Overview

The article delineates four essential steps for the effective utilization of a miniature blower fan in various projects. These steps encompass:

- Understanding the fan’s functionality

- Evaluating key selection criteria

- Integrating the fan into electronics design

- Troubleshooting common issues

Each step is underpinned by comprehensive explanations of critical factors such as:

- Air movement requirements

- Optimal placement for enhanced cooling

- Strategies to address potential problems

This approach ensures efficient performance across diverse applications, empowering readers with the knowledge and skills necessary for successful implementation.

Introduction

In the realm of electronics, the significance of effective cooling is paramount. Miniature blower fans have emerged as essential components, proficiently managing heat in compact spaces across a multitude of applications, from automotive to industrial environments. Their innovative design, utilizing centrifugal force, facilitates enhanced airflow, which is critical in preventing the overheating of electronic components.

However, the process of selecting and integrating the appropriate fan entails more than merely choosing a model off the shelf; it necessitates a meticulous evaluation of factors such as:

- Airflow requirements

- Noise levels

- Static pressure

This article explores the functionality of miniature blower fans, guiding readers through the selection process, integration techniques, and troubleshooting common issues to ensure optimal performance in their electronic designs.

Understand the Functionality of Miniature Blower Fans

The miniature blower fan units from Gagner-Toomey Associates are expertly designed to circulate air effectively in confined areas, making them ideal for a variety of applications, including:

- Electronics temperature regulation

- Automotive

- Telecom

- Industrial purposes

Operating on the principle of centrifugal force, these fans utilize a rotating impeller to draw air into the center and expel it at high velocity through an outlet. This mechanism proves especially efficient for cooling electronic components, significantly enhancing circulation and dissipating heat.

Understanding key specifications, such as airflow rate (measured in CFM) and static pressure, is crucial for selecting the appropriate fan for your project. Gagner-Toomey offers an extensive range of products, including:

- DC input tube axial fans

- [Centrifugal fans

Sizes](https://gagner-toomey.com/centrifugal-fan-blower-definition-functionality-and-applications/) vary from:

- 15 to 280mm for tube axial fans

- 15 to 225mm for centrifugal fans

With options ranging from standard to custom designs, Gagner-Toomey’s miniature blower fan ventilation solutions are tailored to meet diverse industrial needs, including IP protection available in most models upon request.

