Introduction

High-temperature blowers play a crucial role in electronics engineering, where effective heat management is essential for optimal system performance and reliability. These sophisticated devices not only improve thermal management but also significantly prolong the lifespan of vital components across various applications. As technology advances, however, engineers encounter the challenge of choosing the right blower solutions from a vast array of options. What key insights can guide engineers through the intricate landscape of high-temperature blower technology?

Understanding the significance of these blowers is paramount. They are designed to handle extreme temperatures, ensuring that electronic systems operate efficiently and remain reliable over time. This capability is particularly important in industries where performance and durability are non-negotiable. Yet, with the multitude of choices available, engineers must navigate this complexity with precision.

To effectively address this challenge, engineers should consider several factors when selecting high-temperature blowers. These include:

- The specific thermal requirements of their applications

- The blower’s efficiency ratings

- Its compatibility with existing systems

By focusing on these critical aspects, engineers can make informed decisions that enhance both performance and longevity.

In conclusion, as the demand for advanced thermal management solutions grows, so does the necessity for engineers to stay informed about the latest developments in high-temperature blower technology. By leveraging key insights and understanding the intricacies of these devices, they can ensure their systems not only meet but exceed performance expectations.

Gagner-Toomey Associates: Innovative Solutions for High-Temperature Blower Applications

Gagner-Toomey Associates leads the charge in high temp blower technology, addressing the unique challenges engineers face in the electronics sector. With a commitment to innovation, they provide tailored solutions that leverage advanced materials and cutting-edge design techniques. This ensures reliability and efficiency in demanding thermal environments.

By collaborating with top manufacturers, Gagner-Toomey equips engineers with access to state-of-the-art blowers. These blowers significantly enhance thermal management in critical applications, optimizing performance while extending the longevity of electronic components. This focus on innovation makes Gagner-Toomey an indispensable resource for professionals navigating the complexities of applications involving a high temp blower.

In a field where precision and reliability are paramount, Gagner-Toomey’s advancements not only address immediate challenges but also pave the way for future developments. Their expertise empowers engineers to achieve superior results, ensuring that they remain at the forefront of technology.

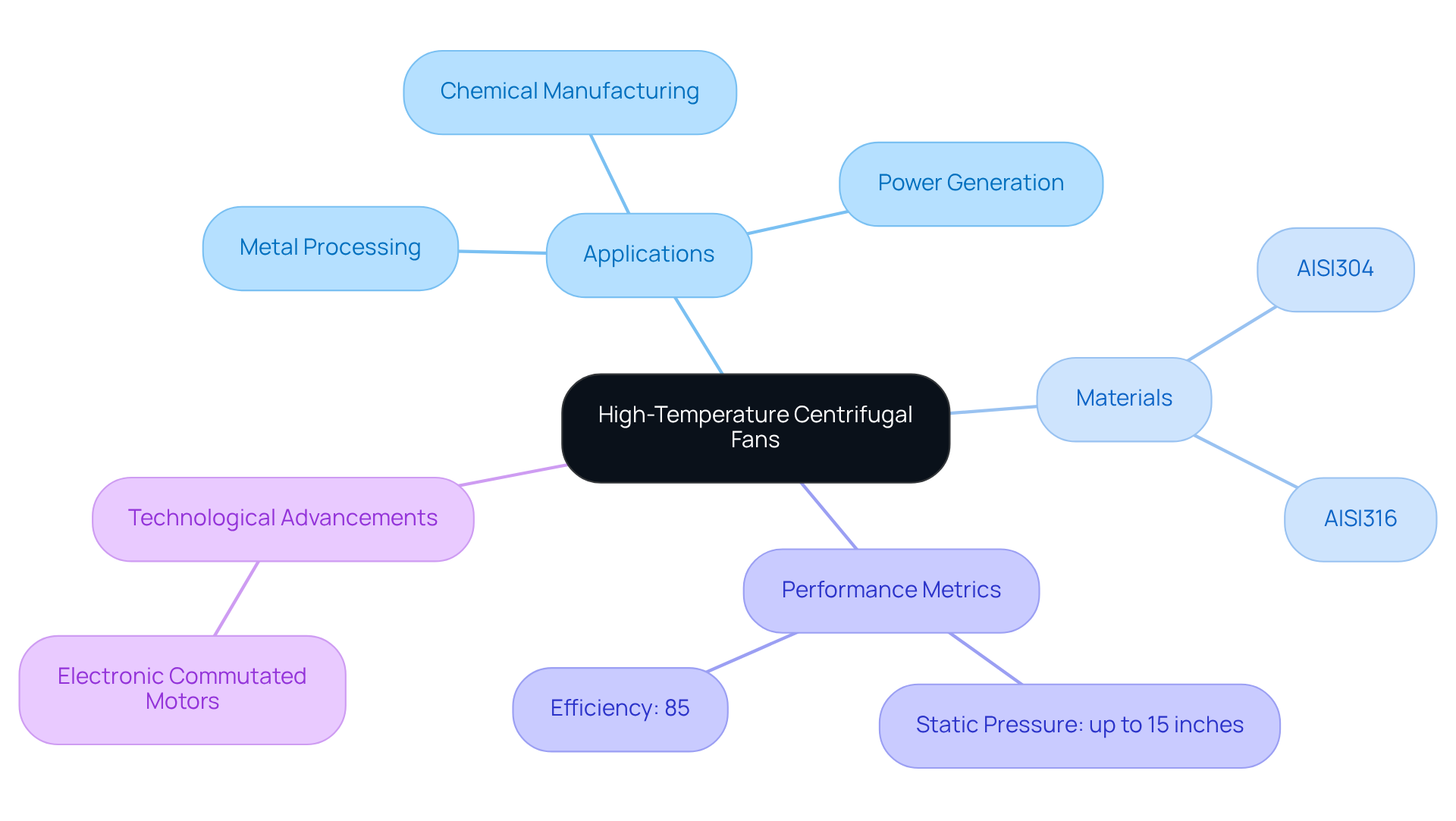

High-Temperature Centrifugal Fans: Essential for Industrial Processes

High temp blowers play a vital role in industrial processes where effective heat management is non-negotiable. These devices, engineered to withstand elevated temperatures, deliver high airflow rates and pressure, making them indispensable in demanding environments such as metal processing, chemical manufacturing, and power generation. Their robust construction, often utilizing materials like AISI304 and AISI316, guarantees durability and reliability even under extreme conditions.

