Overview

This article provides a comprehensive analysis of the performance differences between axial and centrifugal fans, emphasizing their design, efficiency, application suitability, and cost considerations. It establishes that axial fans are optimal for high airflow at low pressure, rendering them ideal for ventilation applications. In contrast, centrifugal fans are superior in high-pressure scenarios, which is essential for systems that demand precise airflow regulation. This knowledge equips engineers to make informed decisions tailored to specific project requirements.

Introduction

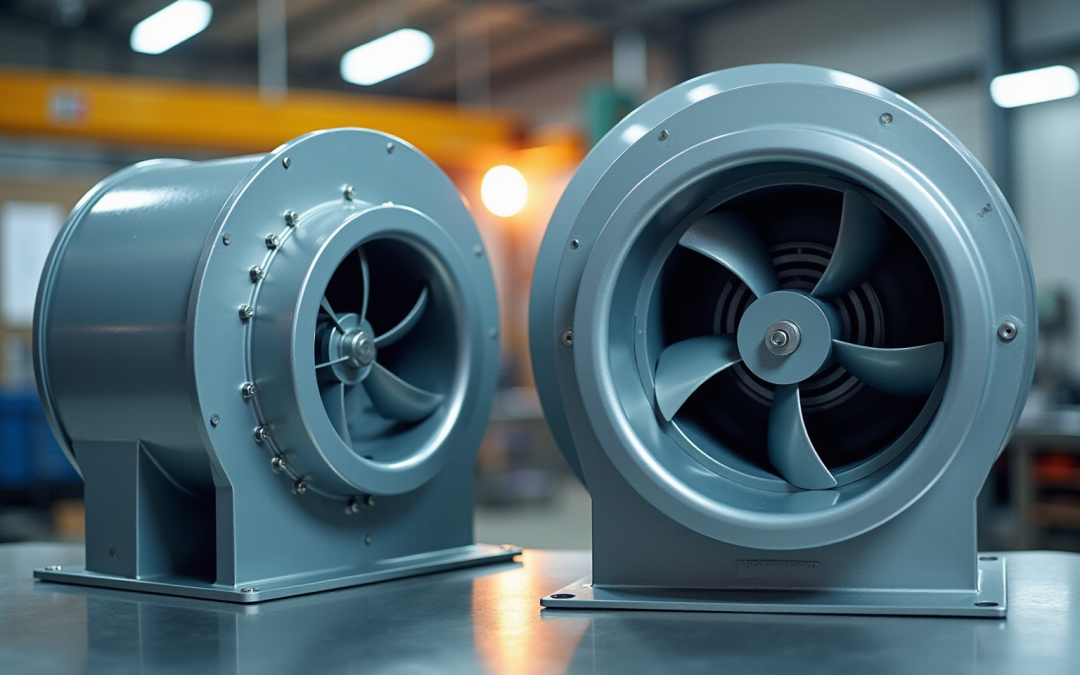

In the competitive landscape of the electronics industry, effective cooling solutions are paramount for ensuring optimal performance and longevity of critical components. Gagner-Toomey Associates stands at the forefront of this sector, offering an impressive range of axial and centrifugal fans tailored to meet diverse cooling needs.

As technology continues to advance, the demand for efficient airflow management becomes increasingly significant, with projections indicating substantial market growth. This article delves into the innovative designs and applications of axial and centrifugal fans, exploring their unique functionalities, efficiency metrics, and the critical factors engineers must consider when selecting the right cooling solution for their specific projects.

Understanding these dynamics not only aids in making informed decisions but also highlights the essential role of cooling technologies in driving industry success.

Gagner-Toomey Associates: Innovative Cooling Solutions for Axial and Centrifugal Fans

Gagner-Toomey Associates stands at the forefront of state-of-the-art temperature control solutions tailored for the electronics industry. As the leading producer of both standard and custom air movers globally, their expertise in axial vs centrifugal fan designs enables them to meet a wide array of temperature regulation requirements, ensuring optimal performance and energy efficiency. Their comprehensive product lineup includes:

- DC input tube radial devices ranging from 15 to 280mm

- Centrifugal blowers from 15 to 225mm

All featuring advanced technologies that enhance airflow management and thermal control. This commitment to innovation positions them as a trusted partner for engineers in search of efficient temperature control solutions, especially considering the projected growth of the axial vs centrifugal fan market, anticipated to reach USD 7,715.55 million by 2033.

The market for axial vs centrifugal fans, marked by relatively low barriers to entry, has experienced heightened competition, influencing both pricing and innovation. As highlighted by industry leader Anglo American, the integration of advanced systems in their operations ensures equipment longevity and energy efficiency, underscoring the practical applications of these temperature-regulating technologies.

Recent findings from the case study titled “Qualitative Insights into Market Trends” indicate that while the market is evolving, challenges such as high initial costs, limited availability of skilled labor, and complex regulatory compliance persist as significant obstacles for engineers. Understanding these factors is crucial for navigating the broader market landscape and informing strategic planning within the temperature control technology sector. Gagner-Toomey’s cutting-edge temperature regulation solutions, which encompass an extensive range of thermal management products such as:

- Extruded aluminum heatsinks

- Copper-based heat sinks

Play a vital role in addressing these challenges, ultimately shaping the future of electronic temperature management.

