Overview

This article delineates four fundamental steps crucial for mastering speed control in electronic systems:

- Selecting the appropriate actuator and controller

- Connecting components

- Programming the microcontroller

- Evaluating the setup

It underscores the significance of employing tools such as electronic speed controllers and feedback sensors to achieve precise speed regulation. These steps are essential for enhancing performance and efficiency in applications, including robotics and industrial machinery. By following this structured approach, professionals can ensure optimal operation and reliability in their systems.

Introduction

In the realm of electronic systems, speed control emerges as a critical factor that dictates the performance and efficiency of various applications, from robotics to industrial machinery. This intricate process encompasses a range of techniques designed to regulate motor speeds, ensuring precision and reliability under varying conditions. As technology advances, methods such as pulse width modulation and feedback systems are becoming increasingly sophisticated, facilitating smoother operations and enhanced control.

With the rise of Variable Frequency Drives and innovative solutions like microstepping, the landscape of speed control is evolving rapidly. It is essential for engineers and technicians to stay abreast of these developments. Understanding the tools and methodologies for effective speed control not only optimizes functionality but also addresses the challenges associated with implementing these systems in a technology-driven world.

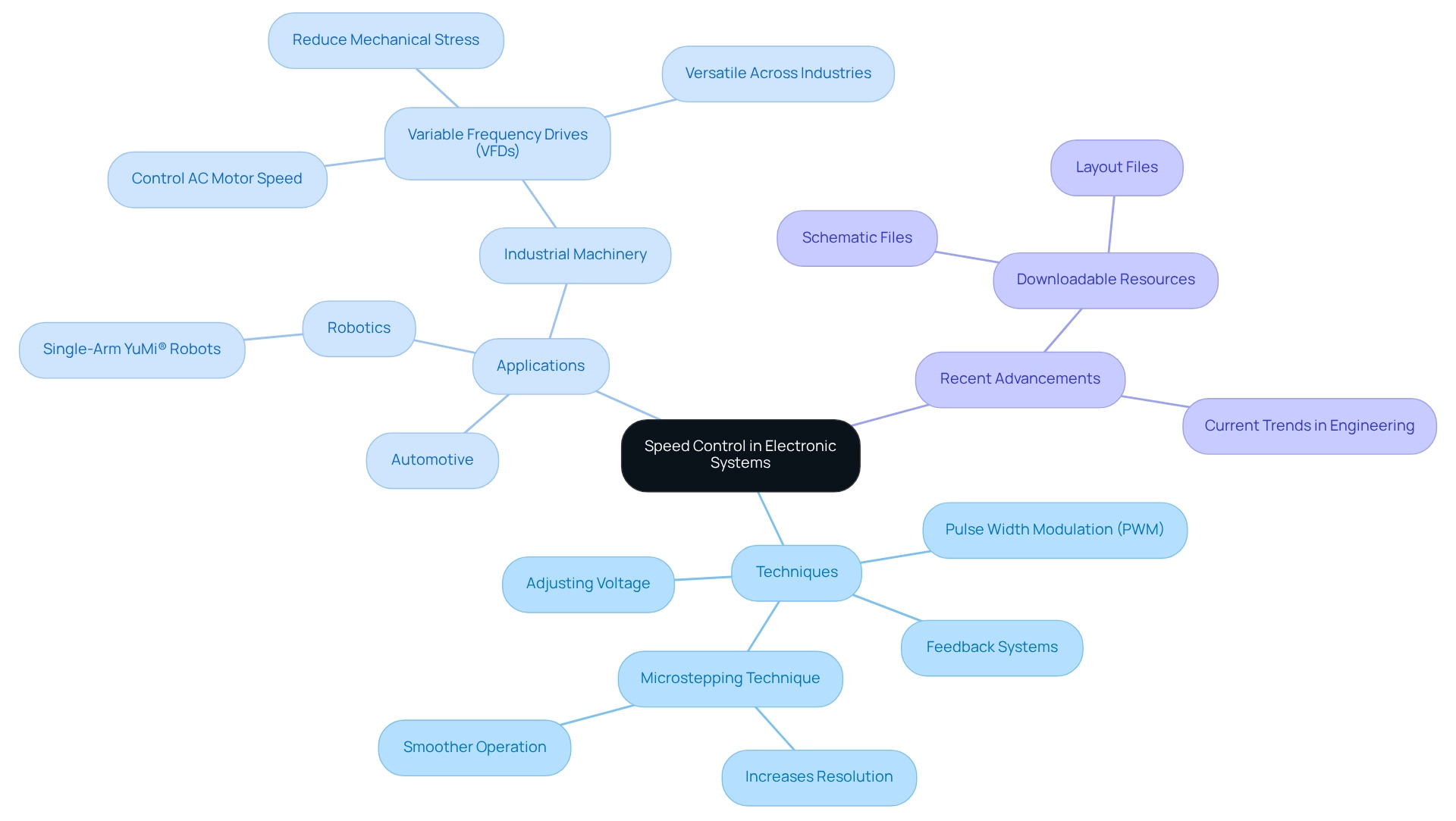

Define Speed Control in Electronic Systems

Velocity management in electronic setups involves speed control techniques and methods used to regulate the rotational rate of motors and other mechanical elements. This regulation is crucial in applications that demand precise speed control of motion, such as robotics, automotive technologies, and industrial machinery. Common methods include:

