Overview

Selecting the right high CFM blower fan requires a comprehensive understanding of key specifications, including:

- CFM

- Static pressure

- Air density

Additionally, evaluating environmental factors such as temperature and altitude is paramount. These considerations are not merely recommendations; they are crucial for ensuring optimal fan performance tailored to specific applications. Insights into the impact of air density on efficiency underline the importance of these specifications. Furthermore, recognizing the significance of local support for maintenance and replacement parts cannot be overstated. This multifaceted approach guarantees that the chosen fan will meet the demands of its intended environment effectively.

Introduction

Selecting the right high CFM blower fan is crucial for maximizing ventilation efficiency; however, many neglect the essential specifications that govern performance. A thorough understanding of metrics such as:

- CFM

- Static pressure

- Air density

not only elevates decision-making but also guarantees that the selected fan aligns with specific environmental requirements. How can one adeptly navigate these complexities to pinpoint the ideal blower fan that strikes a balance between power and efficiency tailored to their unique application?

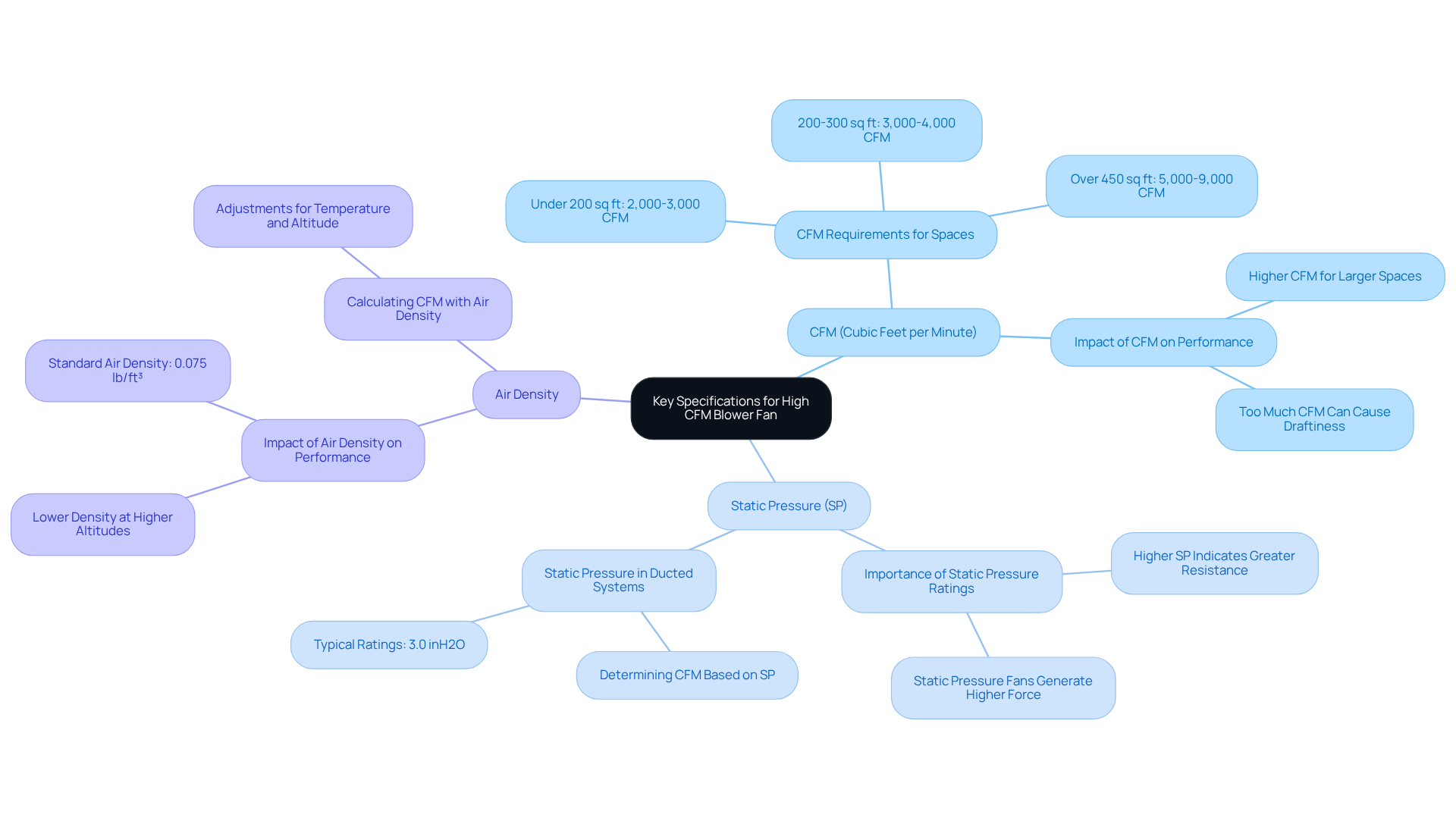

Understand Key Specifications: CFM, SP, and Air Density

To select the right , it is essential to understand several that will guide your decision-making process:

- CFM (Cubic Feet per Minute): This metric quantifies the volume of air the fan can move in one minute. Determining the necessitates considering the size of the space and its airflow needs. For example, spaces exceeding 450 square feet typically require a CFM ranging from 5,000 to 9,000 to ensure .

