing mechanical stress. This is achieved through features such as ‘soft start’ and ‘soft stop’, which mitigate wear and tear on components. By investing in energy-efficient models equipped with VFDs, engineers can realize considerable savings on utility bills while advancing sustainability goals, ultimately fostering a more eco-friendly environment.

Additionally, the affordability of VFDs has improved, thereby shortening the payback period for businesses. This development makes VFDs an economically viable option for enhancing energy efficiency, encouraging more organizations to adopt these advanced technologies.

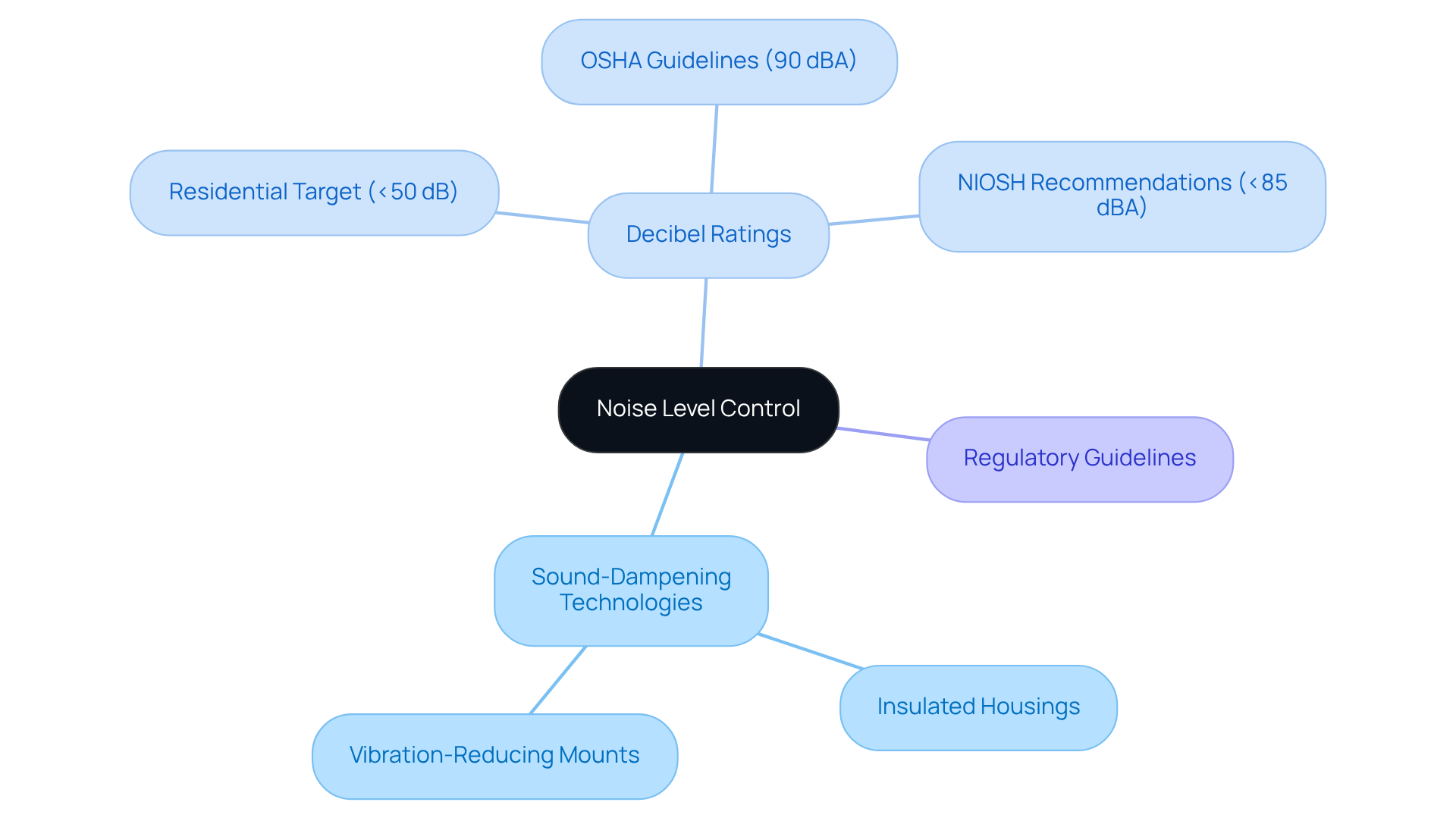

Noise Level Control: Ensuring a Quiet Operation

Noise level management is essential in designing a 3 phase exhaust fan, particularly in environments such as laboratories and commercial kitchens, where excessive noise can disrupt operations. Engineers must prioritize sound output, as many modern exhaust systems now incorporate advanced sound-dampening technologies. Features such as insulated housings and vibration-reducing mounts play a critical role in minimizing operational noise, thereby ensuring a quieter working environment.

Selecting devices with lower decibel ratings—typically below 50 dB for residential use—can enhance comfort and ensure compliance with noise regulations, which often set allowable exposure limits at 90 dBA according to OSHA and recommend levels below 85 dBA as per NIOSH guidelines. Furthermore, it is crucial to understand the logarithmic nature of decibel measurement; even minor changes in decibel levels can result in significant differences in perceived noise.

By integrating these sound-dampening features, engineers can design systems that not only meet quality benchmarks but also foster a more pleasant environment for users.