Axial Fans: Design, Functionality, and Key Applications

The operation of axial vs centrifugal fan devices involves moving air parallel to their axis of rotation, using blades that create a pressure difference to facilitate airflow. This straightforward design allows for high airflow rates, which makes the comparison of axial vs centrifugal fan particularly relevant in applications that demand efficient cooling within low-pressure environments. As of 2025, directional blowers are recognized for their efficiency, with design enhancements significantly boosting their performance across various sectors. Recent data indicates that horizontal blowers have seen a marked improvement in efficiency, contributing to their growing acceptance in the market.

Common applications encompass HVAC systems, where the comparison of axial vs centrifugal fan adeptly circulates air, and electronic temperature management, where they regulate heat dissipation in sensitive components. Additionally, industrial ventilation systems benefit from fans due to their ability to swiftly move large volumes of air. Recent case studies, including one titled “,” underscore their pivotal role in HVAC and electronic cooling, demonstrating how innovative designs have enhanced functionality and reliability. These case studies highlight the importance of forecasting models in predicting future consumption and resource distribution within the fan market.

Furthermore, market segmentation of ventilation devices reveals diverse applications across regions such as Eastern Europe, Russia, South America, Brazil, the Middle East, and Africa, underscoring the global relevance of these units. As the demand for efficient temperature regulation continues to rise, these ventilators remain essential in the electronics sector, providing critical support for high-performance applications. As noted by Serdal Holding, a UAE-based holding company, the emphasis on promoting and developing varied businesses highlights the necessity of reliable cooling solutions across multiple sectors.

Centrifugal Fans: Mechanism, Benefits, and Common Uses

Centrifugal blowers operate by drawing air into their center and expelling it at a right angle through an impeller. This design enables them to generate significantly higher pressures than those produced by an axial vs centrifugal fan, making them especially efficient in applications that require overcoming resistance in ductwork, such as exhaust systems and air conditioning units.

In 2025, centrifugal blowers are increasingly recognized for their vital role in industrial processes, particularly in pneumatic systems that convey materials like grains, powders, and sawdust. Their ability to maintain consistent airflow is critical in these settings, ensuring efficient operation.

Furthermore, advancements in have enhanced their performance metrics, allowing for improved pressure capabilities and energy efficiency. Understanding the limitations of centrifugal blowers, especially in comparison to axial vs centrifugal fan performance related to static and dynamic pressure, is essential for accurate specification and installation, ensuring optimal performance in practical applications.

Installation errors can lead to underperformance, underscoring the importance of meticulous planning. Industry leaders highlight that these devices are versatile, accommodating various airflow and pressure combinations, which enhances their utility across multiple sectors.

As Gagner-Toomey Associates strives to assist clients in bringing world-changing ideas to market, recognizing the significance of fan housing shape and size for performance is crucial. As Angela Edward noted, “Centrifugal blowers are beneficial for various airflow/pressure combinations,” emphasizing their versatility across different applications.

