Overview

The article explores best practices for selecting cooler fans in electronics design, underscoring their essential role in maintaining optimal temperatures and ensuring the reliability of electronic devices. It articulates critical considerations such as:

- Thermal requirements

- Air movement

- Noise levels

- Size

- Energy efficiency

Furthermore, it emphasizes the necessity of regular maintenance and innovative technologies, including variable speed control, to enhance cooling performance.

Introduction

In the intricate world of electronics design, the significance of cooling fans is paramount. These essential components are pivotal in maintaining optimal temperatures, ensuring that devices operate efficiently and reliably. As electronic components generate heat, the looming risk of overheating can lead to performance degradation and even catastrophic failures. With the rising demand for high-performance systems, understanding the various types of cooling fans and their applications is crucial.

From axial fans, which provide efficient airflow, to centrifugal fans that can overcome significant resistance, the landscape of cooling technology is continuously evolving. As engineers navigate the complexities of thermal management, adopting best practices for selecting and optimizing cooling fans will be key to enhancing performance and prolonging the lifespan of electronic systems.

This article delves into the importance of cooling fans, explores their diverse types, and outlines strategies for effective selection and implementation, paving the way for future advancements in electronic reliability and efficiency.

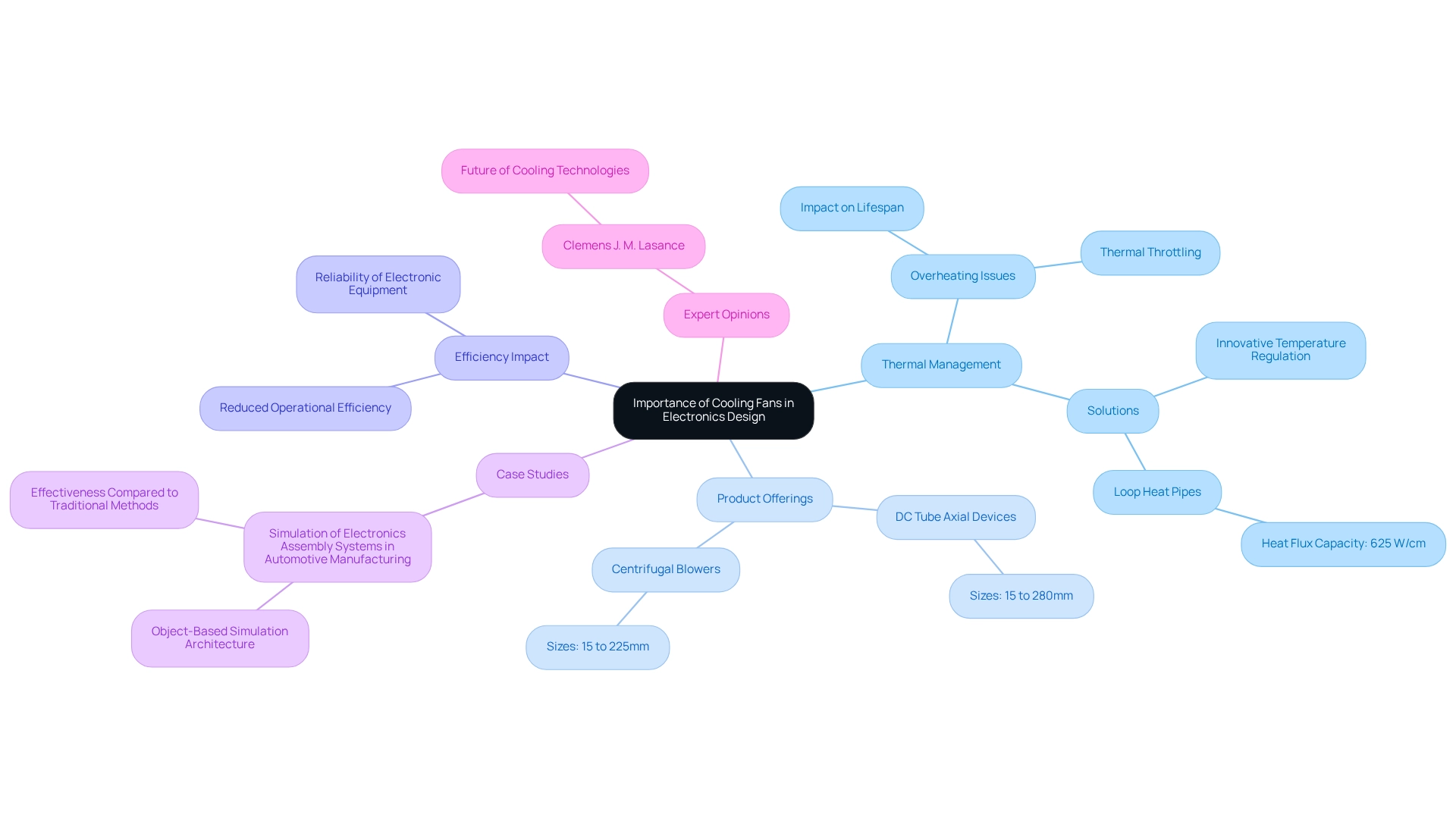

Understand the Importance of Cooling Fans in Electronics Design

Cooler fans are indispensable components in electronics design, facilitating airflow and effectively dissipating heat generated by electronic components. Overheating can severely impact operation, resulting in reduced lifespan and potentially catastrophic breakdowns. The ramifications of excessive heat are significant, with data indicating that inadequate temperature regulation can lead to efficiency declines across numerous applications. For example, in high-performance computing systems, insufficient temperature management may trigger thermal throttling, causing processors to automatically reduce their speed to prevent damage, which significantly affects overall efficiency.