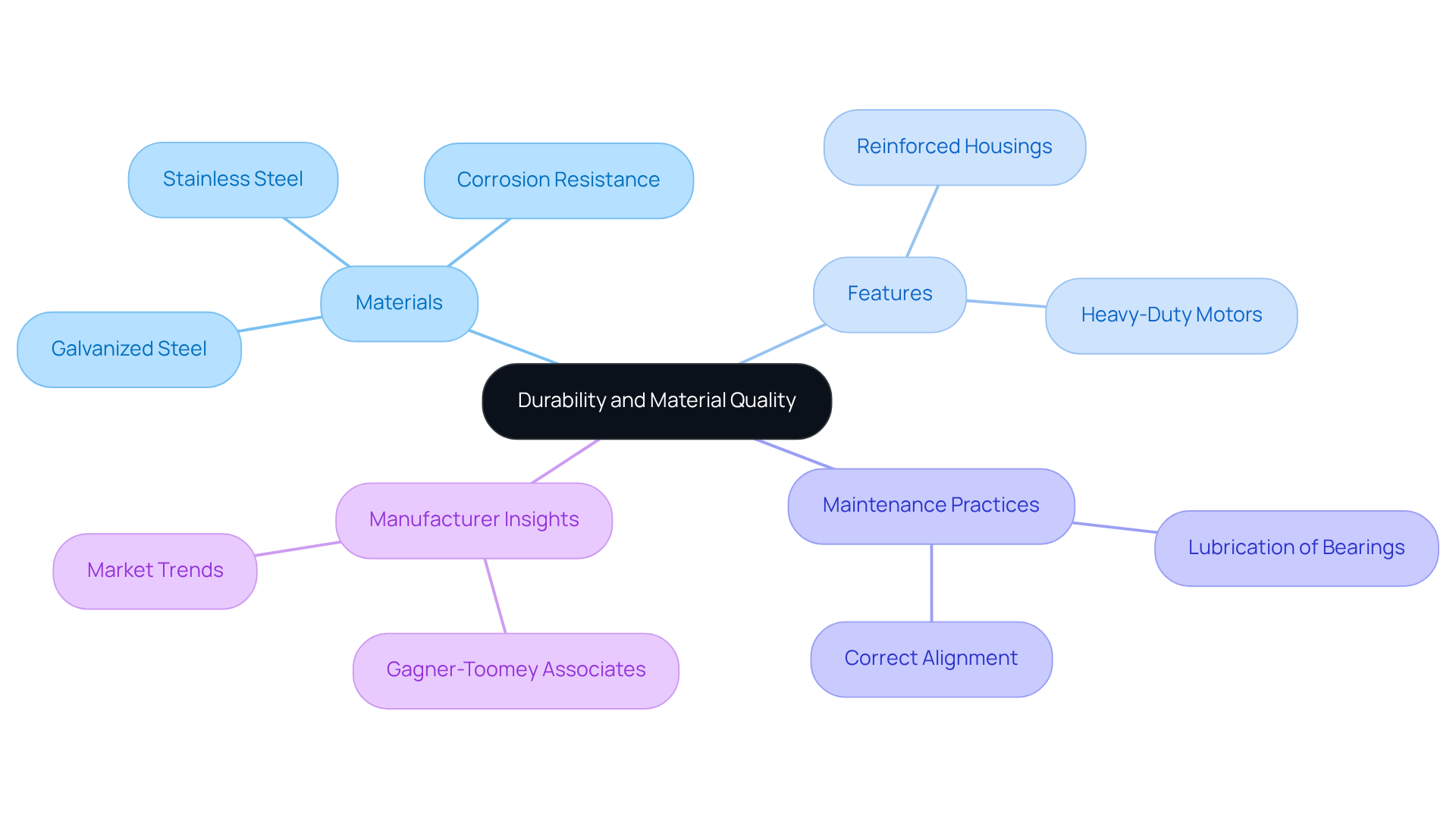

Durability and Material Quality: Key to Long-Lasting Performance

The durability of 3 phase exhaust fan units is fundamentally influenced by the materials chosen for their construction. Utilizing high-quality materials, such as galvanized steel and corrosion-resistant alloys like stainless steel, is crucial for enduring the harsh conditions often found in industrial environments. These materials not only resist corrosion but also enhance the fan’s overall strength and longevity.

Gagner-Toomey Associates, recognized as the globe’s largest producer of standard and custom air-movers, underscores the significance of durable materials in their product offerings. Their range encompasses DC input Tube Axial devices and Centrifugal Blowers, all fine-tuned for functionality and efficiency. Notably, many models offer IP protection, ensuring reliability across various applications. Stainless steel is particularly ideal for industries with stringent hygiene requirements, providing both strength and resistance to corrosion.

Features such as reinforced housings and heavy-duty motors further contribute to the fan’s durability, ensuring reliable operation over time. Engineers should prioritize 3 phase exhaust fans that have robust construction to minimize maintenance requirements and extend service life. The failure rates of inferior materials can lead to costly downtime and repairs, emphasizing the need for quality.

Furthermore, correct alignment and lubrication of bearings are crucial to reduce vibration and prolong fan lifespan, significantly influencing efficiency. The 3 phase exhaust fan, constructed with advanced materials, has demonstrated exceptional performance, showcasing its ability to withstand demanding applications while maintaining efficiency. To further enhance reliability, implementing a predictive maintenance program is advisable, as it can help identify potential issues before they lead to failures.

Airflow Capacity: Maximizing Ventilation Efficiency

Airflow capacity is a critical specification for a 3 phase exhaust fan, as it directly influences the volume of air transported per minute. Engineers must meticulously calculate the required airflow for effective ventilation in relation to a 3 phase exhaust fan tailored to specific applications. In environments characterized by high heat loads or elevated pollutant levels, devices with higher CFM (cubic feet per minute) ratings are essential. For example, in industrial settings, exhaust systems may need to achieve airflow rates exceeding 24,000 CFM to maintain optimal air quality and safety. By selecting devices that meet or surpass these airflow criteria, engineers can significantly enhance ventilation performance, thereby ensuring a safe and comfortable environment.