Performance metrics reveal that these fans can achieve static pressures of up to 15 inches of water gauge, with efficiencies reaching an impressive 85%. This capability significantly enhances operational efficiency, a critical factor in industrial settings. Engineers emphasize the importance of selecting the right fan design and materials to optimize efficiency, particularly when using a high temp blower in high-temperature applications. As one engineer noted, the ability to adjust blower specifications can markedly improve system efficiency and effectiveness.

Recent advancements in blower technology, including the integration of Electronic Commutated Motors, further bolster energy efficiency. This innovation positions Gagner-Toomey’s elevated-temperature centrifugal units as a strategic investment for industrial operations, ensuring that businesses not only meet but exceed their performance goals.

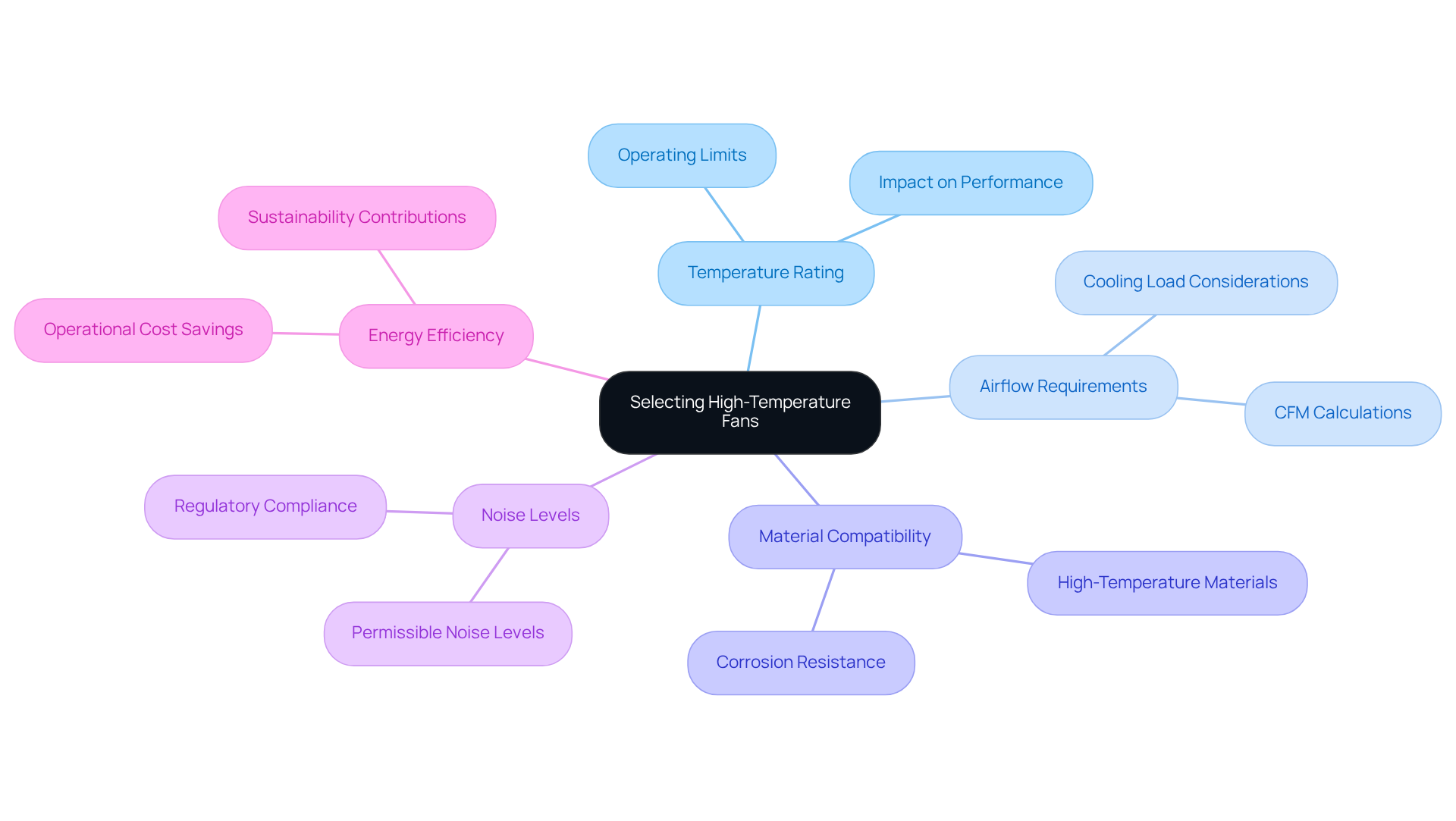

Selecting High-Temperature Fans: Key Considerations for Engineers

When selecting a high temp blower, engineers face critical considerations that can significantly impact performance and efficiency.

- Temperature Rating: It is essential to ensure that the fan can operate at the required temperature without compromising performance. This factor is crucial for maintaining system integrity under extreme conditions.

- Airflow Requirements: Calculating the necessary airflow (CFM) is vital to maintain optimal cooling. Insufficient airflow can lead to overheating and system failures.