Gagner-Toomey Associates stands out as the world’s largest producer of standard and custom air-movers, offering a broad range of DC input tube axial devices from 15 to 280mm and centrifugal blowers from 15 to 225mm, all optimized for performance, efficiency, and low noise. are vital for electronics and automotive applications, ensuring devices operate reliably under demanding conditions. Most models also provide IP protection upon request, enhancing their adaptability to various environments.

The importance of ventilation devices, such as cooler fans, extends beyond mere preference; they are a critical design element that directly influences the reliability and efficiency of electronic equipment. Recent studies highlight that loop heat pipes can accommodate a heat flux of up to 625 W/cm, demonstrating advancements in thermal management technologies capable of handling high-heat flux applications. This capability underscores the necessity of efficient refrigeration solutions, as they are essential to the functionality of air movers and the overall reliability of the system.

Furthermore, case studies, such as the simulation of electronics assembly systems in automotive manufacturing, illustrate how effective thermal management solutions were devised to maintain the functionality of electronic systems in vehicles. These studies showcase the crucial role of cooler fans in achieving optimal efficiency in practical applications.

Expert opinions reinforce this viewpoint, with Clemens J. M. Lasance stating, “Considering the range of efforts underway to extend traditional temperature regulation technologies, as well as develop new ones, the future appears promising for accommodating high-heat flux applications.” This emphasizes the encouraging advancements in temperature control technologies, highlighting that as the demand for efficient thermal management continues to rise, selecting the appropriate cooler fans becomes essential for ensuring optimal performance and longevity of electronic devices.

Explore Different Types of Cooling Fans and Their Applications

Cooling devices, such as cooler fans, are essential components in electronics design, categorized into three primary types:

- Axial types

- Centrifugal types

- Blowers

Axial blowers operate by moving air parallel to the unit’s axis, making them ideal for due to their efficiency and simple design. They are frequently used in various electronic devices where space is constrained and ventilation requirements are moderate.