This focus on CFM ratings not only aids in compliance with ventilation standards but also promotes energy conservation. Systems designed with appropriate airflow capacities operate more efficiently, resulting in reduced operational costs and improved overall performance. Engineers are thus encouraged to prioritize airflow capacity in their designs, ensuring that their ventilation solutions are both effective and economical.

Ease of Installation and Maintenance: Enhancing Operational Efficiency

The design of the 3 phase exhaust fan units is crucial for minimizing downtime and enhancing operational efficiency. By incorporating features such as pre-wired connections and modular designs, installation processes are streamlined, significantly reducing setup time.

Furthermore, devices engineered for easy access to motors and filters facilitate routine maintenance, enabling quicker inspections and repairs. Statistics reveal that maintenance costs can be decreased by up to 40% with easy-access designs, which allow for more efficient servicing.

Additionally, 41% of manufacturers indicate that the lack of resources or staff poses their greatest challenge in maintenance, underscoring the necessity for efficient maintenance processes. Engineers must prioritize these maintenance-friendly features when selecting a 3 phase exhaust fan, ensuring it integrates seamlessly into existing systems and promotes long-term reliability.

As noted by Glacier Technology, ‘The benefits of a well-maintained industrial fan are far reaching,’ emphasizing the critical importance of these design considerations.

Safety Features: Protecting Users and Equipment

Safety attributes in a 3 phase exhaust fan are paramount for safeguarding both users and equipment from potential hazards. These units commonly incorporate safety mechanisms such as:

- Thermal overload protection, which effectively prevents motor overheating

- Automatic shut-off systems that engage in the event of a malfunction

Additionally, it is crucial to provide guards to protect supporters from accidental contact with moving components. Engineers must ensure that the selected ventilation devices, such as the 3 phase exhaust fan, comply with relevant safety standards, thus significantly reducing risks in the workplace.

Control Options: Customizing Fan Performance

Control options for the 3 phase exhaust fan are crucial in customizing functionality to meet specific operational requirements. The integration of technologies such as variable frequency drives (VFDs) facilitates precise speed control, empowering users to adjust airflow according to real-time conditions. Furthermore, the implementation of smart controls allows for seamless integration with building management systems, enabling automated operations that significantly enhance energy efficiency. Engineers are encouraged to thoroughly explore the available control options to optimize fan performance and adapt to ever-changing environmental needs.

