Overview

The primary inquiry explored in the article “4 Steps to Select the Right Axial Fan Blower” revolves around the effective selection of an axial fan tailored to specific project needs. This article delineates a methodical approach that encompasses:

- Comprehending project requirements

- Assessing critical performance metrics such as CFM and static pressure

- Investigating available options

- Addressing common selection challenges

This structured methodology guarantees that the chosen fan adheres to both operational and efficiency standards, thereby ensuring optimal performance.

Introduction

Selecting the right axial fan blower is crucial for enhancing the efficiency and effectiveness of ventilation systems across diverse applications. It is imperative to understand the intricacies of airflow requirements, environmental conditions, and regulatory standards to make an informed choice. With numerous factors influencing the decision, how can one ensure that the selected fan not only meets performance metrics but also aligns with specific project needs? This guide will provide a structured approach to axial fan selection, addressing common challenges and offering insights to navigate the decision-making process with confidence.

Understand Project Requirements for Axial Fans

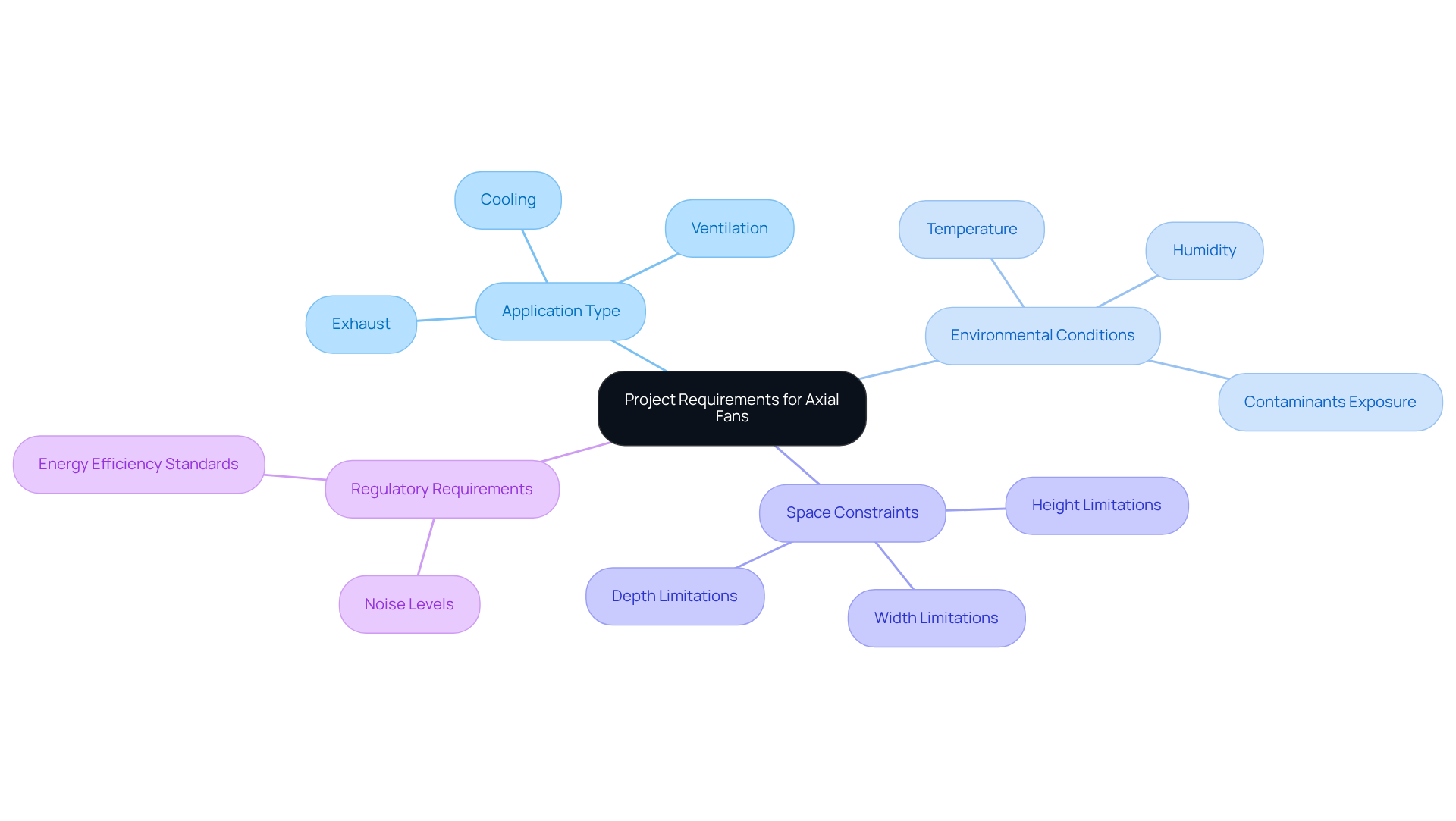

To effectively for your project, it is essential to start with a clear understanding of its intended purpose. Key factors must be considered:

- Application Type: Determine whether the fan will be utilized for cooling, ventilation, or exhaust. Each application demands specific requirements that influence fan operation.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and potential exposure to contaminants. These factors can significantly affect the fan’s efficiency and longevity.

- Space Constraints: Measure the available installation space, considering height, width, and depth limitations. Axial fan blowers are available in various dimensions, and ensuring a suitable fit is critical for optimal functionality.

- Regulatory Requirements: Be mindful of any industry standards or regulations that may impact fan selection, such as noise levels and energy efficiency standards. Adherence to these regulations is crucial for project success.

By thoroughly gathering this information, you will establish a solid foundation for the subsequent stages in the fan selection process, ensuring that the chosen fan meets both efficiency and regulatory standards.

Evaluate Key Performance Metrics: CFM and Static Pressure

To effectively evaluate the performance metrics of axial fans, follow these essential steps:

-

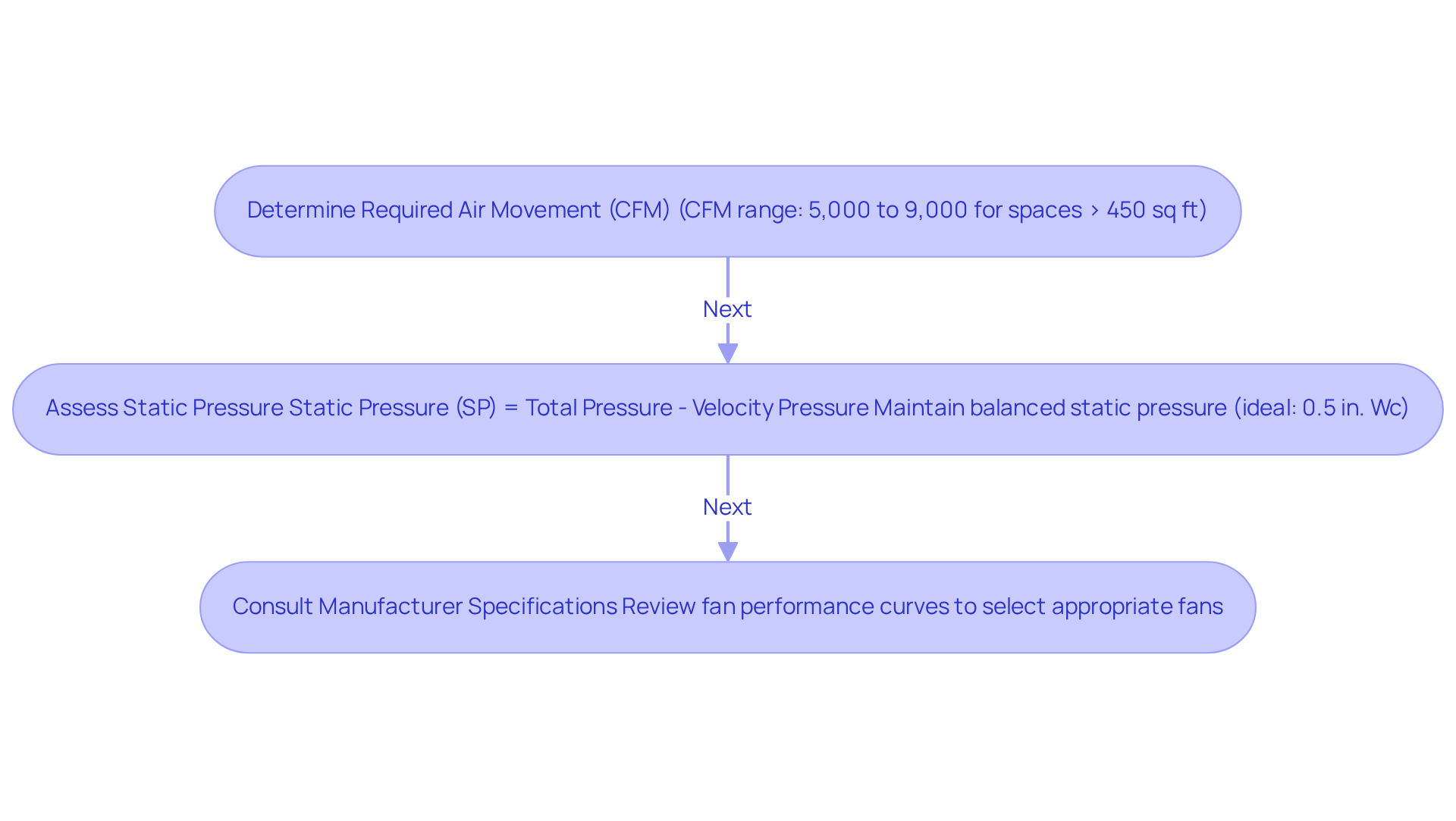

Determine Required Air Movement (CFM): Begin by calculating the necessary air movement for your application. Measure the volume of the space and the desired air changes per hour. For spaces exceeding 450 square feet, CFM requirements typically range from 5,000 to 9,000, providing a solid benchmark.

-

Assess Static Pressure: Next, measure the resistance to air movement within your system, which encompasses ductwork, filters, and any other components that may impede air circulation. The formula for calculating static pressure is:

Static Pressure (SP) = Total Pressure - Velocity PressureIt is crucial to maintain balanced static pressure, ideally around 0.5 inches water column (in. Wc), as this directly impacts the efficiency of movement and overall system functionality. Elevated static pressure can lead to increased energy usage, with the HVAC system exerting more effort to sustain circulation, potentially raising energy costs by as much as 30%. Common causes of high static pressure include undersized ducts and restrictive filters, factors that engineers must consider when assessing their systems.

-

Consult Manufacturer Specifications: Finally, review the fan performance curves provided by manufacturers to identify fans that meet your calculated CFM and static pressure requirements. Understanding these specifications is essential for selecting the right fan for your application, ensuring and energy efficiency.

By precisely assessing these metrics, you can guarantee that the fan operates efficiently and effectively in your application, leading to enhanced indoor comfort and reduced operational expenses.