Comparative Analysis: Key Differences Between Axial and Centrifugal Fans

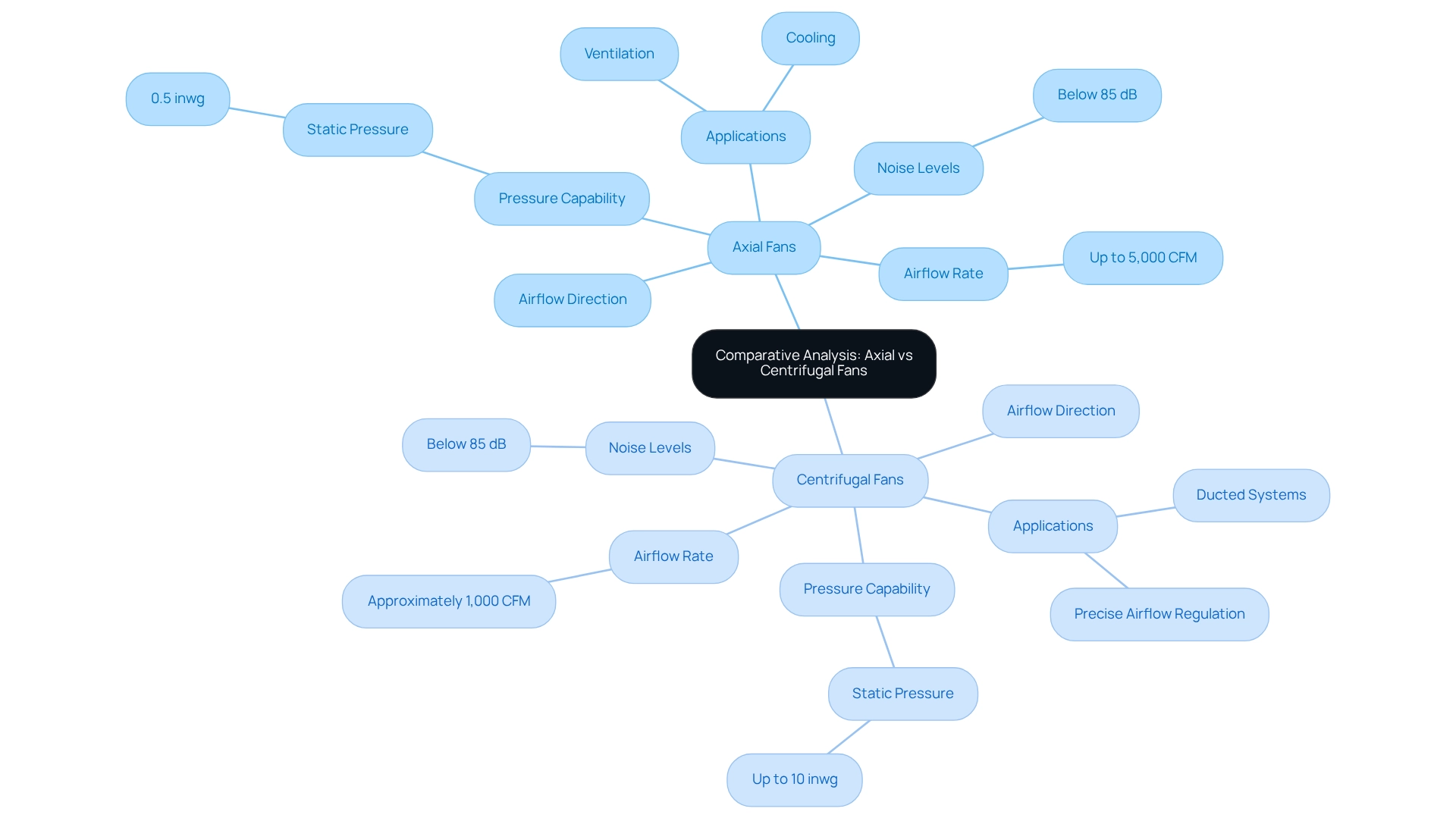

The fundamental distinction between axial vs centrifugal fan devices lies in their airflow direction and pressure capabilities. When comparing , it is clear that axial devices are engineered to move substantial volumes of air at low pressures, making them particularly effective for ventilation and cooling applications. They can achieve airflow rates of up to 5,000 cubic feet per minute (CFM) with a static pressure of 0.5 inches of water gauge (inwg). In contrast, when comparing axial vs centrifugal fan designs, centrifugal blowers are specifically engineered for high-pressure situations, ensuring steady airflow even against resistance. These devices can produce pressures up to 10 inwg while sustaining a volumetric airflow of approximately 1,000 CFM, making them ideal for ducted systems and environments that require precise airflow regulation.

Noise levels in workplace settings must be maintained below 85 dB to prevent hearing loss, a significant consideration when selecting fans for various applications. Practical uses underscore the differences in performance when considering axial vs centrifugal fan. For instance, Pelonis Technologies emphasizes the necessity of choosing the appropriate fan based on specific requirements and environmental factors. Key considerations include:

- The size of the space to be cooled

- The operating environment

- Mounting options

All of which are crucial for making an informed decision. Their customized guidance ensures optimal performance and satisfaction across diverse industrial and commercial applications. As industry specialist Ryan Smoot observes, ‘Choosing the optimal choice will genuinely rely on the intended use, available space, and overall thermal demands of the final system.’ This tailored approach, coupled with planned maintenance and equipment upgrades, is essential for maximizing efficiency and ensuring long-term performance.

Efficiency and Performance: Evaluating Axial vs Centrifugal Fans

In terms of efficiency, rotary devices excel in low-resistance applications, utilizing less power while delivering high airflow rates with minimal energy input. This characteristic renders them particularly advantageous for ventilation and cooling tasks, where space and energy conservation are paramount.

For example, Mainstream Fluid & Air LLC showcases its expertise in the comparison of axial vs centrifugal fan equipment, underscoring its versatility, which can be customized to various specifications, including size and airflow rate, to meet specific operational needs. Conversely, centrifugal systems, while generally requiring more energy, are engineered to generate higher static pressure and maintain consistent airflow. This design makes them ideal for applications encountering greater resistance, such as ducted systems or scenarios where airflow must navigate significant obstacles.

Recent analyses suggest that centrifugal units are increasingly preferred in situations demanding robust performance, with energy consumption statistics indicating a notable rise in their usage despite higher energy demands.

As we approach 2025, energy consumption statistics indicate that straight-flow systems continue to lead in efficiency metrics, particularly in environments characterized by low resistance. Engineers must meticulously evaluate these performance characteristics to select the most suitable fan type, specifically considering , for their cooling requirements, thereby ensuring optimal operation and energy efficiency in their designs.

The growing trend toward online purchasing is reshaping the distribution landscape for specific devices, simplifying access for engineers to a broader array of options tailored to their unique specifications. A representative from a Global Consulting Firm noted, ‘Our company has been collaborating with them for several years now, and we are very satisfied with the quality of the reports provided by the company.’ This statement underscores the critical role of reliable information in making informed decisions regarding fan performance.