- Adjusting voltage

- Utilizing pulse width modulation (PWM)

- Implementing feedback systems to maintain desired rates, even under varying load conditions

Recent advancements, such as the microstepping technique, significantly enhance resolution by subdividing each full step into smaller increments, thereby improving the device’s resolution and enabling smoother operation and superior management.

The significance of velocity regulation is underscored by its impact on performance, efficiency, and reliability across diverse applications. For instance, Variable Frequency Drives (VFDs) play a pivotal role in regulating AC motor rates by modifying the frequency and voltage of the supplied electricity. This not only fine-tunes motor pace and torque but also reduces mechanical stress, making VFDs indispensable in modern industrial environments. In robotics and automotive applications, effective speed control is vital for enhancing functionality and ensuring safety. As noted by ABB Inc. regarding their Single-Arm YuMi® collaborative robots, speed control is essential for improving operational efficiency.

As engineers and technicians navigate the complexities of electronic frameworks, a solid understanding of these concepts is crucial for devising innovative solutions that meet the demands of today’s technology-driven landscape. Additionally, staying informed about current trends and technologies in engineering is essential, as courses are regularly updated to reflect these advancements. For practical applications, downloadable schematic and layout files for the voltage regulator and sensor array circuits utilized in the robot are available, offering valuable resources for electronics engineers.

