Overview

The article addresses a critical challenge in electronics: the selection of high volume fans. It highlights two essential practices:

- Understanding fan specifications

- Aligning fan characteristics with project requirements

Key specifications such as airflow and static pressure are emphasized, underlining their significance in achieving optimal performance. Moreover, the article stresses the necessity of matching fan features to specific cooling needs, which is pivotal for ensuring energy efficiency in electronic applications. By focusing on these practices, professionals can enhance their decision-making processes and achieve superior results in their projects.

Introduction

In the realm of high-volume fans, the stakes are elevated when selecting the appropriate equipment for optimal cooling solutions. Engineers face numerous specifications to consider—airflow, static pressure, and energy efficiency—navigating a complex landscape to ensure their choices align seamlessly with project requirements.

A critical analysis of performance curves, alongside the impact of noise levels and maintenance practices, is essential for achieving reliable and efficient operation. As technology evolves and the demand for cooling solutions intensifies, the ability to tailor fan selection to specific applications becomes increasingly crucial, paving the way for enhanced performance and longevity across various industries.

Understand High Volume Fan Specifications

Understand High Volume Fan Specifications

Selecting necessitates a comprehensive understanding of critical specifications, including , , and power consumption. Airflow quantifies the volume of air a fan can circulate, while static pressure indicates its capacity to overcome system obstacles. , recognized as the world’s largest producer of standard and custom air-movers, offers an extensive selection of (available in sizes from 15 – 280mm) and (sizes from 15 – 225mm). These products are , making them ideal for applications in electronics and automotive sectors.

Moreover, factors such as noise levels, efficiency ratings, and operational lifespan are paramount. For example, a fan may boast a high CFM rating; however, if its static pressure is inadequate, it may struggle in environments with significant airflow obstructions. This underscores the importance of , which depicts its functionality under varying conditions. Such insights are essential for ensuring that the chosen fan not only meets the required airflow but also operates efficiently within the constraints of the system.

Recent studies indicate that can lead to heightened resistance and reduced airflow, emphasizing the necessity of meticulous design in cooling systems. As engineers navigate the intricacies of fan specifications, grasping these dynamics will aid in the selection of optimal cooling solutions tailored to specific applications.

Johann Tang, Product Specialist at , aptly noted, “Increased loss of resistance leads to a larger decrease in airflow and characteristics of equilibrium pressure.” This statement highlights the critical importance of considering fixed force in fan selection. Furthermore, many models from Gagner-Toomey Associates are equipped with IP protection, enhancing their applicability across diverse environments.

Match Fan Characteristics to Project Requirements

To effectively align fan characteristics with project requirements, it is crucial to first define of your application. Key considerations include:

- The heat load produced by electronic components

- The available physical space for fan installation

- Environmental conditions that may impact performance

In densely packed electronic enclosures, for instance, selecting a fan with a is essential to ensure sufficient airflow through the components. Furthermore, should not be overlooked; opting for fans with a can lead to significant reductions in operational costs over time. Projects that prioritize this matching process often report fewer failures and .

Research on optimizing pin-fin designs in PCM-based heat sinks has demonstrated that the shape and number of pin-fins can greatly , emphasizing the importance of in attaining optimal . Additionally, it is essential to acknowledge that an ideal filling ratio is present for vapor chambers, which can greatly influence thermal resistance and efficiency. The eco-friendliness of phase change materials (PCM) should also be taken into account, along with their advancements in thermal enhancement.

As one expert noted, ‘The , fan curves, and fan laws can help meet this goal.’ Moreover, statistics indicate that hybrid cooling methods can improve heat flux by up to 65.6% compared to traditional spray cooling, highlighting the impact of innovative materials like the gallium-indium eutectic mixture on cooling solutions.