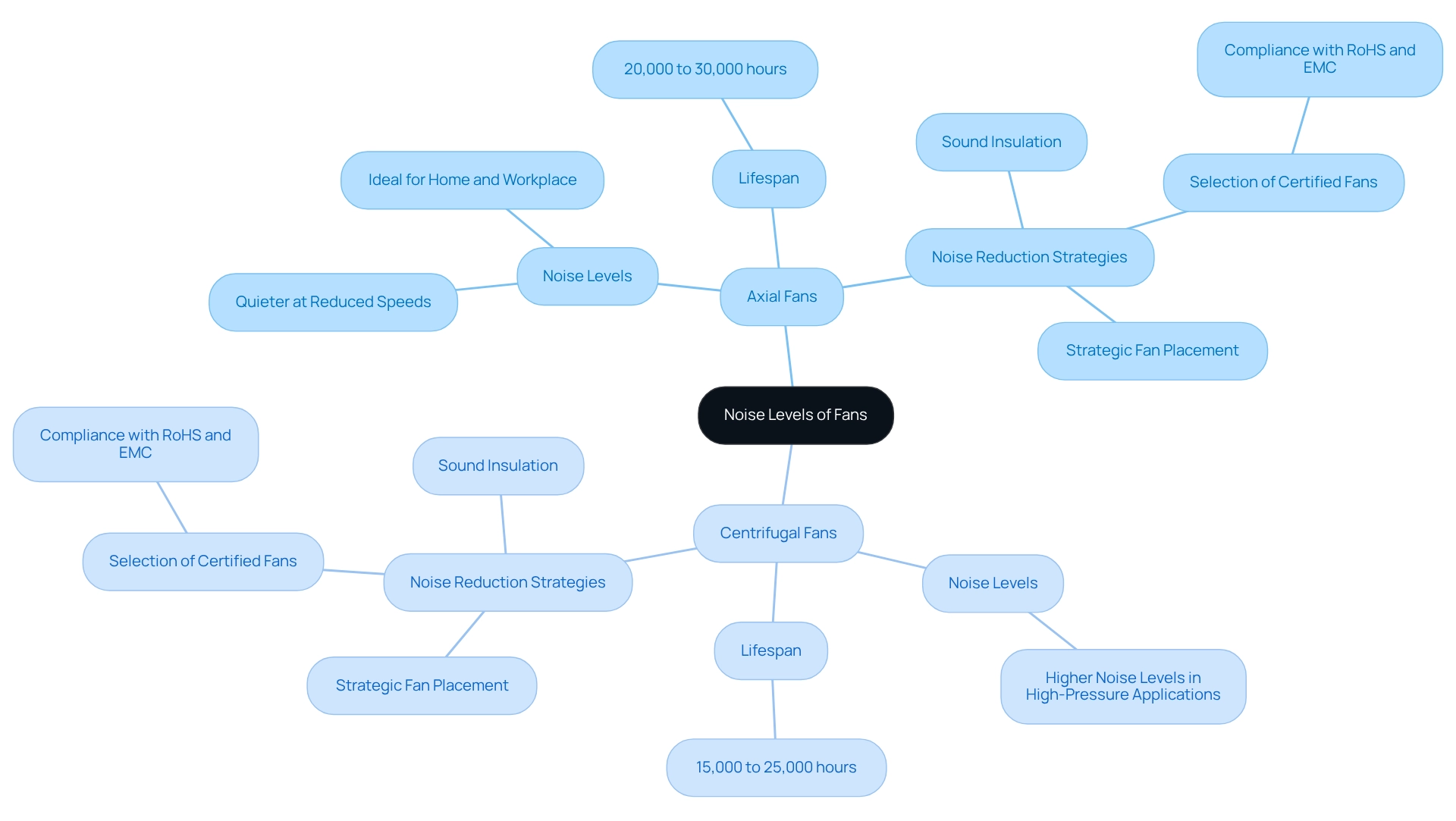

Noise Levels: Understanding the Acoustic Impact of Axial and Centrifugal Fans

Noise levels between axial vs centrifugal fans exhibit significant differences that can greatly influence their application across various settings. When considering axial vs centrifugal fan options, it is evident that axial blowers typically operate at , particularly at reduced speeds, making them ideal for home and workplace environments where auditory comfort is paramount. In contrast, when discussing axial vs centrifugal fans, centrifugal blowers generate higher noise levels, especially in high-pressure applications, due to their inherent design and operational characteristics. For instance, the lifespan of an industrial axial blower ranges from 20,000 to 30,000 hours, while centrifugal blowers generally last between 15,000 and 25,000 hours. This longevity can impact noise performance over time, as wear and tear may exacerbate noise levels in centrifugal designs.

Engineers must prioritize noise reduction strategies to mitigate the acoustic impact of fan installations in sensitive environments. Techniques such as:

- Sound insulation

- Strategic fan placement

- Selection of certified fans—compliant with safety and environmental standards like RoHS and EMC

can significantly contribute to quieter operations. A case study titled ‘Environmental and Safety Considerations’ underscores that selecting certified devices not only ensures compliance but also fosters safer and more environmentally friendly operations, which is essential in contemporary engineering practices. Real-world examples illustrate that implementing these strategies can lead to substantial reductions in noise levels, thereby enhancing the overall user experience in residential applications.

As the industry evolves, understanding the acoustic effects of cooling devices remains crucial, particularly in light of ongoing advancements in technology and design. Shira Daltrop’s findings reveal that foliage test results demonstrated both scattering and absorption, affecting barrier performance by as much as 4 dB. This underscores the necessity of considering acoustic performance during fan selection. By taking these factors into account, engineers can make informed decisions that effectively balance performance with noise control.