Centrifugal blowers, on the other hand, expel air at a right angle to the intake, enabling them to produce higher pressure and air movement. This capability makes them particularly suitable for applications such as HVAC systems and environments where overcoming airflow resistance is critical. Notably, centrifugal blowers have an energy efficiency rating of around 60%, rendering them an economical option for various industrial applications. Their robust construction often results in lower maintenance requirements, enhancing their appeal for long-term use.

As the ventilation fan market undergoes innovative technological advancements, engineers can anticipate enhanced performance and efficiency in these systems, especially with cooler fans that provide focused air movement, making them ideal for reducing temperatures of specific components in tightly packed electronic systems. Cooler fans are especially efficient in situations where focused temperature control is necessary, such as in high-performance computing environments.

When selecting cooler fans, it is essential to consider particular application needs, including the air movement rate (measured in CFM), static pressure, and noise levels. For example, in server settings, high static pressure fans are crucial for managing the resistance to movement created by closely arranged racks. As a best practice, engineers should verify fan efficiency and make adjustments if needed so that airflow and temperature regulation can be optimal. Comprehending these parameters guarantees optimal operation and longevity of electronic systems, ultimately contributing to their efficiency and dependability.

Furthermore, a case study named ‘Industrial Fan Repair by ProcessBarron’ emphasizes the significance of upkeep in fan operation. ProcessBarron offers comprehensive on-site services for industrial fan removal, repair, and installation, focusing on minimizing production downtime through emergency repairs and planned maintenance. This illustrates how proper maintenance can enhance plant efficiency and reduce carbon output, ensuring that operations remain on schedule while maintaining equipment performance.