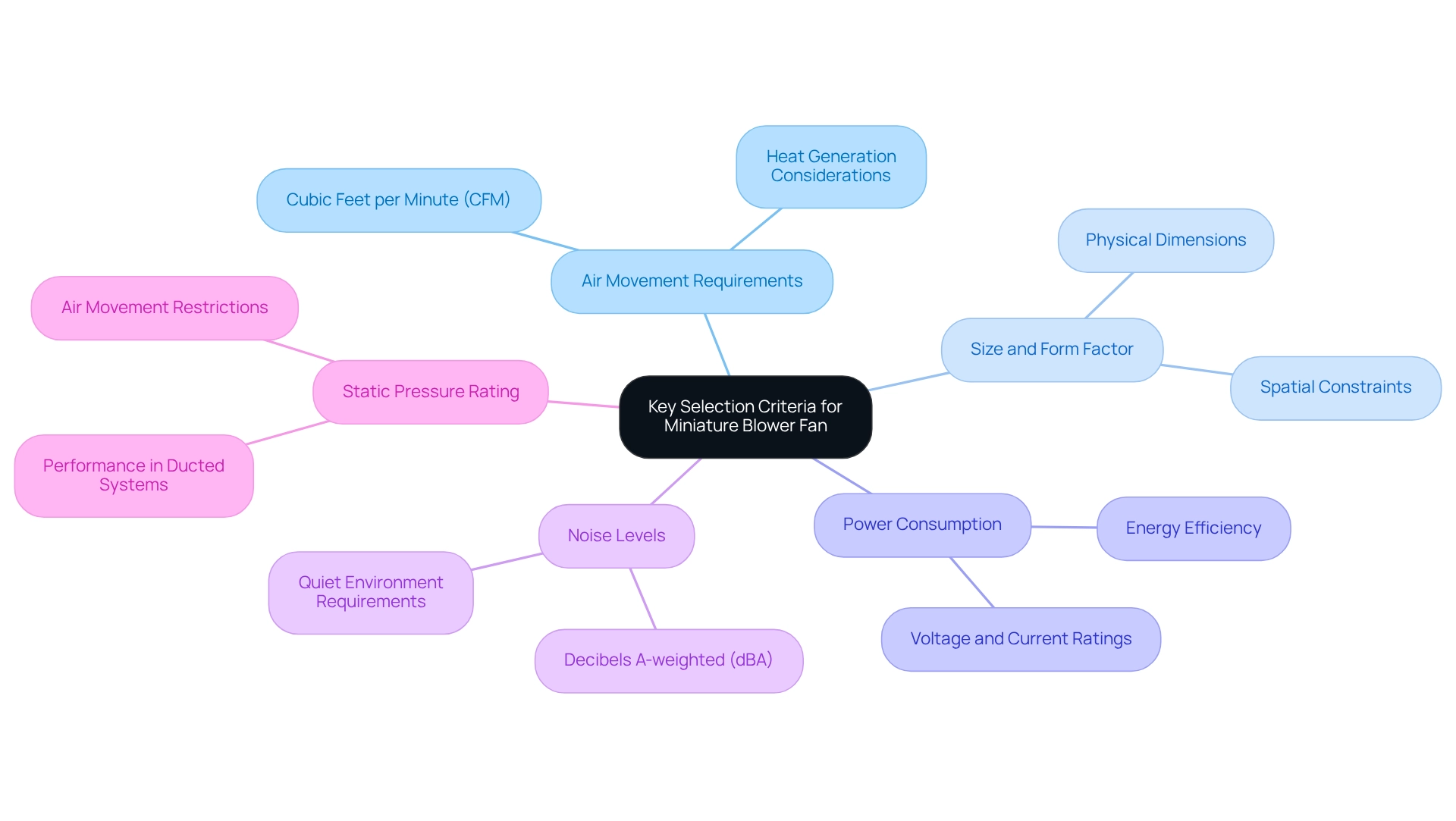

Evaluate Key Selection Criteria for Your Project

When choosing a miniature blower fan, it is crucial to take into account several important criteria that will guarantee optimal performance for your application.

- Air Movement Requirements: Start by assessing the required air circulation, quantified in cubic feet per minute (CFM), for your particular application. This requirement will depend on the heat generated by the components you are cooling, making it a critical first step in your selection process.

- Size and Form Factor: Next, assess the physical dimensions of the fan in relation to your project’s spatial constraints. It is vital to measure the available space accurately and compare it with the fan’s dimensions to ensure a proper fit.

- Power Consumption: Evaluate the voltage and current ratings of the fan to confirm compatibility with your power supply. Opt for energy-efficient models whenever possible, as they can significantly reduce operational costs over time.

- Noise Levels: Consider the noise output, expressed in decibels A-weighted (dBA), particularly if your application requires a quiet environment. For sensitive applications where minimal disruption is essential, a miniature blower fan with lower noise ratings is preferable.

Finally, assess the static pressure rating of the miniature blower fan, especially if it will be used in a ducted system or in environments where air movement is restricted. Higher static pressure ratings from a miniature blower fan indicate superior performance under such conditions, making this a vital factor in your decision-making process.