Follow a Step-by-Step Selection Process for Axial Fans

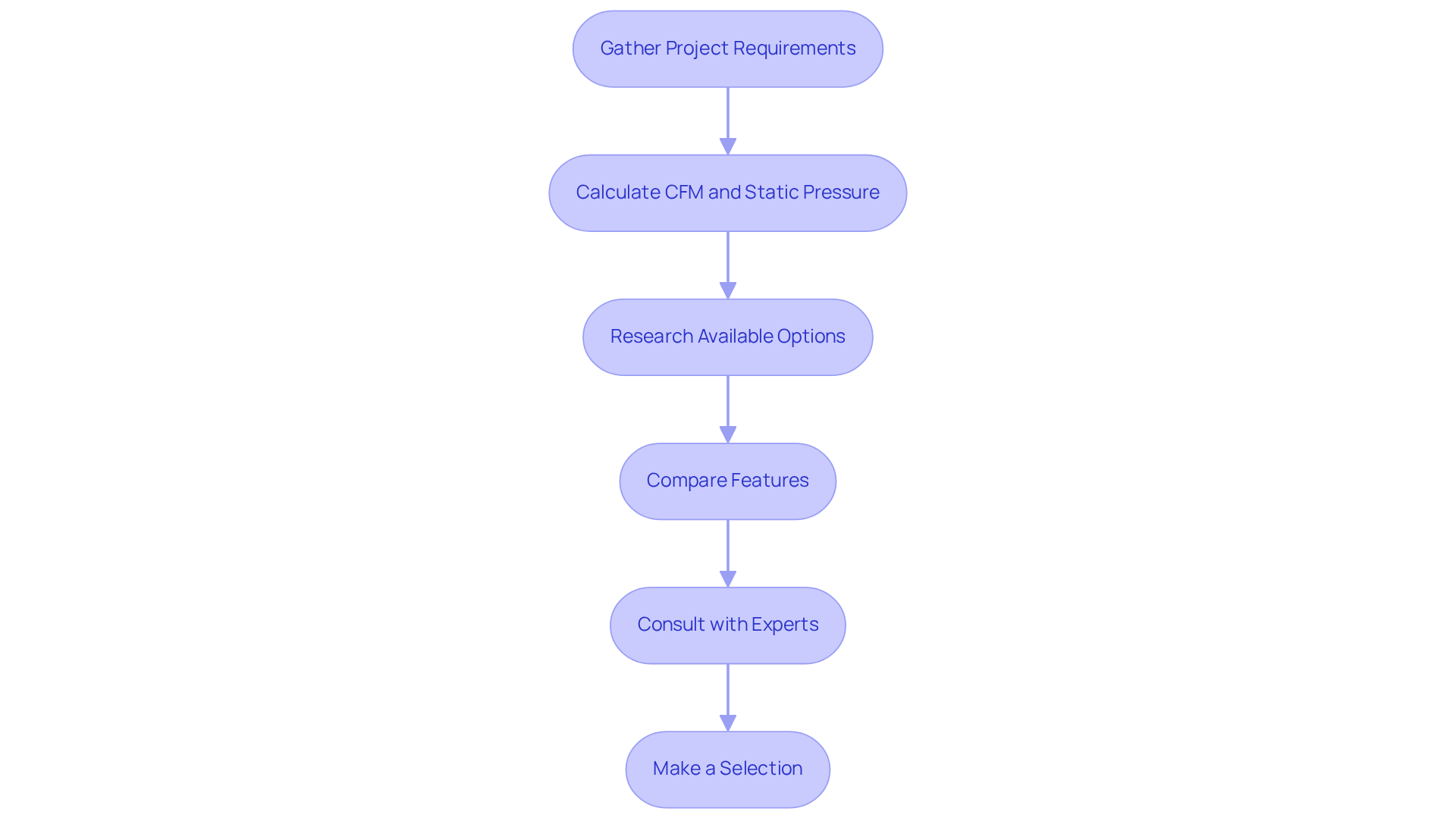

To select the right axial fan, follow these steps:

- Gather Project Requirements: Begin by referencing the requirements identified in the initial section, which include the intended application and environmental conditions.

- Calculate CFM and Static Pressure: Utilize the metrics evaluated previously to ascertain your airflow needs in cubic feet per minute (CFM) and the necessary static pressure, measured in inches of water gauge (SPWG). It is crucial to account for the total pressure drop in your system, including ductwork and filters, to ensure accurate fan selection.

- Research Available Options: Investigate axial devices that meet your CFM and static pressure requirements. Leverage manufacturer catalogs and online resources to explore current market options, including energy-efficient models that align with sustainability initiatives. Notably, the global axial fans market is projected to grow with a CAGR of 5.98% through 2029, reflecting a rising demand for efficient solutions.

- Compare Features: Assess additional features such as noise levels, energy efficiency ratings, and motor types (AC vs. DC). Lower decibel (dB) ratings signify quieter operation, which is essential for noise-sensitive environments. Furthermore, consider the durability of materials used in fan construction, particularly for harsh conditions where corrosion-resistant materials like stainless steel or plastic composites may be necessary.