- (SP): This specification refers to the resistance the fan must overcome to effectively move air through the system. A higher static pressure indicates greater resistance, which may necessitate a more powerful fan. Understanding the for high CFM blower fans in the electronics sector is crucial, as these ratings significantly influence performance.

- : The density of air plays a critical role in the fan’s performance. At higher altitudes or temperatures, air density decreases, potentially impacting the fan’s efficiency in moving air. For calculations, use the standard air density of 0.075 lb/ft³ as a baseline.

By comprehending these specifications, you can evaluate the of various air movers more effectively and make informed decisions. Recent insights from industry specialists underscore the necessity of balancing CFM and static pressure when selecting ventilation units, thereby ensuring optimal performance tailored to specific applications. Additionally, it is vital to consider the , which typically ranges from 15 to 20 years, and fans, which generally last about 10 to 15 years, to secure long-term solutions.

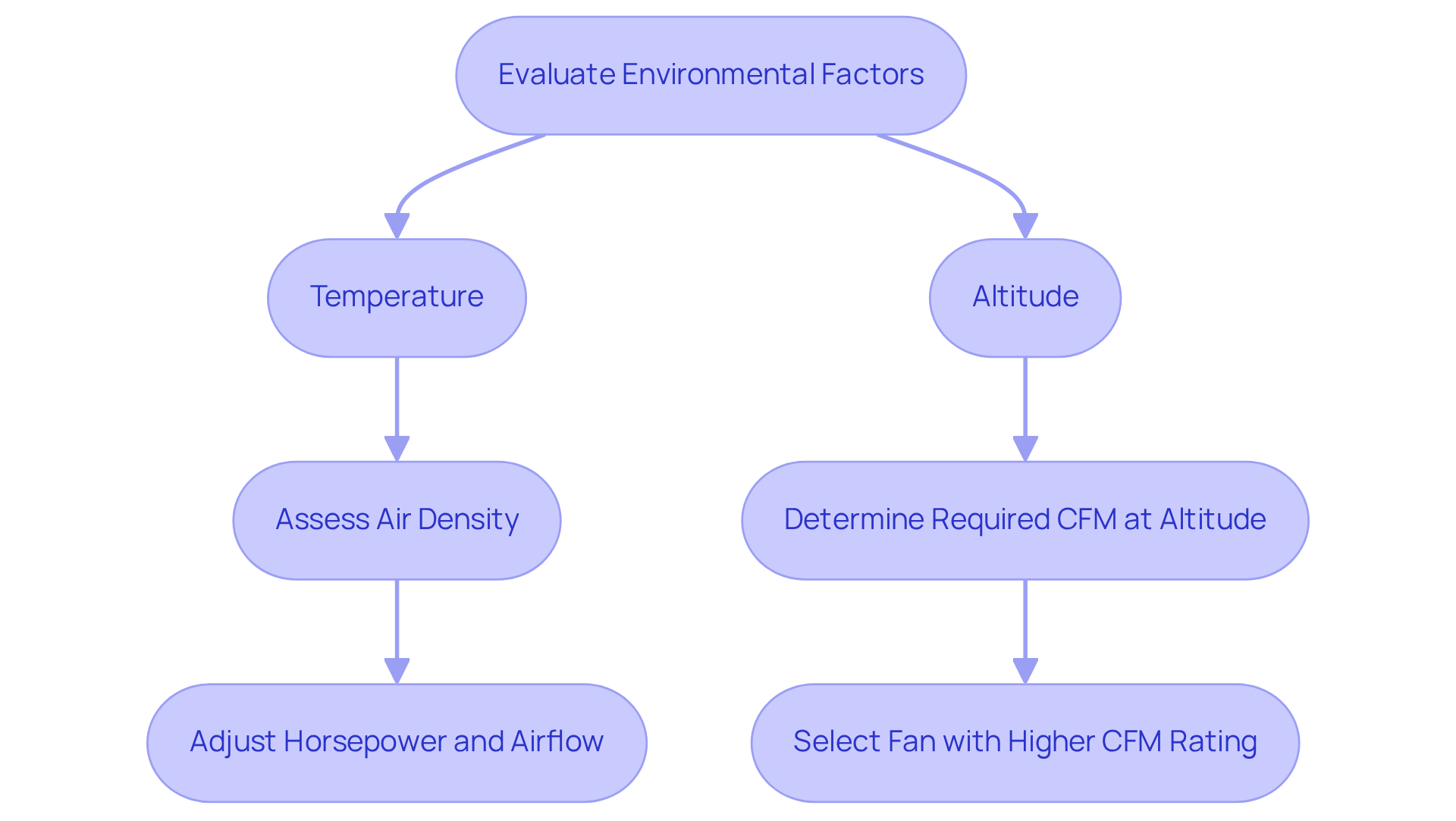

Evaluate Environmental Factors: Temperature and Altitude Adjustments

When selecting a , it is essential to consider several that can significantly impact its performance.

- Temperature: in , thus affecting fan efficiency. According to ASHRAE Standard Air Density, at sea level, the density of air is 0.075 lbs/ft³ at 70ºF. In applications involving high temperatures, it is crucial to select a fan specifically designed to accommodate these conditions. This may require adjustments in horsepower and airflow to maintain , as diminished air density can impede .

- Altitude: With increasing altitude, air density decreases, resulting in . For example, cooling a 340W load at sea level necessitates approximately 40 CFM, whereas at 25,000 feet, this requirement escalates to about 86 CFM. To achieve the desired airflow in high-altitude settings, it is often necessary to choose a with a higher CFM rating. Furthermore, it is vital to ensure that the fan operates efficiently under these conditions, as lower air mass can adversely affect cooling performance. As Ed Neese pointed out, variations in air density relative to Standard Air density will influence system pressure and fan motor BHP in proportion to the air density ratio.

By thoroughly evaluating these environmental factors, along with insights derived from ‘s , you can ensure that the selected ventilation fan delivers optimal performance tailored to your specific application.

