Introduction

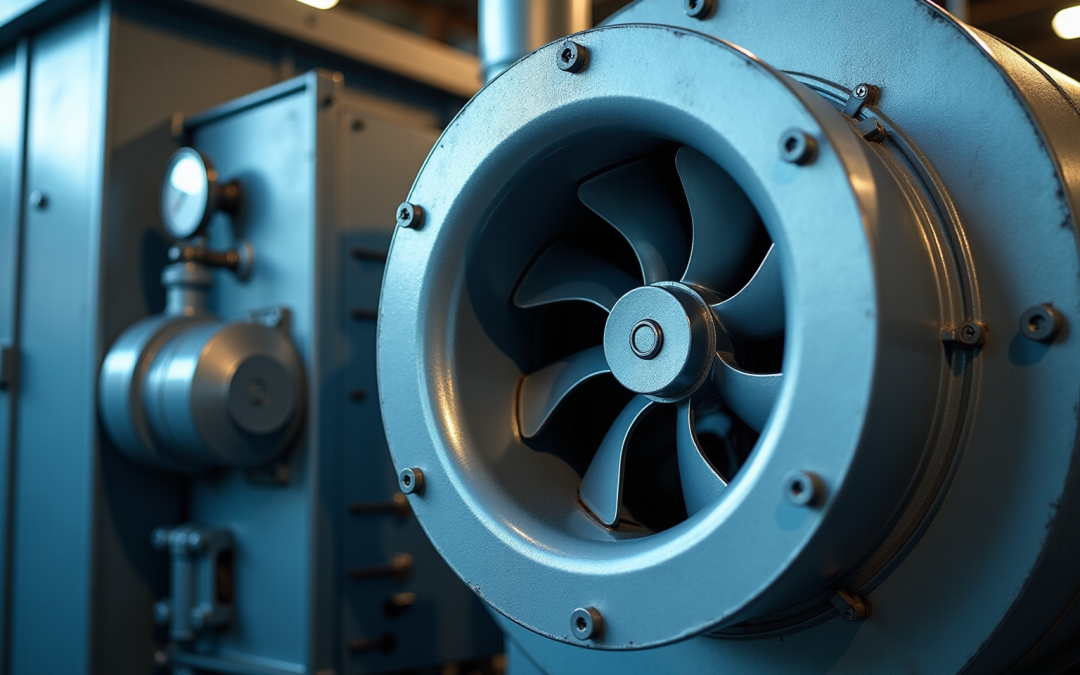

High-temperature centrifugal fans play a crucial role in various industrial sectors, significantly enhancing efficiency and safety in extreme environments. As industries grapple with increasing power densities and stringent cooling demands, it becomes essential for engineers to grasp the intricacies of these fans. What insights can guide professionals in the effective selection and implementation of these vital technologies? This article explores ten pivotal aspects of high-temperature centrifugal fans, providing valuable knowledge aimed at improving operational performance and reliability in challenging applications.

Gagner-Toomey Associates: Innovative Cooling Solutions for High-Temperature Applications

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions tailored for high temperature centrifugal fan applications. As power densities in data centers rise-some chips are projected to exceed 2,000 watts-the demand for advanced cooling methods has never been more critical. This trend highlights the urgent need for effective cooling solutions, such as two-phase immersion cooling, which significantly outperforms traditional methods in both capacity and efficiency.

By collaborating with a diverse array of manufacturers, Gagner-Toomey equips engineers with access to cutting-edge technologies that enhance performance in challenging environments. Their commitment to exceptional customer service ensures that engineers receive the support necessary to implement these advanced solutions effectively. This dedication solidifies Gagner-Toomey’s reputation as a trusted partner in the electronics industry.

Successful implementations of cooling technologies, such as:

- High temperature centrifugal fans

- Energy-efficient blowers

- Liquid cooling systems

showcase the potential for substantial operational savings and a reduced environmental impact. These advancements position Gagner-Toomey as a pivotal player in the evolution of cooling technologies, driving the industry forward with innovative solutions that meet the demands of modern applications.