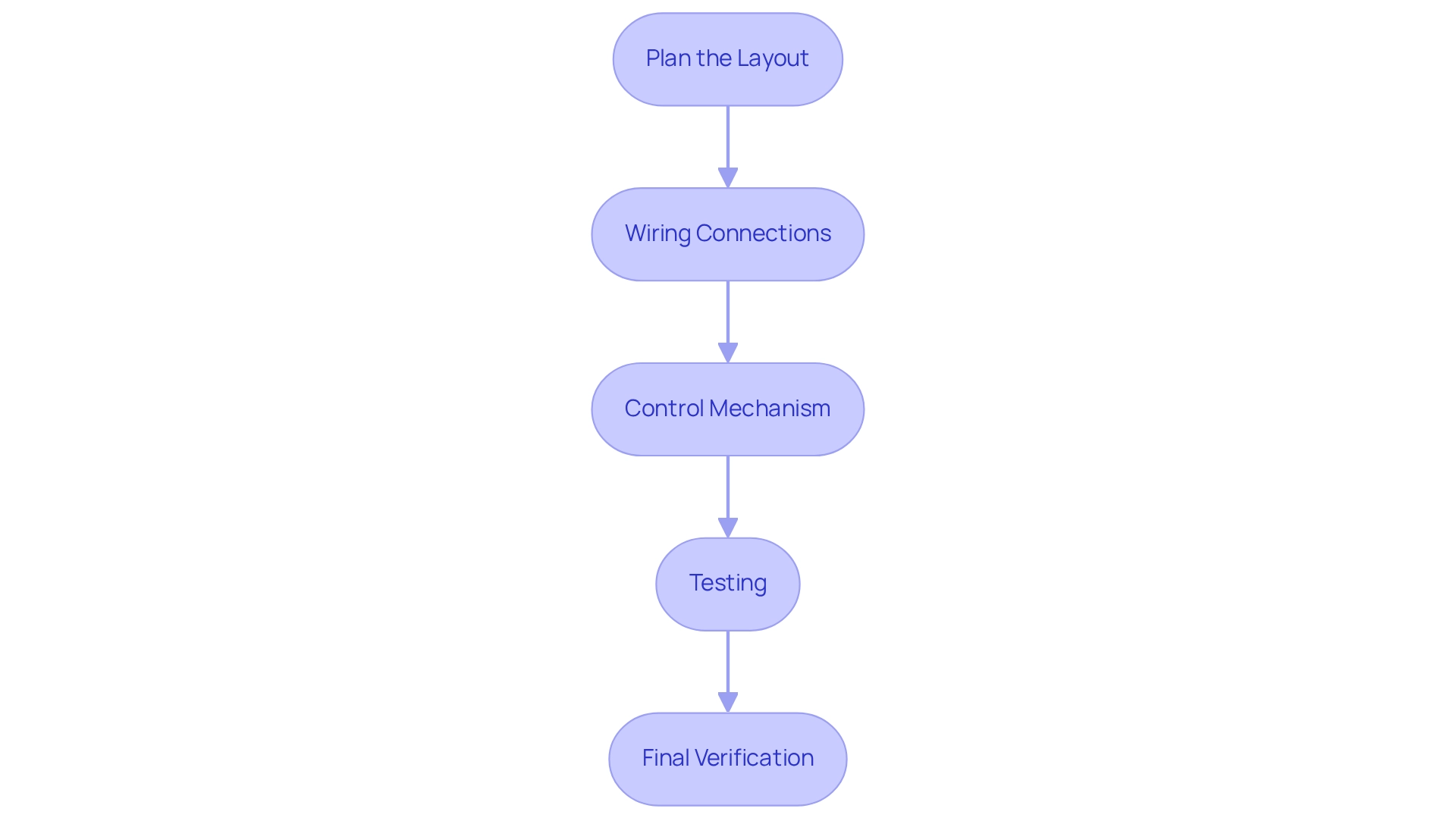

Integrate the Miniature Blower Fan into Your Electronics Design

Incorporating a miniature blower fan into your electronics design involves several essential steps to ensure optimal performance and effective temperature management.

- Plan the Layout: Begin by identifying the best location for the miniature blower fan within your project. Thoughtful placement enhances air movement over critical components that generate heat, facilitating efficient temperature regulation. As David A. Nelson notes, optimal fan placement is crucial for improving temperature management efficiency in electronic designs.

- Wiring Connections: Next, connect the fan to your power supply, which typically operates on DC voltage ranging from 5V to 12V. It is vital to use appropriately gauged wires to prevent overheating and ensure reliable operation. Best practices dictate employing wires that can accommodate the fan’s current without significant voltage drop, which is essential for maintaining performance.

- Control Mechanism: To achieve adjustable fan speed, implement a PWM (Pulse Width Modulation) controller. This method not only facilitates efficient speed regulation but also minimizes noise, thereby enhancing the overall user experience.

