Introduction

Understanding the complexities of 12 volt blower fans is crucial for anyone aiming to optimize air movement across various applications, from cooling electronics to improving automotive ventilation. This article explores best practices for selecting and maintaining these essential devices, providing readers with the insights needed to boost system efficiency and performance. With a plethora of options and technical specifications available, how can you ensure that you’re making the right choice for your specific needs?

By delving into the intricacies of these fans, you’ll not only enhance your understanding but also empower yourself to make informed decisions that can significantly impact your projects. Whether you’re a seasoned professional or a curious enthusiast, grasping the fundamentals of blower fan technology is key to achieving optimal results.

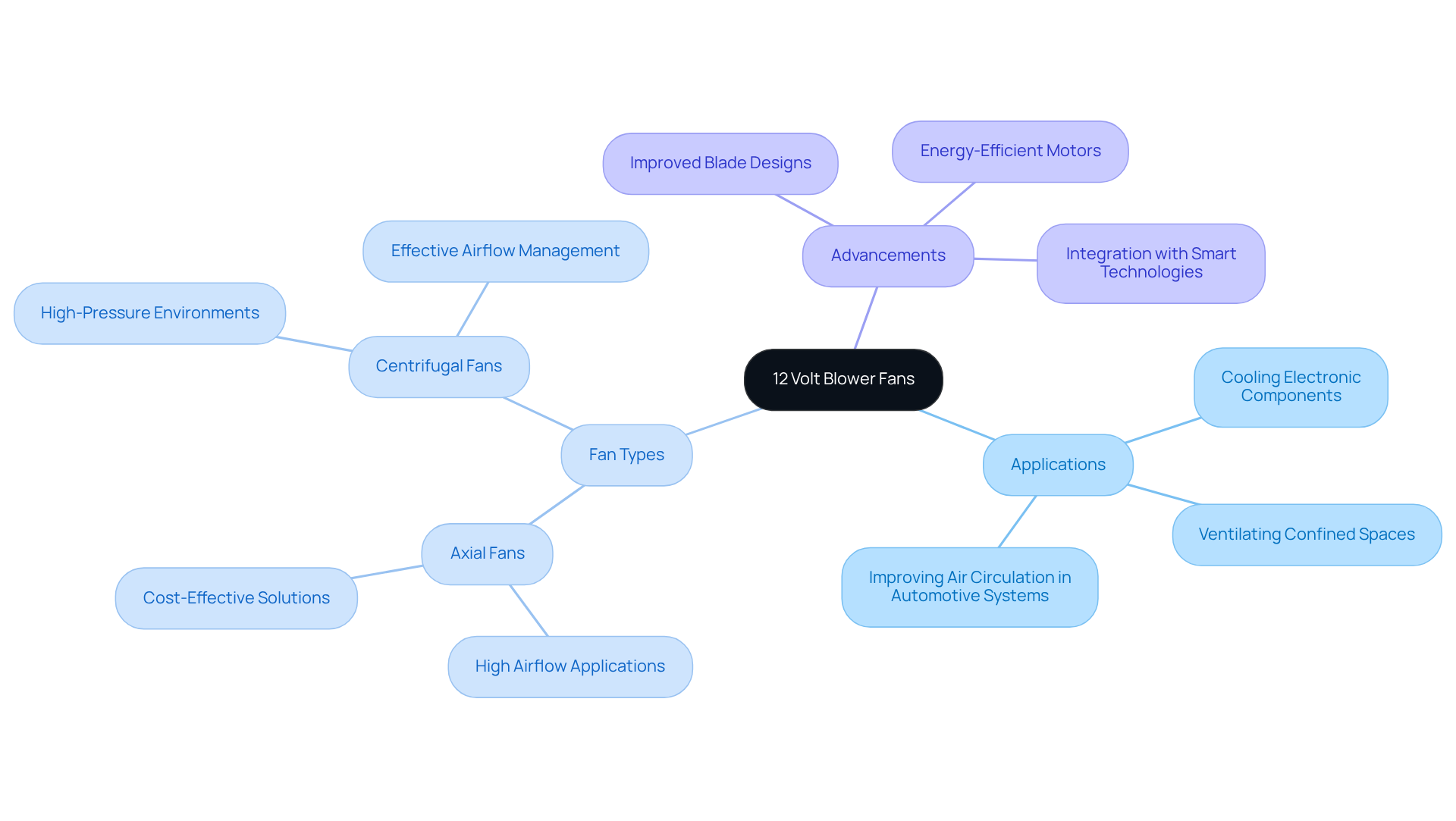

Understand the Functionality of 12 Volt Blower Fans

A 12 volt blower fan, which is an electromechanical device, plays a crucial role in efficiently moving air or gas by converting electrical energy into mechanical energy through a motor that drives the fan blades. This airflow is essential for various applications, including:

- Cooling electronic components

- Ventilating confined spaces

- Improving air circulation in automotive systems

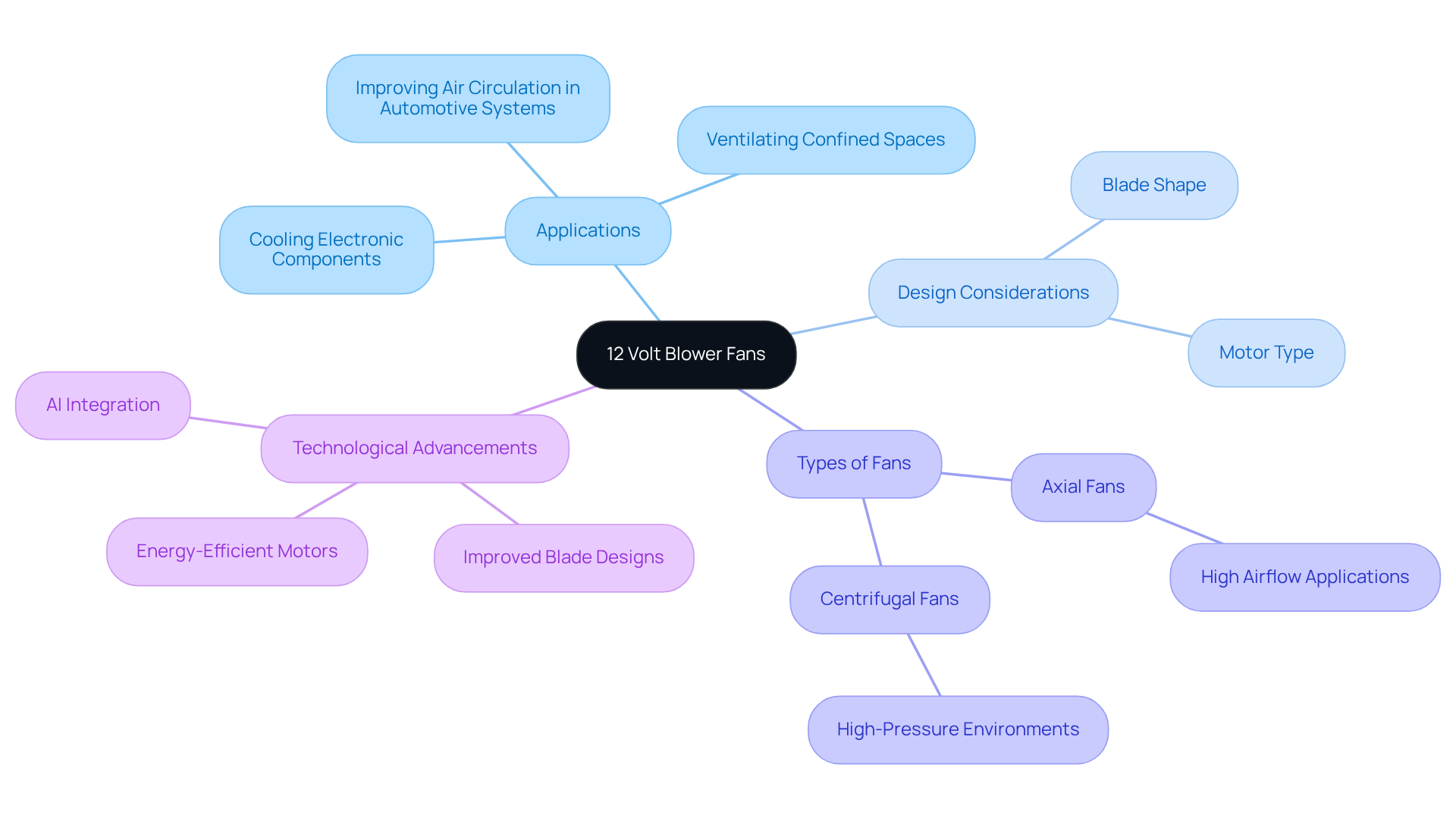

Understanding the fan’s design – such as blade shape and motor type – is vital for optimizing performance. For instance:

- Axial fans excel in high airflow applications, making them ideal for cooling tasks.

- Centrifugal fans are preferred in high-pressure environments, where they effectively manage airflow.

Engineers who comprehend these functionalities can make informed decisions when selecting fans, ensuring effective thermal management and enhanced system efficiency. Recent advancements in technology related to the performance and reliability of the 12 volt blower fan, including improved blade designs and energy-efficient motors, further enhance their capabilities. Real-world applications demonstrate the effectiveness of axial versus centrifugal fans in thermal management, showcasing how the right choice can significantly impact cooling efficiency in electronic systems.