System Compatibility: Ensuring Seamless Integration

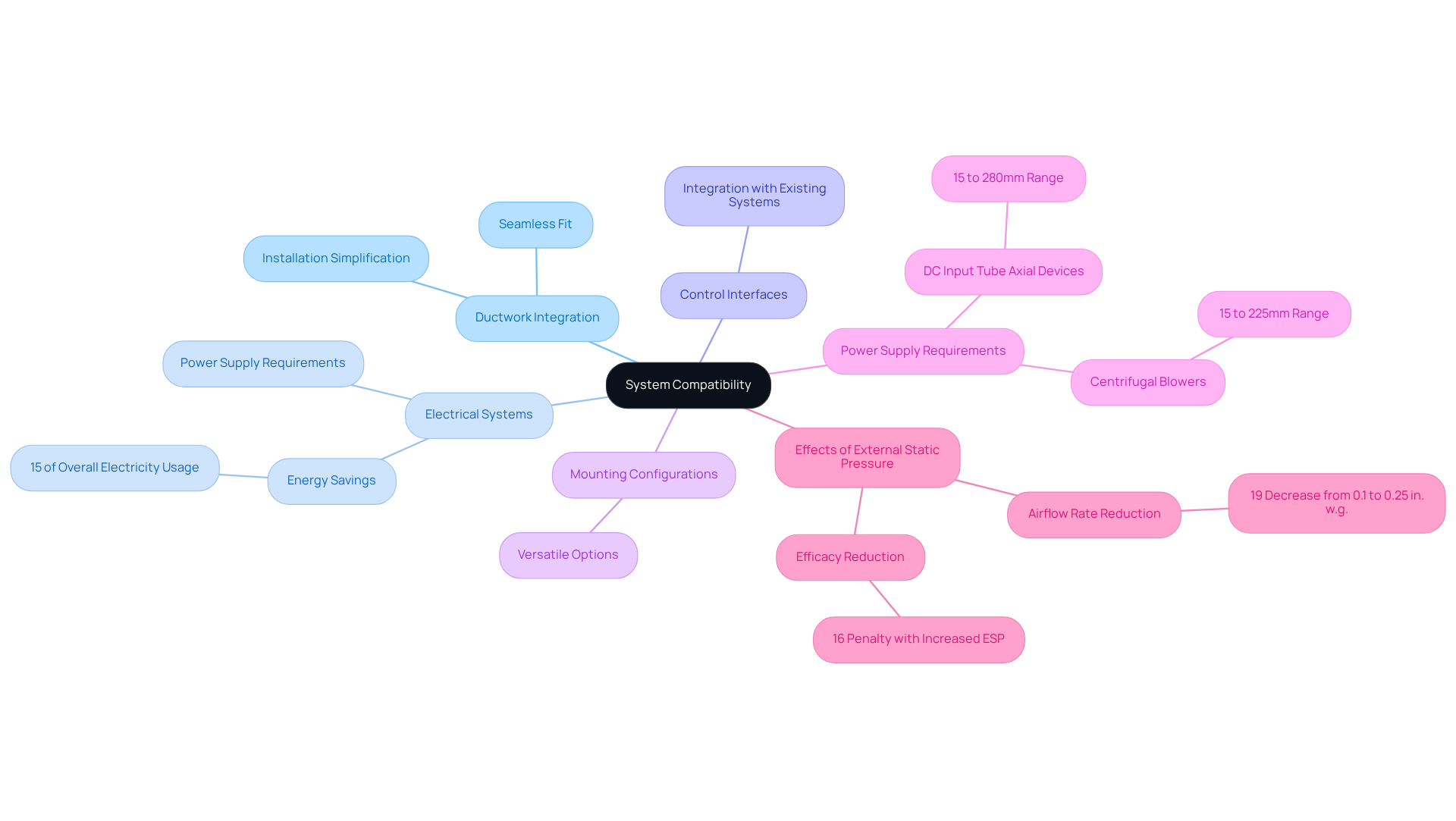

When selecting 3 phase exhaust fan units, system compatibility is paramount. Engineers must ensure that these units can integrate seamlessly with existing ductwork, electrical systems, and control interfaces. This compatibility extends to various mounting configurations and power supply requirements, which are crucial to prevent costly modifications during installation.

Gagner-Toomey Associates, a prominent producer of standard and custom air-movers, offers a diverse range of DC input tube axial devices, spanning from 15 to 280mm, alongside centrifugal blowers from 15 to 225mm, all optimized for functionality and effectiveness. Research indicates that efficient incorporation of ventilation systems can lead to significant energy savings, as these systems account for approximately 15% of overall electricity usage in home environments. Furthermore, increasing the external static pressure (ESP) from 0.1 to 0.25 in. w.g. results in a 19% decrease in average fan airflow rate and a 16% reduction in efficacy.

By selecting devices designed for seamless integration, such as those from Gagner-Toomey’s extensive selection, engineers can simplify installation processes and enhance overall system functionality. This ultimately contributes to improved energy efficiency and reduced operational expenses. Understanding the nuances of integration challenges is essential, as it facilitates the optimization of existing systems while minimizing disruptions and maximizing functionality.

Manufacturer Support and Warranty: Ensuring Reliability and Peace of Mind

When selecting a 3 phase exhaust fan, the level of manufacturer support and warranty is crucial for ensuring reliability and peace of mind. Gagner-Toomey Associates (GTA) excels in this aspect, having cultivated robust relationships with engineers across diverse industries such as Telecom, Automotive, and Medical. A strong warranty from GTA not only reflects their confidence in the durability and performance of their products but also reassures clients about their investment. Satisfied customers, like Joseph Dir. from Delta Products Corp., emphasize GTA’s exceptional support, highlighting its significance in their operational success.

