Overview

Small axial fans play a crucial role in enhancing electronics projects by delivering efficient airflow that effectively regulates temperature. This regulation not only improves performance but also extends the lifespan of electronic components. By preventing overheating, these fans significantly reduce operational costs and facilitate seamless integration into various applications.

The importance of effective thermal management in modern electronics design cannot be overstated. As electronic devices become more compact and powerful, the need for reliable cooling solutions grows. Small axial fans address this challenge head-on, ensuring that components operate within optimal temperature ranges.

Incorporating small axial fans into your projects is not just a technical enhancement; it’s a strategic decision that can lead to long-term benefits. By prioritizing thermal management, you can enhance the reliability and efficiency of your electronic designs, ultimately leading to greater satisfaction for end-users.

In conclusion, leveraging the capabilities of small axial fans is essential for anyone involved in electronics design. Their ability to manage heat effectively makes them indispensable in today’s fast-paced technological landscape.

Introduction

In an era where electronic devices are becoming increasingly compact and powerful, managing heat effectively has become a critical challenge. Small axial fans have emerged as essential components in enhancing thermal management across a variety of electronics projects, from consumer gadgets to industrial machinery. These compact ventilation devices can significantly improve performance, reliability, and efficiency in electronic applications.

How can engineers and hobbyists alike leverage these small yet powerful tools to overcome the challenges posed by heat generation and ensure optimal operation? This article delves into ten compelling ways to utilize axial fans, providing actionable insights that can transform your approach to thermal management.

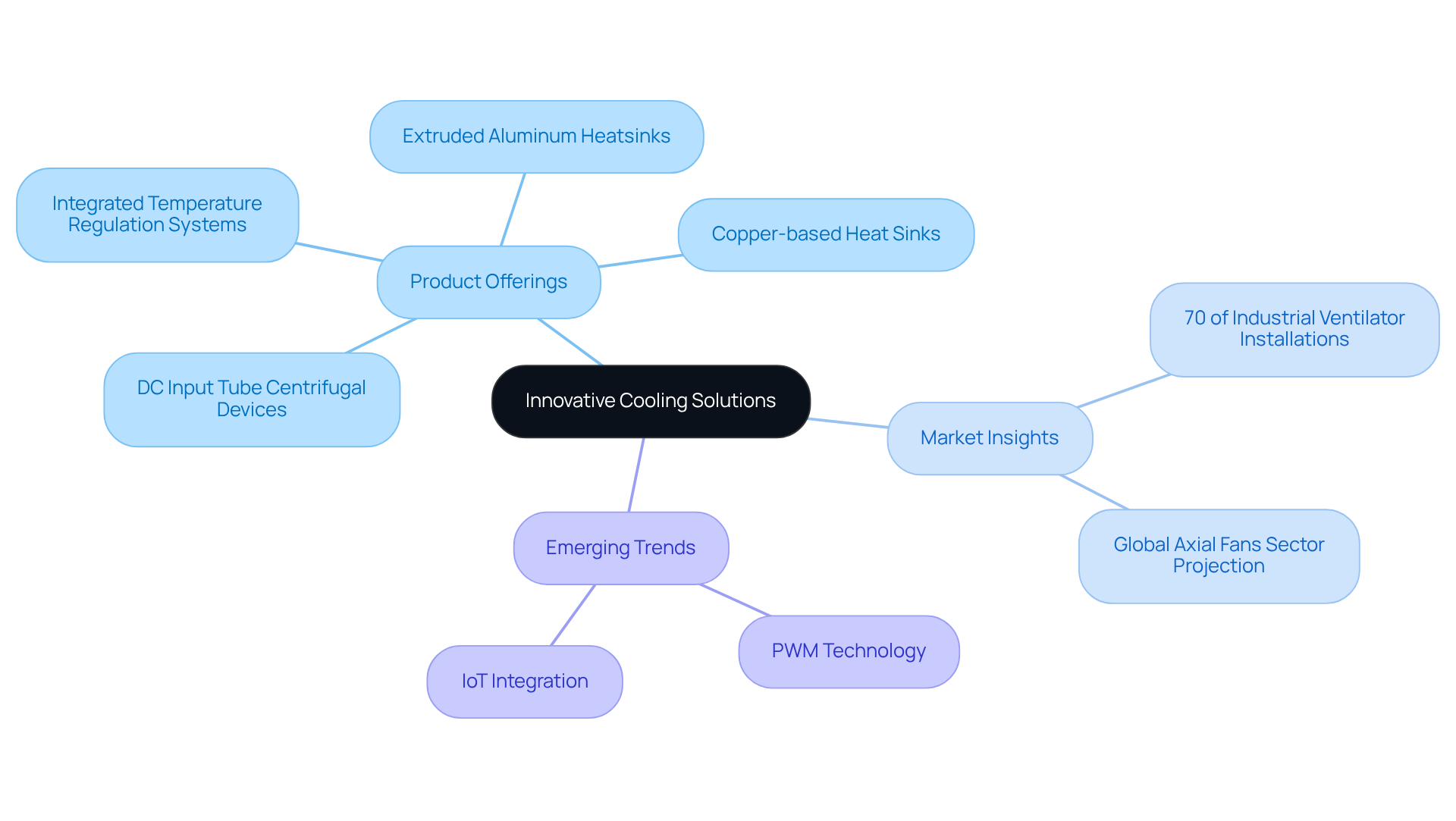

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Projects

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions tailored for the electronics industry. As the world’s largest producer of both standard and custom air-movers, Gagner-Toomey is committed to enhancing performance and efficiency through cutting-edge products, including a diverse range of DC input tube centrifugal devices. These devices are essential for regulating heat across various electronic applications, significantly boosting the reliability and lifespan of components.

With over 70% of industrial ventilator installations falling into this category, their role in electronics temperature regulation is paramount. The global axial fans sector is projected to reach USD 3.85 billion by 2030, highlighting the increasing demand for these vital solutions. Gagner-Toomey’s unwavering dedication to excellence in customer service and product representation positions it as a trusted partner for engineers seeking effective and efficient temperature control solutions.

The company’s extensive portfolio showcases innovative thermal management solutions, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated temperature regulation systems

Moreover, emerging trends such as the adoption of PWM technology and IoT integration are shaping the future of cooling solutions, making Gagner-Toomey’s offerings even more relevant in today’s rapidly evolving electronics landscape.