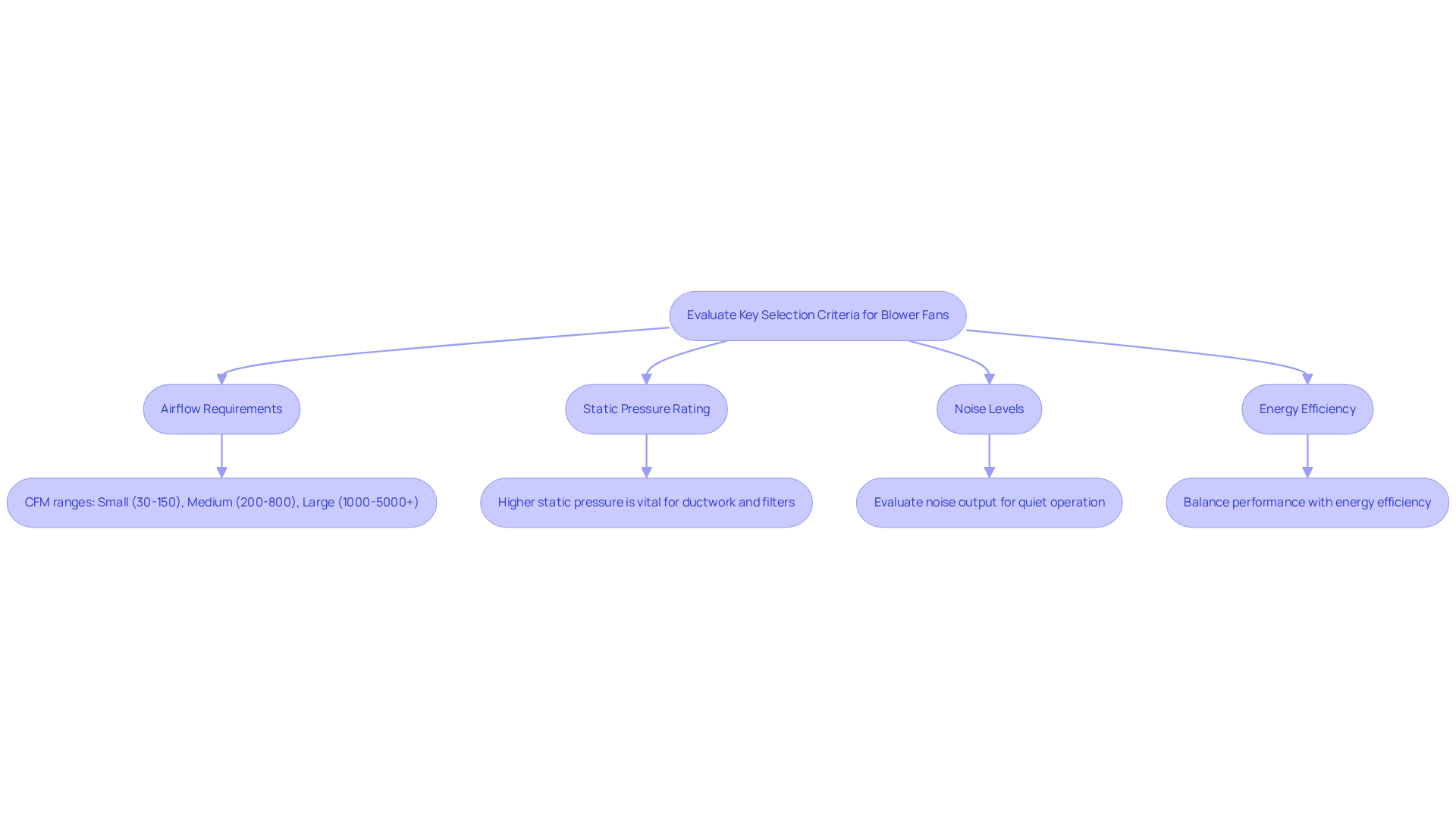

Evaluate Key Selection Criteria for Blower Fans

Choosing a 12 volt blower fan is a critical decision that requires careful evaluation of several key criteria to ensure optimal performance. Start by assessing the airflow requirements, typically quantified in cubic feet per minute (CFM). This metric is essential for cooling applications, as it indicates the volume of air the fan can move. For example:

- Small electronic cooling blowers generally range from 30 to 150 CFM.

- Medium-sized industrial blowers can achieve 200 to 800 CFM.

- Larger HVAC blowers may exceed 1000 CFM.

Next, consider the static pressure rating, which reflects the fan’s ability to overcome resistance within the system. A higher static pressure is vital for applications involving ductwork or filters that can impede airflow. Static pressure fans typically generate force ratings around 3.0 inH2O, making them suitable for high-resistance environments where maintaining airflow is critical.

Noise levels are another important factor, particularly in settings where quiet operation is essential. Engineers should evaluate the fan’s noise output, as excessive noise can disrupt operations and affect user comfort. For instance, static pressure fans often facilitate quieter operation compared to ventilation fans, which may produce more noise in high airflow scenarios.

Finally, assess the fan’s energy efficiency and power consumption to ensure it aligns with project specifications. Selecting a blower fan that balances performance with energy efficiency can lead to significant cost savings and reduced environmental impact. By carefully considering these factors, engineers can choose a blower fan that not only meets their specific cooling needs but also enhances overall system performance.