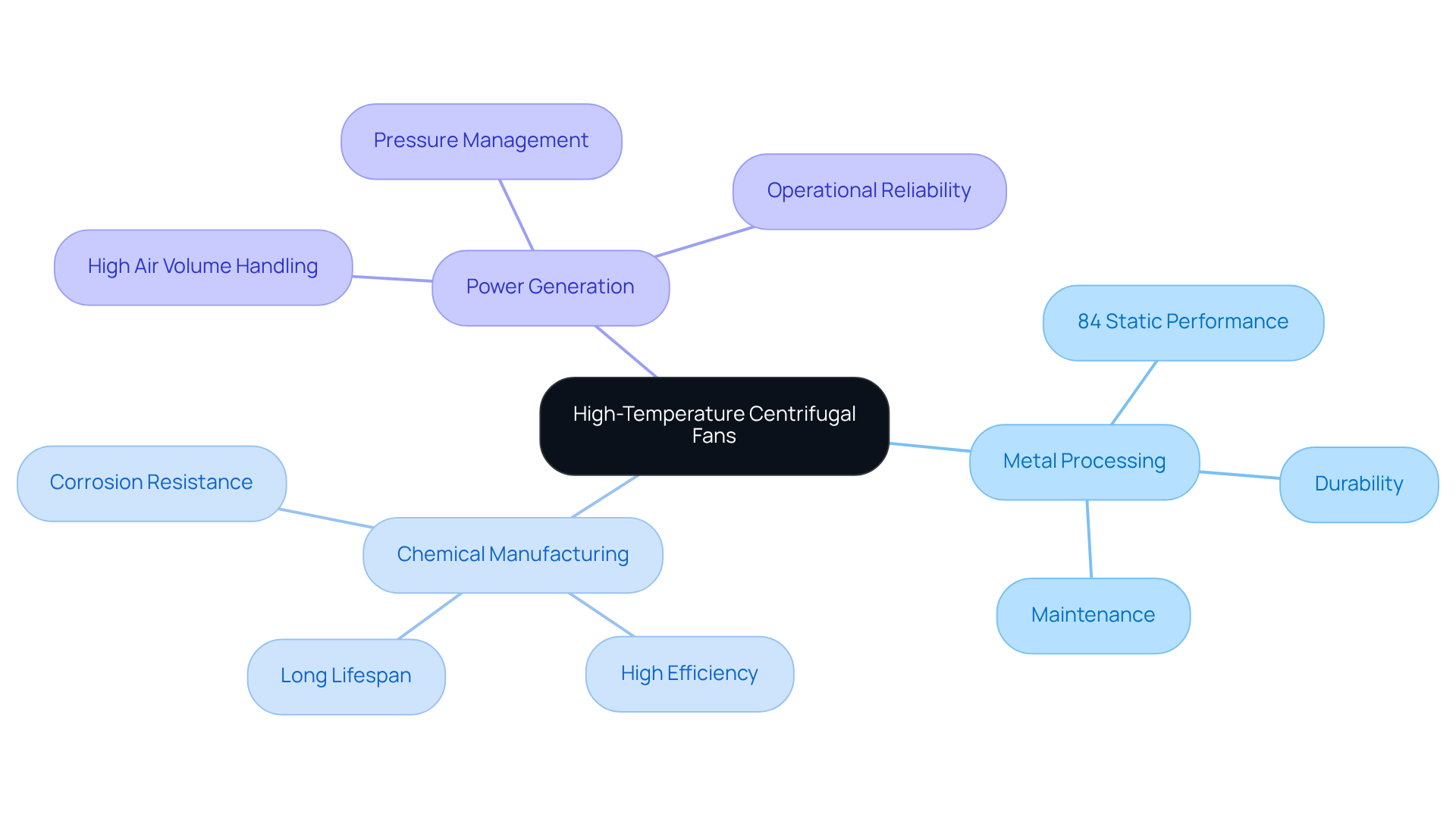

High-Temperature Centrifugal Fans: Critical Applications in Extreme Industrial Environments

High-temperature centrifugal fans play a critical role in demanding industrial environments, including metal processing, chemical manufacturing, and power generation. These devices, known as high temperature centrifugal fans, are engineered to endure elevated temperatures and corrosive conditions, ensuring reliable airflow for cooling and ventilation. Their robust construction, utilizing materials like AISI304 and AISI316, enables them to operate effectively where standard models would fail, making them indispensable for maintaining safety and performance in essential processes.

In metal processing, for instance, these blowers can achieve up to 84% static performance, significantly enhancing operational reliability and contributing to reduced energy costs in air handling applications. Similarly, in power generation, elevated-temperature axial blowers are designed to handle substantial air volumes and high pressures, ensuring efficient cooling and ventilation even in the most challenging environments.

Engineers emphasize that the durability and performance of these blowers are crucial for preventing equipment failures and ensuring uninterrupted production. With a lifespan exceeding 80,000 operating hours when properly maintained, high temperature centrifugal fans represent a long-term investment in operational safety and efficiency. Regular inspections and maintenance schedules are vital to optimize performance and extend the lifespan of these essential components.