Cooling Electronic Components: Utilizing Small Axial Fans

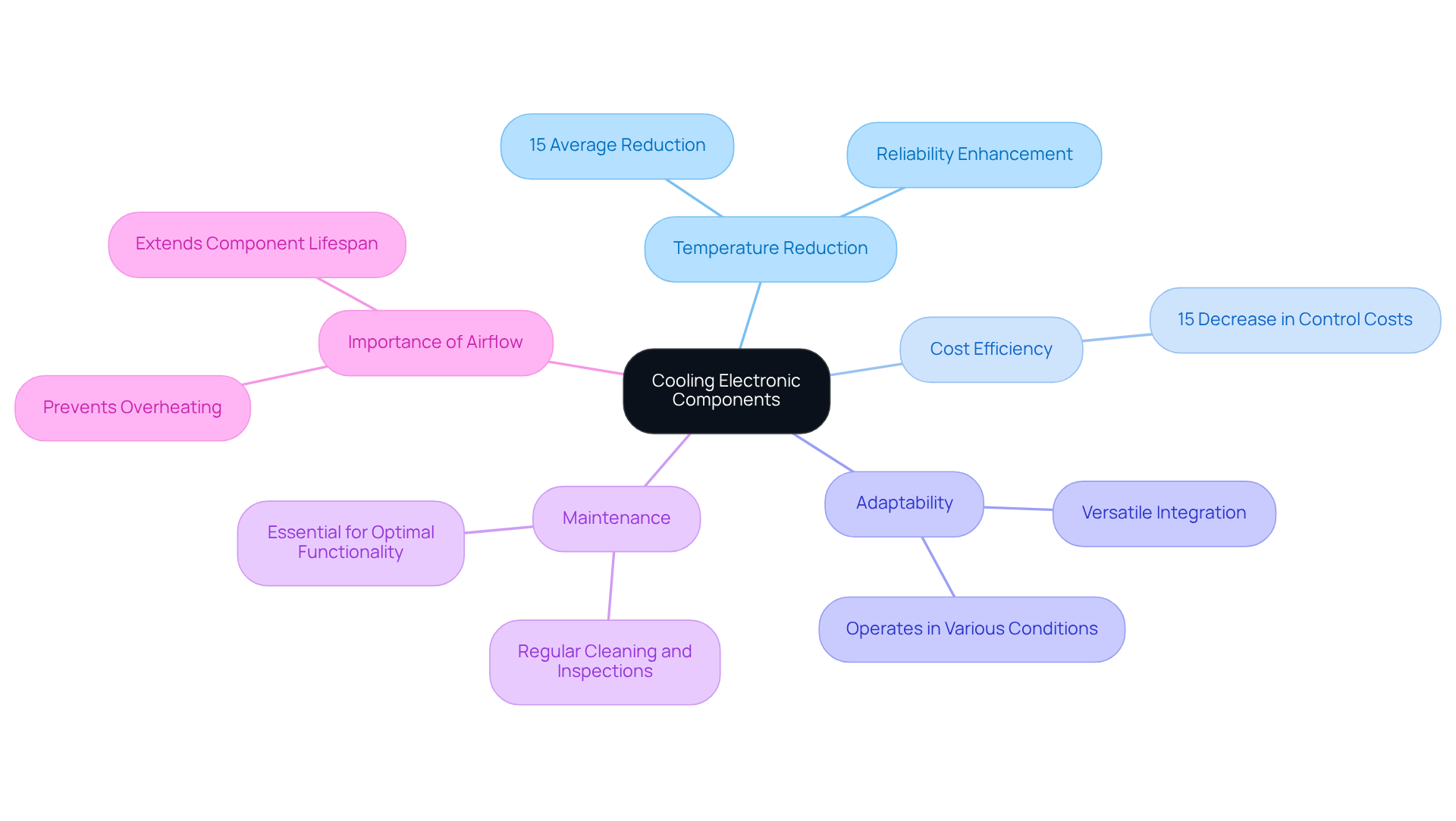

Gagner-Toomey Associates’ compact ventilation devices utilize a small axial fan to effectively circulate air around electronic components, efficiently dispersing the heat generated during operation. This steady airflow is crucial in preventing overheating, which can lead to component failure and diminished performance. Research indicates that small axial fans can achieve average temperature reductions of up to 15%, significantly enhancing the reliability of electronic systems.

Moreover, DC fans from Gagner-Toomey Associates can lead to a 15% decrease in temperature control costs, underscoring their financial benefits in temperature management applications. Their compact design allows for seamless integration into various devices, making them particularly suitable for space-constrained applications, such as consumer electronics and industrial machinery.

Engineers stress the importance of airflow in electronics cooling, asserting that effective thermal management is vital for maintaining optimal performance and extending component lifespan. Additionally, the adaptability of DC ventilation units to different power configurations enhances their versatility across diverse environments.

Regular maintenance practices, including cleaning and inspections, are essential for ensuring the optimal functionality of these devices. For instance, in server environments, compact cooling devices are critical for temperature management, ensuring that sensitive equipment operates within safe limits.

In summary, the strategic implementation of small axial fans from Gagner-Toomey Associates is indispensable in modern electronics design, facilitating improved thermal management and operational efficiency.

