Overview

The article delineates three critical steps essential for selecting the appropriate fan and blower:

- Comprehending key selection criteria—CFM, static pressure, and air density

- Evaluating application requirements

- Considering energy efficiency standards as well as regulatory compliance

Each step is bolstered by comprehensive explanations detailing how these factors impact fan performance and project sustainability. This underscores the necessity of thorough assessment to guarantee optimal functionality and cost-effectiveness across diverse applications.

Introduction

Selecting the right fan and blower for a project presents a significant challenge, particularly when navigating the numerous factors that impact performance and efficiency. For engineers focused on optimizing airflow across various applications, grasping key metrics such as CFM, static pressure, and air density is essential. Yet, with the increasing demands of energy efficiency standards and regulatory compliance, how can one guarantee that the selected equipment fulfills operational requirements while aligning with sustainability objectives? This article explores critical steps for making informed selections, ensuring that projects not only achieve effectiveness but also maintain compliance.

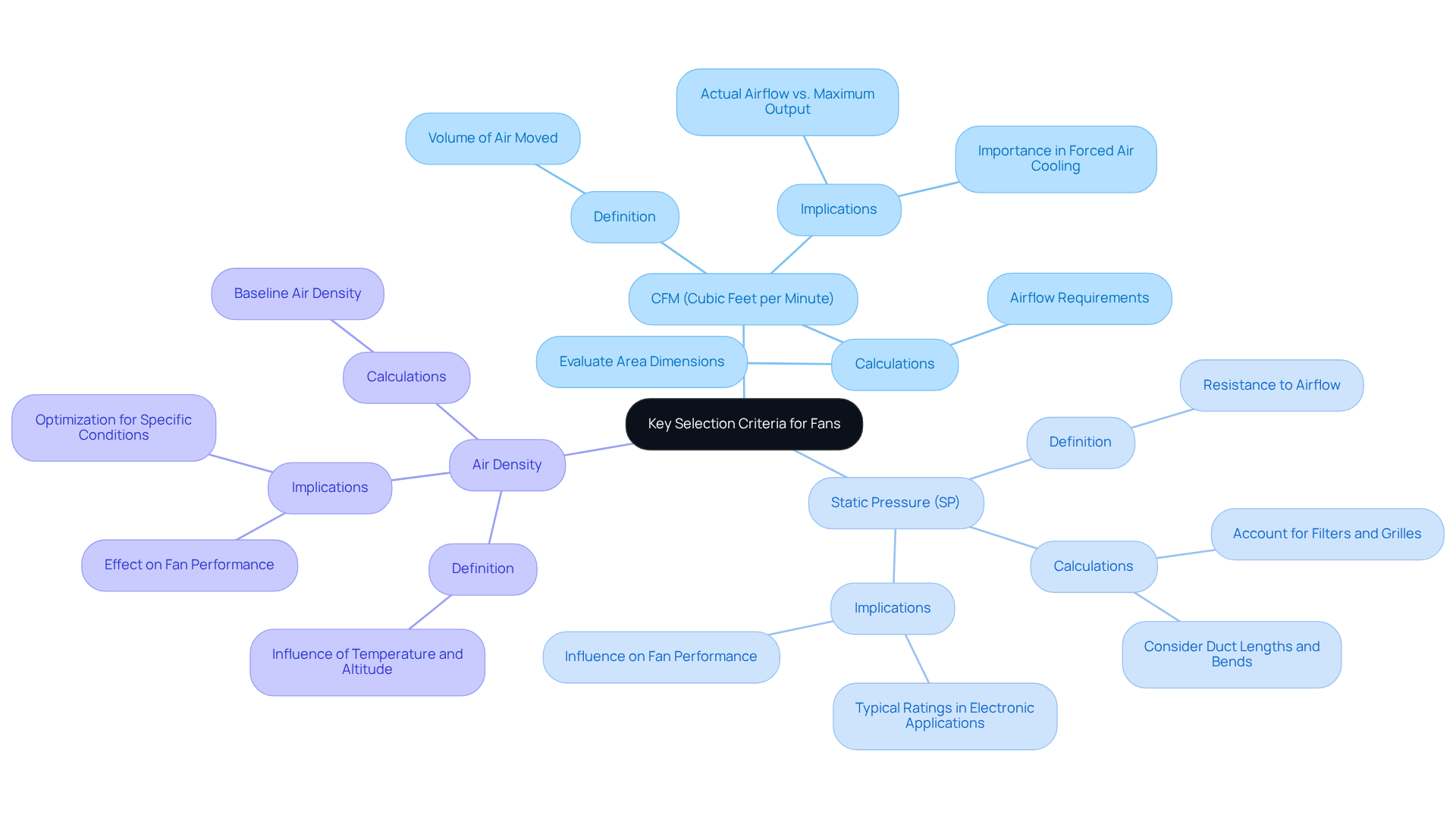

Understand Key Selection Criteria: CFM, SP, and Air Density

Selecting the right fan or blower hinges on understanding three essential metrics:

- CFM (): This metric quantifies the volume of air a fan can move. To determine the necessary CFM for your application, evaluate the dimensions of the area and the specific . In numerous forced air cooling scenarios, actual airflow frequently attains approximately half of the fan’s maximum output, making precise calculations essential. provides a comprehensive range of , varying from 15 to 280mm, enhanced for performance and efficiency, including low noise alternatives.