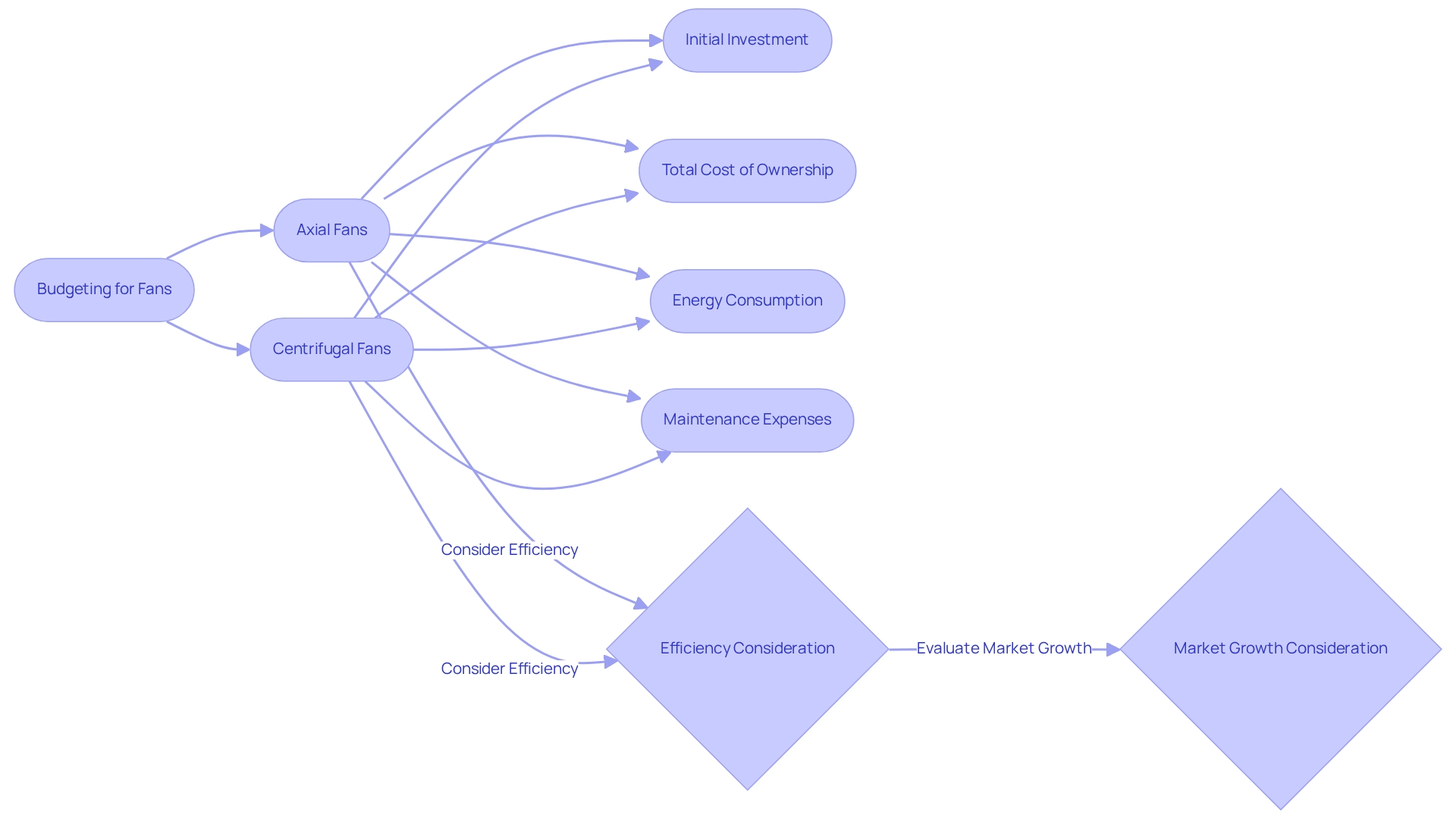

Cost Considerations: Budgeting for Axial and Centrifugal Fans

When budgeting for ventilation devices, the comparison of axial vs centrifugal fan types typically shows that axial types necessitate a smaller initial investment compared to centrifugal types. However, a comprehensive analysis of total cost of ownership is essential, as it encompasses not only the purchase price but also energy consumption and maintenance expenses.

While axial vs centrifugal fan comparisons may indicate that centrifugal fans involve higher upfront costs, they frequently offer , potentially leading to reduced operational costs over time. Regular maintenance, such as cleaning and proper installation, can significantly enhance the longevity and efficiency of both fan types, as demonstrated in case studies focused on optimal fan performance.

These studies indicate that consistent maintenance can result in improved airflow and temperature regulation, ultimately impacting the overall cost of ownership favorably. Furthermore, the European axial fan market is anticipated to witness moderate growth, with a CAGR of approximately 4.8%, highlighting the importance of fan selection within the electronics industry.

Engineers must carefully evaluate both immediate and long-term financial implications to make informed purchasing decisions, particularly when considering the differences between axial vs centrifugal fan options, ensuring that their choice aligns with the specific cooling requirements of their projects in the electronics sector.