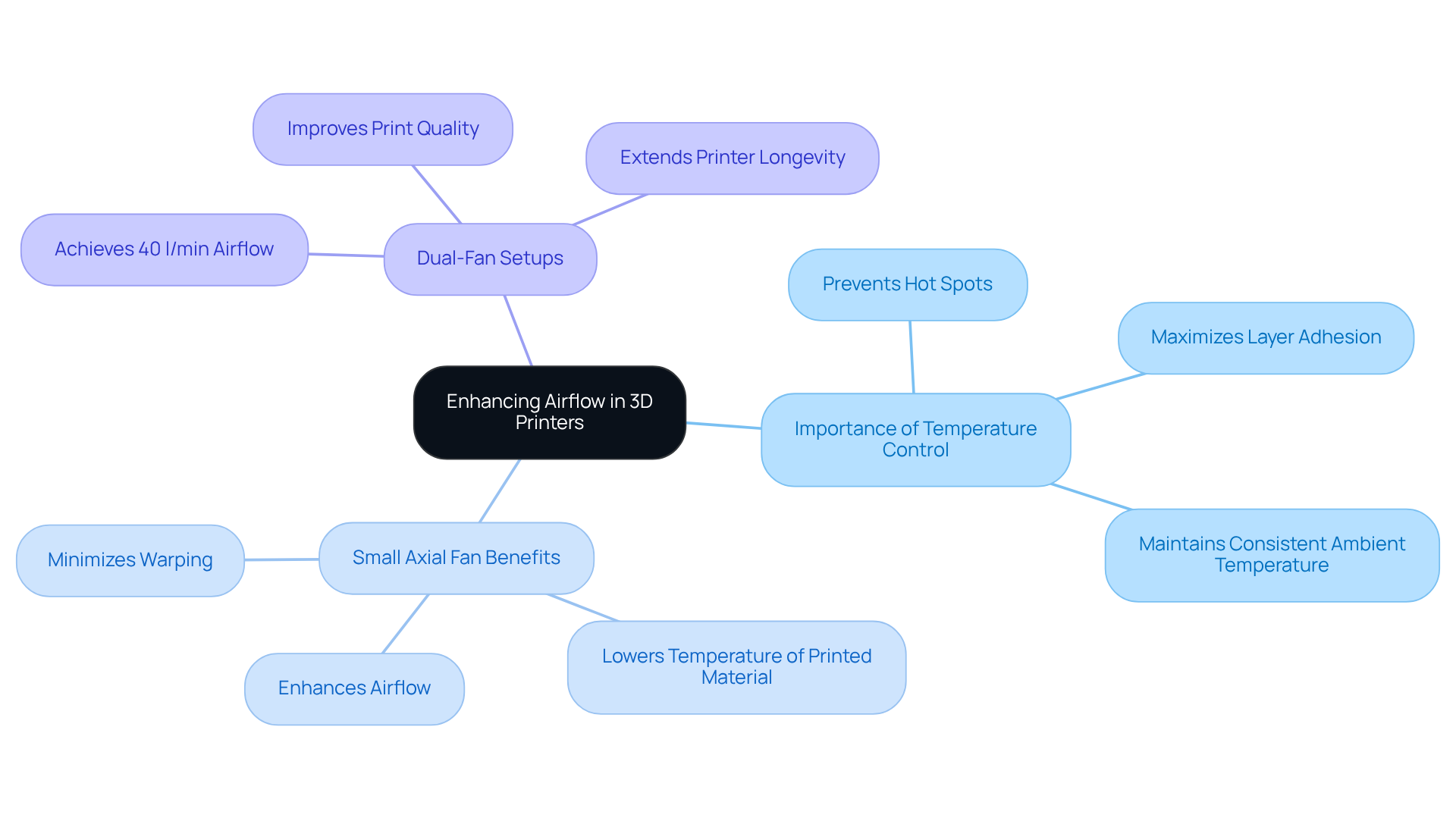

Enhancing Airflow in 3D Printer Enclosures with Small Axial Fans

In the realm of 3D printing, maintaining optimal temperatures within the enclosure is crucial for achieving high-quality prints. The challenge lies in ensuring even temperature distribution to prevent hot spots, which can lead to defects in the final product. A small axial fan can be strategically placed to enhance airflow, effectively lowering the temperature of both the printed material and the printer’s components. This proactive approach significantly minimizes the likelihood of warping and other printing flaws.

For instance, studies indicate that implementing a dual-fan setup can markedly improve airflow efficiency, achieving an airflow rate of 40 l/min for controlled cooling effects in FDM printing. This method not only enhances print quality but also extends the longevity of the printer by preventing overheating. Experts in the field underscore the importance of proper airflow management, as it directly impacts the mechanical properties and surface finish of the printed parts.

As Florens Wasserfall aptly notes, “Ensure proper printing temperature to maximize layer adhesion, and consider adjusting print orientation to align layers perpendicular to the primary stress direction.” By leveraging the capabilities of small axial fans, engineers can significantly enhance their 3D printing processes, leading to superior outcomes in their projects. This strategic implementation of airflow management is not just a recommendation; it is essential for anyone serious about advancing their 3D printing capabilities.