- Material Compatibility: Selecting materials that can withstand high temperatures and corrosive environments is non-negotiable. The right materials will enhance durability and longevity.

- Noise Levels: Evaluating permissible noise levels for the application is important, as high temp blowers can be louder than standard units. This consideration affects both operational comfort and compliance with regulations.

- Energy Efficiency: Opting for devices that deliver high performance while minimizing energy usage is key to reducing operational expenses. Energy-efficient fans not only save costs but also contribute to sustainability efforts.

By carefully considering these factors, engineers can ensure the selection of high temp blowers that meet both performance and operational needs.

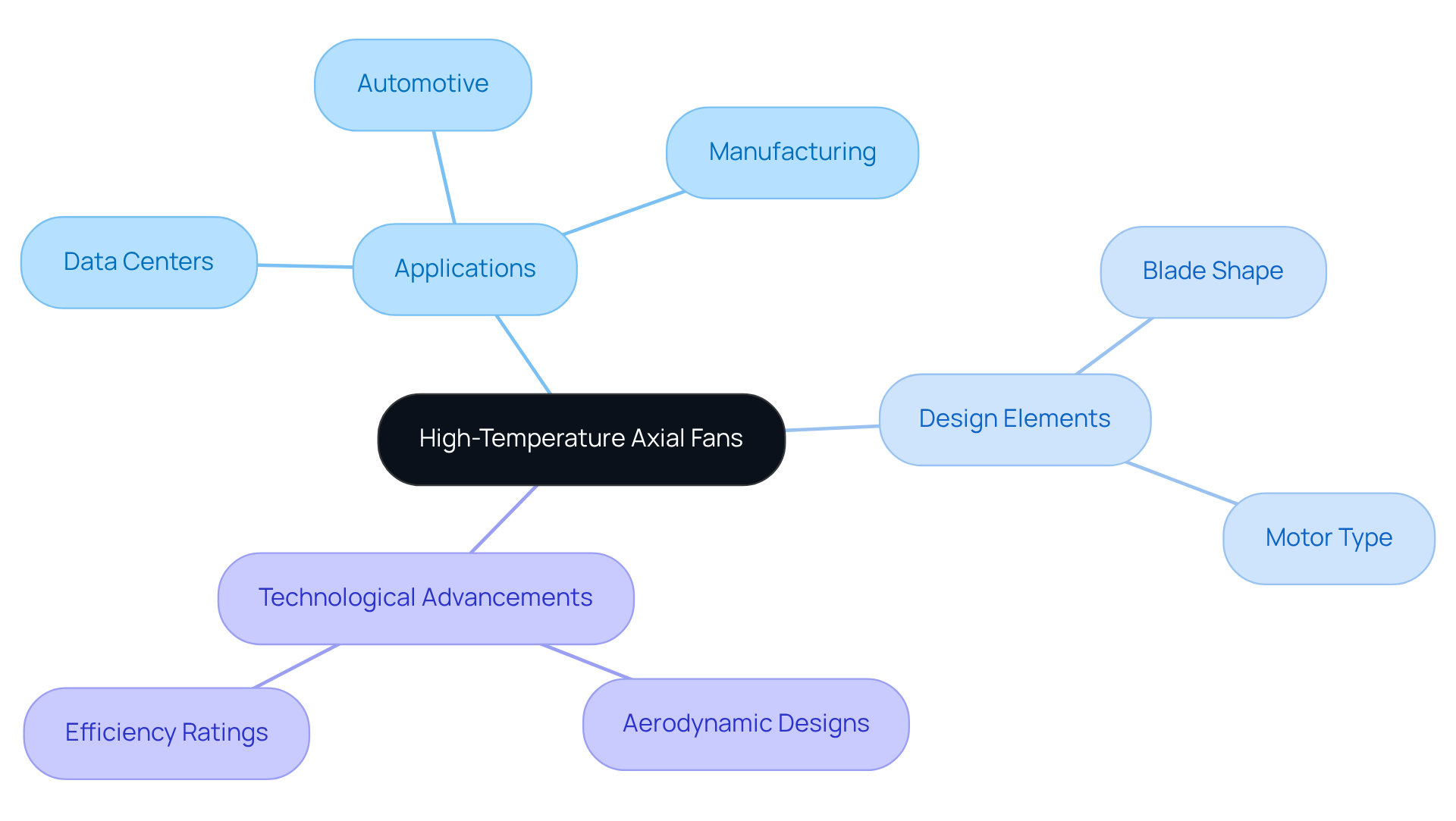

High-Temperature Axial Fans: Critical for Effective Cooling Solutions

High temp blowers are essential components in cooling solutions for both the electronics and industrial sectors. These devices are engineered to circulate substantial volumes of air, which is vital for maintaining optimal conditions in high-power electronic equipment and machinery. Their robust construction enables them to operate efficiently in elevated temperature environments, making them indispensable in data centers, automotive applications, and manufacturing processes.

Engineers must meticulously evaluate various design elements, including blade shape and motor type, to enhance airflow and cooling efficiency. Recent advancements in high temp blower technology have resulted in improved efficiency ratings, allowing these devices to function reliably under demanding conditions. Innovations such as advanced aerodynamic blade designs and high-efficiency motors significantly reduce energy consumption while maintaining performance.

Successful implementations of these blowers in data centers demonstrate their effectiveness in heat management, ensuring the reliability of critical systems. In automotive applications, the high temp blower contributes to engine cooling and overall vehicle performance, showcasing its versatility and importance in modern engineering.