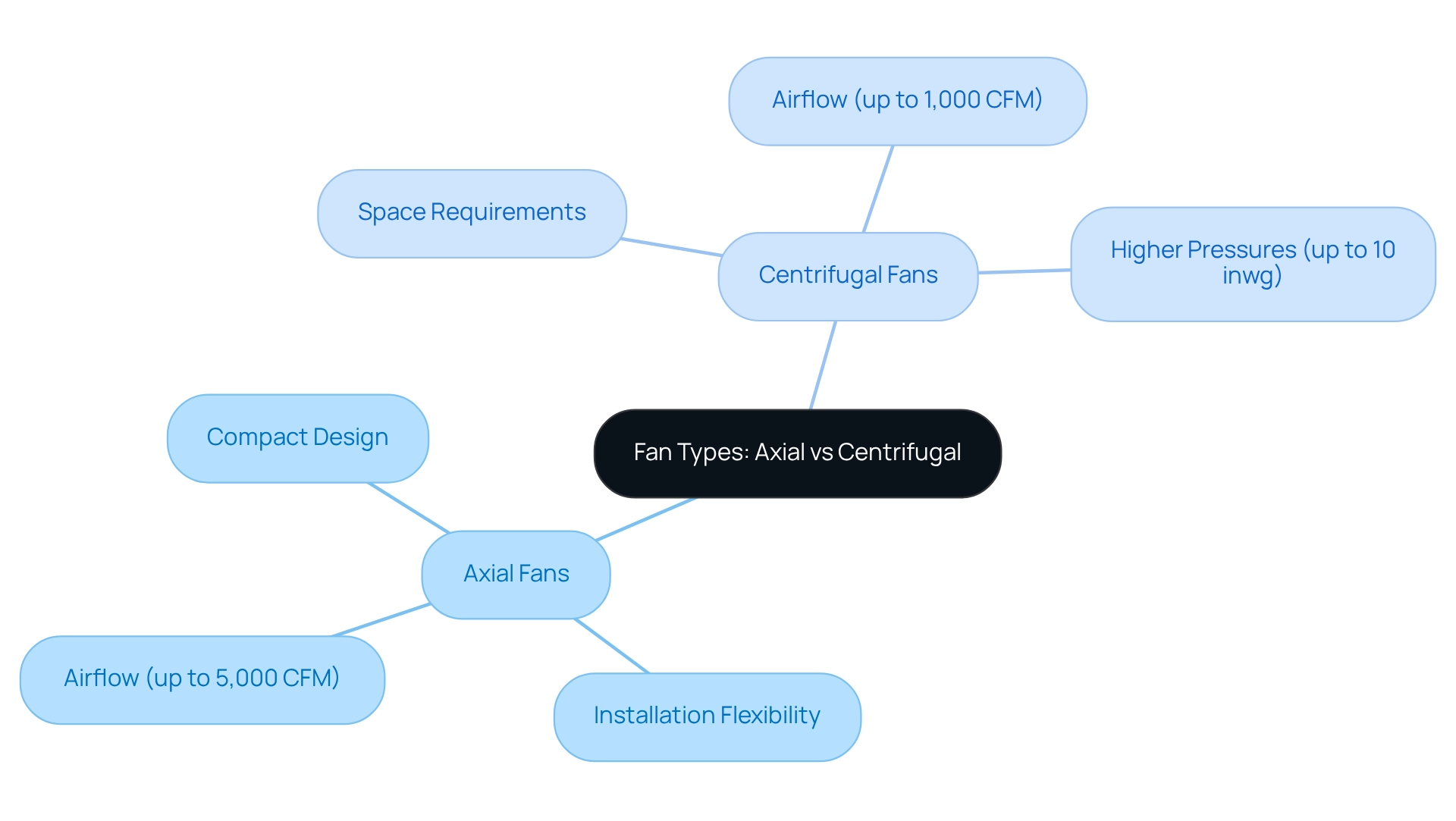

Installation and Space Requirements: Axial vs Centrifugal Fans

Axial blowers are celebrated for their compact designs, rendering them particularly suitable for installations in confined spaces. Their versatility facilitates mounting in various orientations, thereby enhancing installation flexibility. In contrast, when comparing axial vs centrifugal fans, centrifugal blowers typically demand more space due to their larger dimensions and the ducting required for efficient operation.

Proper installation is crucial for both fan types to attain optimal performance; this necessitates careful consideration of airflow direction and required clearance. For example, high-performance units in the comparison of axial vs centrifugal fan can move up to 5,000 cubic feet of air per minute (CFM) with a static pressure of 0.5 inwg, while centrifugal devices can generate pressures of up to 10 inwg with a volumetric airflow of 1,000 CFM.

Furthermore, airfoil (AF) impellers, designed akin to airplane wings, are recognized as the most efficient configuration, which is vital for engineers to contemplate when selecting fan types. Case studies underscore the importance of adhering to environmental and safety regulations, such as RoHS and EMC certifications, which ensure that devices operate safely and reliably, ultimately enhancing the overall quality of the system.