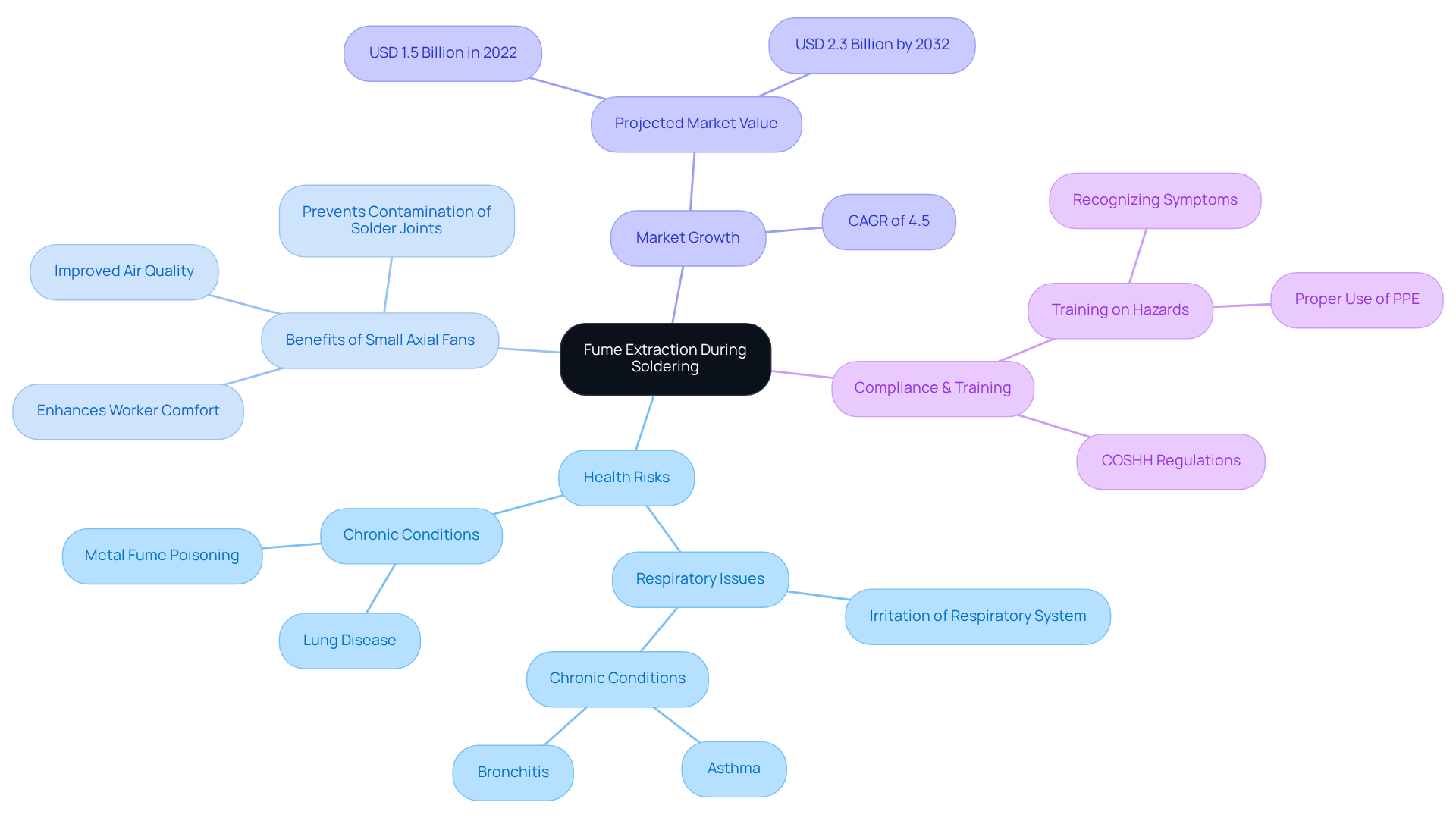

Fume Extraction During Soldering: The Role of Small Axial Fans

Soldering generates harmful fumes that pose significant health risks to operators, including respiratory issues and chronic conditions with prolonged exposure. Compact ducted blowers, such as a small axial fan, are essential for efficient fume removal, strategically placed to pull fumes away from the workspace. By incorporating small axial fans into fume extraction systems, workplaces not only enhance safety but also maintain optimal airflow, which is crucial for preventing contamination of solder joints. This proactive approach protects worker health and improves the quality of soldering by ensuring a cleaner environment.

Health and safety experts emphasize the necessity of effective fume extraction systems, noting that they can significantly reduce the risk of exposure to toxic substances, thereby fostering a healthier workplace. For instance, the use of small axial fans in soldering settings has led to notable advancements in air quality, contributing to better worker comfort and productivity.

As the global fume extractor market is projected to expand notably—from USD 1.5 Billion in 2022 to USD 2.3 Billion by 2032 at a CAGR of 4.5%—the implementation of advanced fume extraction solutions, including small axial fans and compact blower systems, is becoming increasingly essential in electronics manufacturing. Compliance with regulations such as COSHH is crucial, and training workers on the hazards of solder fumes is vital for maintaining a safe working environment.

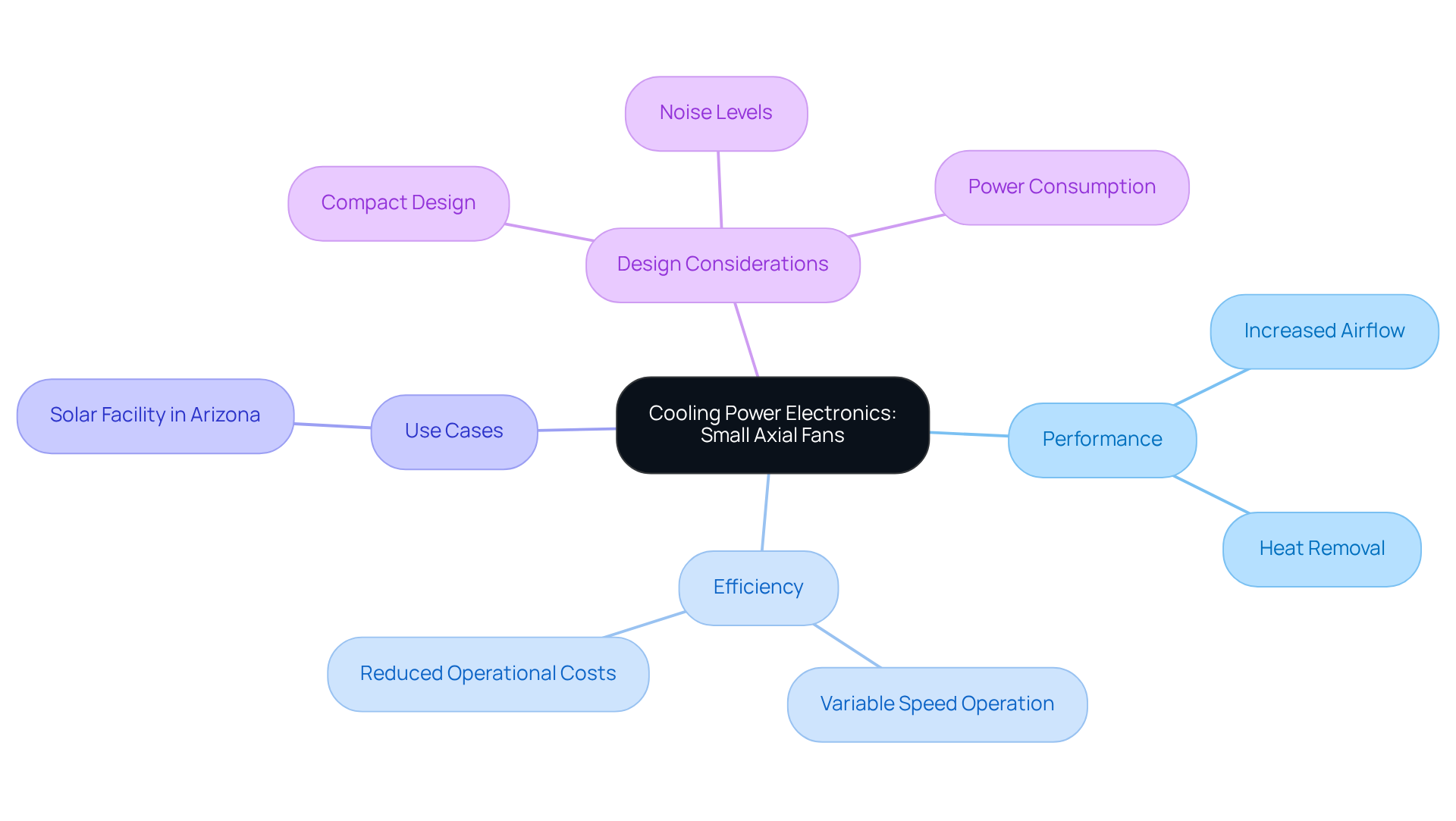

Cooling Power Electronics: Benefits of Small Axial Fans

Power electronics generate considerable heat during operation, making efficient temperature control solutions essential for maintaining performance and reliability. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a comprehensive range of DC input air movers, available in sizes from 15 to 280mm, optimized for performance, efficiency, and low noise. These compact directional blowers provide an effective means of regulating temperatures by significantly enhancing airflow and heat removal.

