Overview

The article presents a systematic approach to the effective wiring and troubleshooting of Brushless DC (BLDC) motors. It begins by outlining essential steps for wiring, which are crucial for establishing a solid foundation. Key components involved in the process are identified, providing the reader with a comprehensive understanding of the system. Additionally, the article offers troubleshooting techniques for common issues, emphasizing the significance of proper connections and maintenance. These practices are vital to ensuring optimal motor performance, thereby facilitating an efficient operation.

Introduction

Brushless DC motors have transformed the realm of electric machinery, delivering exceptional efficiency and longevity when compared to their brushed counterparts. However, the wiring of these sophisticated devices can pose challenges that, if left unaddressed, may impede their performance. This guide explores the critical steps for effective BLDC wiring and troubleshooting, empowering readers with the expertise needed to unlock the full potential of these advanced motors.

What common pitfalls could derail a project?

How can engineers ensure that their brushless systems operate seamlessly?

By addressing these questions, we aim to provide actionable insights that enhance operational success.

Understand the Basics of Brushless DC Motors

represent a significant advancement in electric machinery technology, operating without brushes through electronic commutation. These devices consist of a rotor embedded with permanent magnets and a stator equipped with windings. The is pivotal, switching the current through the windings to generate a rotating magnetic field that drives the rotor.

Key Advantages of BLDC Motors:

- : BLDC motors are recognized for their exceptional efficiency, converting electrical energy into mechanical energy more effectively than their brushed counterparts. Most brushless direct current machines achieve efficiency ratings of 80% or higher, substantially reducing energy consumption and heat generation. Consequently, brushless motors typically exhibit greater efficiency than brushed alternatives, leading to minimized heat production and a lower risk of overheating and malfunction.

- : The absence of brushes diminishes wear and tear, allowing to operate for 10,000 hours or more under optimal conditions. In contrast, brushed devices generally last between 2,000 to 5,000 hours, positioning BLDC variants as a more reliable choice for long-term applications. A brushless device can sustain up to 10,000 operating hours or beyond when adhering to the manufacturer’s recommended limits for continuous use.

- Better Control: These machines provide , making them suitable for a wide range of applications, from consumer electronics to medical devices. Their capability to maintain performance under varying loads is particularly advantageous in high-demand environments.

It is essential to address maintenance considerations, as include water or dust contamination, which can significantly impact the lifespan of brushless DC machines. Regular inspections and maintenance are vital for .

Understanding these fundamental aspects of brushless direct current devices is critical for , which ensures optimal performance across diverse electronic applications.

Identify Key Components for Wiring a BLDC Motor

Understanding the for a BLDC device is crucial for achieving optimal performance and efficiency. The primary elements include:

- Motor Phase Wires: Labeled as U, V, and W, these wires connect the motor to the , facilitating the necessary phase interactions for rotation.

- : Typically consisting of five conductors, these cables are essential for delivering real-time feedback on the rotor’s position. This feedback is vital for the ESC to manage engine operation effectively, ensuring precise control and efficiency. Engineers emphasize that the reliability of Hall sensor cables directly influences the machine’s performance, as accurate rotor position detection is essential for seamless operation. As industry specialists note, “The is crucial; any inaccuracies can result in considerable .”

- : These wires connect the device to the power source, delivering the required voltage and current to operate the equipment. For instance, a 400W brushless direct current device typically has a winding resistance of approximately 6Ω, which is essential for understanding power supply needs.

- Electronic Speed Controller (ESC): This component manages the energy supplied to the engine, regulating both speed and direction. The performance of the ESC heavily relies on the accurate feedback provided by the Hall sensors, allowing for dynamic adjustments during operation. However, it is important to recognize that Hall effect sensors can be sensitive to external magnetic sources and temperature variations, which may affect their accuracy.

Acquainting yourself with these components not only simplifies the process of but also enhances the overall performance of the brushless direct current device. Incorporating best practices in wiring techniques and sensor integration is essential for engineers aiming to elevate performance.