- Testing: After integration, power on the system and verify the fan’s operation. Ensure that airflow is unobstructed and monitor the temperature of the components to confirm efficient heat dissipation. Research indicates that optimal fan positioning can significantly enhance cooling efficiency, with the miniature blower fan, Thin ‘Super-Flow Micro’, achieving a flow rate of 0.60 cfm, making it an excellent choice for compact designs.

By adhering to these steps, you can effectively integrate a miniature blower fan into your electronic projects, ensuring dependable performance and improved thermal management.

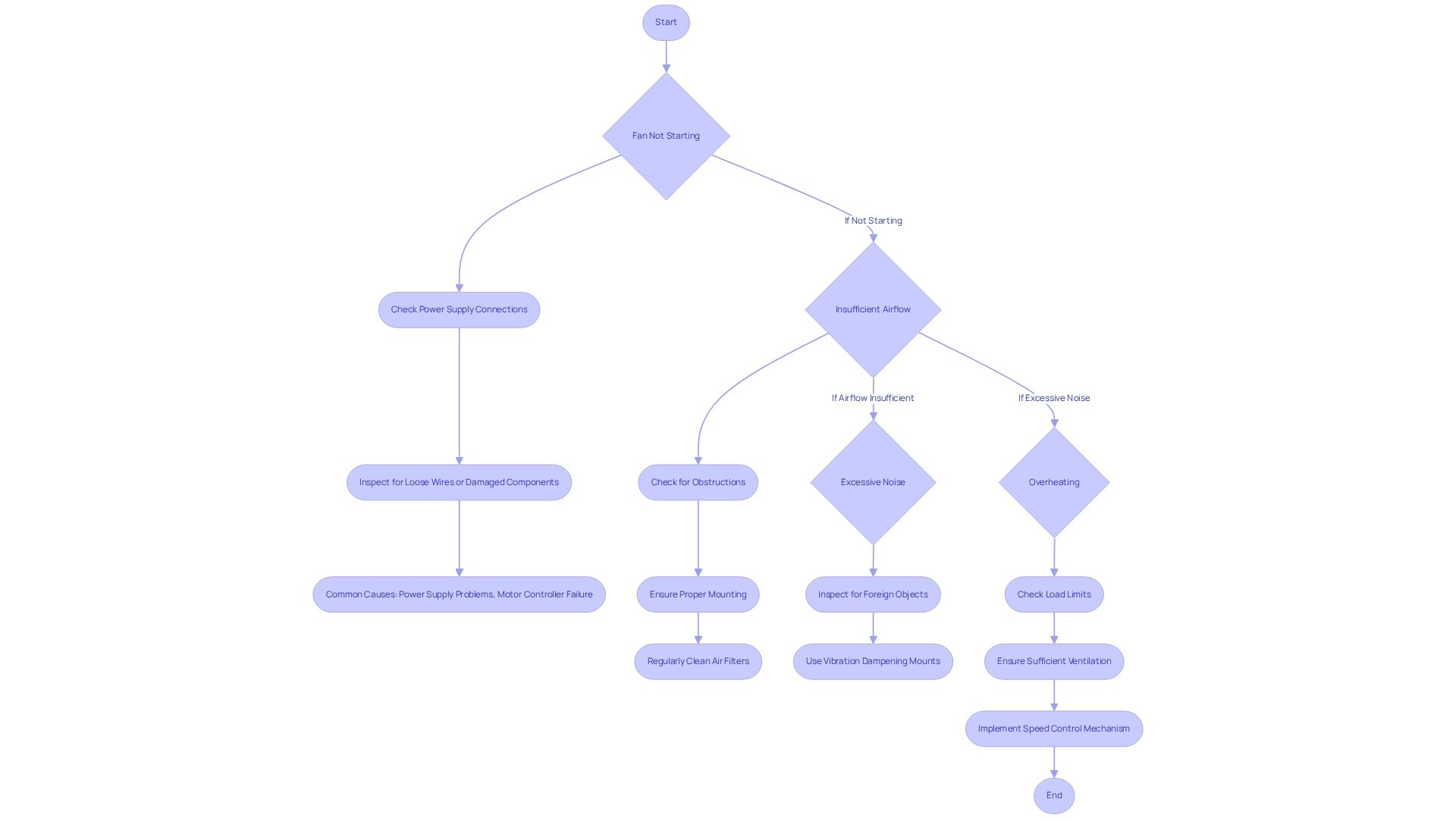

Troubleshoot Common Issues with Miniature Blower Fans

Miniature blower fan units are essential components in various electronic applications; however, they can encounter several common issues that may hinder their performance. Understanding these key problems and their solutions is crucial for ensuring optimal functionality.