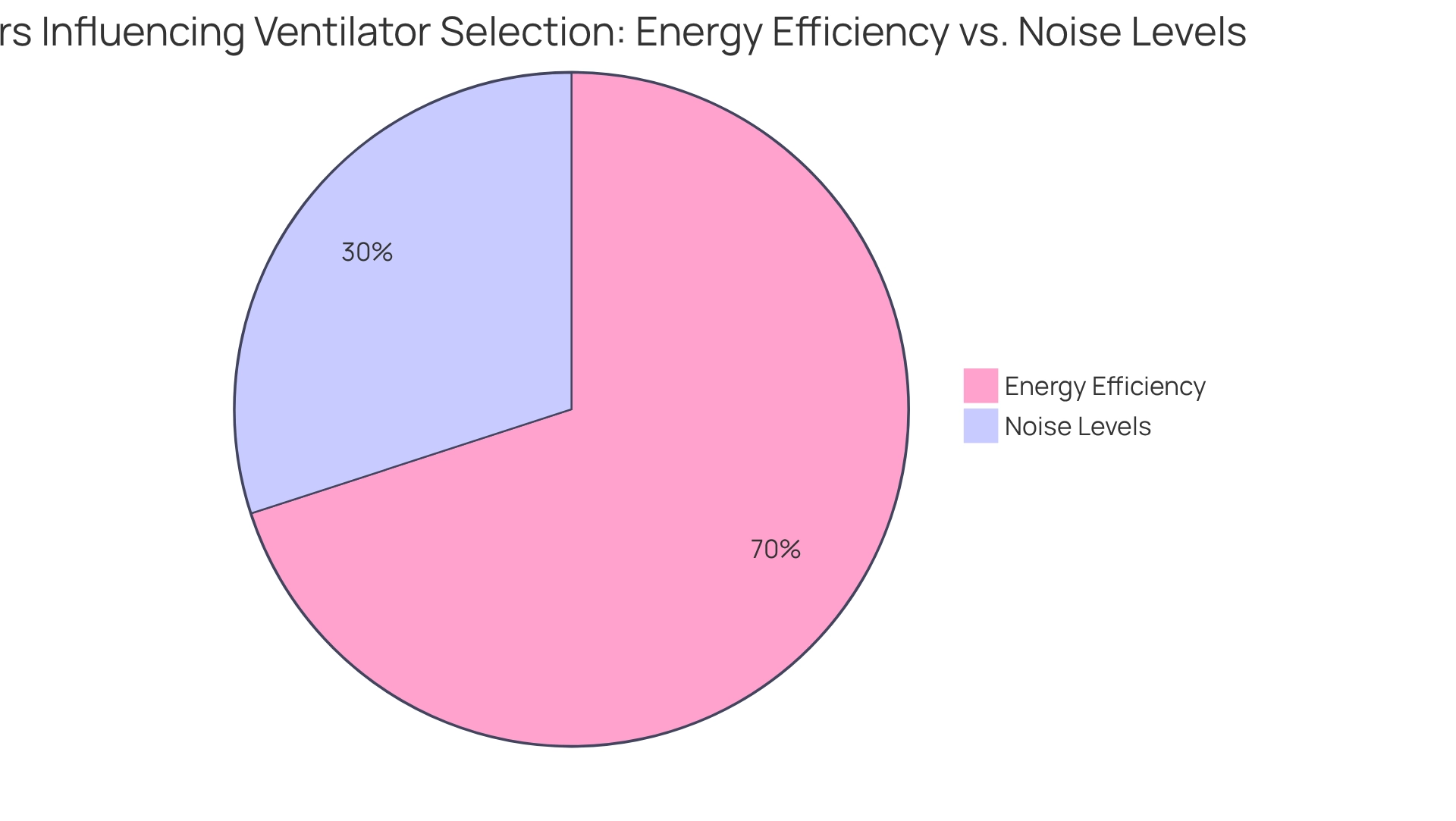

Evaluate Energy Efficiency and Noise Levels

When selecting , , typically evaluated in CFM per watt, are paramount. Fans that deliver can result in significant savings over time. Current statistics reveal that HVLS units achieve an impressive rated airflow performance of 368 CFM/W, highlighting their efficiency. Additionally, these devices often come with , reinforcing their reliability and .

Noise levels play a critical role, particularly in settings where sound reduction is essential. Opt for devices equipped with advanced noise-reduction technologies, such as optimized blade designs and vibration dampening features. A noteworthy case study in a data center demonstrated that transitioning to quieter, more efficient ventilation systems not only decreased energy costs but also markedly reduced , thereby cultivating a more productive work environment. This case underscores the significance of in fan design.

Moreover, there is a recognized necessity for of destratification technology, which underscores the importance of thorough evaluation in fan selection. This dual focus on energy efficiency and noise management is crucial for optimizing fan selection in electronics applications.

Consider Maintenance and Longevity

Selecting devices designed for minimal upkeep is essential for optimal functionality and longevity. Features such as easily accessible components and and maintenance efforts.

For example, a manufacturing facility that implemented a witnessed an impressive 30% increase in fan lifespan, along with a . This supports the principle that investing in lower costs over time, underscoring the importance of .

Fans constructed from robust materials exhibit greater resilience in challenging environments, thereby lessening the likelihood of failure. As Henry Ford aptly remarked, “,” which underscores the .