Follow the Step-by-Step Wiring Process for BLDC Motors

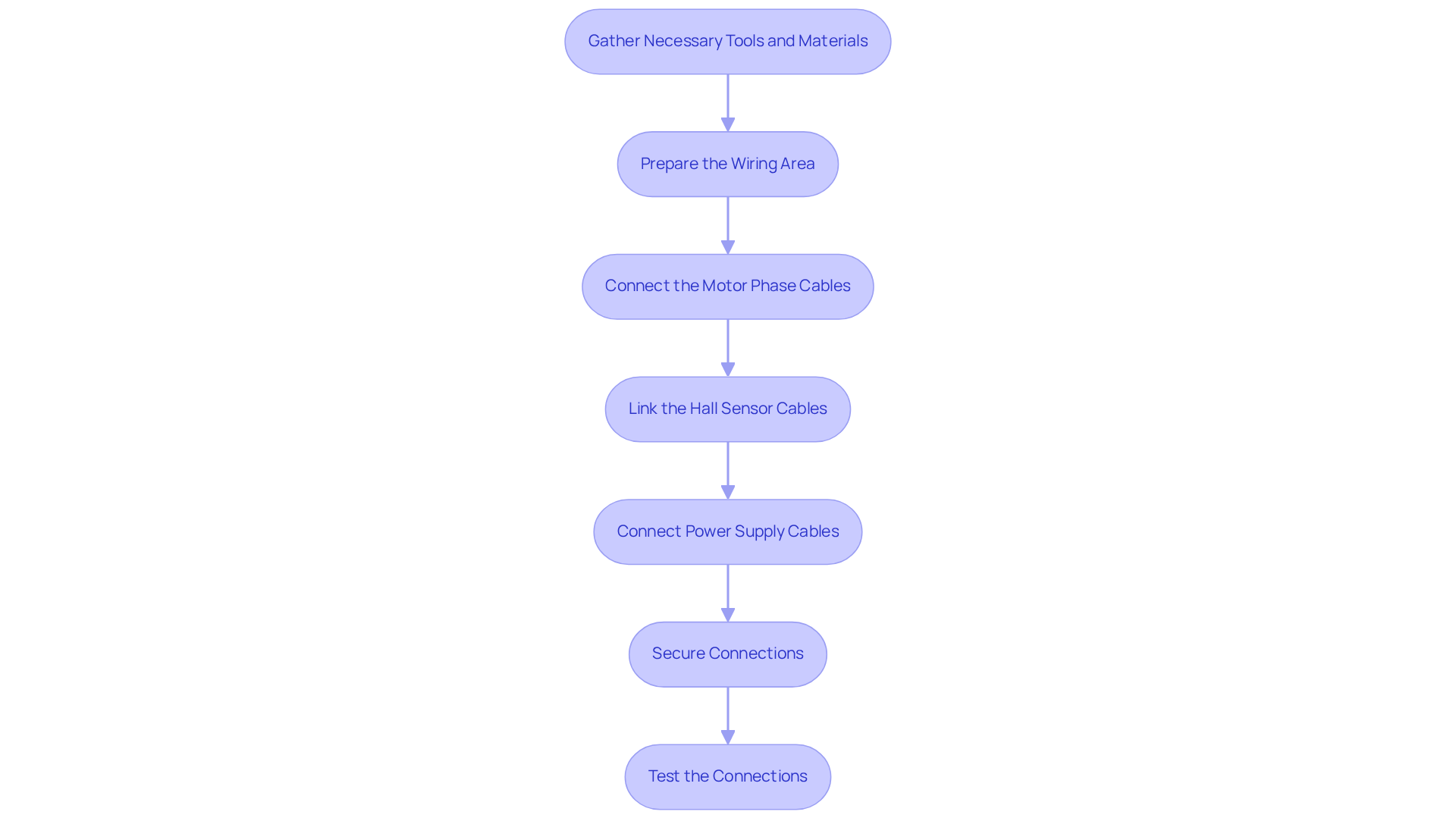

To wire a BLDC motor effectively, follow these :

- Gather Necessary Tools and Materials: Begin by ensuring you have cable strippers, a soldering iron, heat shrink tubing, and a multimeter. These tools are crucial for establishing secure and .

- Prepare the Wiring Area: Clear a workspace and ensure that all components are easily accessible. A tidy area minimizes the risk of errors and enhances efficiency during the .

- : Identify the U, V, and W connections from the device and connect these to the corresponding outputs on the ESC. Note that the order may be modified if the device does not rotate in the intended direction.