Their ability to operate at variable speeds allows for dynamic cooling solutions that adapt to changing thermal loads. For instance, a solar facility in Arizona successfully stabilized its output during a heatwave by incorporating Gagner-Toomey’s DC directional devices, ensuring revenue forecasts were met while protecting equipment durability. It’s important to note that a 20-degree increase in temperature can result in a 10 percent drop in solar panel performance, highlighting the urgent need for effective thermal management.

By integrating Gagner-Toomey’s small axial fan devices into power electronic systems, engineers can improve thermal management, extend component lifespan, and enhance overall system efficiency. Effective thermal management ensures that panels operate efficiently, minimizing the risk of warranty claims and boosting reliability. This strategy not only mitigates overheating risks but also strengthens the reliability of electronic devices, ultimately leading to lower operational costs and reduced maintenance needs.

Additionally, most models offer IP protection upon request, further increasing their appeal. To fully leverage these benefits, engineers should consider incorporating advanced thermal solutions from Gagner-Toomey early in the design process.

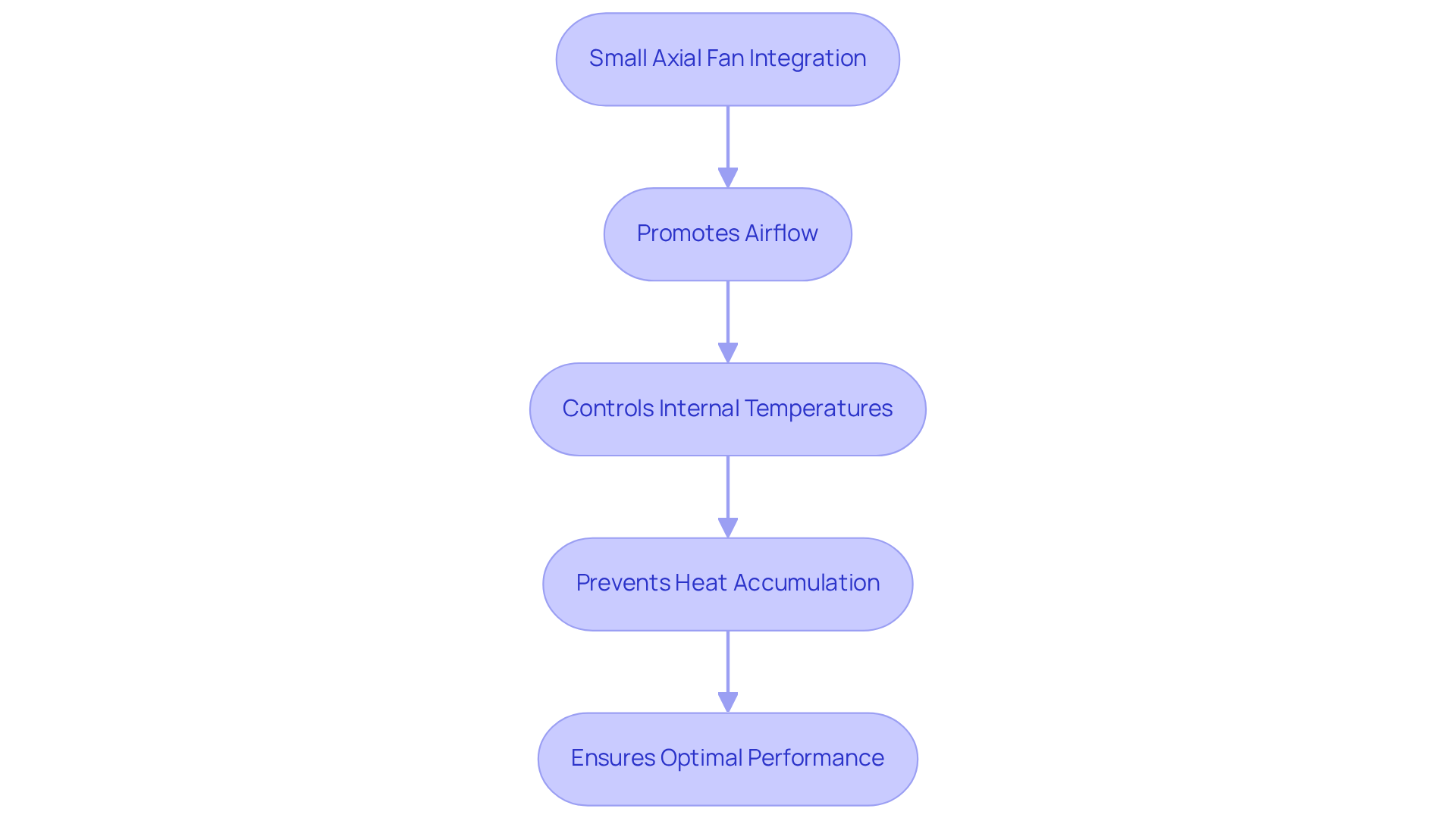

Ventilation Systems for Electronics Enclosures: Small Axial Fans in Action

Compact ventilators, specifically small axial fans, play a crucial role in ventilation systems designed for electronics enclosures. The small axial fan is vital for promoting airflow, which helps control internal temperatures and prevents heat accumulation that could jeopardize the functionality of sensitive components. A well-constructed ventilation system, which includes a small axial fan, significantly enhances the thermal regulation of enclosures, ensuring that electronic devices operate within safe temperature limits. This is especially critical in applications where high-density packaging of components generates substantial heat.

To illustrate, consider a scenario where multiple high-performance processors are housed within a single enclosure. Without adequate ventilation, the heat produced can lead to thermal throttling or even permanent damage. By integrating a small axial fan, engineers can effectively manage airflow, thereby safeguarding the integrity and performance of the components.