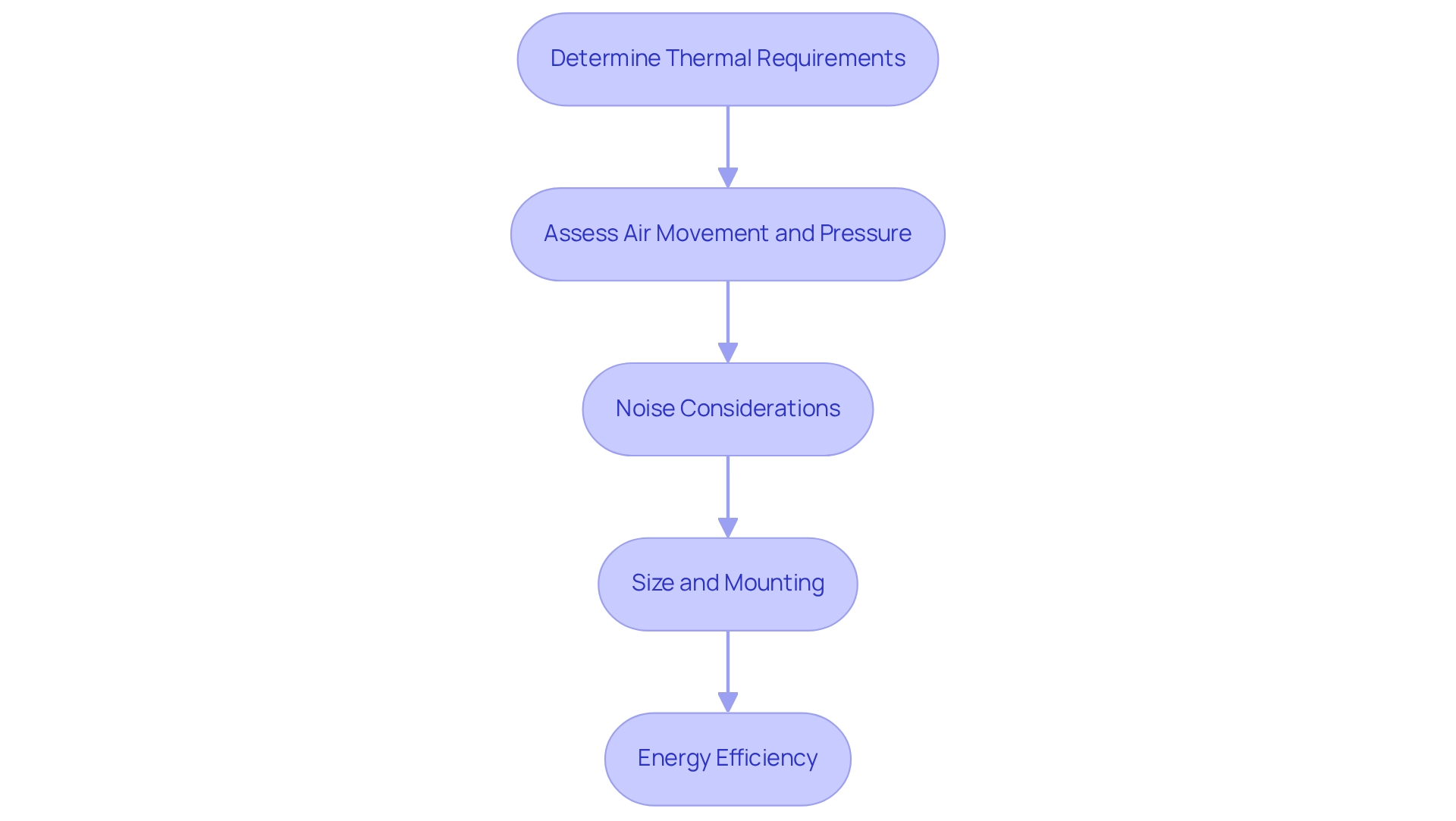

Implement Best Practices for Selecting Cooling Fans

When selecting cooler fans, engineers must adhere to the following best practices:

- Determine Thermal Requirements: Conduct a comprehensive thermal evaluation to assess the heat generated by components and establish the necessary ventilation to maintain optimal temperatures. With a safety factor of 2, the required volume of air should be approximately 1.00 m³/min. This analysis is crucial as it ensures that the cooler fans in the temperature regulation system can effectively manage the heat output of the components.

- and Pressure: Choose blowers that provide adequate air circulation (measured in CFM) and static pressure to meet system requirements. In applications with significant airflow resistance, selecting a fan with a higher RPM may be essential to ensure effective cooling. Manufacturers such as Kooltronic offer a variety of NEMA-rated ventilators suitable for different enclosure applications, which can be beneficial in these scenarios.

- Noise Considerations: Consider the noise levels (dBA) of the units, especially in environments where sound levels are critical, such as residential or office settings. Opting for models equipped with cooler fans can enhance user comfort without compromising performance.

- Size and Mounting: Confirm that the fan fits within the designated space and can be securely mounted. Proper installation is vital for optimal functioning and longevity.

- Energy Efficiency: Prioritize energy-efficient models, such as brushless DC units, which not only reduce power consumption but also minimize heat production. This contributes to the overall effectiveness of the system by enabling engineers to adopt optimal methods for selecting cooler fans that meet operational standards, thereby enhancing the reliability and efficiency of electronic systems.

A case study titled ‘Selecting the Appropriate Cooling Fan for Electronics Projects‘ underscores the importance of understanding airflow, fan types, and performance requirements. The findings suggest that a well-chosen fan can significantly enhance thermal management solutions. As a SPAL representative noted, ‘This guarantees the quality of every step in the design and manufacturing process and continues to advance technologies that help keep our cars and trucks cool, even in the most demanding situations.

Optimize the Use of Cooling Fans for Enhanced Performance

To maximize the efficiency of ventilation fans in electronics design, consider the following strategies:

- Implement Variable Speed Control: Employ (PWM) to dynamically adjust fan speeds according to real-time thermal conditions. This method not only enhances temperature regulation efficiency but also reduces noise during low-load situations. The incorporation of variable speed drive (VSD) systems has shown considerable technical and economic benefits, especially in maintaining optimal temperatures for circulated water in industrial applications. A case study on variable speed drive systems in tower ventilators emphasizes the practical elements of applying VSD setups, demonstrating their potential for cost savings and enhanced performance.