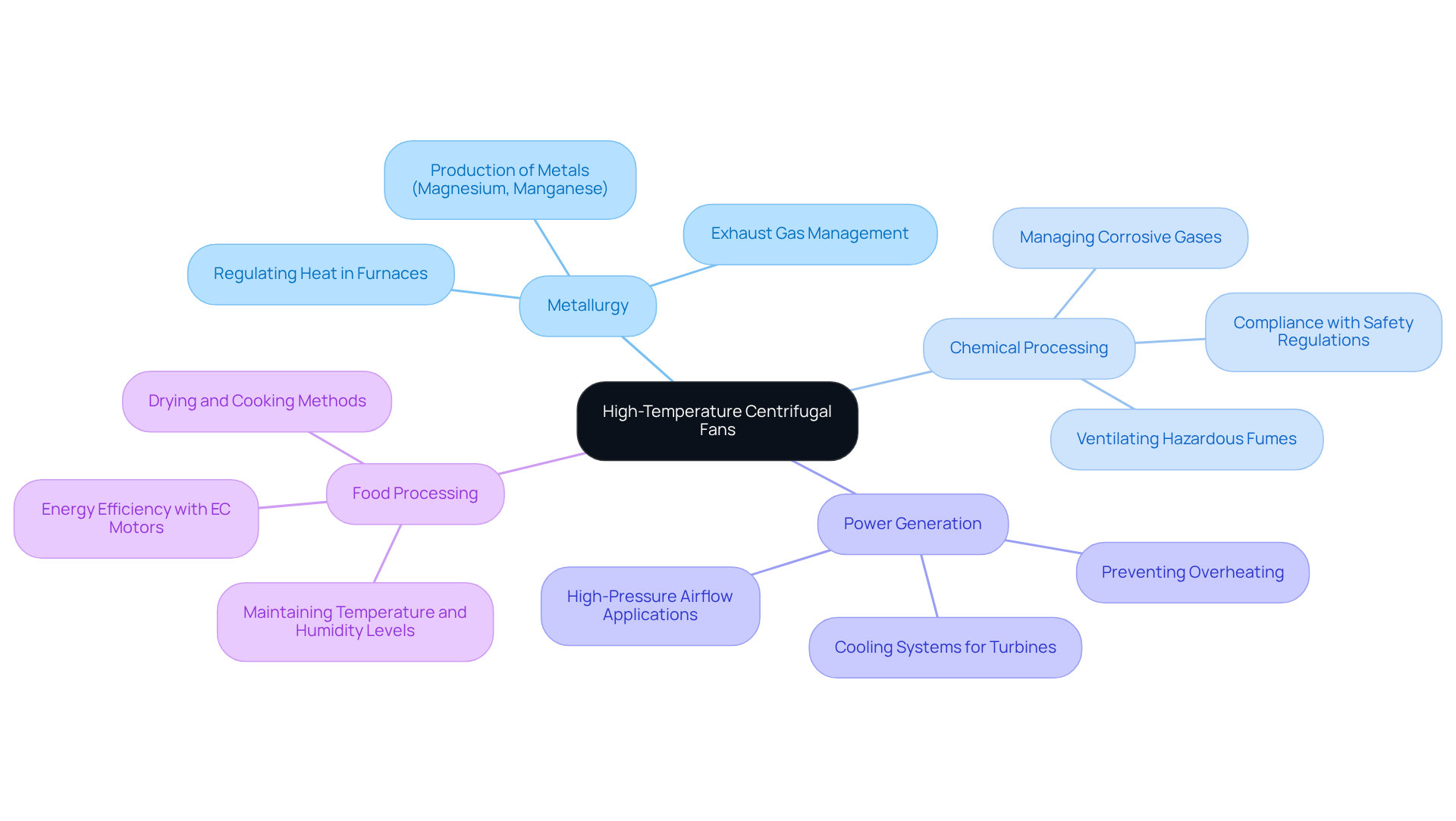

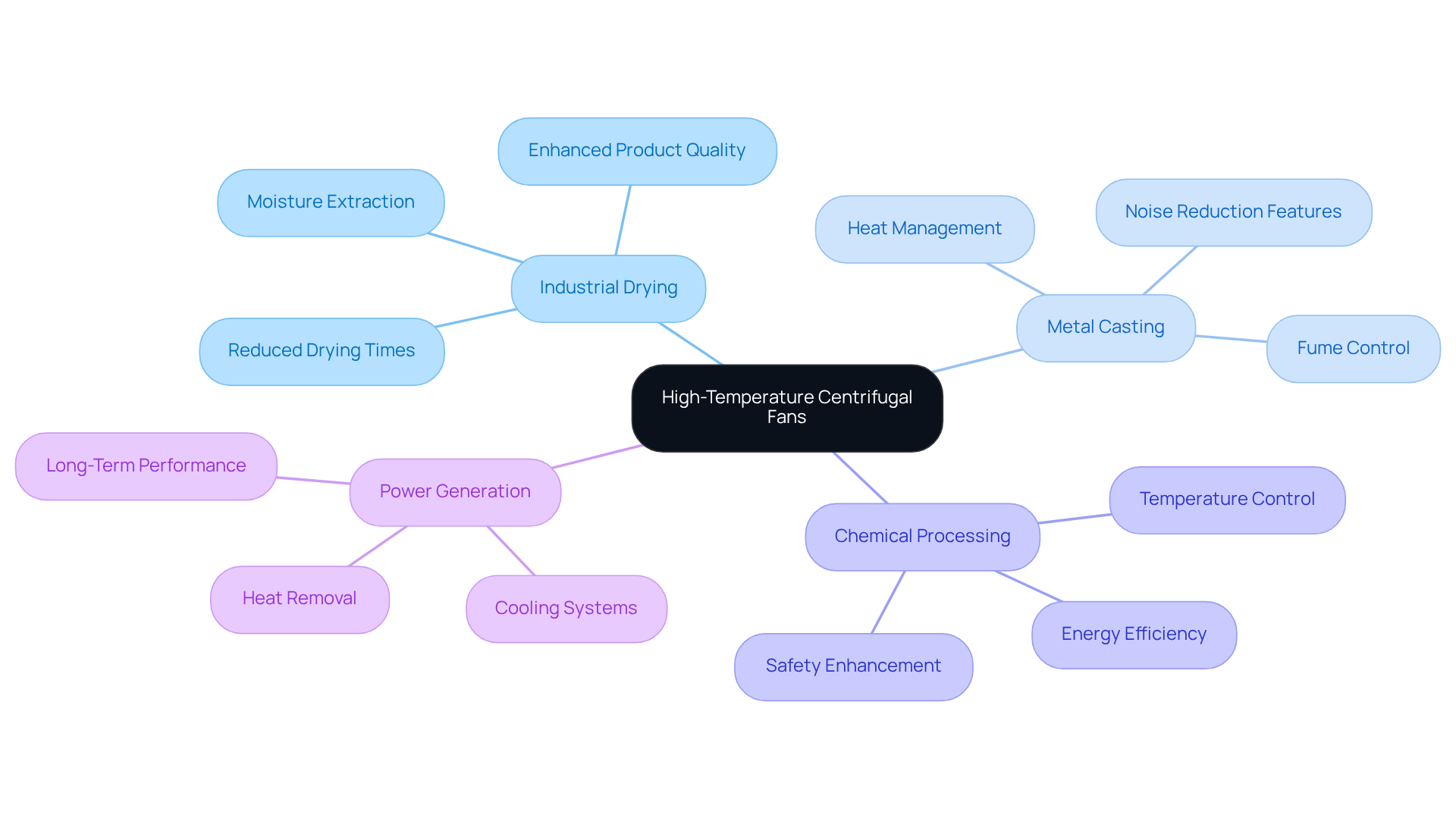

Key Industries Utilizing High-Temperature Centrifugal Fans for Enhanced Performance

High-temperature rotating blowers are indispensable in several key industries, significantly enhancing operational efficiency and safety. In metallurgy, these devices play a vital role in regulating heat and exhaust gases in furnaces and kilns, ensuring optimal performance even under extreme conditions. Their ability to maintain stable airflow at high temperatures is crucial for processes involving the production of metals like magnesium and manganese, where precise temperature control is essential.

In the chemical processing sector, high temperature centrifugal fans are critical for managing hot, corrosive gases. They effectively ventilate hazardous fumes, maintaining safe operational conditions, which is increasingly important due to stringent regulations on workplace safety and air quality. The integration of advanced materials, such as 316 stainless steel, enhances their durability in these harsh environments.

Power generation facilities rely on these devices for cooling systems in turbines and generators, where efficient airflow is vital to prevent overheating and ensure reliable energy production. Their capability to operate at high pressures makes them ideal for applications that require consistent airflow against significant resistance. Notably, centrifugal blowers produce three times greater static pressure than axial types, reaching up to 15 inches of water gauge, underscoring their superiority in high-pressure applications.

In food processing, elevated-temperature rotary blowers are utilized in drying and cooking methods, where maintaining specific temperature and humidity levels is crucial for food safety and quality. Their robust design allows them to operate effectively in environments demanding both high performance and reliability. Furthermore, incorporating EC motors in these devices can reduce energy consumption by 40% at partial loads, highlighting their energy-saving advantages.

Routine maintenance is essential for prolonging the lifespan of high temperature centrifugal fans, ensuring they function dependably over time. Overall, the effectiveness and reliability of elevated-temperature rotating devices make them a preferred choice in these sectors, contributing to improved operational results and compliance with safety regulations. The global industrial ventilation market was valued at USD 7.64 billion in 2024 and is projected to expand at a CAGR of 4.5% from 2025 to 2034, reflecting the growing demand for these essential systems.