In conclusion, investing in robust ventilation solutions is not merely a recommendation but a necessity for maintaining optimal performance in electronic systems. By prioritizing thermal management through the use of compact ventilators, organizations can ensure reliability and longevity in their electronic devices.

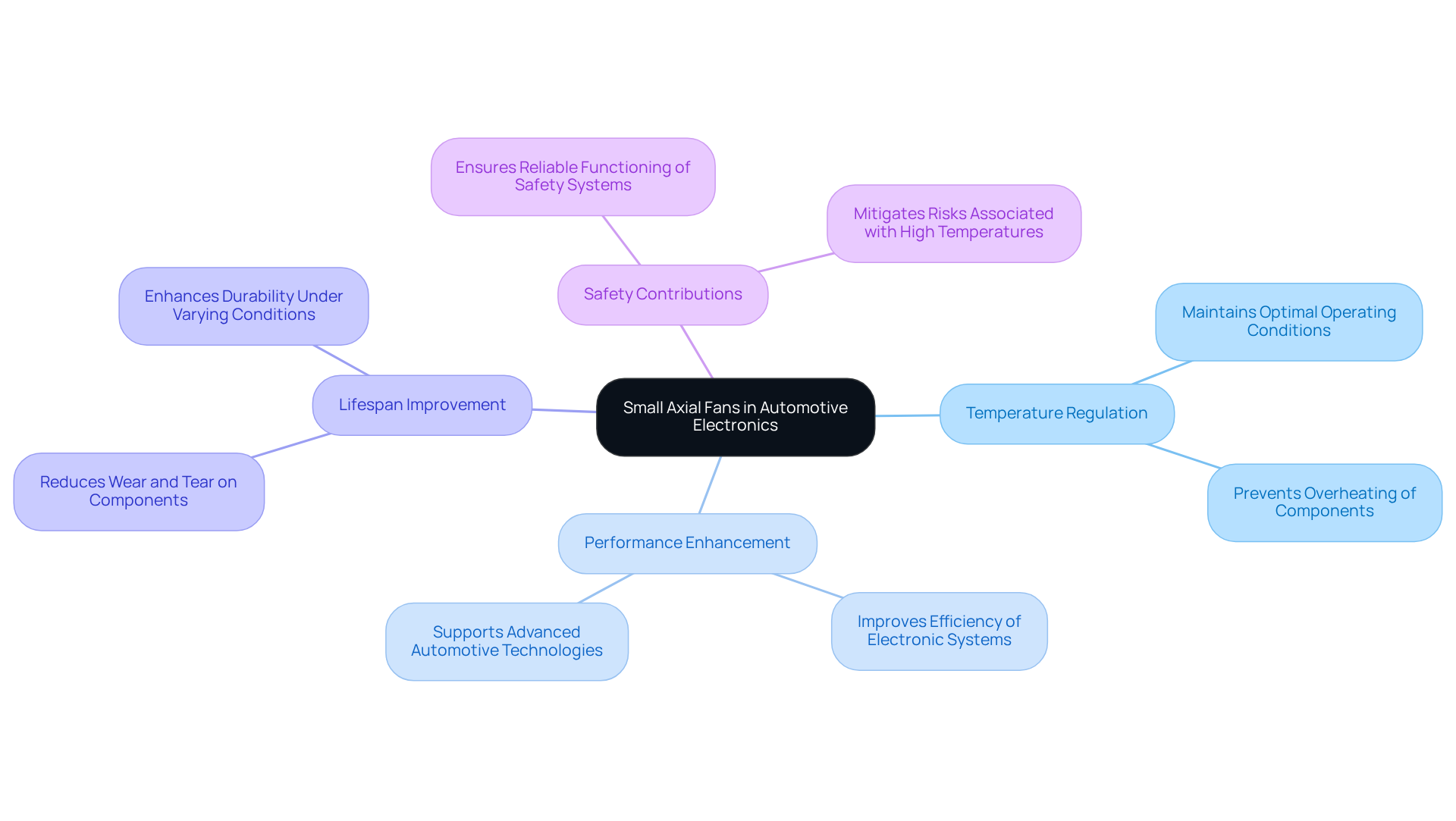

Automotive Electronics: Implementing Small Axial Fans for Cooling

In the automotive sector, compact radial blowers from Gagner-Toomey Associates play a crucial role in regulating the temperatures of electronic components, such as control units and sensors, which often face elevated heat levels. These devices are integral to Gagner-Toomey’s extensive portfolio of standard and custom cooling solutions, ensuring optimal operating conditions. This reliability is vital for automotive electronics, allowing them to function effectively under varying environmental conditions.

By integrating these innovative small axial fans into automotive applications, engineers can significantly enhance the performance and lifespan of electronic systems. This improvement not only aids in the overall efficiency of vehicles but also contributes to their safety. The strategic use of compact radial blowers is a testament to the commitment to advancing automotive technology, ensuring that vehicles meet the demands of modern driving environments.