- (SP): Static pressure represents the resistance the fan must overcome to effectively move air through the system. To calculate total static pressure, consider factors such as duct lengths, bends, and any filters or grilles that may impede airflow. Typical static pressure ratings for fans in electronic applications hover around 1.0 inH2O, but can vary based on system design and requirements. Understanding static pressure is vital, as it directly influences the performance of both fan and blower, especially in . Gagner-Toomey Associates‘ , are engineered to address various static pressure challenges.

- Air Density: Variations in air density, influenced by temperature and altitude, can significantly affect . For standard calculations, use a baseline air density of 0.075 lb/ft³ unless your usage operates under significantly different conditions. Recognizing how air density interacts with CFM and static pressure is essential for optimizing fan selection. Gagner-Toomey Associates offers extensive solutions that address , ensuring that you can locate the appropriate fan & blower for your specific requirements, including models with IP protection available upon request.

By carefully gauging these parameters, engineers can guarantee that the selected fan or ventilator functions effectively within the particular requirements of their application, ultimately improving system efficiency and dependability.

Evaluate Application Requirements: Matching Fans and Blowers to Needs

When evaluating application requirements, it is essential to consider the following factors:

- : Determine whether the fan & blower will be utilized for . Each application has that must be addressed.

- : Assess the operating environment, including temperature, humidity, and potential contaminants. For example, corrosive environments may necessitate devices constructed from specific materials to ensure longevity and performance.

- : Determine the available space for installation. Some devices are designed for compact areas, while others may require additional space for optimal functioning and efficiency.

- : Consider the acceptable noise levels for your application. Certain fans are engineered to operate quietly, which is crucial in residential or office settings where noise reduction is a priority.

By thoroughly , you can your .