By prioritizing maintenance and durability, organizations can , ultimately fostering more efficient operations. However, it is vital to recognize common pitfalls in maintenance practices, such as:

- Misapplying maintenance techniques

These can diminish the advantages of a structured approach.

Utilize Performance Curves for Informed Decisions

serve as essential tools that provide critical insights into a fan’s operation across varying airflow rates and fixed forces. By meticulously analyzing these curves, engineers can pinpoint the for the tailored to their specific applications, thereby ensuring that the high volume fan operates efficiently while circumventing overloads or underperformance. Efficiency metrics are pivotal in this selection process, aiding engineers in evaluating the of various high volume fan options. For example, in a project involving high-density electronic components, the strategic selection of a fan operating at its peak efficiency led to significant improvements in and a marked reduction in energy consumption. Furthermore, it is imperative to consider the potential adverse effects of in variable speed fan systems, which can diminish efficiency and induce fan surges, adversely impacting functionality and equipment lifespan. during the selection process is vital to ensure that the chosen high volume fan meets the specific requirements of your project. As James A. Michener articulated, engineers play a crucial role in transforming theoretical concepts into practical solutions. This method not only bolsters system reliability but also fosters . To effectively leverage efficiency graphs, engineers should:

- Analyze to identify the optimal operating points.

- Consider efficiency metrics to evaluate energy consumption.

- Be cognizant of the implications of fixed static pressure in variable speed systems.

- Review case studies that illustrate successful performance curve analysis leading to enhanced cooling performance.

This methodical approach will ensure informed decisions in fan selection.

Conclusion

Selecting the right high-volume fan is a critical process that necessitates a comprehensive understanding of specifications such as airflow, static pressure, and energy efficiency. Engineers must ensure that the equipment chosen aligns with specific project requirements, thereby enhancing cooling performance and reducing operational costs. Research indicates that well-matched fans lead to fewer failures and extended equipment lifespans, underscoring the importance of thoughtful selection.

Energy efficiency and noise levels are also paramount considerations. High-efficiency fans not only decrease power consumption but also minimize noise, making them ideal for sensitive environments such as data centers. Advanced noise-reduction technologies further bolster their performance.

Moreover, prioritizing maintenance and longevity is essential for ensuring reliable operation. Selecting fans designed for easy upkeep can significantly reduce downtime and enhance efficiency. Utilizing performance curves during the selection process equips engineers to make informed decisions that align fan performance with project demands.

In conclusion, a comprehensive approach that considers specifications, energy efficiency, noise levels, and maintenance is vital for effective high-volume fan selection. As technology evolves, tailoring fan choices to specific applications will become increasingly crucial for achieving optimal performance and longevity. By adopting these principles, organizations can ensure that their cooling solutions are effective, sustainable, and economically viable over time.

Frequently Asked Questions

What are the critical specifications to consider when selecting high volume fans?

Key specifications include airflow (measured in CFM), static pressure, and power consumption. Airflow measures the volume of air a fan can circulate, while static pressure indicates its ability to overcome system obstacles.

What types of fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide selection of DC input Tube Axial fans (sizes ranging from 15 – 280mm) and Centrifugal Blowers (sizes from 15 – 225mm), optimized for efficiency and low noise.

Why is static pressure important in fan selection?

Static pressure is crucial because a fan with a high CFM rating may still struggle in environments with significant airflow obstructions if its static pressure is inadequate.

How can one ensure the chosen fan meets the required airflow efficiently?

Consulting the performance curve of the high volume fan is essential, as it shows the fan’s functionality under varying conditions, helping to ensure it operates efficiently within the system’s constraints.

What factors should be considered when defining cooling needs for an application?

Key considerations include the heat load produced by electronic components, the available physical space for fan installation, and environmental conditions that may impact performance.

Why is energy efficiency important in fan selection?

Selecting fans with a high CFM per watt ratio can lead to significant reductions in operational costs over time, which is essential for projects that prioritize energy efficiency.

What impact does installation density have on cooling systems?

Increased installation density within electronics enclosures can lead to heightened resistance and reduced airflow, emphasizing the need for careful design in cooling systems.

What role do customized fan selections play in thermal management?

Customized fan selections are important for achieving optimal thermal management, as they can significantly improve cooling efficiency based on specific design requirements.

What is the significance of using system curves, fan curves, and fan laws in fan selection?

Utilizing these tools helps engineers align fan characteristics with project requirements, ensuring effective cooling solutions tailored to specific applications.

How can hybrid cooling methods improve heat flux?

Hybrid cooling methods can enhance heat flux by up to 65.6% compared to traditional spray cooling, demonstrating the effectiveness of innovative materials in cooling solutions.