- Improve : within the enclosure by strategically organizing cables and components to reduce obstructions. Efficient air circulation management can significantly enhance the functionality of fans, ensuring that they work at their optimal level.

- Conduct Regular Maintenance: Establish a routine maintenance schedule to remove dust and debris from fan blades and vents. Accumulated particles can obstruct airflow, resulting in reduced temperature regulation and possible overheating of components.

- Monitor Functionality: Utilize thermal sensors to track component temperatures and fan operation. This data enables prompt modifications, ensuring that temperature control systems respond effectively to varying thermal loads. As Z. Lei observes, methods to target minimal circulating water flow rates can significantly improve system efficiency, whether through the water pinch method or the grand composite curve from pinch technology. By adopting these optimization techniques, engineers can enhance the operational efficiency of cooler fans, which in turn extends the lifespan of electronic components and improves overall system performance. Notably, a fan system with four cells can achieve an airflow of 106 cubic meters per second while consuming only 30 kW of power, illustrating the potential for energy-efficient cooling solutions in modern electronics.

Conclusion

Cooling fans are indispensable in the realm of electronics design, serving a critical role in regulating temperatures and ensuring optimal performance. This article has highlighted the various types of cooling fans—axial, centrifugal, and blowers—each tailored for specific applications and environments. Understanding the strengths and limitations of each type is vital for engineers tasked with thermal management in increasingly demanding electronic systems.

Moreover, the significance of selecting the right cooling fan cannot be overstated. By adhering to best practices such as conducting thorough thermal analyses, evaluating airflow requirements, and considering noise levels, engineers can significantly enhance the reliability and efficiency of their designs. The case studies presented reinforce the notion that effective cooling solutions not only prevent overheating but also contribute to improved operational performance and longevity of electronic components.

As technology continues to advance, strategies for optimizing cooling fan performance—such as implementing variable speed control and enhancing airflow management—will be crucial in meeting the challenges posed by high-performance electronics. By prioritizing these best practices and optimization techniques, engineers can ensure that their systems operate reliably under varying conditions, ultimately leading to greater efficiency and sustainability in electronic design. The future of cooling technology is bright, and with it, the potential for further innovations that enhance the reliability of electronic systems across all industries.

Frequently Asked Questions

Why are cooler fans important in electronics design?

Cooler fans are essential for facilitating airflow and dissipating heat generated by electronic components. They help prevent overheating, which can lead to reduced lifespan and operational failures.

What are the consequences of inadequate temperature regulation in electronic devices?

Inadequate temperature regulation can result in efficiency declines, thermal throttling in high-performance systems, and potential damage to processors, significantly affecting overall system performance.

What company is known for producing air-movers for electronic applications?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a variety of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise.

What advancements have been made in thermal management technologies?

Recent advancements include loop heat pipes capable of accommodating a heat flux of up to 625 W/cm, which demonstrates improved efficiency in handling high-heat flux applications.

How do cooler fans impact the reliability and efficiency of electronic equipment?

Cooler fans are critical design elements that directly influence the reliability and efficiency of electronic equipment by ensuring proper ventilation and temperature management.

What role do cooler fans play in automotive applications?

In automotive applications, cooler fans are crucial for maintaining the functionality of electronic systems, as demonstrated by case studies simulating electronics assembly systems in vehicles.

What is the future outlook for temperature regulation technologies?

Experts indicate a promising future for temperature regulation technologies, with ongoing efforts to extend traditional methods and develop new solutions to accommodate high-heat flux applications.

How can IP protection enhance the functionality of cooler fans?

Most cooler fan models can provide IP protection upon request, which enhances their adaptability and reliability in various environmental conditions.