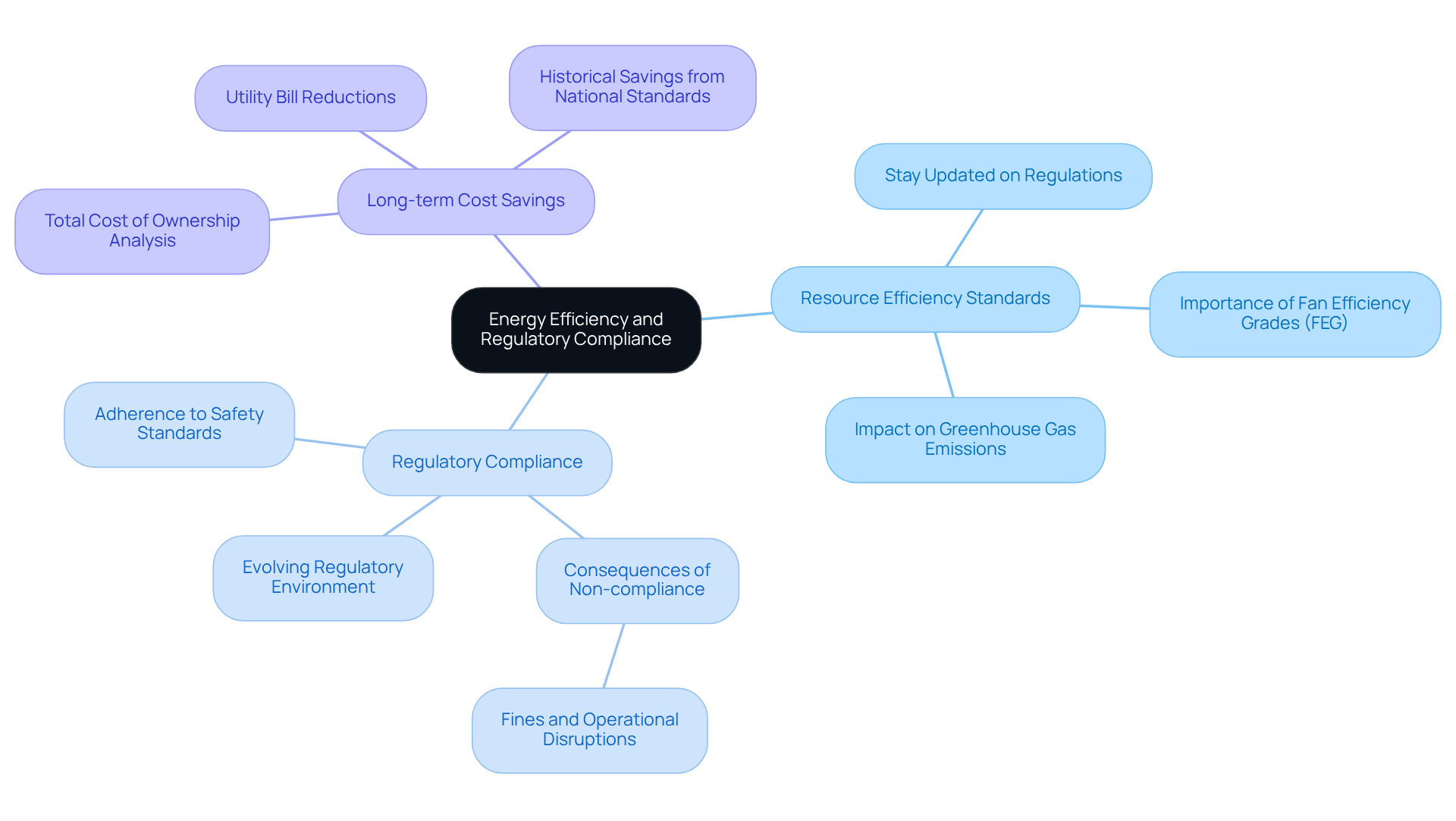

Consider Energy Efficiency Standards and Regulatory Compliance

When selecting a fan or blower, several critical factors must be considered:

- : It is essential to stay updated on the most recent resource efficiency standards established by the Department of Energy (DOE) and local regulations. with (FEG) are crucial for ensuring optimal performance and . Recent suggestions aimed at setting underscore the industry’s emphasis on enhancing efficiency, recognized as a vital approach for decreasing greenhouse gas emissions.

- : Ensuring that the selected equipment adheres to all relevant regulations, including safety standards and environmental guidelines, is vital. Non-compliance can result in significant fines and operational disruptions. The DOE’s recent retraction of suggested conservation standards for fan & blower systems illustrates the continuously evolving regulatory environment that engineers must navigate. A comprehensive understanding of these regulations can help avoid pitfalls in project execution. Furthermore, engineers should remain vigilant, as future proposals may arise, necessitating ongoing compliance efforts.

- : While efficient fans may require a greater upfront expenditure, they can lead to substantial reductions in utility bills over time. A thorough examination of the , encompassing maintenance and power usage, is essential for making informed choices. National appliance standards have historically saved the average U.S. household over $500 annually, demonstrating the financial benefits of . Additionally, efficiency investments by states reached a record peak of approximately $8.8 billion in 2023, reflecting a growing commitment to sustainable practices.

By prioritizing and regulatory compliance, engineers can significantly enhance the sustainability and cost-effectiveness of their projects.

Conclusion

Selecting the appropriate fan or blower for a project is a multifaceted process that necessitates a thorough understanding of key performance metrics, application requirements, and energy efficiency standards. By focusing on crucial parameters such as CFM, static pressure, and air density, engineers can ensure that their chosen equipment operates efficiently and meets the unique demands of their specific applications.

The evaluation of application requirements is paramount. This includes considering the type of application, environmental conditions, mounting constraints, and noise levels. Each of these factors plays a vital role in determining the most suitable fan or blower for a project. Furthermore, compliance with energy efficiency standards and regulatory guidelines is essential, as it not only promotes sustainability but also leads to long-term cost savings.

Ultimately, making informed decisions in fan and blower selection is crucial for optimizing performance and efficiency. By prioritizing these considerations, engineers can enhance the effectiveness of their systems while contributing to broader environmental goals. Embracing best practices and staying updated on industry standards will empower professionals to select the right equipment that aligns with both project requirements and regulatory demands.

Frequently Asked Questions

What is CFM and why is it important in fan selection?

CFM stands for Cubic Feet per Minute and quantifies the volume of air a fan can move. It’s important for determining the necessary airflow for a specific application based on the area dimensions and airflow requirements.

How can I determine the necessary CFM for my application?

To determine the necessary CFM, evaluate the dimensions of the area and the specific airflow requirements. It’s important to note that actual airflow often reaches about half of the fan’s maximum output in many forced air cooling scenarios.

What does static pressure (SP) represent in fan systems?

Static pressure represents the resistance that the fan must overcome to effectively move air through the system. It is influenced by factors such as duct lengths, bends, and any filters or grilles that may impede airflow.

How do I calculate total static pressure?

Total static pressure can be calculated by considering the resistance factors like duct lengths, bends, and any obstructions such as filters or grilles that affect airflow.

What are typical static pressure ratings for fans in electronic applications?

Typical static pressure ratings for fans in electronic applications are around 1.0 inH2O, but these can vary depending on the system design and requirements.

How does air density affect fan performance?

Air density, which can vary due to temperature and altitude, significantly affects fan performance. For standard calculations, a baseline air density of 0.075 lb/ft³ is used unless conditions differ significantly.

Why is it important to understand the relationship between air density, CFM, and static pressure?

Understanding how air density interacts with CFM and static pressure is essential for optimizing fan selection, ensuring that the fan operates effectively within the specific requirements of the application.

What products does Gagner-Toomey Associates offer to address these metrics?

Gagner-Toomey Associates offers a range of DC input Tube Axial devices and centrifugal fans designed to enhance performance and efficiency, including models that address various static pressure challenges and options with IP protection available upon request.