Understanding these installation requirements is essential for engineers to make informed decisions when for their specific applications. However, it is important to recognize that centrifugal blowers have a limitation; they generally exhibit reduced airflow rates compared to radial blowers, which can impact their efficiency in certain applications.

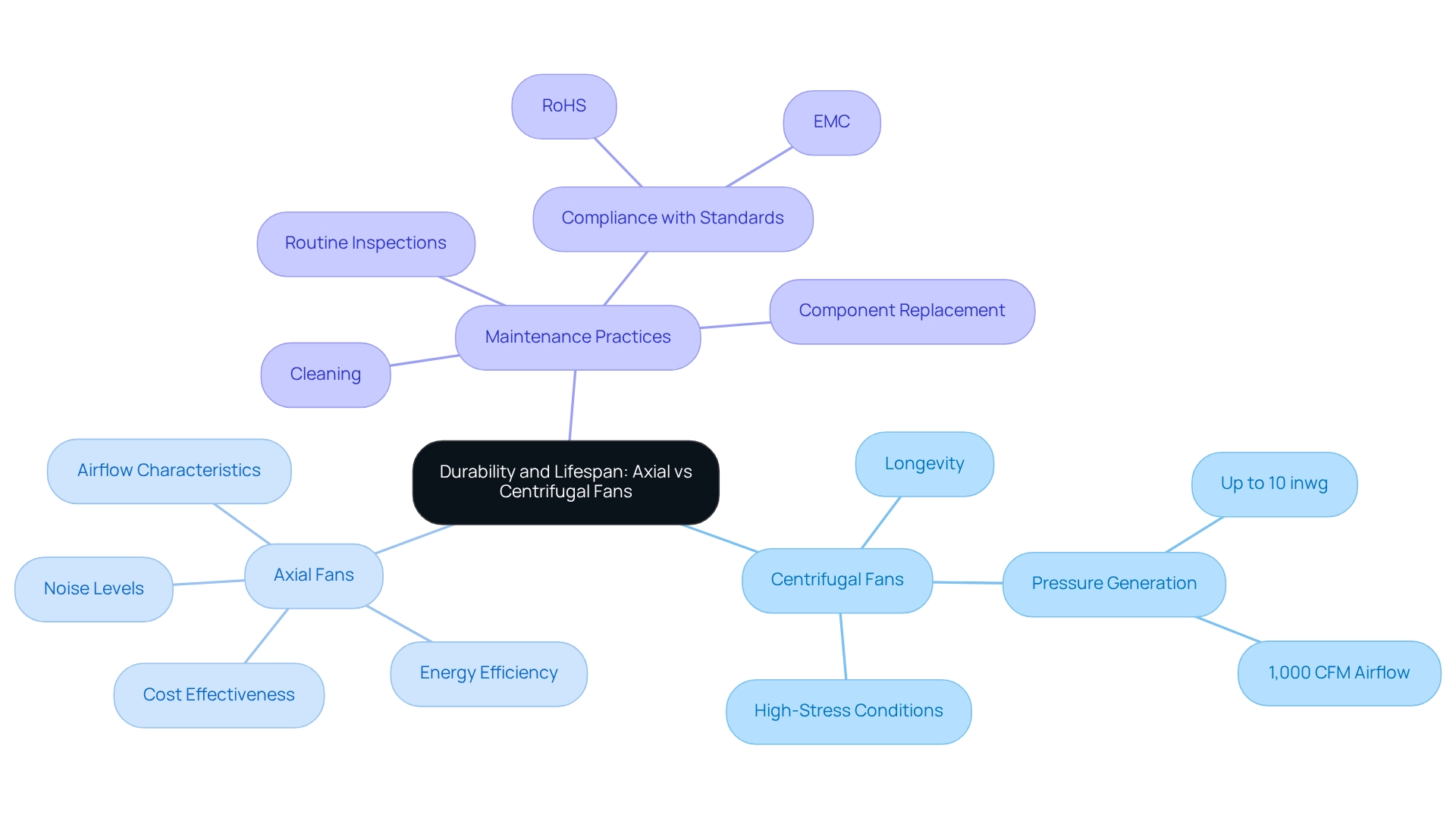

Durability and Lifespan: Comparing Axial and Centrifugal Fans

Centrifugal blowers are renowned for their longevity, often outlasting other types due to their robust design and ability to operate in harsh environments. These devices can while maintaining a volumetric airflow of 1,000 CFM, making them ideal for demanding applications. However, while these blowers are generally reliable, they may experience a reduced lifespan under high-stress conditions. Data shows that HVAC blowers, including both axial vs centrifugal fan types, typically last between 15 to 20 years, although this can vary significantly based on specific applications and maintenance practices. To enhance the longevity of both types, regular maintenance is essential. Implementing routine inspections, cleaning, and timely replacements of worn components can greatly extend their operational life. Moreover, compliance with environmental and safety regulations, such as RoHS and EMC, ensures that these devices not only function reliably but also contribute to overall system safety and efficiency. Real-world examples illustrate that organizations prioritizing maintenance and adhering to these standards witness improved fan performance and durability, particularly in challenging environments.

Key Maintenance Practices:

- Conduct routine inspections to identify wear and tear.

- Clean ventilation systems regularly to prevent dust accumulation.

- Replace worn components promptly to maintain efficiency.