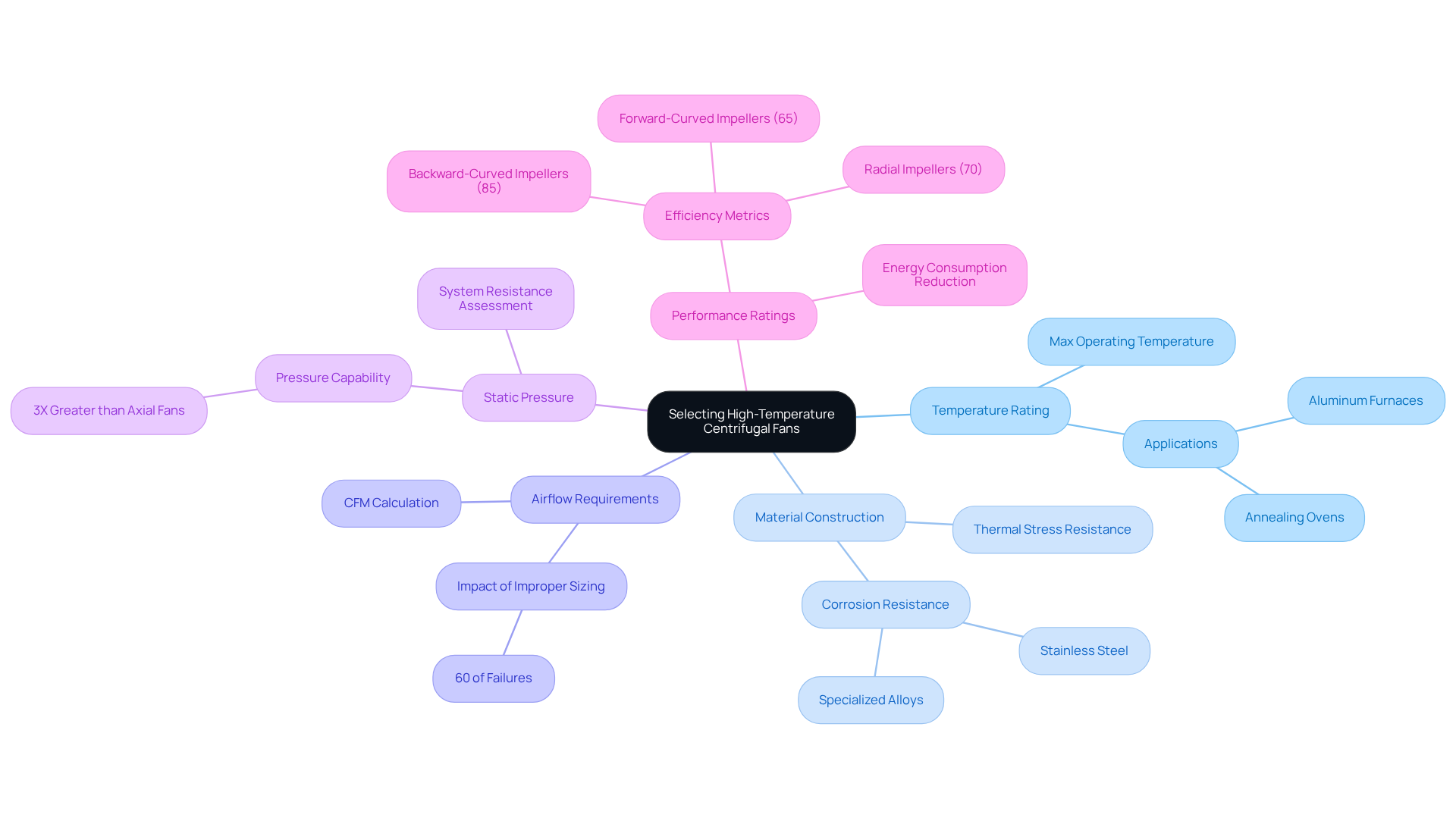

Selecting High-Temperature Centrifugal Fans: Essential Criteria for Engineers

When selecting high temperature centrifugal fans, engineers must prioritize several essential criteria to ensure optimal performance and reliability in demanding applications.

-

Temperature Rating: First and foremost, ensure the fan can operate at the required temperature without degradation. High temperature centrifugal fans are capable of managing process airstreams at temperatures up to 1800°F, making them suitable for critical applications such as aluminum furnaces and annealing ovens.

-

Material Construction: Next, choose materials that resist corrosion and thermal stress, such as stainless steel or specialized alloys. Stainless steel units are particularly recommended for humid and corrosive environments, ensuring durability and dependability in challenging conditions.

-

Airflow Requirements: It’s crucial to calculate the necessary airflow (CFM) to meet system demands. Centrifugal blowers can achieve air volumes of up to 10,000 CFM, which is vital for effective cooling and ventilation. Notably, 60% of premature failures stem from improper sizing, underscoring the importance of accurate calculations.

-

Static Pressure: Assess the system’s resistance to airflow to select a fan capable of overcoming it. Centrifugal blowers excel in pressurized ducts, providing up to three times greater pressure capability than axial units, which is essential for ducted systems.

-

Performance Ratings: Finally, look for fans with high performance to reduce energy consumption and operational costs. For instance, backward-curved impellers achieve an impressive 85% efficiency, significantly lowering energy expenses over time.

Additionally, as highlighted by an AirPro expert, understanding the limitations of the fan and adhering to a preventive maintenance plan are crucial for avoiding catastrophic failures. By following these criteria, engineers can ensure that the chosen high temperature centrifugal fan meets the specific requirements of elevated-temperature applications, ultimately enhancing system performance and reliability.

