Overview

This article delineates four essential practices for optimizing the performance of mini fans in electronic applications:

- Selecting the right specifications

- Evaluating environmental requirements

- Implementing best installation practices

- Establishing maintenance protocols

These practices are crucial as they ensure efficient cooling, enhance reliability, and extend the lifespan of electronic systems. By addressing factors such as airflow, noise levels, and operational conditions, these strategies not only improve performance but also contribute to the overall effectiveness of electronic applications.

Introduction

In the rapidly evolving world of electronics, the performance of mini fans is crucial for ensuring device efficiency and longevity. Engineers and designers encounter the challenge of selecting and integrating these small yet vital components into their systems, balancing airflow, noise levels, and energy consumption. By delving into key practices for optimizing mini fan performance, this article offers insights that can lead to enhanced cooling solutions and improved reliability in electronic applications.

What essential specifications and best practices can transform the operation of mini fans within these devices?

Identify Key Specifications for Mini Fans in Electronics

Selecting mini fans for electronic applications necessitates careful consideration of several key specifications:

- Airflow Rate (CFM): This metric measures the volume of air a fan can move, typically expressed in cubic feet per minute (CFM). It is crucial to ensure that the fan can provide sufficient cooling for the components it serves, especially in high-performance electronics where heat dissipation is vital. Gagner-Toomey Associates offers a wide range of DC input tube axial ventilators, optimized for functionality and efficiency, enabling engineers to find the suitable airflow specifications for their requirements.

- Static Pressure: This specification indicates the fan’s ability to overcome resistance in the airflow path, which is particularly important in environments with restrictive airflow, such as densely packed enclosures. Average static pressure ratings for small units utilized in electronics can differ, but understanding these ratings assists in selecting devices that maintain efficient airflow under load. Gagner-Toomey’s centrifugal blowers are designed to excel in such conditions, providing reliable performance even in challenging environments.

- Noise Level (dBA): For consumer electronics, maintaining a low noise level is often a priority. Selecting fans that operate quietly enhances user experience, especially in applications where noise can be disruptive. Gagner-Toomey Associates prioritizes low noise in their designs, ensuring that users benefit from quieter operation without compromising cooling efficiency.

- Power Consumption: Evaluating the fan’s energy efficiency is critical to reduce the overall power consumption of the electronic setup. This consideration is especially important in battery-operated devices, where power conservation is vital. The energy-saving designs of Gagner-Toomey’s devices assist engineers in enhancing for improved battery life and functionality.

- Size and Form Factor: Ensuring the fan fits within the design constraints of the electronic device is essential. This includes considering both physical dimensions and mounting options to facilitate seamless integration into the overall design. Gagner-Toomey Associates provides a comprehensive portfolio of miniature blower and fan mini solutions, starting from sizes as small as 15x3mm, catering to tight spaces in electronic applications.

- IP Protection: Consider the IP protection available for the devices, as this specification is crucial for ensuring reliability in various environments. Gagner-Toomey Associates offers IP protection in most models upon request, enhancing the durability and efficacy of their cooling solutions.

By thoroughly evaluating these specifications, engineers can select fan mini options that enhance efficiency and reliability in . As Johann Tang, a Product Specialist at Oriental Motor, notes, “It’s important to know that even though maximum values for airflow and static pressure are specified, the fan will not output both maximum values at the same time.” This insight underscores the necessity for a balanced approach in fan selection.