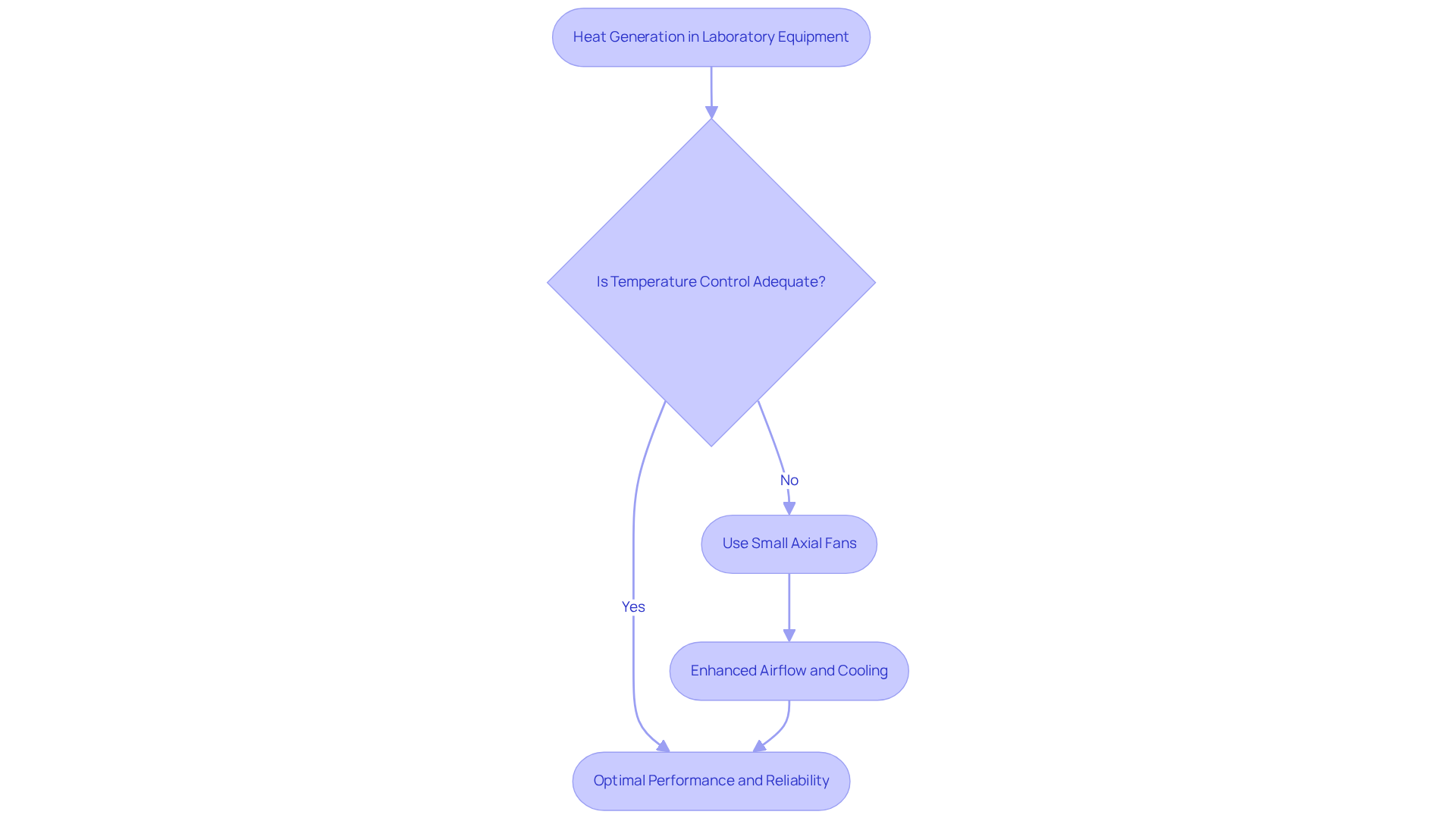

Laboratory Equipment Cooling: The Importance of Small Axial Fans

In laboratory environments, precise temperature control is essential for achieving accurate experimental results and protecting sensitive equipment. The challenge lies in managing heat generated by various devices, which can lead to significant fluctuations in performance. Small axial fans emerge as a vital solution in this context.

These blowers, featuring a small axial fan, effectively cool laboratory devices by enhancing airflow around heat-generating components. This airflow is crucial in preventing overheating, thereby ensuring optimal performance and reliability. Their compact design, akin to a small axial fan, facilitates seamless integration into diverse laboratory setups, making them indispensable tools for researchers and technicians alike.

Consider the implications of inadequate temperature control: laboratories lacking sufficient management can experience average fluctuations of approximately 3 °C. Alarmingly, over 90% of individual assessments are influenced by these temperature variations, underscoring the urgent need for efficient temperature management solutions. As experts emphasize, “The integrity of your samples hinges on effective temperature regulation equipment; even minor deviations from recommended conditions can compromise results irreparably.”

Thus, small directional ventilators not only enhance equipment efficiency but also play a pivotal role in the overall success of laboratory operations. By prioritizing effective temperature regulation, laboratories can safeguard their results and maintain the integrity of their research.

DIY Electronics Projects: Leveraging Small Axial Fans for Custom Solutions

Small axial fans present an ideal solution for DIY electronics tasks, offering efficient temperature regulation across a variety of applications. Hobbyists often turn to small axial fans as cooling devices for custom enclosures, such as those used with Raspberry Pi, where effective heat management is crucial for optimal performance. Their versatility encourages experimentation with different configurations and airflow patterns, significantly enhancing project outcomes.

Moreover, small axial fans operate at low voltages, starting from just 3 Vdc, and are recognized for their energy efficiency, achieving up to a 70% reduction in power consumption compared to traditional temperature regulation methods.

Statistics reveal that 31% of engineers in Asia are inclined to invest more in energy-efficient solutions, highlighting a growing trend among hobbyists who prioritize sustainability in their projects. Real-world examples abound, such as an enthusiast who designed a unique ventilation system for a personal computer, incorporating a small axial fan to improve airflow and reduce heat buildup.

Enthusiasts emphasize the innovative potential of these devices:

‘Utilizing a small axial fan transformed my project; it not only maintained my components’ temperature but also enabled me to explore creative designs that I hadn’t considered before.’

Additionally, the ability of inline blowers to operate in reverse for air expulsion enhances their adaptability, making them indispensable for tailored thermal management in bespoke electronics.