Implement Best Practices for Installation and Usage

To ensure optimal performance of 12 Volt blower fans, it’s essential to follow these best practices during installation and usage:

-

Proper Mounting: Securely mount the fan to minimize vibrations and noise. Using rubber grommets or mounts effectively dampens vibrations, which is crucial since excessive vibration is a leading cause of premature fan failure. Industry data reveals that 51% of motor failures are linked to bearing issues, underscoring the importance of proper mounting.

-

Electrical Connections: Ensure all electrical connections are secure and correctly polarized. Use connectors rated for the fan’s current to prevent overheating, as improper connections can lead to significant efficiency losses. A mining corporation reported a 20% decrease in power expenses after implementing a comprehensive maintenance plan for the 12 volt blower fan, which highlights the financial benefits of appropriate electrical connections.

-

Airflow Direction: Install the fan in the correct orientation to guarantee optimal air movement. Most fans feature arrows indicating the air direction, which is vital for maintaining system efficiency. Misalignment or incorrect installation can lead to inefficiencies and increased energy consumption.

-

Ductwork Considerations: When integrating the fan into a ducted system, design the ductwork to minimize bends and restrictions. Poorly designed duct systems can increase resistance, significantly reducing air movement efficiency. For optimal operation, ensure that the effective length of outlet ducting is at least 2.5 duct diameters for lower velocities. Regular inspections and cleanings are crucial for maintaining ductwork efficiency and preventing dust buildup.