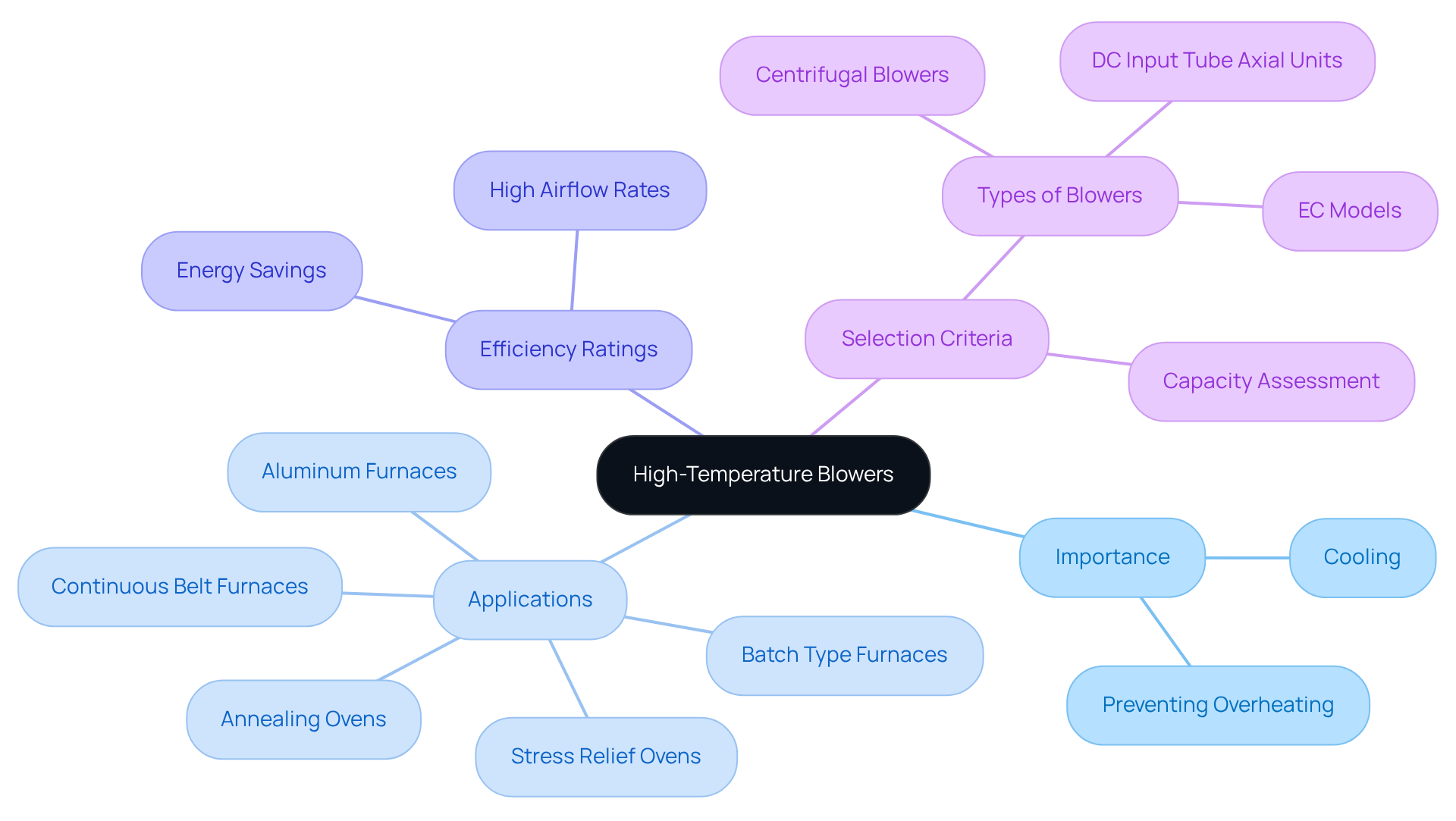

High-Temperature Blowers: Vital for Power Management Systems

High temp blowers are crucial in power management systems, providing effective cooling and airflow to vital components. These high temp blowers are designed to withstand extreme heat, ensuring consistent operation that is essential for preventing overheating in power electronics. Gagner-Toomey Associates, a leading manufacturer of air-movers, offers a diverse selection of centrifugal blowers capable of managing airstreams at temperatures up to 1800°F. This makes them ideal for applications such as aluminum furnaces, annealing ovens, and stress relief ovens.

As the demand for efficient thermal management continues to rise, engineers must meticulously assess blower capacity and efficiency ratings to optimize their designs. The average efficiency ratings of these blowers are increasingly significant, with numerous models achieving substantial energy savings while maintaining high airflow rates. Industry leaders emphasize the necessity of integrating high temp blowers into thermal management strategies to enhance system reliability and efficiency.

By selecting the right blower from Gagner-Toomey’s extensive portfolio, which includes DC input Tube Axial units and EC models, engineers can effectively mitigate overheating risks and improve overall energy efficiency in their designs. This strategic choice not only addresses immediate thermal challenges but also contributes to long-term operational success.