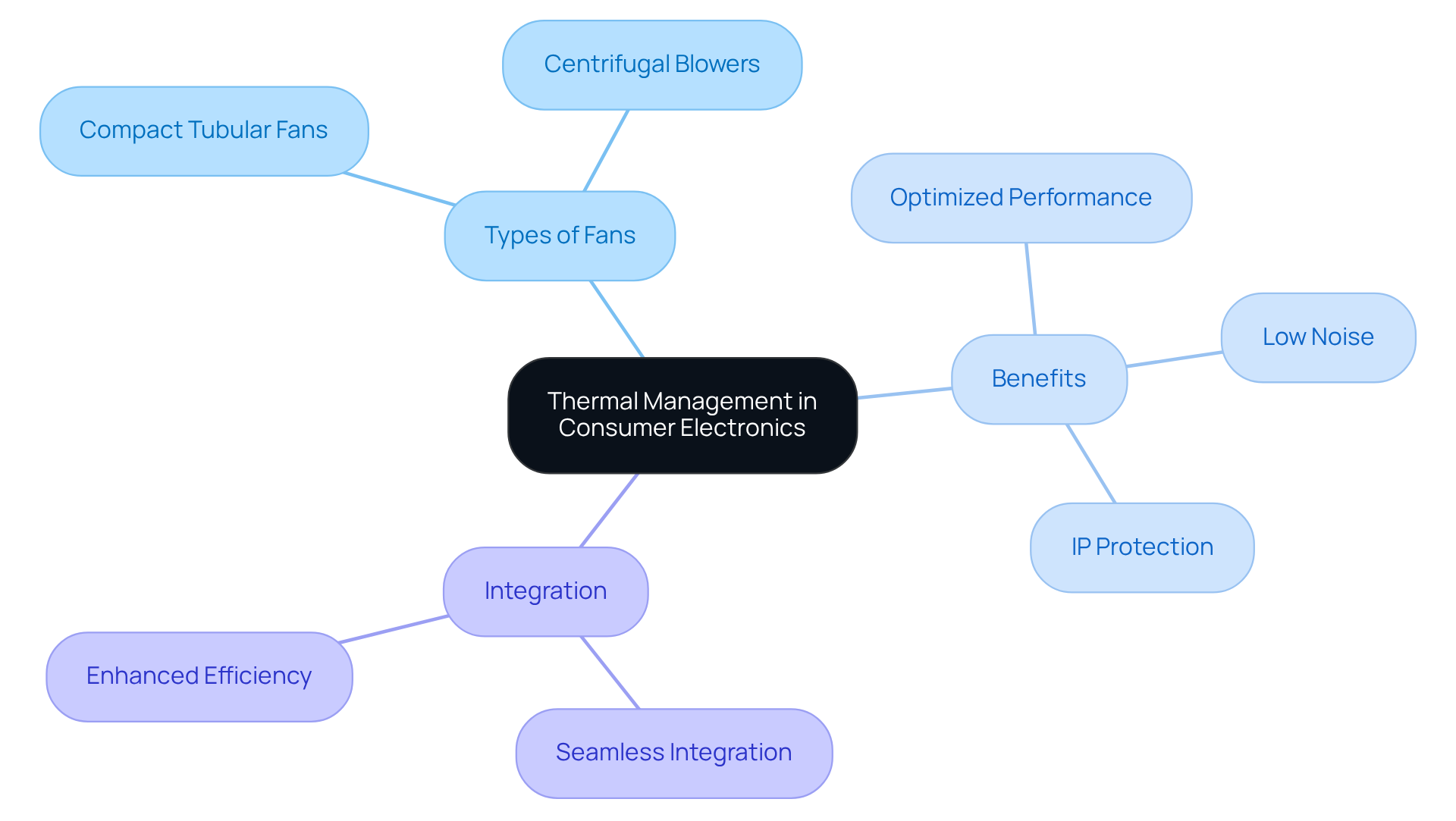

Improving Thermal Management in Consumer Electronics with Small Axial Fans

In the realm of consumer electronics, effective thermal management is crucial for optimizing device performance and extending longevity. Gagner-Toomey Associates stands as the world’s largest manufacturer of both standard and custom air-movers, delivering innovative cooling solutions that markedly enhance thermal management in devices like laptops, gaming consoles, and home entertainment systems.

Their compact tubular and centrifugal blowers are meticulously optimized for performance, efficiency, and low noise. These advanced systems facilitate airflow and effectively dissipate heat, ensuring that devices maintain optimal operating temperatures. Notably, most models offer IP protection upon request, significantly broadening their applicability across various environments. This proactive approach prevents thermal throttling, ultimately enhancing the user experience.

Engineers and designers can seamlessly integrate small axial fans from Gagner-Toomey into their products, achieving superior thermal performance. This integration not only leads to more reliable consumer electronics but also enhances overall efficiency. By choosing Gagner-Toomey, professionals can ensure that their devices operate at peak performance, setting a new standard in thermal management.

Conclusion

The integration of small axial fans into electronics projects marks a significant leap forward in thermal management, enhancing both performance and longevity across a range of devices. These compact ventilation solutions not only facilitate efficient airflow but also play a crucial role in preventing overheating, ensuring that electronic components operate within safe temperature limits.

Several key benefits of small axial fans stand out:

- They improve airflow in 3D printer enclosures.

- They enhance fume extraction during soldering, showcasing their versatility across multiple applications.

- Their role in cooling power electronics and automotive systems further underscores their importance in maintaining optimal operating conditions.

- The financial advantages—such as reduced temperature control costs and improved energy efficiency—reinforce the value of incorporating these devices into modern electronics design.

Ultimately, the significance of small axial fans in electronics cannot be overstated. As technology continues to advance, the demand for effective cooling solutions will only grow. Engineers and hobbyists alike should prioritize the implementation of these innovative devices in their projects. By doing so, they ensure not only improved performance but also the safety and reliability of their electronic systems. Embracing small axial fans is not merely a choice; it is an essential step toward achieving excellence in electronics design and functionality.

Frequently Asked Questions

What innovative solutions does Gagner-Toomey Associates provide for the electronics industry?

Gagner-Toomey Associates offers innovative cooling solutions, including standard and custom air-movers, DC input tube centrifugal devices, extruded aluminum heatsinks, copper-based heat sinks, and integrated temperature regulation systems.

Why are cooling solutions important for electronics?

Cooling solutions are essential for regulating heat in electronic applications, which significantly boosts the reliability and lifespan of components, preventing overheating and potential failure.

What is the projected market size for the global axial fans sector by 2030?

The global axial fans sector is projected to reach USD 3.85 billion by 2030, indicating increasing demand for cooling solutions.

How do small axial fans from Gagner-Toomey Associates improve temperature management?

Small axial fans effectively circulate air around electronic components, achieving average temperature reductions of up to 15%, enhancing reliability and reducing temperature control costs by the same percentage.

What are the key benefits of using DC fans in temperature management?

DC fans provide financial benefits by reducing temperature control costs and are adaptable to different power configurations, making them versatile for various environments.

What maintenance practices are recommended for cooling devices?

Regular maintenance practices, including cleaning and inspections, are essential for ensuring optimal functionality of cooling devices, especially in environments like server rooms.

How can small axial fans enhance 3D printing processes?

Small axial fans improve airflow within 3D printer enclosures, ensuring even temperature distribution and preventing defects like warping, which enhances print quality and extends the printer’s longevity.

What is the significance of airflow management in 3D printing?

Proper airflow management is crucial for maintaining optimal temperatures, which directly impacts the mechanical properties and surface finish of printed parts, leading to higher quality outcomes.

What is a recommended setup for improving airflow efficiency in 3D printing?

Implementing a dual-fan setup can significantly improve airflow efficiency, achieving an airflow rate of 40 l/min for controlled cooling effects in FDM printing.