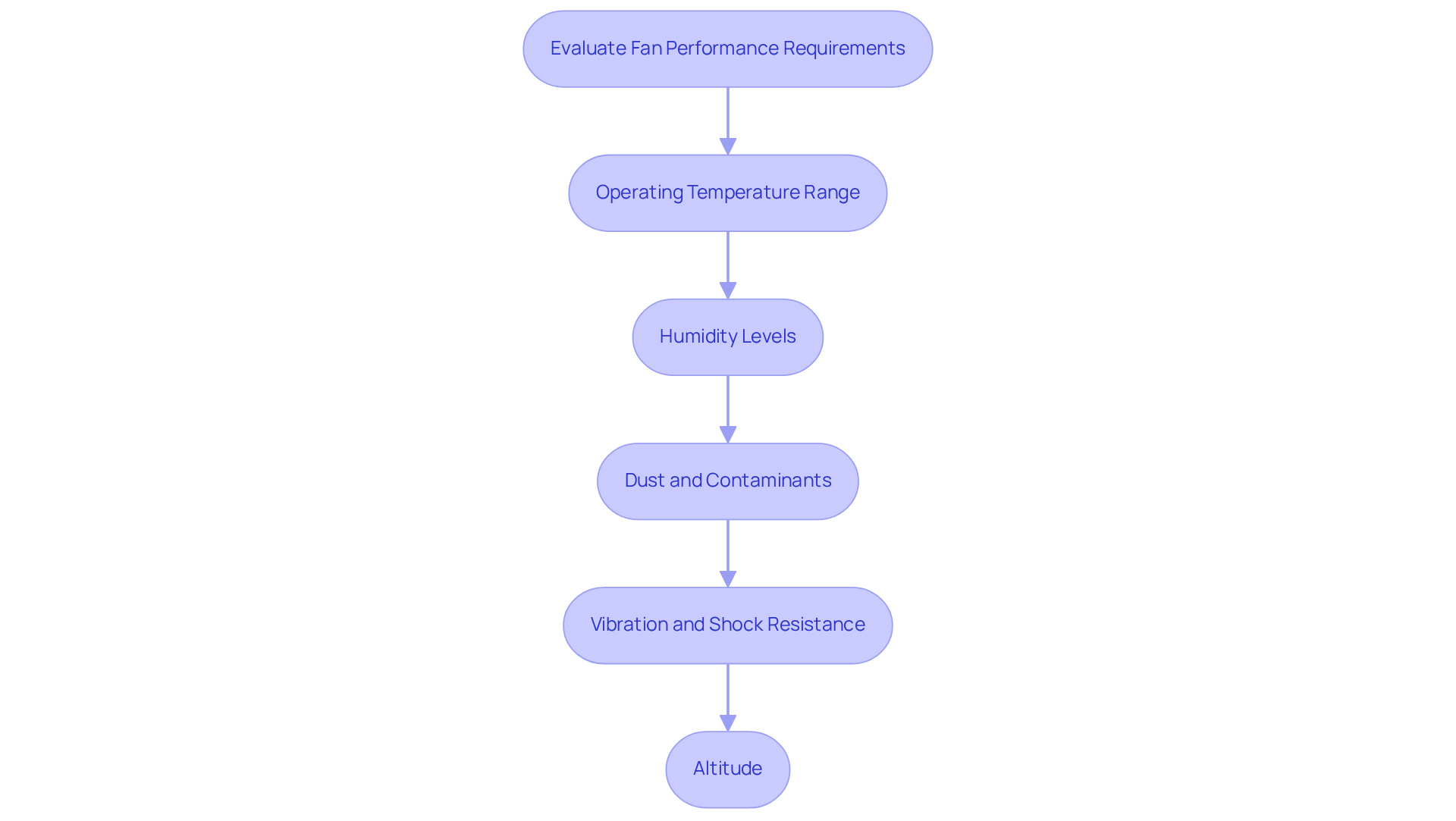

Evaluate Environmental and Application Requirements

To optimize fan performance, it is crucial to evaluate the following environmental and application requirements:

- Operating Temperature Range: Ensure the fan can function effectively within the temperature extremes expected in its application. High temperatures can reduce fan lifespan and efficiency, as various studies indicate that elevated temperatures can significantly diminish both lifespan and performance.

- Humidity Levels: In humid environments, select air circulators with suitable ingress protection (IP) ratings to prevent moisture damage. For instance, mini blowers with IP55 ratings are designed to withstand moisture and dust, making them appropriate for use in humid conditions.

- Dust and Contaminants: Consider devices engineered for dusty environments, which may include features like sealed bearings or filters to prolong operational life. Research shows that devices equipped with these features can greatly diminish wear and tear caused by debris buildup.

- Vibration and Shock Resistance: For applications in mobile or industrial settings, choose devices that can endure vibrations and shocks without sacrificing efficacy. Case studies have demonstrated that fans designed for such conditions maintain reliability even in challenging environments.

- Altitude: At higher elevations, air density decreases, which can affect fan effectiveness. Ensure the fan is rated for the expected altitude of operation, as efficiency can vary significantly in these conditions.

By thoroughly evaluating these factors, engineers can select fan mini blowers that not only meet specifications but also ensure reliability in their intended environments. This careful assessment can lead to and longevity of cooling systems.