- Link the Hall Sensor Cables: from the device to the ESC, ensuring that the wiring matches the ESC’s specifications, which are typically color-coded.

- Connect : Attach the power supply cables to the ESC, ensuring correct polarity (positive to positive, negative to negative).

- : Utilize heat shrink tubing or electrical tape to insulate all connections, preventing short circuits.

- : Before powering on, double-check all connections with a multimeter to ensure there are no shorts or incorrect connections.

By adhering to these steps, you can guarantee an effective BLDC wiring procedure for your , which enhances its performance and dependability across diverse applications. The typical duration required to connect a brushless DC device varies, usually taking between 30 minutes to an hour, depending on the intricacy of the configuration and the user’s experience with the tools and components involved. Given the anticipated expansion of the worldwide brushless DC machine market, expected to reach USD 30,862.4 million by 2030, comprehending the wiring process is essential for engineers aiming to utilize these technologies effectively.

Troubleshoot Common Wiring Issues with BLDC Motors

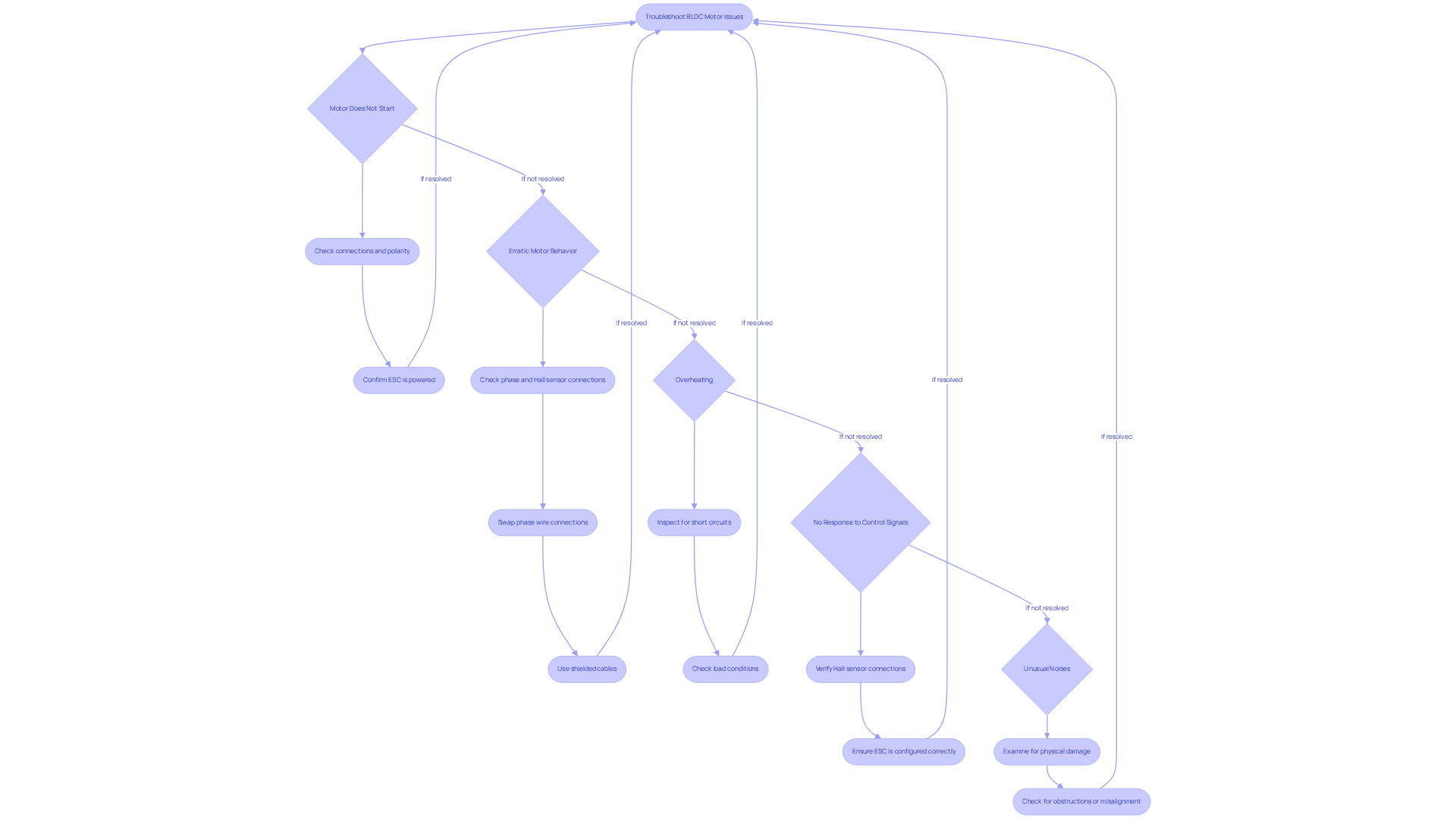

When working with , several may arise, necessitating . Here’s how to address these challenges:

- Motor Does Not Start: First, ensure that all connections are tight and correctly polarized. Confirm that the Electronic Speed Controller (ESC) is powered and functioning properly.

- Erratic Motor Behavior: Erratic behavior can indicate faulty connections of the phase or Hall sensor cables. To stabilize the motor, swap the connections of the phase wires and observe any changes. Additionally, be aware that can affect sensor signals; utilizing shielded cables may help mitigate this issue.

- Overheating: If the motor or ESC is overheating, inspect for short circuits or excessive load conditions. Notably, more than 55% of , making vital. , as mismatched voltage can lead to overheating and damage. As , ‘Selecting the appropriate motor and comprehending its is essential for creating a resilient and effective system.’

- No Response to Control Signals: Verify that the Hall sensor wires are properly connected and ensure the ESC is configured for the specific type of motor being utilized. Incorrect configurations can result in a lack of response.

- Unusual Noises: Noises such as grinding or clicking may indicate . Examine the motor for physical damage, obstructions, or misalignment that could impact performance.

By adhering to these troubleshooting steps, you can effectively diagnose and resolve common issues related to bldc wiring in BLDC motors, ensuring optimal performance and longevity. Incorporating insights from case studies on overheating and preventive strategies can further enhance your troubleshooting approach.

Conclusion