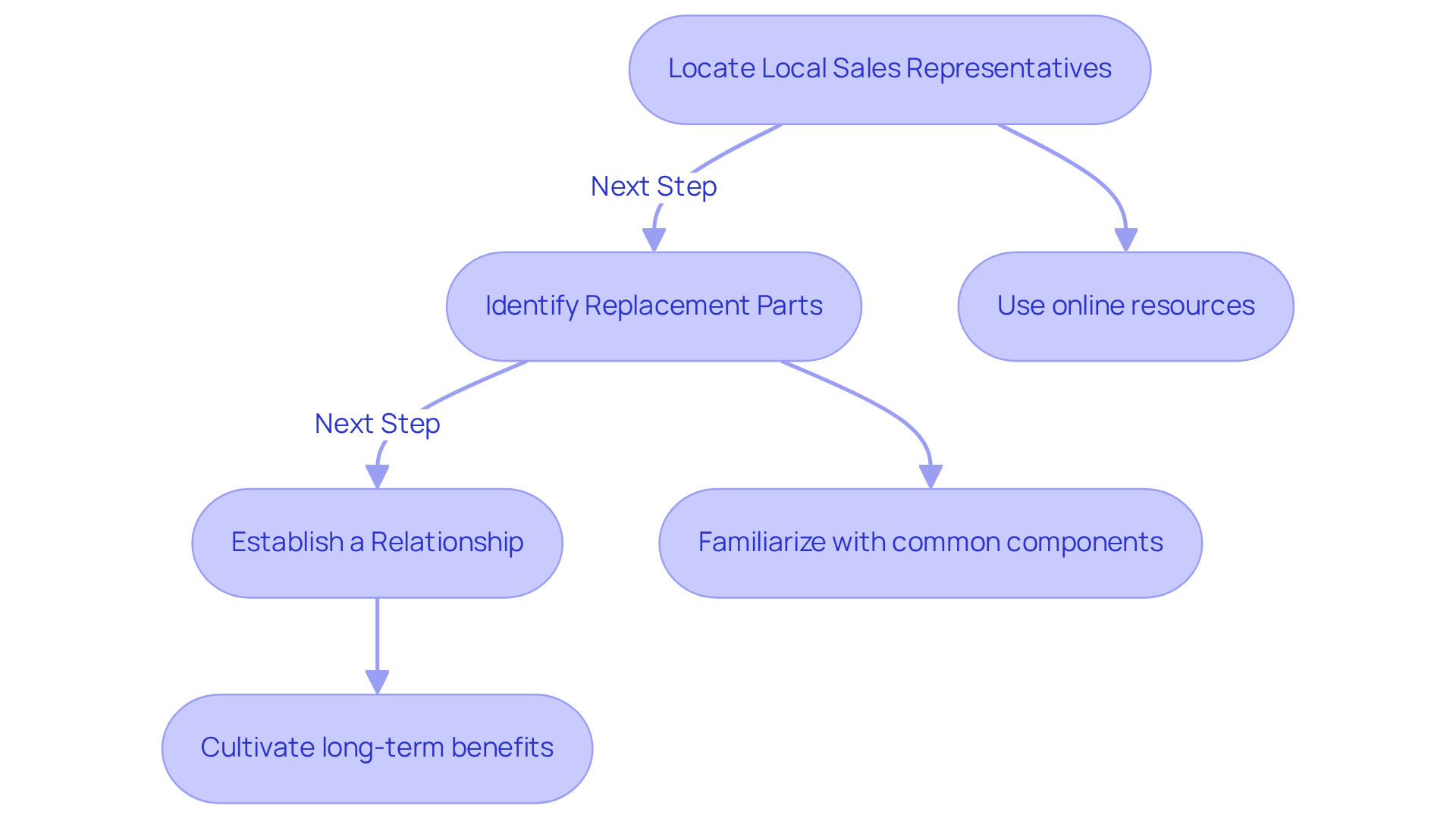

Locate Local Sales Representatives and Replacement Parts

To ensure optimal support for your , consider the following steps:

- Locate : Utilize online resources or manufacturer websites to identify local sales representatives for the fan brands you are evaluating. These professionals offer , guiding you through the selection process and ensuring you choose the right fan for your specific application.

- Identify : Familiarize yourself with the common replacement components essential for your fan, including blades, motors, and filters. Understanding these components is crucial, as can significantly extend . A well-maintained HVAC fan motor can last anywhere from 10 to 20 years. Consult the manufacturer’s website or reach out to your local representative to learn about purchasing these parts.

- Establish a Relationship: Cultivating a relationship with your local sales representative can provide long-term benefits for maintenance, inquiries, and upgrades. They can offer continuous assistance and keep you updated on the , ensuring your fan operates efficiently and effectively.

By actively engaging with local sales representatives and understanding the importance of replacement parts, you can maintain the of your high CFM blower fan and prevent costly downtime. , such as cleaning, checking for problems, lubrication, and replacing worn-out parts, are essential to avoid low efficiency, high energy use, expensive downtime, or breakages.

Conclusion

Selecting the right high CFM blower fan is a critical task that necessitates a comprehensive understanding of various specifications and environmental factors. Recognizing the importance of CFM, static pressure, and air density empowers individuals to make informed choices that ensure optimal performance tailored to their specific needs. The longevity of these systems further underscores the necessity of selecting the right fan from the outset; a well-chosen unit can serve effectively for many years.

Evaluating environmental factors such as temperature and altitude is significant, as these elements can greatly influence fan efficiency and airflow requirements. Understanding the interaction between these factors and fan specifications is vital for achieving the desired performance across different applications. Moreover, engaging with local sales representatives and familiarizing oneself with essential replacement parts can enhance both the operational efficiency and lifespan of the blower fan.