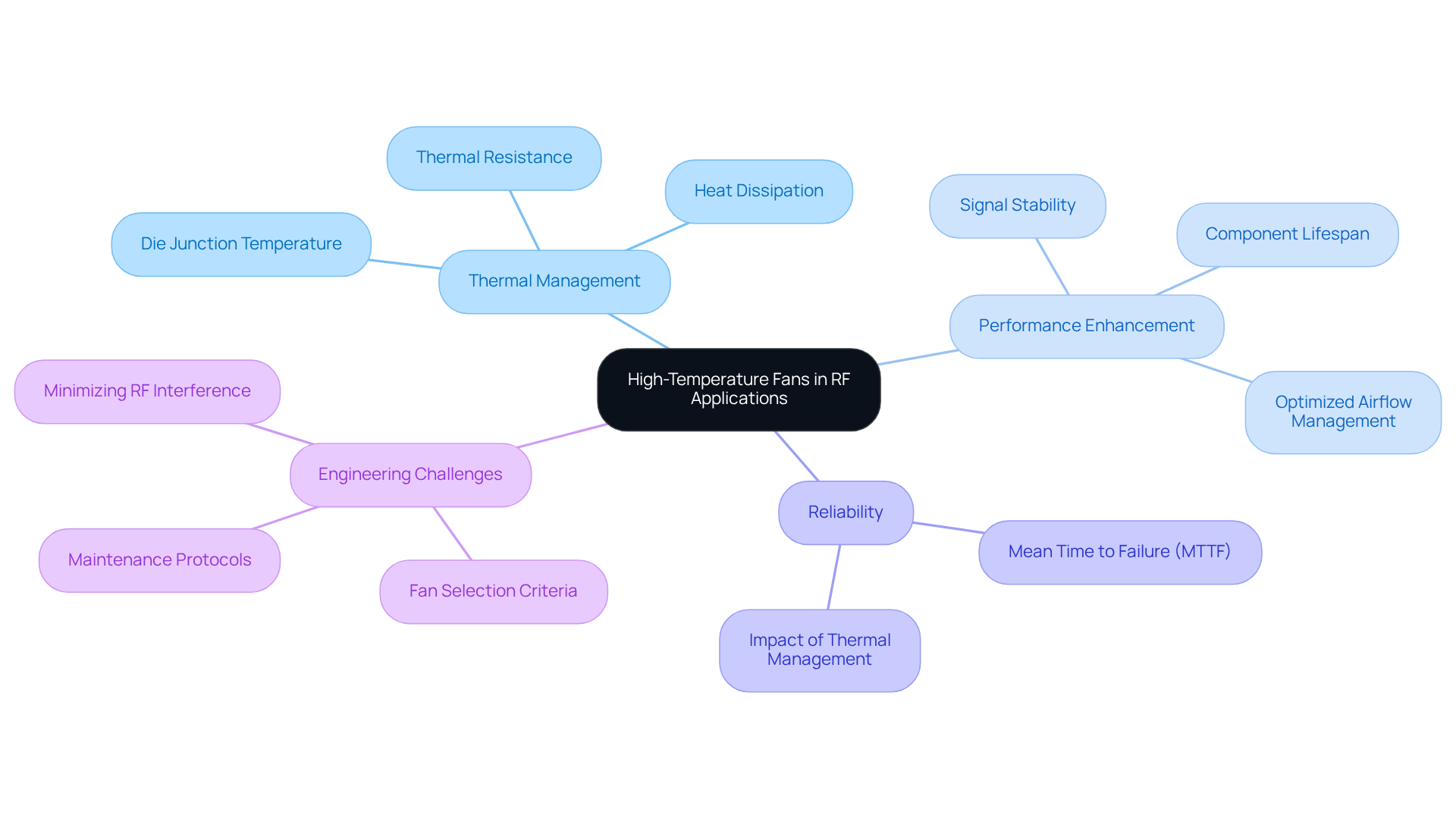

High-Temperature Fans in RF Applications: Enhancing Performance

High temp blowers play a critical role in RF applications, where maintaining optimal heat levels is essential for both performance and reliability. These devices are instrumental in dissipating heat generated by RF components, ensuring stable operation and preventing signal degradation. Engineers face the challenge of selecting fans that operate efficiently at elevated temperatures while minimizing interference with RF signals.

Effective thermal management in RF systems not only enhances functionality but also extends the lifespan of vital components. By prioritizing the right cooling solutions, engineers can significantly improve system performance and reliability.

In summary, the integration of a high temp blower is not merely a technical requirement; it is a strategic decision that impacts the overall effectiveness of RF applications.

High-Temperature Blowers: Ensuring Precision in Timing Applications

High temp blowers are crucial for ensuring precision and accuracy in timing applications. These devices efficiently control heat within timing circuits and components, helping to maintain the operational limits crucial for functionality. Engineers must evaluate the airflow capacity and temperature rating of the high temp blower meticulously to mitigate thermal drift, which can lead to timing inaccuracies.

Consider systems like clocks, timers, and synchronization devices: effective thermal management is not just beneficial; it is vital for reliable operation. Recent advancements in thermal management solutions, particularly the high temp blower from Gagner-Toomey Associates, underscore the industry’s commitment to enhancing timing circuit reliability. Their innovative blower technologies significantly improve operational efficiency, demonstrating a clear path forward for engineers seeking to optimize performance.