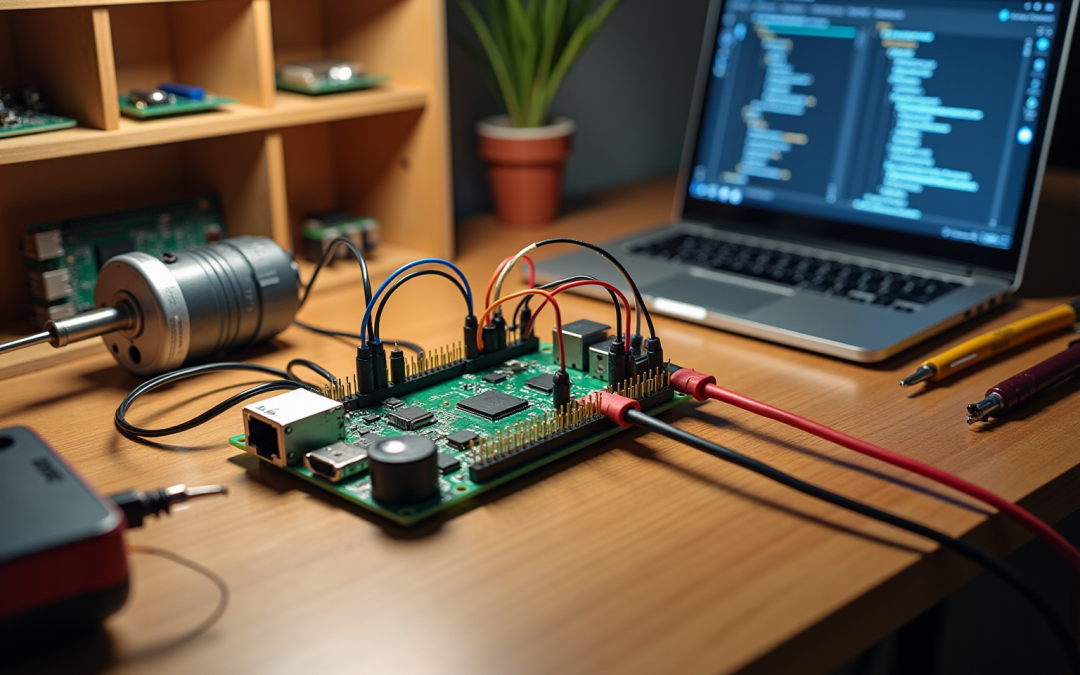

Gather Required Tools and Resources

To successfully implement speed control in electronic systems, a variety of tools and resources are essential:

- Microcontroller or Microprocessor: This component is vital for programming and managing the rotation rate, enabling precise modifications based on real-time information. Notably, the microcontroller market in the U.K. accounted for over 14.0% of the European market in 2023, underscoring its growing significance in modern electronic applications.

- Electronic Speed Controller (ESC): This device is responsible for managing the engine’s speed based on input signals, playing a crucial role in the overall control architecture. A case study on cost analysis revealed that utilizing commercial off-the-shelf (COTS) controllers can lead to substantial savings in development and implementation costs, making them an attractive option for industrial applications.

- Power Supply: A reliable power source is essential to deliver the necessary voltage and current to both the engine and the controller, ensuring stable operation. For applications requiring precision, advanced pump solutions such as solenoid pumps with DC brushless motors can be integrated, offering up to 16 Bar pressure and low noise operation—ideal for sensitive electronic systems. These pumps are also available in NSF and WSAS materials, enhancing their suitability for various applications.

- PWM Signal Generator: This can be constructed using a microcontroller or acquired as a standalone unit. It produces the pulse-width modulation (PWM) signals that are crucial for efficient speed control management.

- Motor: The selection of motor—whether DC, stepper, or brushless—will determine the specific methods employed for regulation. For instance, rotary boost pumps can enhance performance in applications requiring precise regulation and EMI suppression.

- Feedback Sensors: Devices such as encoders or tachometers are essential for monitoring motor velocity, providing real-time information that enables prompt adjustments.

- Wiring and Connectors: High-quality wiring and connectors are necessary for secure and reliable connections among all components.

- Software Tools: Programming environments like Arduino IDE or MPLAB X are crucial for developing and coding management algorithms, enabling customization and enhancement of the velocity regulation setup.

Hartmut emphasizes the significance of utilizing a digital signal generator for speed control, stating, ‘You cannot use a potentiometer for velocity input because it provides a linear straight signal.’ He further notes, “The ESC expects a pulsed signal at very short intervals… You need a digital signal generator – a PWM.” This highlights the importance of incorporating suitable pump solutions to achieve efficient speed control in electronic frameworks.

Equipping yourself with these tools will not only streamline the implementation process but also significantly enhance the effectiveness and reliability of your acceleration solutions.

Implement Speed Control: Step-by-Step Process

To implement speed control in your electronic system, follow these steps:

-

Select the Actuator and Controller: Choose an actuator that fits your application needs, such as DC, stepper, or brushless types, and pair it with a suitable electronic control unit (ESC). Consider the specific requirements of your project, including load and speed characteristics.

-

Connect the Components: Wire the motor to the ESC, ensuring the power supply is connected correctly. Adhere to the manufacturer’s wiring diagram to prevent damage and ensure optimal performance.

-

Program the Microcontroller: Utilize your preferred programming environment to develop a management algorithm. This should encompass:

- Initialization of the PWM signal.

- Reading input from feedback sensors, if applicable.

- Modifying the PWM duty cycle to align with the target velocity. When programming the microcontroller, note that to enter reverse, the sequence is 1300, 1500, 1300 microseconds. Recent advancements in microcontroller programming have demonstrated notable success rates in implementing velocity regulation mechanisms, enhancing overall efficiency.

-

Evaluate the Setup: Turn on the setup and slowly raise the pace using your management interface. Observe the machine’s response and modify the PWM signal as necessary to attain the desired speed. For example, in the RZ/T2M Motor Solution Kit, engineers can assess high voltage applications efficiently, demonstrating the adaptability of drive mechanisms. This kit enables the creation of motion management systems utilizing an RZ/T2M MPU with a high voltage 220V AC servo engine, offering a thorough solution for engineers.