- Fan Not Starting: Begin by checking the power supply connections to ensure they are secure and that the voltage aligns with the fan’s specifications. Inspect for loose wires or damaged components that could disrupt functionality. Common causes of brushless motor failure include power supply problems and motor controller failure, which should be considered during troubleshooting.

- Insufficient Airflow: This issue often arises from obstructions such as debris or improper mounting. Confirm that the miniature blower fan is positioned correctly and meets the required airflow specifications for your application. Regular upkeep, including cleaning air filters, can significantly improve motor efficiency and longevity. Consistently replacing air filters benefits the well-being of the motor and overall system efficiency.

- Excessive Noise: Noisy operation can indicate mechanical obstructions or misalignment. Inspect the fan for any foreign objects and consider employing vibration dampening mounts to minimize noise levels, which can enhance user experience and device performance.

- Overheating: Overloading the fan or inadequate airflow can lead to overheating. Ensure the fan operates within its designed load limits and has sufficient ventilation. If the fan consistently runs at high speeds, implementing a speed control mechanism can help manage heat generation effectively.

Addressing these common issues proactively can save time and resources. For instance, a case study on troubleshooting a non-functioning furnace blower motor illustrates the importance of regular inspection and maintenance, which can extend the lifespan of the fan and ensure optimal performance. As Marcel Kamutzki, an engineering manager, noted, “Knowing the reason for fan failures and making required repairs correctly in the first place will ultimately save you time and money.” By tackling these challenges head-on, engineers can enhance the reliability and efficiency of their projects.

Conclusion

Effective cooling stands as a critical aspect of electronic design, with miniature blower fans playing a vital role in managing heat within compact environments. This article has elucidated the functionality of these fans, showcasing their capacity to enhance airflow through centrifugal force, which is essential for preventing overheating across a spectrum of applications, from automotive to industrial settings.

Selecting the appropriate miniature blower fan necessitates careful consideration of several key factors, including:

- Airflow requirements

- Size

- Power consumption

- Noise levels

- Static pressure

Each criterion significantly influences the fan’s performance and suitability for specific projects, underscoring the importance of a tailored approach to selection. Furthermore, successful integration into electronic designs requires strategic planning, proper wiring, and effective testing to ensure optimal performance.

Common challenges such as starting failures, insufficient airflow, excessive noise, and overheating can impede the effectiveness of miniature blower fans. By comprehending these challenges and implementing proactive troubleshooting measures, engineers can substantially enhance the reliability and efficiency of their cooling solutions.

Ultimately, miniature blower fans are indispensable for maintaining optimal temperatures in electronic systems. By adhering to the guidelines presented in this article, designers can make informed decisions that lead to improved thermal management, ensuring the longevity and performance of their electronic components. Prioritizing effective cooling solutions transcends mere technical necessity; it represents a crucial investment in the overall success of any electronic project.

Frequently Asked Questions

What are the applications of miniature blower fan units from Gagner-Toomey Associates?

The miniature blower fan units are ideal for applications such as electronics temperature regulation, automotive, telecom, and industrial purposes.

How do the blower fans operate?

These fans operate on the principle of centrifugal force, utilizing a rotating impeller to draw air into the center and expel it at high velocity through an outlet, which is efficient for cooling electronic components.

What specifications should be considered when selecting a blower fan?

Key specifications to consider include airflow rate (measured in CFM) and static pressure, which are crucial for selecting the appropriate fan for a project.

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers an extensive range of products, including DC input tube axial fans and centrifugal fans.

What are the size ranges for the tube axial and centrifugal fans?

Tube axial fans range from 15 to 280mm, while centrifugal fans range from 15 to 225mm.

Are there customization options available for the fans?

Yes, Gagner-Toomey offers options ranging from standard to custom designs, including IP protection available in most models upon request.