-

Regular Monitoring: Implement a monitoring system to track the fan’s operation, including airflow and noise levels. Regular inspections can help identify issues early, ensuring optimal operation and extending the fan’s lifespan. Industry experts note that adopting a reliability-centered maintenance (RCM) approach can significantly reduce emergency repair costs.

By adhering to these practices, engineers can enhance the reliability and efficiency of their fan systems, ultimately leading to improved operational outcomes.

Maintain and Troubleshoot for Optimal Performance

To effectively maintain and troubleshoot 12 Volt blower fans, adopting best practices is essential for ensuring optimal performance:

-

Regular Cleaning: Dust and debris can accumulate on the fan blades and housing, significantly reducing efficiency. Regularly clean the fan using compressed air or a soft brush to eliminate buildup and maintain airflow.

-

Lubrication: For fans equipped with bearings, ensure they are lubricated according to the manufacturer’s specifications. Proper lubrication minimizes friction and can extend the fan’s lifespan, enhancing reliability.

-

Inspect Electrical Connections: Periodically check all electrical connections for signs of wear or corrosion. Replacing any damaged connectors is essential to prevent electrical failures that could compromise fan operation.

-

Monitor Effectiveness: Keep a close watch on the fan’s effectiveness metrics, such as airflow and noise levels. A sudden drop in performance may indicate a blockage or mechanical failure that requires immediate attention.

-

Troubleshooting Common Issues: If the fan is not operating, first check the power supply to ensure the fan is receiving the correct voltage. If the fan runs but produces unusual noises, inspect for loose components or debris caught in the blades.

By following these maintenance and troubleshooting tips, engineers can ensure the efficient and reliable operation of their 12 volt blower fan, ultimately enhancing system performance.

Conclusion

Selecting and maintaining a 12 volt blower fan is not just a task; it’s a critical responsibility that directly influences the efficiency and functionality of various systems. Understanding how these fans operate and adhering to best practices in selection and maintenance is essential for engineers and enthusiasts alike. The right blower fan enhances cooling and air circulation while contributing to overall energy efficiency and system longevity.

When choosing a blower fan, several key considerations come into play. Assessing airflow requirements, static pressure ratings, noise levels, and energy efficiency are paramount. Additionally, proper installation practices – such as secure mounting, correct electrical connections, and thoughtful ductwork design – are crucial for maximizing fan performance. Regular maintenance routines, including cleaning, lubrication, and monitoring, are vital in preventing common issues and extending the lifespan of the fan.

Ultimately, the insights gained from this exploration empower users to make informed decisions that lead to improved system performance. Whether cooling electronic components or enhancing air circulation in confined spaces, the effective use of 12 volt blower fans is indispensable. By embracing these best practices, you not only optimize performance but also foster a more sustainable and efficient approach to engineering challenges.

Frequently Asked Questions

What is a 12 volt blower fan?

A 12 volt blower fan is an electromechanical device that moves air or gas by converting electrical energy into mechanical energy through a motor that drives the fan blades.

What are the main applications of 12 volt blower fans?

The main applications include cooling electronic components, ventilating confined spaces, and improving air circulation in automotive systems.

Why is understanding the fan’s design important?

Understanding the fan’s design, such as blade shape and motor type, is vital for optimizing performance and ensuring effective thermal management.

What are the differences between axial and centrifugal fans?

Axial fans excel in high airflow applications, making them ideal for cooling tasks, while centrifugal fans are preferred in high-pressure environments where they effectively manage airflow.

How can engineers benefit from understanding 12 volt blower fans?

Engineers can make informed decisions when selecting fans, ensuring effective thermal management and enhanced system efficiency.

What recent advancements have been made in 12 volt blower fan technology?

Recent advancements include improved blade designs and energy-efficient motors, which enhance the performance and reliability of 12 volt blower fans.

How do real-world applications demonstrate the effectiveness of different fan types?

Real-world applications showcase how the right choice between axial and centrifugal fans can significantly impact cooling efficiency in electronic systems.