-

Implement Feedback Control (Optional): For improved accuracy, incorporate input from sensors to dynamically modify the PWM signal according to the actual rate of the engine. This approach can significantly improve load regulation and transient response, critical factors in high-performance applications. As Raghu Tumati noted, “I only need the motor to spin in one direction for my two co-axial motors,” emphasizing the significance of accurate management in specific applications.

By adhering to these steps, you can efficiently apply speed control in your electronic setups, which will result in enhanced performance and efficiency.

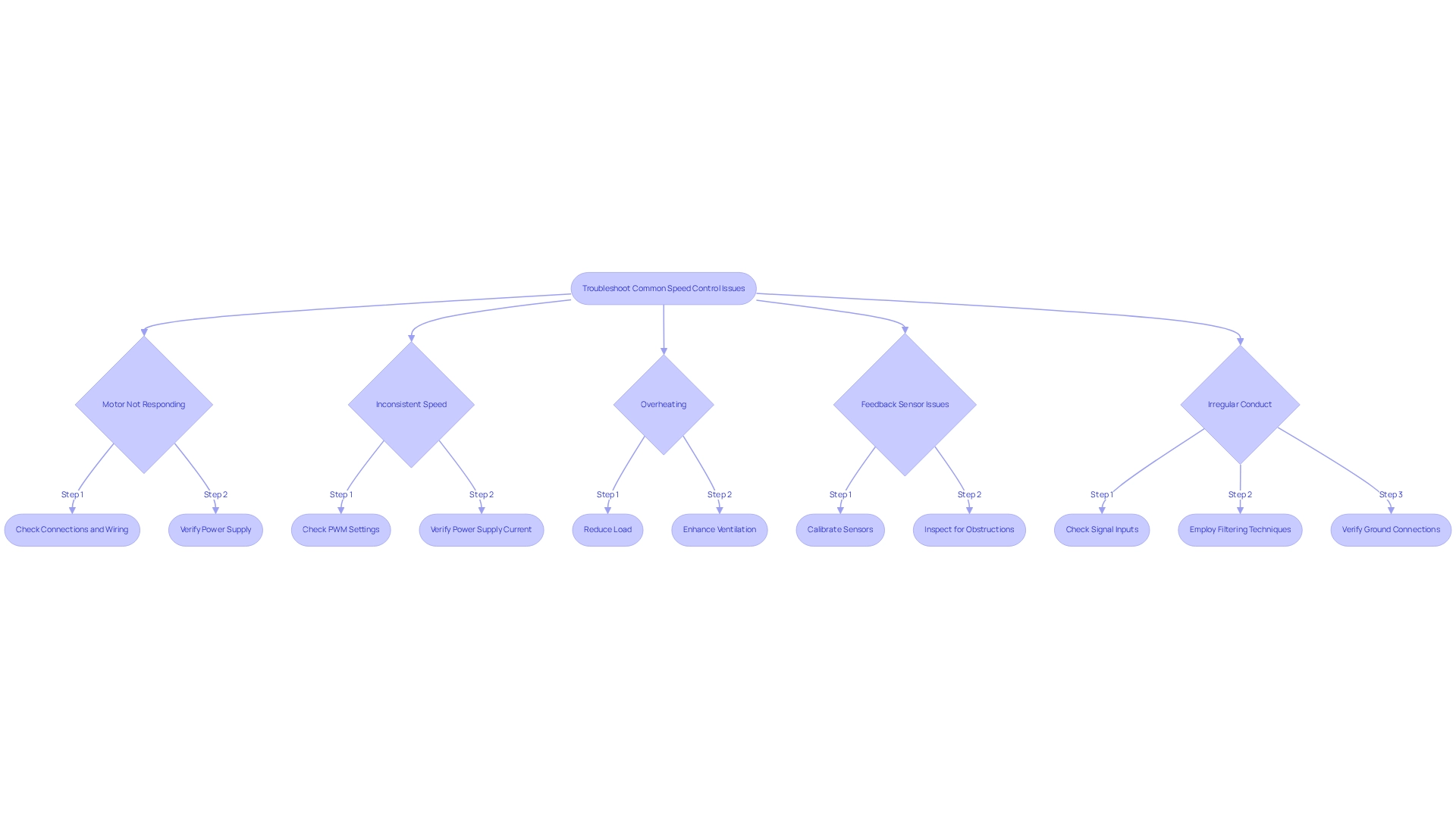

Troubleshoot Common Speed Control Issues

Introducing velocity regulation in electronic setups can pose several difficulties. To effectively address these common issues, consider the following essential troubleshooting tips:

- Motor Not Responding: Ensure all connections are secure and correctly wired. Verify that the power supply is operational and delivering the appropriate voltage.