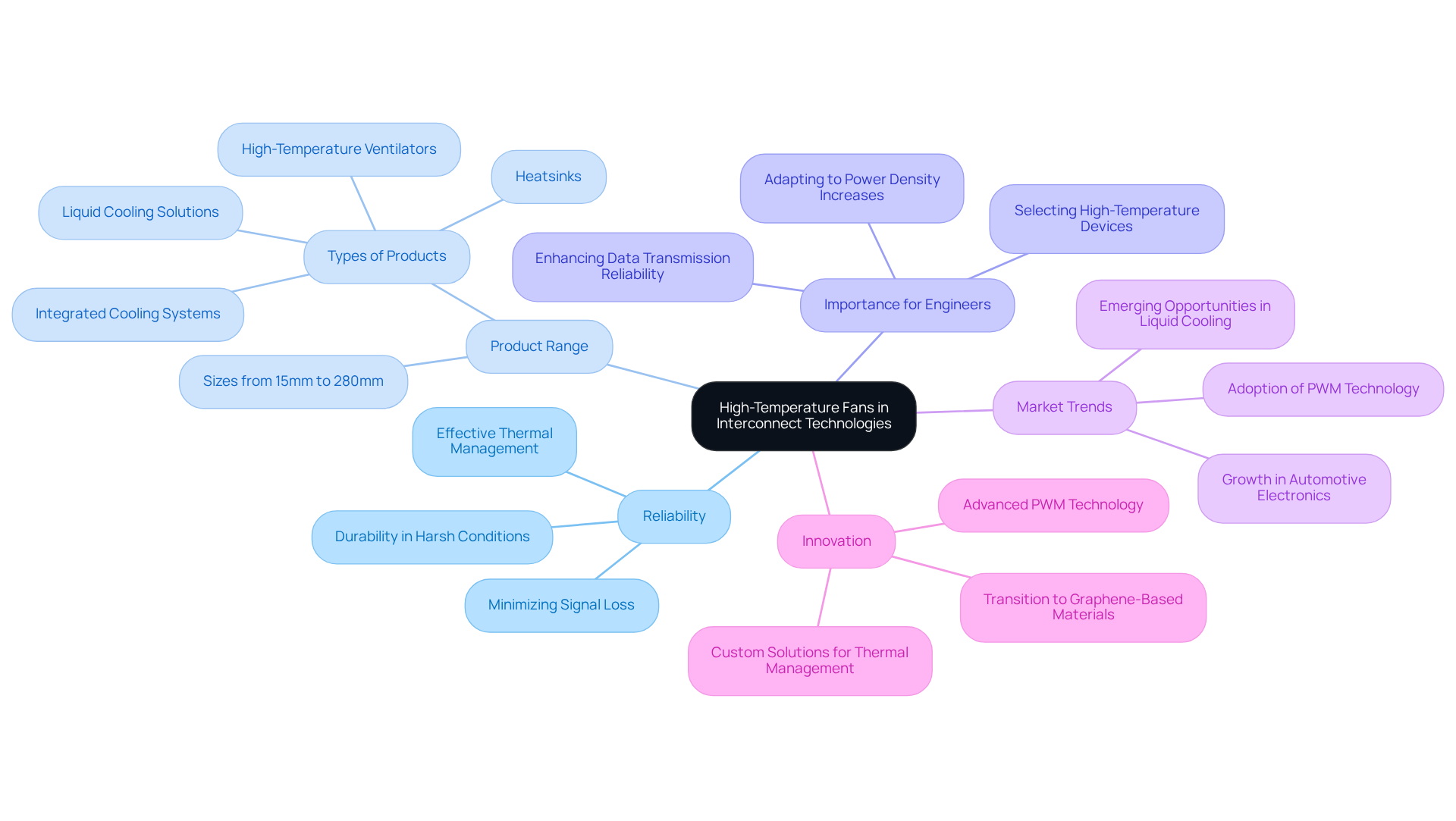

High-Temperature Fans in Interconnect Technologies: Ensuring Reliability

The reliability in interconnect technologies is crucially supported by a high temp blower, where effective thermal management is essential for optimal performance. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, provides a comprehensive range of high-temperature ventilators, available in sizes from 15mm to 280mm. These ventilators are specifically designed to dissipate heat generated by interconnect components, preventing overheating and maintaining stable operation.

For engineers, selecting devices that can withstand high temperatures while delivering adequate airflow is vital. This effective thermal management not only enhances the reliability of data transmission but also minimizes signal loss – an increasingly critical factor as power densities in electronic systems rise. Notably, data centers employing advanced PWM technology have reported efficiency improvements in temperature management of up to 30%.

As the market evolves, the integration of high temp blowers from Gagner-Toomey is becoming standard practice in sectors such as automotive electronics, high-performance computing, and advancements showcased by Foxconn Interconnect Technology at the 2025 OCP Global Summit. This trend underscores the significance of high temp blowers in modern interconnect systems.

Gagner-Toomey’s commitment to innovation is evident in their extensive portfolio, which includes not only high temp blowers but also heatsinks, liquid cooling solutions, and integrated cooling systems. This ensures comprehensive thermal management for electronics. As the industry continues to advance, Gagner-Toomey remains at the forefront, equipping engineers with the necessary tools for efficient thermal management.