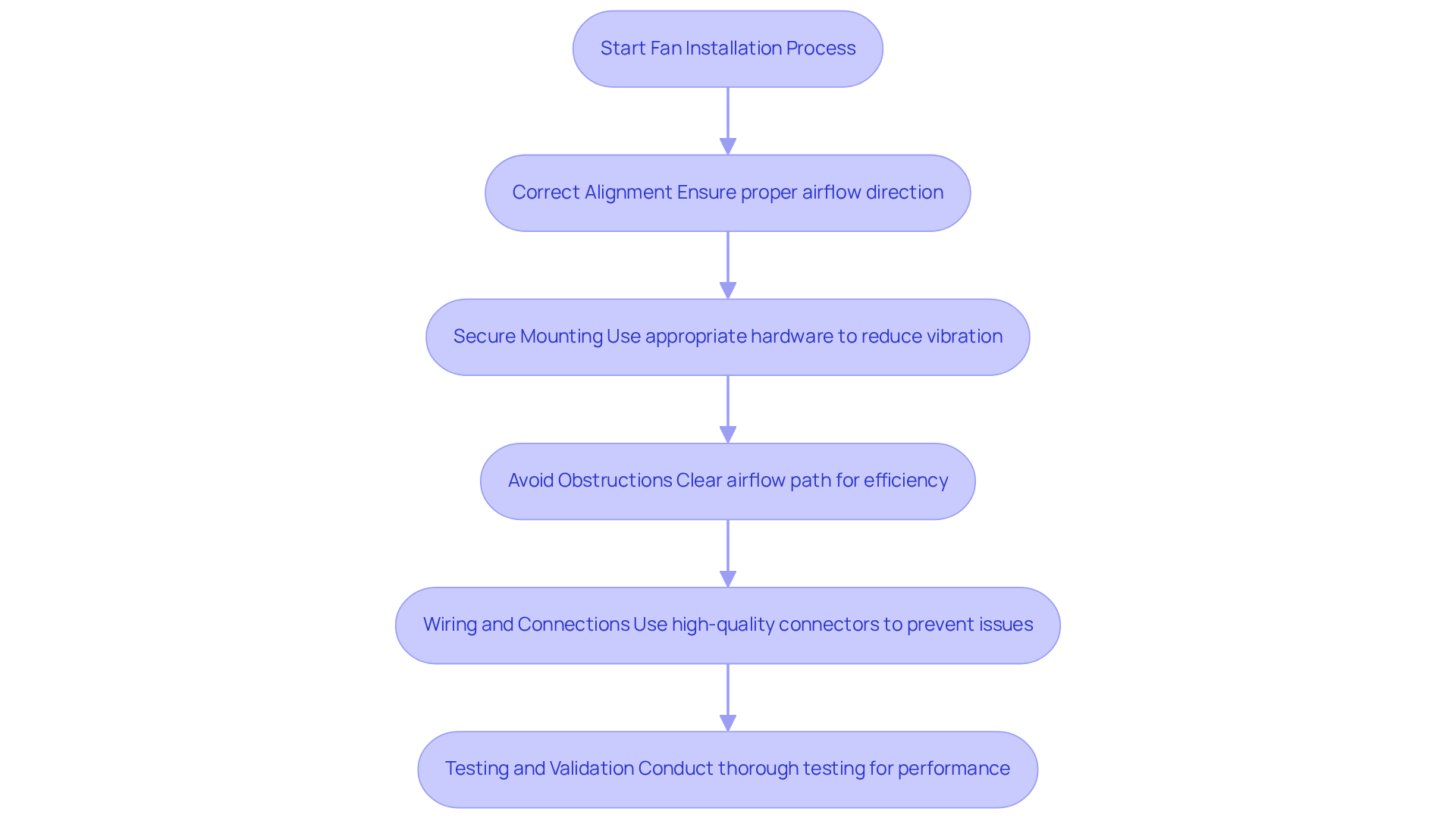

Implement Best Practices for Fan Installation and Integration

To ensure optimal performance of mini fans, it is essential to adhere to best practices during installation and integration:

- Correct Alignment: Install ventilators in the correct orientation to ensure proper airflow direction. Misalignment can result in insufficient temperature regulation, with studies suggesting that improper fan placement can significantly decrease efficiency. For instance, the chilling effect produced by desk units is more localized compared to the wider chilling effect of computer devices, emphasizing the importance of orientation in achieving uniform air distribution. Moreover, the average room air speed in the occupied zone increases proportionally with fan air speed and diameter, further underscoring the necessity for correct fan orientation.

- Secure Mounting: Utilize appropriate mounting hardware to secure the fan, thereby reducing vibration and noise. A stable installation minimizes movement during operation, which can otherwise disrupt airflow and lead to inefficiencies.

- Avoid Obstructions: Ensure that the airflow path is clear of obstructions. Positioning fans away from components that can block airflow or create turbulence is crucial, as obstructions can diminish cooling capacity and increase energy consumption.

- Wiring and Connections: Employ high-quality connectors and wiring to . Secure and insulated connections are essential to avoid shorts or disconnections that could compromise fan function.