- Consult with Experts: If feasible, engage in discussions with a sales representative or an engineer to validate your findings. As Johann Tang, a Product Specialist at Oriental Motor USA Corp., notes, “It’s essential to understand that although peak values for air movement and static pressure are indicated, the fan will not deliver both peak values simultaneously.”

- Make a Selection: Choose the fan that best aligns with your project needs and efficiency metrics, ensuring it can deliver the required airflow while maintaining energy efficiency. Selecting axial fan blowers with , as highlighted in the case study on the energy efficiency of axial fan blowers.

By adhering to this organized method, you can confidently select a fan that meets your project’s requirements and enhances overall system performance.

Troubleshoot Common Selection Challenges

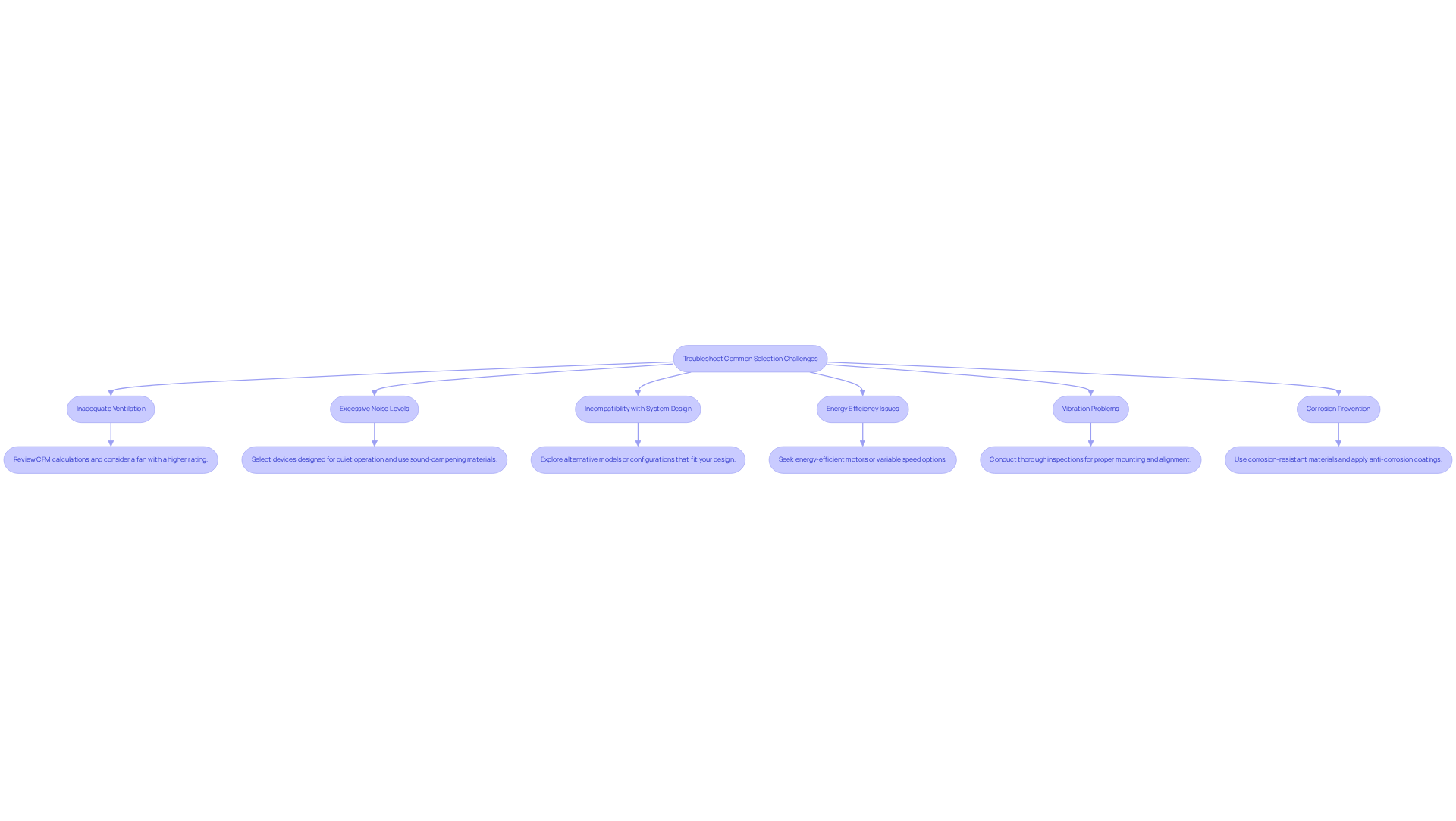

Selecting an axial fan can present several challenges that require careful consideration:

- Inadequate Ventilation: Insufficient air movement can hinder performance. Review your cubic feet per minute (CFM) calculations and consider a fan with a higher rating. Consistent observation of operating conditions aids in early detection of airflow issues, ensuring optimal efficiency. The analytical model for forecasting the aerodynamic performance curve of cooling devices serves as a technical foundation for diagnosing airflow problems.

- Excessive Noise Levels: Noise is a prevalent concern in fan applications. Engineers recommend selecting devices specifically designed for quiet operation. Typical noise levels for ducted ventilators in electronics applications range from 30 to 50 dBA, influenced by design and operating conditions. Additionally, incorporating sound-dampening materials can significantly mitigate noise levels.

- Incompatibility with System Design: It is crucial to ensure that the fan’s dimensions and mounting options align with your installation space. If the selected fan does not fit, explore alternative models or configurations that accommodate your design requirements.

- : High energy consumption poses a significant drawback. Seek devices equipped with energy-efficient motors or variable speed options to optimize energy use without sacrificing performance.

- Vibration Problems: Excessive vibration may indicate misalignment or imbalance within the fan system. Conduct a thorough inspection of the installation to ensure proper mounting and alignment. Regular inspections can prevent long-term damage and sustain operational efficiency.

- Corrosion Prevention: Selecting fans constructed with corrosion-resistant materials is vital, especially in harsh environments. Applying anti-corrosion coatings and conducting regular inspections can extend the fan’s efficiency and lifespan.

By understanding these challenges and implementing effective solutions, you can confidently select tailored to your specific needs.

Conclusion

Selecting the right axial fan blower is a critical process that hinges on a thorough understanding of project requirements and performance metrics. By focusing on the specific application, environmental conditions, and regulatory standards, one can lay the groundwork for making an informed decision that ensures efficiency and compliance.

Key considerations, such as calculating the necessary CFM and assessing static pressure, are paramount in the selection process. Evaluating available options, comparing features, and consulting with experts further refine the choices, allowing for a selection that not only meets operational needs but also aligns with energy efficiency goals. Additionally, being aware of common challenges and their solutions can greatly enhance the likelihood of a successful fan selection.

Ultimately, the significance of selecting the appropriate axial fan blower extends beyond mere functionality; it impacts overall system performance, energy consumption, and operational costs. By following a structured approach and remaining diligent in assessing all factors, one can achieve optimal airflow solutions that contribute to a more efficient and sustainable environment. Embrace the steps outlined in this guide to ensure the axial fan selected is not just a choice but a strategic investment in your project’s success.

Frequently Asked Questions

What is the first step in selecting the right axial fan for a project?

The first step is to have a clear understanding of the fan’s intended purpose, which includes determining its application type.

What application types should be considered when selecting an axial fan?

The main application types to consider are cooling, ventilation, and exhaust, as each has specific requirements that influence fan operation.

Why is it important to assess environmental conditions for axial fans?

Assessing environmental conditions, such as temperature, humidity, and potential exposure to contaminants, is important because these factors can significantly affect the fan’s efficiency and longevity.

How do space constraints impact the selection of an axial fan?

Space constraints impact selection by requiring measurements of the available installation space, including height, width, and depth limitations, to ensure a suitable fit for optimal functionality.

What regulatory requirements should be considered when choosing an axial fan?

Regulatory requirements include industry standards or regulations related to noise levels and energy efficiency, which are crucial for project success.

How does gathering information about project requirements benefit the fan selection process?

Gathering this information establishes a solid foundation for the fan selection process, ensuring that the chosen fan meets both efficiency and regulatory standards.