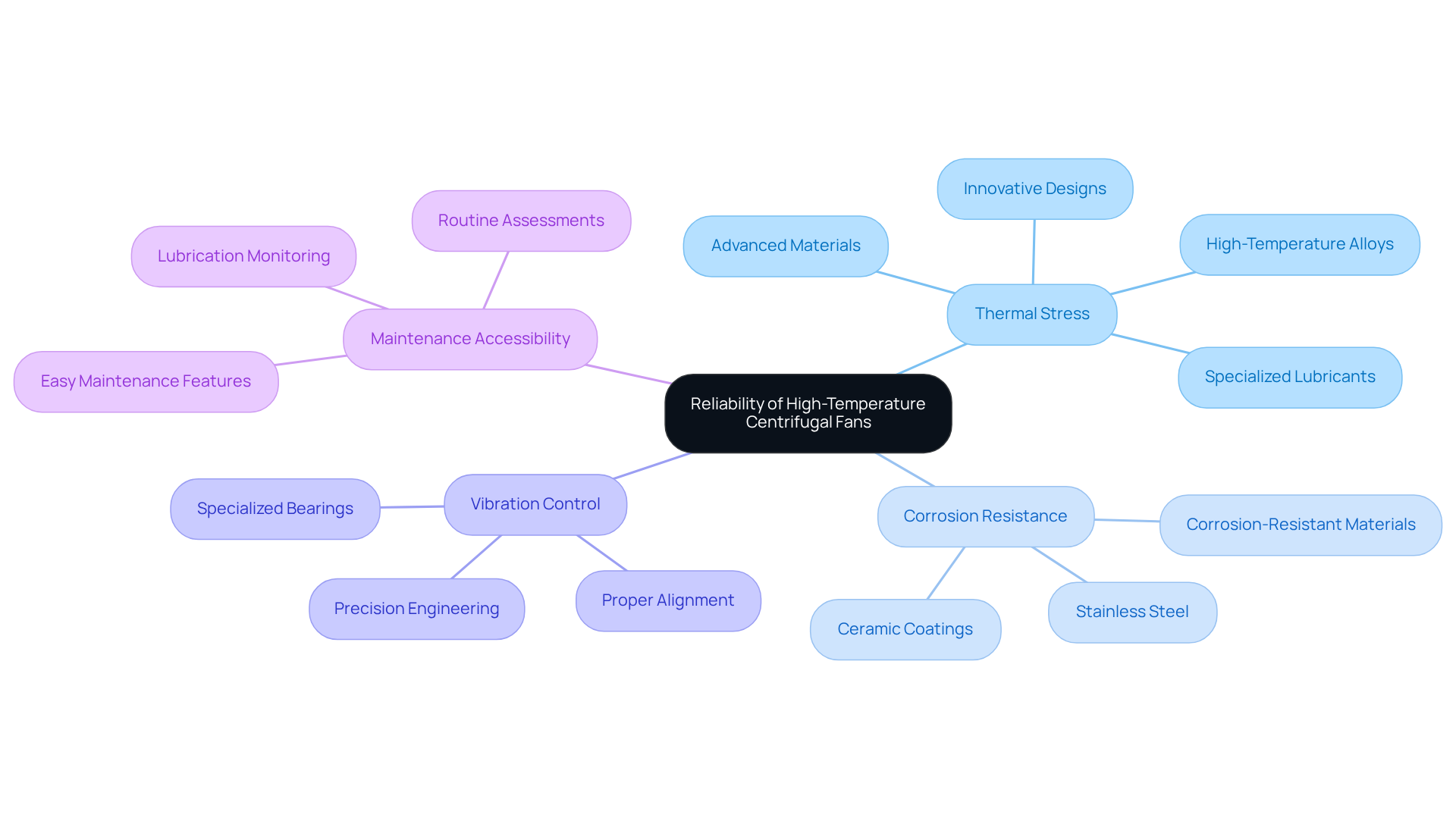

Overcoming Challenges: How High-Temperature Centrifugal Fans Ensure Reliability

High-temperature centrifugal fans are expertly engineered to address several critical challenges, ensuring reliable performance in extreme conditions:

- Thermal Stress: By utilizing advanced materials and innovative designs, these fans significantly mitigate the risk of thermal fatigue, thereby promoting long-term operational reliability. High-temperature alloys and specialized lubricants are employed to endure extreme heat, preventing premature failure. Notably, industrial centrifugal blowers typically boast a lifespan of 15 to 20 years, underscoring their durability in demanding applications.

- Corrosion Resistance: The integration of specialized coatings and corrosion-resistant materials, such as stainless steel and ceramic coatings, safeguards fans from harsh environments, extending their lifespan. This is particularly vital in sectors where corrosive gases are prevalent, as these materials are engineered to withstand the challenges posed by elevated temperature applications.

- Vibration Control: Precision engineering is essential in minimizing vibration, a common cause of mechanical failure in high-temperature settings. Ensuring proper alignment and support, along with the use of specialized bearings and lubricants designed for high temperatures, allows these devices to maintain optimal performance and reduce wear on components.

- Maintenance Accessibility: Thoughtful design features that facilitate easy maintenance are crucial for sustaining operational efficiency. Routine assessments and upkeep procedures, such as monitoring lubrication levels and inspecting for wear, can prevent costly repairs and ensure that devices operate at peak performance.

By effectively addressing these challenges, high-temperature centrifugal fans provide dependable performance, making them indispensable in demanding industrial applications.

Centrifugal vs. Axial Fans: Performance Comparison in High-Temperature Applications

When comparing centrifugal and axial fans for high-temperature applications, it’s crucial to understand their distinct characteristics:

-

Airflow Direction: Centrifugal fans operate by moving air perpendicular to the intake, which generates higher pressure. In contrast, axial fans move air parallel, making them suitable for high volume but lower pressure scenarios.

-

Effectiveness: Centrifugal blowers excel in high-resistance applications, achieving an effectiveness of around 60%. This makes them ideal for systems with complex ductwork. On the other hand, axial blowers boast an efficiency of approximately 70%, making them preferable for applications that require high airflow at lower pressures.

Temperature management is crucial, and a high temperature centrifugal fan is often more suitable for extreme temperatures due to its robust design, ensuring durability and reliable performance. While axial blowers are efficient, they typically have a shorter lifespan of 20,000 to 30,000 hours compared to 15,000 to 25,000 hours for radial blowers.

-

Noise Levels: Axial fans generally operate more quietly, around 60 dB, which is beneficial in noise-sensitive environments. In contrast, radial units can reach noise levels of up to 75 dB.

-

Cost Considerations: Axial units are usually more cost-effective than other types, making them a more economical choice for various applications.

By understanding these differences, engineers can select the most effective fan type for their specific needs, balancing efficiency, noise, and operational demands. It’s essential to consider the specific application requirements and long-term costs associated with each fan type.