- Testing and Validation: After installation, conduct thorough testing to validate airflow, noise levels, and temperature management. Modify fan speed settings as necessary to enhance performance, ensuring efficient operation under varying conditions. Findings from energy consumption analysis indicate that using computer fans can lead to significant energy savings without compromising comfort, reinforcing the importance of proper fan orientation.

By implementing these best practices, engineers can enhance the reliability and efficiency of fan mini setups in electronic applications, ultimately contributing to improved energy savings and occupant comfort. As Charles Rush, a director of a lab developing test equipment, stated, “Observe the results from the test equipment, then think about what it was telling you and evaluate if and how that information was distorted.” This mindset is crucial for ensuring optimal fan operation.

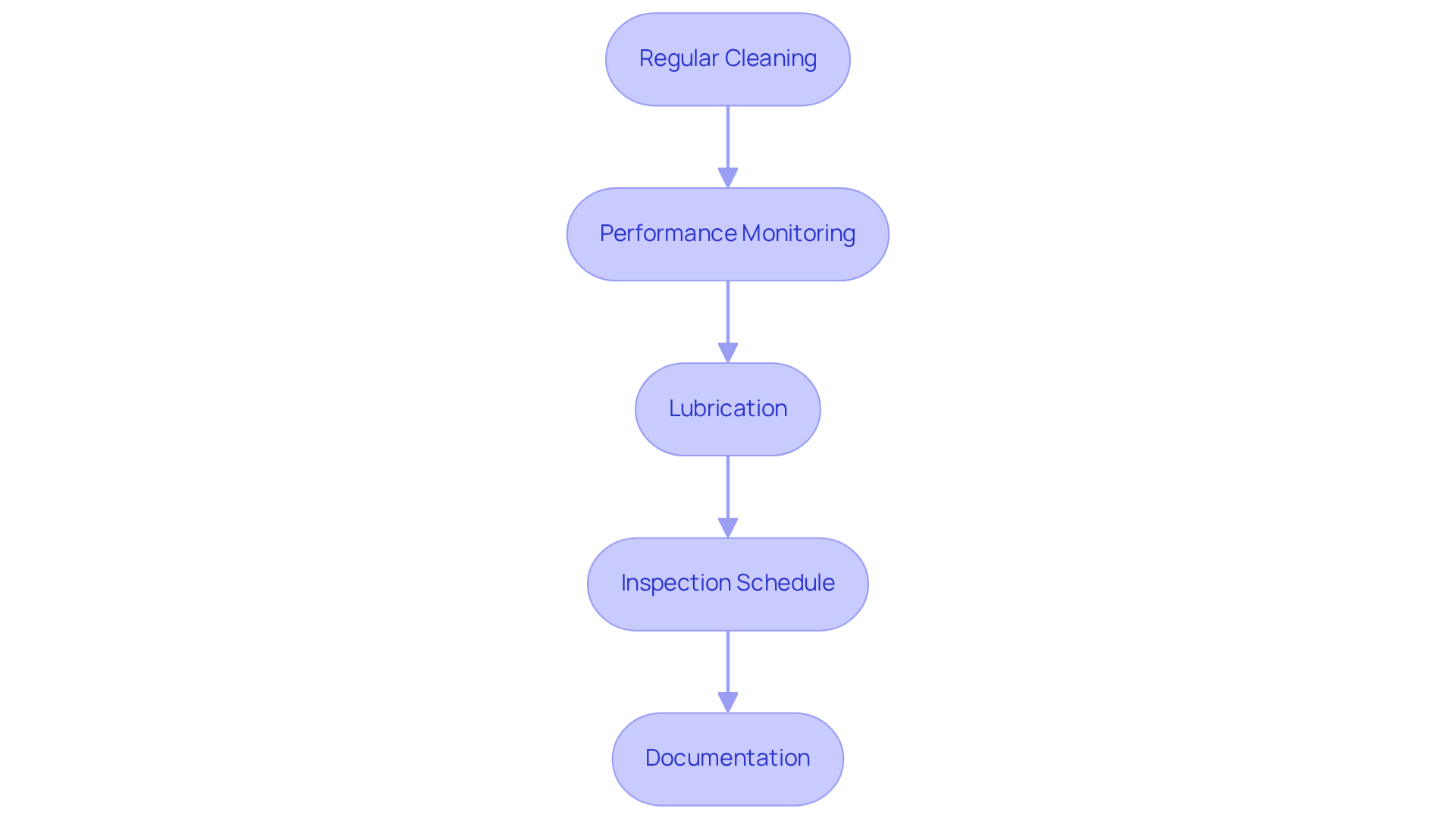

Establish Maintenance and Monitoring Protocols for Mini Fans

To ensure optimal performance and longevity of mini fans in electronic systems, it is essential to implement the following maintenance and monitoring protocols:

- Regular Cleaning: Schedule routine cleaning of fan blades and housing to eliminate dust and debris that can obstruct airflow and elevate noise levels. Utilizing appropriate cleaning tools is crucial to prevent damage.