Understanding the intricacies of Brushless DC (BLDC) motors is paramount for professionals engaged in their application, wiring, and troubleshooting. Recognizing the advantages of BLDC technology—efficiency, longevity, and superior control capabilities—illustrates why these motors are increasingly preferred across diverse sectors. Furthermore, mastering the wiring process and familiarizing oneself with essential components ensures optimal operational performance.

This article elaborates on the critical steps for effective BLDC wiring, from gathering necessary tools to testing connections. It underscores the significance of each component, including:

- motor phase wires

- Hall sensor cables

- the electronic speed controller

in achieving peak functionality. Additionally, common troubleshooting techniques are highlighted, addressing challenges such as:

- erratic behavior

- overheating

- connection failures

thereby equipping users with the knowledge to maintain their equipment effectively.

Ultimately, the importance of proper wiring and maintenance cannot be overstated. As the global market for BLDC motors continues to expand, understanding effective wiring techniques and troubleshooting methods is essential for engineers and technicians. Embracing these practices not only enhances performance but also contributes significantly to the longevity and reliability of brushless DC motors across various applications.

Frequently Asked Questions

What are brushless DC motors?

Brushless DC motors (BLDC) are electric machines that operate without brushes, using electronic commutation. They consist of a rotor with permanent magnets and a stator with windings, with an electronic controller that generates a rotating magnetic field to drive the rotor.

What are the key advantages of brushless DC motors?

The key advantages of BLDC motors include higher efficiency (typically 80% or more), an extended lifespan of over 10,000 hours, and better control for precise speed and torque regulation.

How does the efficiency of brushless DC motors compare to brushed motors?

Brushless DC motors are more efficient than brushed motors, converting electrical energy into mechanical energy more effectively, which reduces energy consumption and heat generation.

What is the lifespan of brushless DC motors?

Brushless DC motors can operate for 10,000 hours or more under optimal conditions, while brushed motors typically last between 2,000 to 5,000 hours.

What maintenance considerations are important for brushless DC motors?

Regular inspections and maintenance are crucial to prevent premature failure due to water or dust contamination, which can significantly impact the lifespan of brushless DC motors.

In what applications are brushless DC motors commonly used?

BLDC motors are suitable for a wide range of applications, including consumer electronics and medical devices, due to their precise speed and torque regulation capabilities.