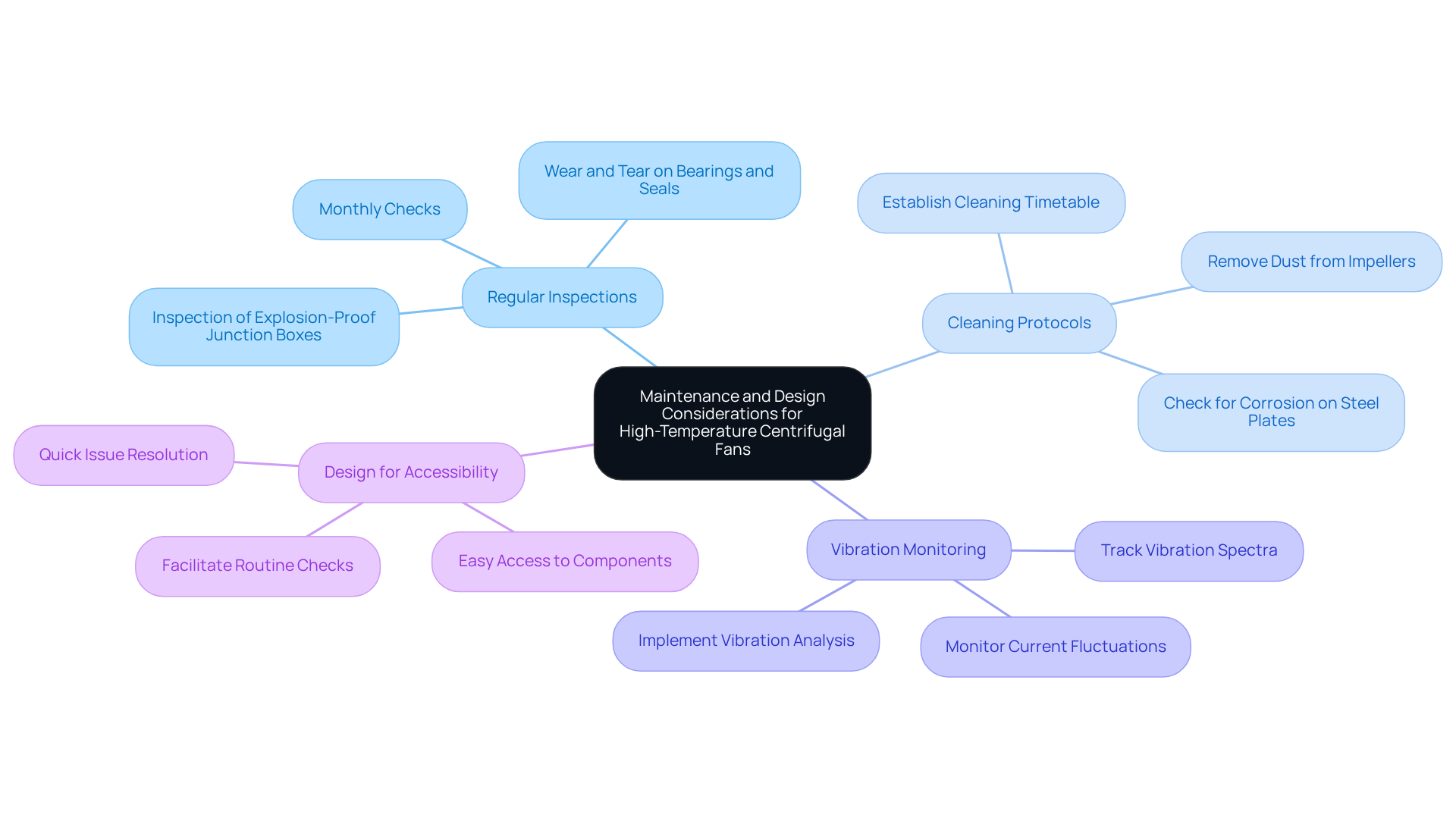

Maintenance and Design Considerations for High-Temperature Centrifugal Fans

To ensure optimal performance and longevity of high-temperature centrifugal fans, engineers must prioritize specific maintenance and design practices:

- Regular Inspections: Routine checks for wear and tear, particularly on bearings and seals, are essential. Monthly inspections can significantly extend the service life of ventilators, which can last between 20,000 and 40,000 hours of continuous operation or 10 to 20 years when properly maintained.

- Cleaning Protocols: Establishing a cleaning timetable to eliminate dust and debris is crucial, as accumulated particles can obstruct airflow and performance. Monthly maintenance should include removing dust from impellers, especially on backward-inclined blades, to maintain optimal performance.

- Vibration Monitoring: Implementing vibration analysis allows for early detection of potential issues, preventing catastrophic failures. Regularly tracking vibration spectra and current fluctuations enhances predictive maintenance strategies.

- Design for Accessibility: Fans should be designed for easy access to components during maintenance tasks. This consideration not only facilitates routine checks but also ensures that engineers can quickly address any issues that arise, thereby enhancing reliability.

As Quimipol emphasizes, “Preventive maintenance of rotating blowers is a crucial practice to ensure operational effectiveness, extend equipment lifespan, and reduce operating expenses.” By adhering to these methods, engineers can significantly enhance the reliability and performance of high temperature centrifugal fans, ultimately leading to improved operational results and minimized downtime.