Furthermore, GTA’s responsive customer support proves invaluable, assisting engineers with installation, troubleshooting, and maintenance inquiries. This comprehensive support structure not only enhances the user experience but also fosters long-term satisfaction. By prioritizing manufacturers like GTA that provide extensive support and warranty options, engineers can effectively safeguard their investments, ensuring both reliability and peace of mind.

Conclusion

The exploration of 3 phase exhaust fans highlights their essential role in engineering applications, particularly in enhancing performance, energy efficiency, and operational reliability. Understanding key features such as energy efficiency, noise control, durability, and advanced control options enables engineers to make informed decisions that lead to optimized ventilation solutions tailored to specific needs.

Key insights from this analysis underscore the importance of integrating technologies like variable frequency drives for energy savings, employing sound-dampening features for quieter operations, and selecting durable materials to ensure longevity. Moreover, the significance of ease of installation, robust safety features, and comprehensive manufacturer support cannot be overstated, as these factors contribute to the overall effectiveness and reliability of exhaust fan systems.

Ultimately, advancements in 3 phase exhaust fan technology promise not only improved performance but also alignment with sustainability goals and operational cost reductions. Engineers are encouraged to prioritize these features when selecting exhaust fans, ensuring that their systems are efficient, safe, and capable of meeting the demands of modern industrial environments. Embracing these innovations will enhance operational efficiency while facilitating a commitment to energy conservation and environmental responsibility.

Frequently Asked Questions

What innovative solutions does Gagner-Toomey Associates provide for 3 phase exhaust fans?

Gagner-Toomey Associates offers cutting-edge cooling solutions specifically designed for 3 phase exhaust fans, utilizing advanced technologies to enhance performance and energy conservation.

What is the projected growth of the Three Phase Cooling Fans Market?

The Three Phase Cooling Fans Market is projected to grow from USD 1.2 billion in 2024 to USD 2.5 billion by 2033, with a compound annual growth rate (CAGR) of 9.2%.

How do advanced cooling technologies contribute to energy savings?

Advanced cooling technologies, such as PWM devices, can reduce power consumption by up to 30% compared to conventional models, leading to substantial energy savings.

Why is energy efficiency important for 3 phase exhaust fans?

Energy efficiency is crucial as it minimizes energy consumption while maximizing airflow, which helps reduce operational costs and aligns with sustainability goals.

How do variable frequency drives (VFDs) improve energy efficiency in fan applications?

VFDs allow for precise regulation of fan speed, enabling users to customize performance, leading to energy savings of up to 70% and a potential decrease in energy usage by 50%.

What additional benefits do VFDs provide beyond energy savings?

VFDs enhance operational flexibility and prolong equipment lifespan by reducing mechanical stress through features like ‘soft start’ and ‘soft stop’, which minimize wear and tear on components.

How have the costs of VFDs affected their adoption by businesses?

The affordability of VFDs has improved, resulting in shorter payback periods for businesses, making them an economically viable option for enhancing energy efficiency.

Why is noise level control important in 3 phase exhaust fan design?

Noise level control is essential in environments like laboratories and commercial kitchens where excessive noise can disrupt operations, making sound management a priority in fan design.

What technologies are used to manage noise levels in exhaust fans?

Advanced sound-dampening technologies, such as insulated housings and vibration-reducing mounts, are incorporated to minimize operational noise and create a quieter working environment.

What are the recommended noise levels for residential and occupational settings?

For residential use, devices should ideally have decibel ratings below 50 dB, while OSHA sets allowable exposure limits at 90 dBA, recommending levels below 85 dBA as per NIOSH guidelines.