- Performance Monitoring: Establish monitoring setups, such as the Tachometer Output and from Comair Rotron, to continuously track fan speed, temperature, and noise levels. Sensors can identify irregularities, offering early alerts of possible breakdowns, which is crucial for preserving reliability. Notably, more than 500,000 sysadmins utilize PRTG for comprehensive network monitoring, underscoring the necessity of such systems.

- Lubrication: For fans with moving components, apply lubrication according to manufacturer specifications to minimize friction and wear, thereby enhancing operational efficiency.

- Inspection Schedule: Develop a methodical inspection timetable to detect indications of wear, loose connections, or other problems that may affect functionality. Promptly addressing any identified problems can prevent costly replacements and ensure continuous operation. As emphasized in a case study on tracking fan health in aerospace and defense, effective monitoring solutions can significantly influence the reliability of temperature regulation mechanisms.

- Documentation: Keep detailed records of maintenance activities, inspections, and any issues encountered. This documentation aids in recognizing trends and refining future maintenance strategies. Early detection of a low-speed condition might need a simple bearing replacement instead of replacing an entire unit, emphasizing the cost-saving benefits of thorough documentation and monitoring.

Implementing these protocols not only enhances the reliability of fan mini but also contributes to the overall efficiency of electronic systems, as evidenced by the significant impact of effective cooling on system performance.

Conclusion

Selecting and optimizing mini fans for electronic applications is a multifaceted process that demands careful attention to various specifications and best practices. Understanding key specifications such as airflow rate, static pressure, noise level, power consumption, size, and IP protection is paramount. These elements ensure that the chosen fan can effectively meet the cooling demands of electronic components while maintaining efficiency and reliability.

In addition to specifications, evaluating environmental and application requirements is vital for optimal fan performance. Factors such as operating temperature range, humidity levels, dust exposure, vibration resistance, and altitude must be considered to select fans that can operate effectively in their intended environments. Furthermore, implementing best practices during installation—including correct alignment, secure mounting, and unobstructed airflow—ensures that the fans function at their best.

Ultimately, the significance of establishing maintenance and monitoring protocols cannot be overstated. Regular cleaning, performance monitoring, lubrication, and thorough documentation of maintenance activities contribute to the longevity and efficiency of mini fans in electronic systems. By adhering to these practices, engineers and designers can enhance the reliability of their cooling solutions, ultimately leading to improved performance and energy savings in electronic devices. Prioritizing these considerations will not only optimize mini fan performance but also elevate the overall functionality of electronic applications.

Frequently Asked Questions

What is the airflow rate in mini fans, and why is it important?

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air a fan can move. It is crucial for ensuring sufficient cooling for electronic components, particularly in high-performance applications where heat dissipation is essential.

How does static pressure affect mini fan performance?

Static pressure measures a fan’s ability to overcome resistance in the airflow path, which is important in environments with restricted airflow, such as densely packed enclosures. Understanding static pressure ratings helps in selecting fans that maintain efficient airflow under load.

Why is noise level an important specification for mini fans in consumer electronics?

A low noise level is often a priority in consumer electronics to enhance user experience, especially in applications where noise can be disruptive. Selecting fans that operate quietly ensures efficient cooling without compromising comfort.

What role does power consumption play in selecting mini fans?

Evaluating a fan’s energy efficiency is critical to reduce overall power consumption, particularly in battery-operated devices where power conservation is vital. Energy-efficient designs improve battery life and functionality in electronic systems.

How do size and form factor influence the selection of mini fans?

The size and form factor of a fan must fit within the design constraints of the electronic device, considering both physical dimensions and mounting options for seamless integration into the overall design.

What is IP protection, and why is it significant for mini fans?

IP protection indicates the level of protection a device has against environmental factors, ensuring reliability in various conditions. Many models from Gagner-Toomey Associates offer IP protection upon request, enhancing the durability of cooling solutions.

What should engineers consider when selecting mini fans for electronics?

Engineers should evaluate key specifications such as airflow rate, static pressure, noise level, power consumption, size and form factor, and IP protection to select fan options that enhance efficiency and reliability in their designs.