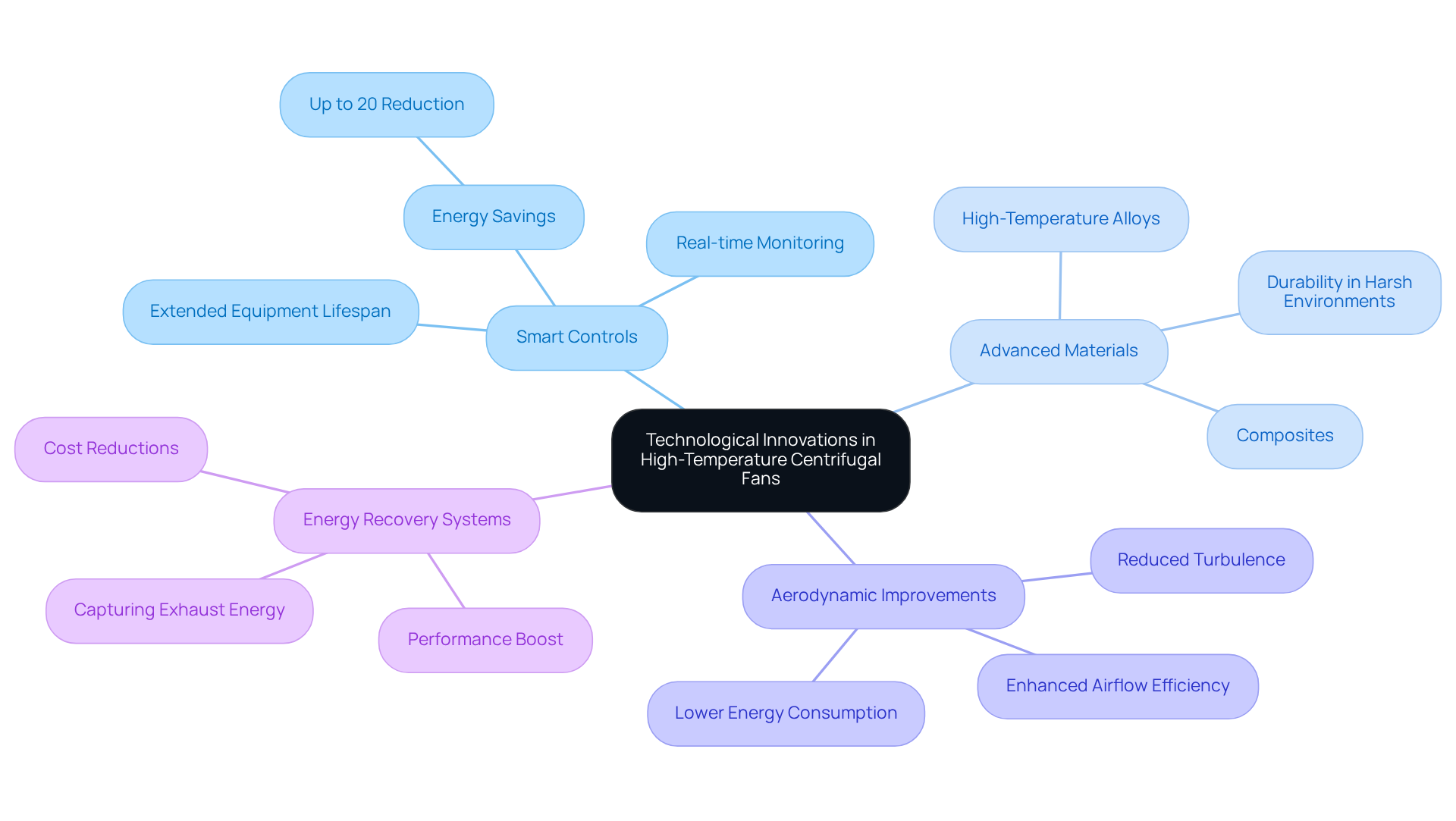

Technological Innovations in High-Temperature Centrifugal Fans for Improved Efficiency

Recent advancements in high-temperature centrifugal fans highlight a range of innovative technologies that significantly enhance efficiency and performance:

- Smart Controls: The integration of IoT and smart sensors allows for real-time monitoring and adjustments, optimizing fan performance based on varying operational conditions. This capability not only boosts productivity but also extends the lifespan of the equipment by preventing overexertion. Industry leaders assert that smart controls can reduce energy consumption by up to 20%, establishing them as a critical component in modern fan technology.

- Advanced Materials: The use of high-temperature alloys and composites greatly improves the durability and performance of blowers operating in extreme conditions. These materials are engineered to withstand harsh environments while maintaining optimal performance, which is increasingly vital as industrialization in developing regions drives the demand for effective ventilation and cooling systems.

- Aerodynamic Improvements: Innovations in blade design have resulted in reduced turbulence and enhanced airflow efficiency. Improved aerodynamics lead to lower energy consumption, making these devices more sustainable and economical. The global cooling devices market is projected to reach USD 5044 million by 2031, underscoring the growing importance of these advancements.

- Energy Recovery Systems: Contemporary blowers are increasingly equipped with energy recovery systems that capture energy from exhaust air, further boosting overall performance. This feature is particularly advantageous in industrial settings where energy costs are a significant concern. Recent case studies reveal that companies implementing these systems have experienced substantial reductions in operational costs.

These technological advancements position high temperature centrifugal fans as essential components in modern industrial applications, enhancing both operational effectiveness and sustainability.

Specific Applications of High-Temperature Centrifugal Fans in Industrial Drying and Ventilation

High-temperature centrifugal fans are indispensable in various industrial applications, underscoring their versatility and necessity:

-

Industrial Drying: These fans are essential in processes like drying wood, textiles, and food products, where consistent airflow and temperature control are paramount. Their capacity to generate significant pressure differences facilitates efficient moisture extraction, enhancing product quality and reducing drying times. Notably, a 20% increase in airflow requires a 73% rise in power to avoid excessive energy costs, highlighting the importance of efficiency in these applications.

-

In metal casting operations, high temperature centrifugal fans effectively manage heat and fumes, ensuring a safe working environment. Their advanced designs often incorporate noise reduction features, making them suitable for noise-sensitive areas while efficiently expelling harmful gases. This capability is vital for maintaining compliance with safety regulations and improving worker comfort.

-

In chemical processing, high temperature centrifugal fans are used in reactors and distillation columns to help maintain optimal temperatures and prevent overheating, which is crucial for safety and efficiency in chemical manufacturing. The integration of high-efficiency devices significantly reduces energy consumption and operating costs, further emphasizing their economic benefits.

-

Power generation relies on high temperature centrifugal fans, which are critical for cooling systems in turbines and generators, assisting in the removal of excess heat. Their robust construction ensures long-term performance even in demanding environments, contributing to the reliability of power generation facilities. As the market for high-pressure turbines is projected to grow significantly, the demand for these technologies in power generation is expected to increase.

These applications highlight the importance of elevated-temperature rotary blowers in enhancing operational efficiency and safety across various industrial sectors. Moreover, insights from case studies demonstrate their role in energy conservation and environmental protection, reinforcing the necessity of these devices in modern industrial applications.