Ultimately, the selection of a high CFM blower fan transcends mere product choice; it involves a thorough assessment of specifications, environmental conditions, and ongoing maintenance strategies. By applying the insights shared in this guide, individuals can ensure their ventilation systems operate at peak efficiency, leading to improved performance and reduced operational costs. Embracing these best practices will facilitate the right choice and foster a proactive approach to maintenance and support, ensuring long-term satisfaction and reliability.

Frequently Asked Questions

What does CFM stand for and why is it important?

CFM stands for Cubic Feet per Minute, and it quantifies the volume of air a fan can move in one minute. It is important because determining the required CFM for your application depends on the size of the space and its airflow needs, ensuring adequate ventilation.

How do I determine the required CFM for my space?

For spaces exceeding 450 square feet, a CFM ranging from 5,000 to 9,000 is typically needed to ensure adequate ventilation.

What is Static Pressure (SP) and why is it significant?

Static Pressure (SP) refers to the resistance the fan must overcome to move air through the system. A higher static pressure indicates greater resistance, which may require a more powerful fan. Understanding average SP ratings is crucial for assessing fan performance, especially in the electronics sector.

How does air density affect fan performance?

Air density plays a critical role in fan performance, as it can decrease at higher altitudes or temperatures, potentially impacting the fan’s efficiency in moving air. The standard air density of 0.075 lb/ft³ is used as a baseline for calculations.

What should I consider when selecting ventilation units?

It is essential to balance CFM and static pressure to ensure optimal performance tailored to specific applications. Additionally, consider the lifespan of air movers and fans, which typically ranges from 15 to 20 years for air movers and about 10 to 15 years for fans, to secure long-term solutions.