- Inconsistent Speed: This issue often arises from an inadequate power supply or incorrect PWM settings. Verify that the PWM duty cycle is suitably set and that the power supply satisfies the current requirements of the device. Notably, around fifty percent of U.S. motorists would embrace technologies that actively reduce their vehicles’ pace, emphasizing the necessity of dependable speed control in contemporary applications.

- Overheating: If the engine or electronic speed controller (ESC) is overheating, it may indicate excessive load or insufficient cooling. Consider reducing the load or enhancing ventilation around the components to prevent thermal issues.

- Feedback Sensor Issues: For setups utilizing feedback sensors, ensure they are properly calibrated and functioning. Inspect for obstructions or misalignments that could interfere with accurate readings.

- Irregular Conduct: If the motor displays erratic behavior, examine possible noise in the signal inputs. Employ effective filtering techniques and verify that ground connections are secure to minimize interference. As highlighted by the Auto Repair Guys, defective parts like a ‘cork spring’ or ‘spiral cable’ can greatly affect performance.

By methodically tackling these troubleshooting steps, you can successfully resolve frequent performance issues, ensuring optimal functioning in electronic systems. Additionally, implementing best practices from successful speed safety camera programs can provide valuable insights into effective speed management strategies, reinforcing the critical nature of speed control in engineering applications.

Conclusion

Speed control in electronic systems stands as a cornerstone of efficiency and performance across diverse applications, transcending mere technical necessity. This exploration has illuminated various methods, such as pulse width modulation and feedback systems, which are essential for achieving precise motor regulation. The evolution of technologies, including Variable Frequency Drives and microstepping, exemplifies the continuous advancements that enhance control and reliability in speed management.

Equipping engineers and technicians with the right tools—ranging from microcontrollers to electronic speed controllers—is paramount for implementing effective speed control systems. The outlined step-by-step process underscores the importance of proper selection, connection, programming, and testing, ensuring optimal system functionality under varying conditions. Moreover, addressing common troubleshooting issues reinforces the necessity for vigilance and adaptability in maintaining system performance.

In an era marked by ever-increasing technological demands, staying informed about the latest developments in speed control methodologies is crucial. A robust understanding of these concepts not only optimizes functionality but also effectively addresses the challenges of modern electronic applications. By prioritizing effective speed control, engineers are positioned to drive innovation and enhance system performance, ultimately leading to safer and more efficient operations in robotics, automotive systems, and beyond.

Frequently Asked Questions

What is velocity management in electronic setups?

Velocity management in electronic setups involves speed control techniques used to regulate the rotational rate of motors and other mechanical elements, which is essential for applications requiring precise motion control.

What are some common methods for regulating speed in electronic systems?

Common methods for regulating speed include adjusting voltage, utilizing pulse width modulation (PWM), and implementing feedback systems to maintain desired rates under varying load conditions.

What is the microstepping technique and its significance?

The microstepping technique enhances resolution by subdividing each full step of a motor into smaller increments, resulting in improved device resolution, smoother operation, and superior management.

How do Variable Frequency Drives (VFDs) function in speed regulation?

Variable Frequency Drives (VFDs) regulate AC motor rates by modifying the frequency and voltage of the supplied electricity, which fine-tunes motor pace and torque while reducing mechanical stress.

Why is effective speed control important in robotics and automotive applications?

Effective speed control is vital in robotics and automotive applications for enhancing functionality and ensuring safety, as it directly impacts operational efficiency.

What resources are available for electronics engineers regarding speed control applications?

Downloadable schematic and layout files for voltage regulator and sensor array circuits used in robots are available, providing valuable resources for electronics engineers.

Why is it important for engineers and technicians to understand velocity regulation concepts?

A solid understanding of velocity regulation concepts is crucial for engineers and technicians to devise innovative solutions that meet the demands of today’s technology-driven landscape.