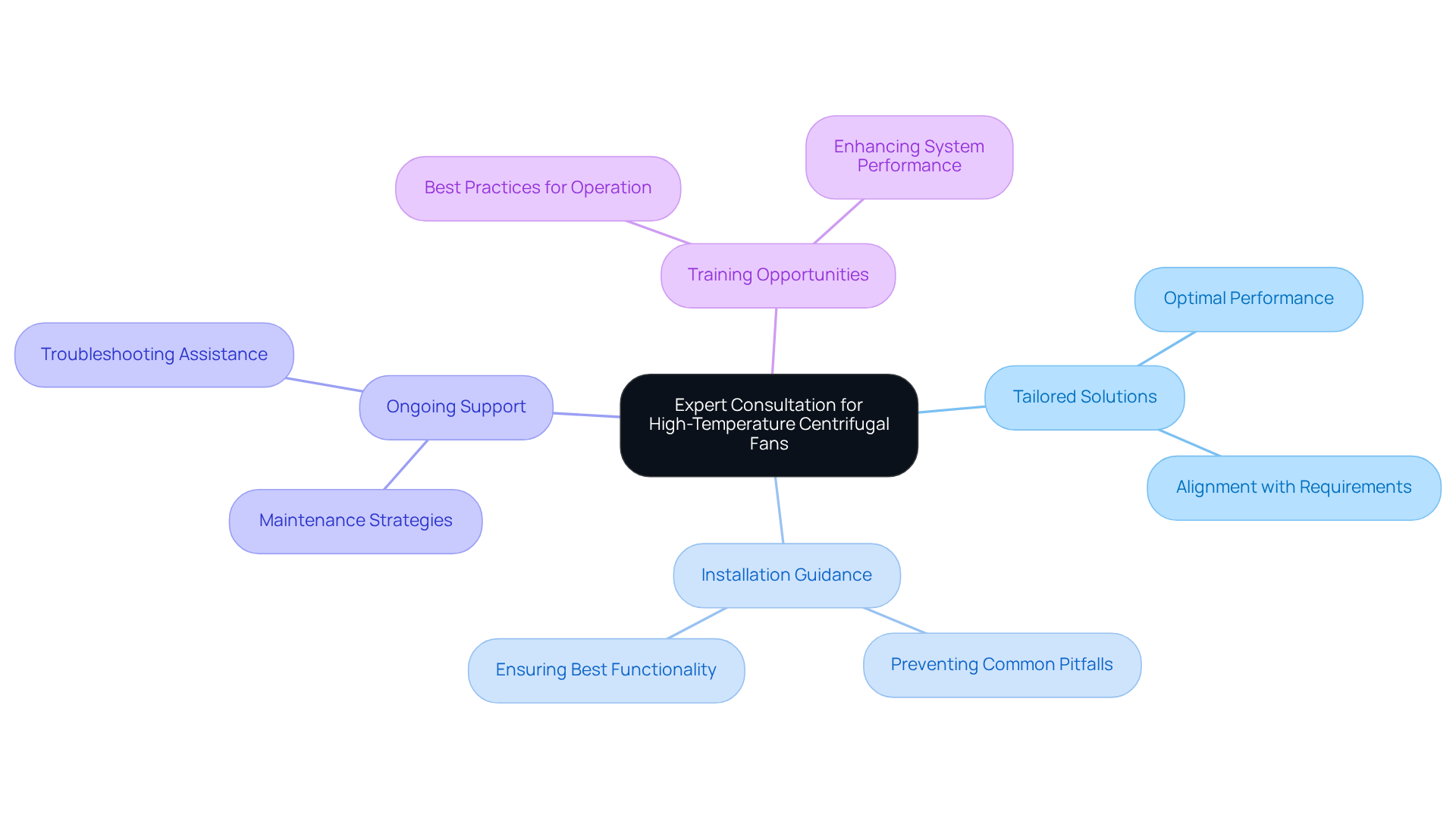

Expert Consultation: Ensuring Optimal Use of High-Temperature Centrifugal Fans

Engaging with experts in high temperature centrifugal fans offers significant advantages that can transform operational efficiency.

- Tailored Solutions: Experts assist engineers in selecting fans that align with specific operational requirements and environmental conditions, ensuring optimal performance.

- Installation Guidance: Professional advice during installation helps prevent common pitfalls, guaranteeing that systems function at their best from the very beginning.

- Ongoing Support: Experts provide maintenance strategies and troubleshooting assistance, which are crucial for long-term reliability and efficiency.

- Training Opportunities: Offering training for engineering teams on best practices for fan operation and maintenance can significantly enhance overall system performance.

By leveraging expert consultation, engineers can ensure the optimal use of high temperature centrifugal fans in their applications, leading to improved outcomes and sustained operational success.

Conclusion

High-temperature centrifugal fans play a crucial role in various industrial applications, delivering reliable airflow and cooling solutions even in extreme conditions. Their capacity to endure elevated temperatures and corrosive environments renders them indispensable in sectors like metallurgy, chemical processing, and power generation. As industries evolve, the demand for these robust fans is anticipated to rise, underscoring the necessity of selecting the right technology to boost operational efficiency and safety.

This article provides key insights into the critical applications of high-temperature centrifugal fans, outlining their performance benefits, selection criteria, and maintenance importance. Engineers should consider factors such as:

- Temperature ratings

- Material construction

- Airflow requirements

when selecting fans tailored to their specific needs. Furthermore, advancements in technology, including smart controls and energy recovery systems, highlight the potential for enhanced efficiency and sustainability in fan operations.

As industries confront growing challenges related to energy consumption and operational reliability, the insights presented here serve as a valuable guide for engineers. By prioritizing expert consultation and adhering to best practices in maintenance, they can not only extend the lifespan of high-temperature centrifugal fans but also optimize their performance. Embracing these innovative solutions is essential for driving progress in industrial applications, ensuring that systems operate efficiently while meeting the demands of modern manufacturing and processing environments.

Frequently Asked Questions

What innovative solutions does Gagner-Toomey Associates provide for high-temperature applications?

Gagner-Toomey Associates offers advanced cooling solutions tailored for high-temperature centrifugal fan applications, including two-phase immersion cooling, which outperforms traditional cooling methods in capacity and efficiency.

Why is there a growing demand for cooling solutions in data centers?

The demand for cooling solutions in data centers is increasing due to rising power densities, with some chips projected to exceed 2,000 watts, necessitating effective cooling methods.

What types of cooling technologies does Gagner-Toomey implement?

Gagner-Toomey implements various cooling technologies, including high-temperature centrifugal fans, energy-efficient blowers, and liquid cooling systems.

What industries benefit from high-temperature centrifugal fans?

High-temperature centrifugal fans are critical in industries such as metal processing, chemical manufacturing, power generation, and food processing.

How do high-temperature centrifugal fans contribute to operational efficiency?

They enhance operational efficiency by providing reliable airflow for cooling and ventilation, which is essential in extreme industrial environments, thus reducing energy costs and preventing equipment failures.

What materials are used in the construction of high-temperature centrifugal fans?

High-temperature centrifugal fans are constructed using durable materials like AISI304 and AISI316, allowing them to withstand elevated temperatures and corrosive conditions.

What is the lifespan of high-temperature centrifugal fans?

When properly maintained, high-temperature centrifugal fans can have a lifespan exceeding 80,000 operating hours.

How do high-temperature centrifugal fans perform in the metallurgy industry?

In metallurgy, these fans regulate heat and exhaust gases in furnaces and kilns, achieving up to 84% static performance and enhancing operational reliability.

What role do high-temperature centrifugal fans play in chemical processing?

They manage hot, corrosive gases and ventilate hazardous fumes, ensuring safe operational conditions in compliance with stringent safety regulations.

What advantages do high-temperature centrifugal fans provide in power generation?

They ensure efficient cooling and ventilation in turbines and generators, capable of operating at high pressures to maintain consistent airflow against significant resistance.

How do high-temperature centrifugal fans benefit food processing?

They are used in drying and cooking methods, maintaining specific temperature and humidity levels crucial for food safety and quality.

What is the projected growth of the global industrial ventilation market?

The global industrial ventilation market was valued at USD 7.64 billion in 2024 and is projected to expand at a CAGR of 4.5% from 2025 to 2034.