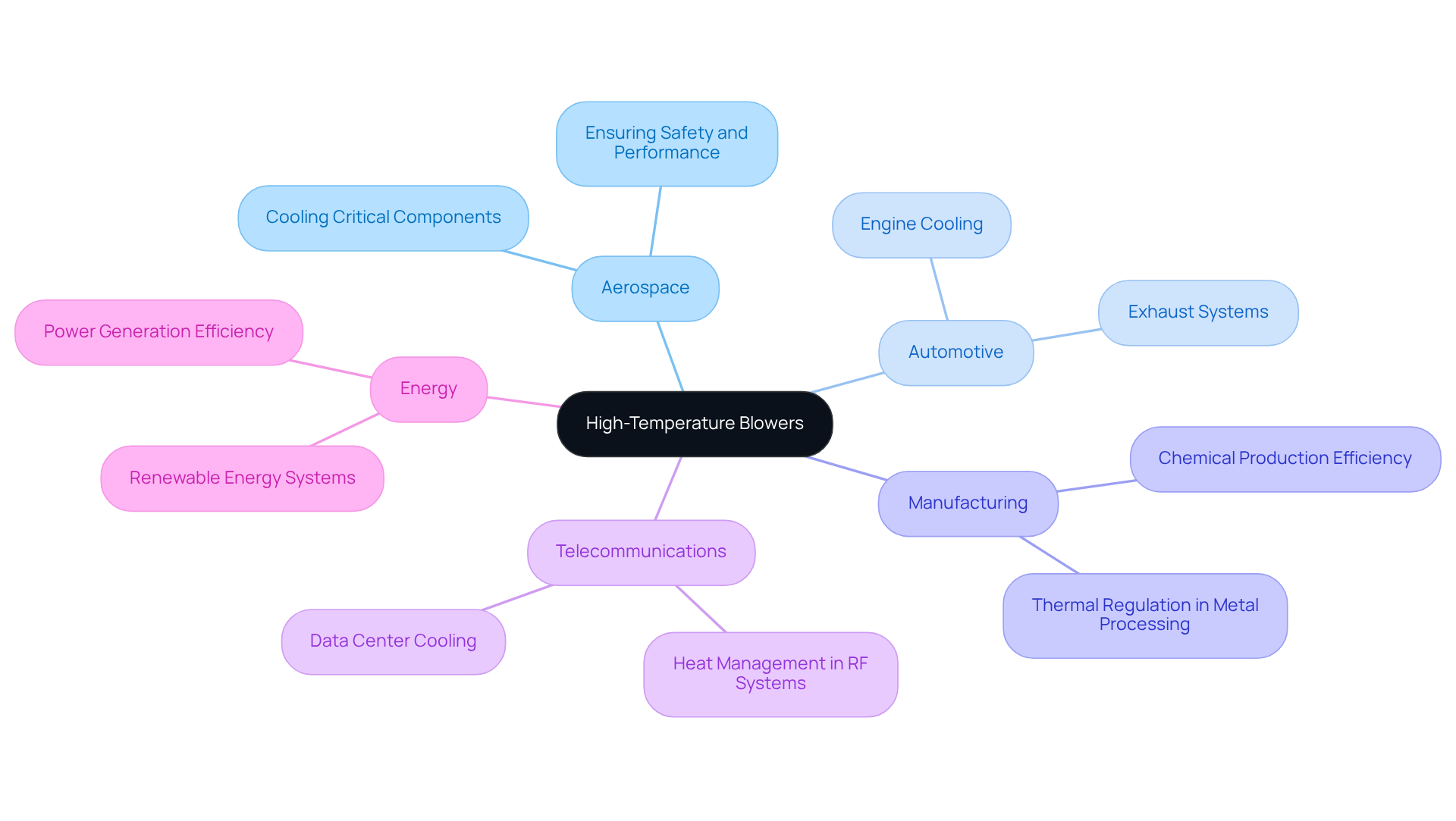

Industries Utilizing High-Temperature Blowers: A Comprehensive Overview

High temp blowers play a crucial role across various industries, addressing specific thermal management challenges.

- Aerospace: The high temp blower is essential for cooling critical components in aircraft and spacecraft, ensuring safety and performance under extreme conditions.

- Automotive: In the automotive sector, high temp blowers are integral to engine cooling and exhaust systems, assisting in maintaining optimal operating temperatures.

- Manufacturing: Industries requiring precise thermal regulation, such as metal processing and chemical production, rely on high temp blowers to enhance both efficiency and product quality.

- Telecommunications: They manage heat effectively in RF systems and data centers with a high temp blower, safeguarding sensitive equipment from overheating.

- Energy: In power generation and renewable energy systems, the use of a high temp blower contributes to improved energy efficiency and reliability.

Understanding these applications empowers engineers to tailor their designs to meet the specific requirements of each industry, ultimately driving innovation and performance.