- Ensure compliance with environmental and safety standards to enhance reliability and safety.

Choosing the Right Fan: Axial vs Centrifugal for Your Application

Selecting involves engineers evaluating several critical factors in the context of axial vs centrifugal fan. Airflow needs are paramount; in the comparison of axial vs centrifugal fan, axial blowers excel in delivering high airflow at low pressure, making them ideal for applications such as ventilation and cooling of extensive spaces. In contrast, when considering axial vs centrifugal fan options, centrifugal blowers are designed for high-pressure environments, making them perfect for systems requiring concentrated airflow, such as HVAC systems, and pressure requirements also significantly influence fan selection.

For example, in scenarios where air must be pushed through filters or ductwork, the comparison of axial vs centrifugal fan often shows that centrifugal blowers are favored due to their capability to sustain performance under higher resistance, while space constraints and noise levels are additional considerations. When considering the differences in design, the axial vs centrifugal fan comparison reveals that axial fans typically feature a more compact design, advantageous in confined areas, while centrifugal models may operate more quietly depending on the specific application. Budget considerations cannot be overlooked; both the initial cost and long-term operational efficiency can impact the decision-making process. Engineers must also assess the specific temperature regulation needs of their applications, as the right fan can profoundly affect system performance.

Recent market trends indicate a growing demand for effective temperature regulation solutions, with the AC axial fans market anticipated to expand due to technological advancements and increased efficiency requirements. The overall market size is projected to reach USD 19.18 million in 2024, growing at a CAGR of 8.7%. This underscores the necessity of making informed decisions based on current industry developments.

Moreover, the case study titled ‘Outlook for AC Axial Fans Market’ suggests that the market is expected to experience positive growth driven by rising demand for effective temperature regulation solutions. This highlights the importance for engineers to remain abreast of market dynamics when selecting fan types.

As noted by Cognitive Market Research, the direct sales segment holds the largest share in the global Cooling Fan market, emphasizing the significance of understanding market trends in fan selection.

Ultimately, by meticulously assessing airflow and pressure needs, space constraints, noise levels, and budgetary limitations, alongside expert guidance and real-world examples of decision-making processes, engineers can make informed choices that align with their cooling requirements and project objectives.

Conclusion

In the rapidly evolving electronics industry, the significance of effective cooling solutions is paramount. Gagner-Toomey Associates stands at the forefront with their advanced axial and centrifugal fans, meticulously designed to meet a diverse array of cooling needs while ensuring optimal performance and energy efficiency. This article has delved into the unique functionalities of these fans, illuminating their applications across various sectors—from HVAC systems to industrial ventilation—and illustrating how they contribute to the longevity and reliability of critical electronic components.

The key differences between axial and centrifugal fans have been thoroughly elucidated, showcasing their distinct operational mechanisms and pressure capabilities. Axial fans excel in low-pressure environments, delivering high airflow rates with remarkable efficiency, whereas centrifugal fans are engineered for high-pressure applications, rendering them indispensable in scenarios that demand robust airflow management. The discussion surrounding efficiency metrics and noise levels further underscores the necessity of selecting the appropriate fan type based on specific application requirements.

As the demand for effective cooling solutions continues to escalate, engineers must adeptly navigate the complexities of fan selection with a clear understanding of their project needs. By meticulously considering factors such as installation space, cost implications, and performance characteristics, informed decisions can be made that not only enhance system efficiency but also align with the broader objectives of sustainability and innovation within the electronics industry. The ongoing advancements in fan technology herald a promising future, where tailored cooling solutions will play a pivotal role in driving industry success.

Frequently Asked Questions

What types of temperature control solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates offers state-of-the-art temperature control solutions specifically for the electronics industry, including standard and custom air movers, DC input tube radial devices, and centrifugal blowers.

What are the specifications of the air movers offered by Gagner-Toomey Associates?

Their product lineup includes DC input tube radial devices ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm.

How do Gagner-Toomey Associates’ products enhance airflow management and thermal control?

Their products feature advanced technologies that improve airflow management and thermal control, ensuring optimal performance and energy efficiency.

What is the projected growth of the axial vs centrifugal fan market?

The axial vs centrifugal fan market is anticipated to reach USD 7,715.55 million by 2033.

What challenges do engineers face in the axial vs centrifugal fan market?

Engineers face challenges such as high initial costs, limited availability of skilled labor, and complex regulatory compliance.

What types of thermal management products does Gagner-Toomey Associates offer?

They provide a range of thermal management products, including extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid temperature control solutions.

How do axial and centrifugal fans operate?

Axial fans move air parallel to their axis of rotation using blades to create a pressure difference, while centrifugal fans draw air into their center and expel it at a right angle through an impeller.

In what applications are axial and centrifugal fans commonly used?

Common applications include HVAC systems for air circulation, electronic temperature management for heat dissipation, and industrial ventilation systems for moving large volumes of air.

What advantages do centrifugal blowers have over axial fans?

Centrifugal blowers generate significantly higher pressures, making them efficient in applications requiring resistance overcoming, such as exhaust systems and air conditioning units.

What is important for the installation of centrifugal blowers?

Meticulous planning is essential to avoid installation errors that can lead to underperformance, ensuring optimal performance in practical applications.