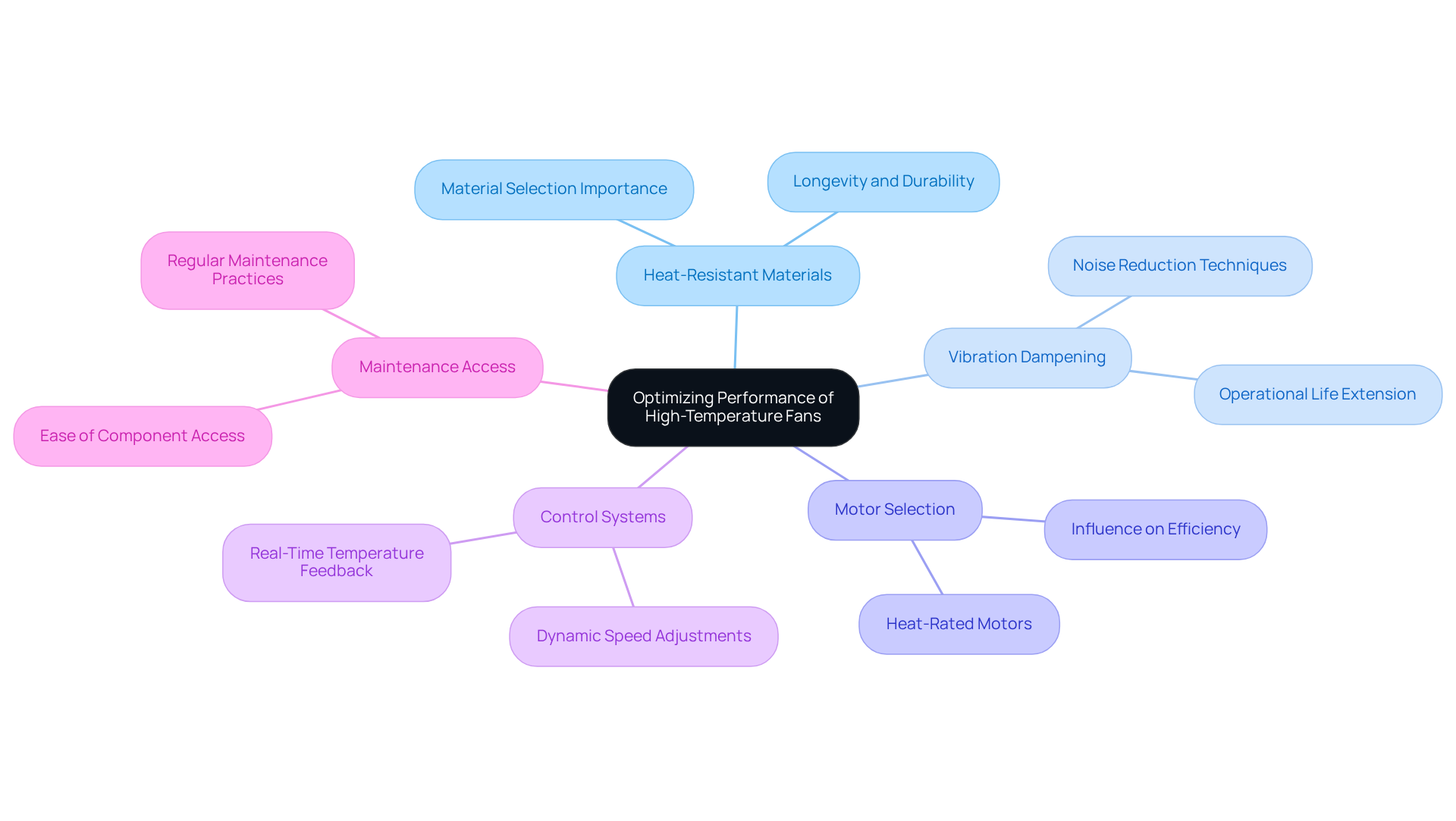

Accessory and Design Considerations for High-Temperature Fans: Optimizing Performance

To optimize the performance of high-temperature fans, engineers must focus on several key accessories and design elements:

- Heat-Resistant Materials: Selecting materials that can withstand extreme temperatures is crucial. This choice prevents degradation and ensures longevity. High temp blowers are engineered to operate efficiently in environments that exceed standard fan capabilities, making material selection vital for their performance.

- Vibration Dampening: Implementing vibration dampening solutions not only reduces noise but also extends the operational life of the fan. This enhancement is essential for reliability in demanding environments. Managing acoustic impact is particularly important in sensitive applications, as it contributes significantly to overall system performance.

- Motor Selection: Choosing motors specifically rated for elevated heat is critical. This guarantees consistent and dependable performance under challenging conditions. The type of motor selected can significantly influence the fan’s efficiency and quiet operation.

- Control Systems: Advanced control systems that allow for dynamic speed adjustments based on real-time temperature feedback can greatly improve efficiency and responsiveness. This adaptability is crucial for maintaining optimal working conditions.

- Maintenance Access: Designing ventilators with easy access to components facilitates regular maintenance and inspection. This practice is vital for sustaining optimal performance over time. Proper installation and maintenance are critical for the longevity of high temp blower systems.

These considerations are integral to maximizing the efficiency and durability of high-temperature devices, ultimately contributing to the reliability of electronic systems in harsh environments. As the market for DC cooling fans is projected to reach USD 3.2 billion by 2033, understanding these factors becomes increasingly relevant for engineers.

Conclusion

High-temperature blowers play a crucial role in effective thermal management across various engineering applications, especially in the electronics sector. Their capacity to endure extreme conditions while delivering high airflow rates is vital for optimizing performance and prolonging the lifespan of critical components. Recent advancements in blower technology, led by companies like Gagner-Toomey Associates, underscore the necessity of selecting the right blower for specific applications to tackle the challenges presented by high-temperature environments.

This article has explored essential insights into the functionality and selection of high-temperature blowers. Engineers must evaluate several factors, including:

- Temperature ratings

- Airflow requirements

- Material compatibility

- Energy efficiency

when determining the most suitable blower. The incorporation of cutting-edge technologies, such as Electronic Commutated Motors and advanced aerodynamic designs, significantly boosts the efficiency and reliability of these systems. Various applications across industries – from aerospace to telecommunications – illustrate the versatility and critical importance of high-temperature blowers in sustaining optimal operational conditions.

In summary, the importance of high-temperature blowers is paramount. As engineering demands continue to evolve, so does the necessity for robust thermal management solutions. By prioritizing the appropriate blower technology and design considerations, engineers can not only ensure the reliability of their systems but also foster innovation within their fields. Embracing these advancements will lead to improved performance, enhanced energy efficiency, and ultimately, the successful execution of complex engineering projects.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for leading the development of high-temperature blower technology, providing innovative and tailored solutions for engineers in the electronics sector.

How do Gagner-Toomey’s solutions benefit engineers?

Gagner-Toomey’s solutions enhance reliability and efficiency in demanding thermal environments, allowing engineers to optimize performance and extend the longevity of electronic components.

What industries utilize high-temperature centrifugal fans?

High-temperature centrifugal fans are essential in industrial processes such as metal processing, chemical manufacturing, and power generation, where effective heat management is crucial.

What are the performance capabilities of high-temperature blowers?

High-temperature blowers can achieve static pressures of up to 15 inches of water gauge and efficiencies reaching 85%, significantly enhancing operational efficiency in industrial settings.

What materials are commonly used in the construction of high-temperature fans?

Common materials include AISI304 and AISI316, which ensure durability and reliability under extreme conditions.

What key factors should engineers consider when selecting a high-temperature blower?

Engineers should consider temperature rating, airflow requirements, material compatibility, noise levels, and energy efficiency when selecting a high-temperature blower.

Why is airflow calculation important in high-temperature applications?

Calculating the necessary airflow (CFM) is vital to maintain optimal cooling, as insufficient airflow can lead to overheating and system failures.

What advancements have been made in blower technology recently?

Recent advancements include the integration of Electronic Commutated Motors, which enhance energy efficiency and position Gagner-Toomey’s blowers as strategic investments for industrial operations.

How does noise level impact the selection of high-temperature blowers?

Evaluating permissible noise levels is important for operational comfort and compliance with regulations, as high-temperature blowers can be louder than standard units.

What is the significance of energy efficiency in high-temperature fans?

Energy-efficient fans reduce operational expenses and contribute to sustainability efforts, making them a key consideration in the selection process.