Overview

The article emphasizes the critical importance of optimizing the installation and performance of high power fans, essential for effective cooling in electronic devices. It presents five key steps for installation, including:

- Selecting the right location

- Securing the fan

- Implementing control strategies

These steps are designed to enhance airflow and energy efficiency, ultimately ensuring the reliability and longevity of electronic components.

Introduction

In the realm of electronics, where performance critically depends on effective cooling solutions, high power fans emerge as vital components. As technology progresses and power demands escalate, the importance of these fans in maintaining optimal operating temperatures for sensitive components cannot be overstated.

With a diverse array of fan types tailored to specific applications, it is essential for engineers to understand their functionality and installation to enhance system reliability and efficiency. This article delves into the intricacies of airflow dynamics and the latest advancements in cooling technology, offering valuable insights on:

- Selection

- Installation

- Control

- Maintenance

By empowering professionals with this knowledge, we aim to facilitate the optimization of cooling strategies in an ever-evolving landscape.

Understand the Role of High Power Fans in Electronics Cooling

Powerful ventilators are indispensable for regulating temperatures in electronic devices, as they facilitate circulation and effectively dissipate heat generated by high-density components. As we approach 2025, their importance is magnified by the escalating power demands of modern electronics, where sustaining optimal temperatures is vital for enhancing performance and reliability. Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, provides an extensive array of DC input tube axial devices, ranging from 15 to 280mm, alongside centrifugal blowers, from 15 to 225mm, designed for performance, effectiveness, and low noise, making them ideal for diverse applications in electronics, including:

- Automotive

- Telecom

- IT

To improve thermal management solutions, engineers must grasp the intricacies of air movement dynamics and the thermal load of their systems. Strategically positioning high power fans can create efficient circulation patterns, ensuring that hot air is expelled while cool air is drawn in. This proactive methodology not only mitigates overheating but also prolongs the lifespan of electronic components. For instance, Charles Rush, a laboratory director, underscored the importance of critically analyzing test outcomes, which aligns with the necessity for engineers to maintain a questioning attitude when assessing air movement dynamics.

Recent advancements in high power fan technology, including Gagner-Toomey’s cutting-edge temperature management solutions such as:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated thermal systems

have yielded enhanced efficiency and quieter operation, making high power fans even more suitable for sensitive electronic environments. Most models also provide IP protection upon request. Expert opinions highlight that effective ventilation management is crucial for the reliability of electronic devices. As engineers continue to innovate, the role of high power fans in electronics cooling remains a cornerstone of successful design and implementation.

Identify Different Types of High Power Fans

High power fans are essential components in a variety of electronic applications, each specifically designed to meet certain airflow and pressure requirements. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, provides an extensive product line optimized for performance, efficiency, and low noise. Most models can be equipped with IP protection upon request.

Axial Units: These devices operate by moving air along their axis, making them ideal for scenarios that demand high air movement at low pressure. Gagner-Toomey’s DC input Tube Axial devices, available in sizes from 15 to 280mm, are particularly effective in cooling expansive areas, rendering them a preferred choice in numerous electronic systems.

Centrifugal Devices: Engineered to draw air into the center and expel it at a right angle, Gagner-Toomey’s centrifugal blowers, ranging from 15 to 225mm, excel in high-pressure applications. They generate increased pressure at the expense of flow rate, ensuring reliable operation in demanding environments where flow resistance is a concern.

Mixed-Flow Devices: These systems merge the characteristics of both axial and centrifugal designs, offering versatility for various pressure conditions. Their adaptability makes them suitable for a broad spectrum of applications, including those within the electronics and automotive industries.

When selecting the appropriate fan type, it is imperative to consider factors such as the required airflow, pressure, and the specific operational environment. A comprehensive understanding of a system’s thermal dynamics is vital for implementing efficient cooling solutions. Recent reports have highlighted the critical role of high power fans and blowers in maintaining optimal airflow and temperature regulation within the manufacturing sector. Ultimately, the choice among axial, centrifugal, and mixed-flow high power fans should be guided by expert insights and performance assessments, ensuring that the selected device aligns with the specific cooling requirements of the application. As mechanical engineering expert Jeff Smoot emphasizes, grasping the intricacies of fan technology is essential for optimizing performance in electronic systems.

Install High Power Fans Correctly for Maximum Efficiency

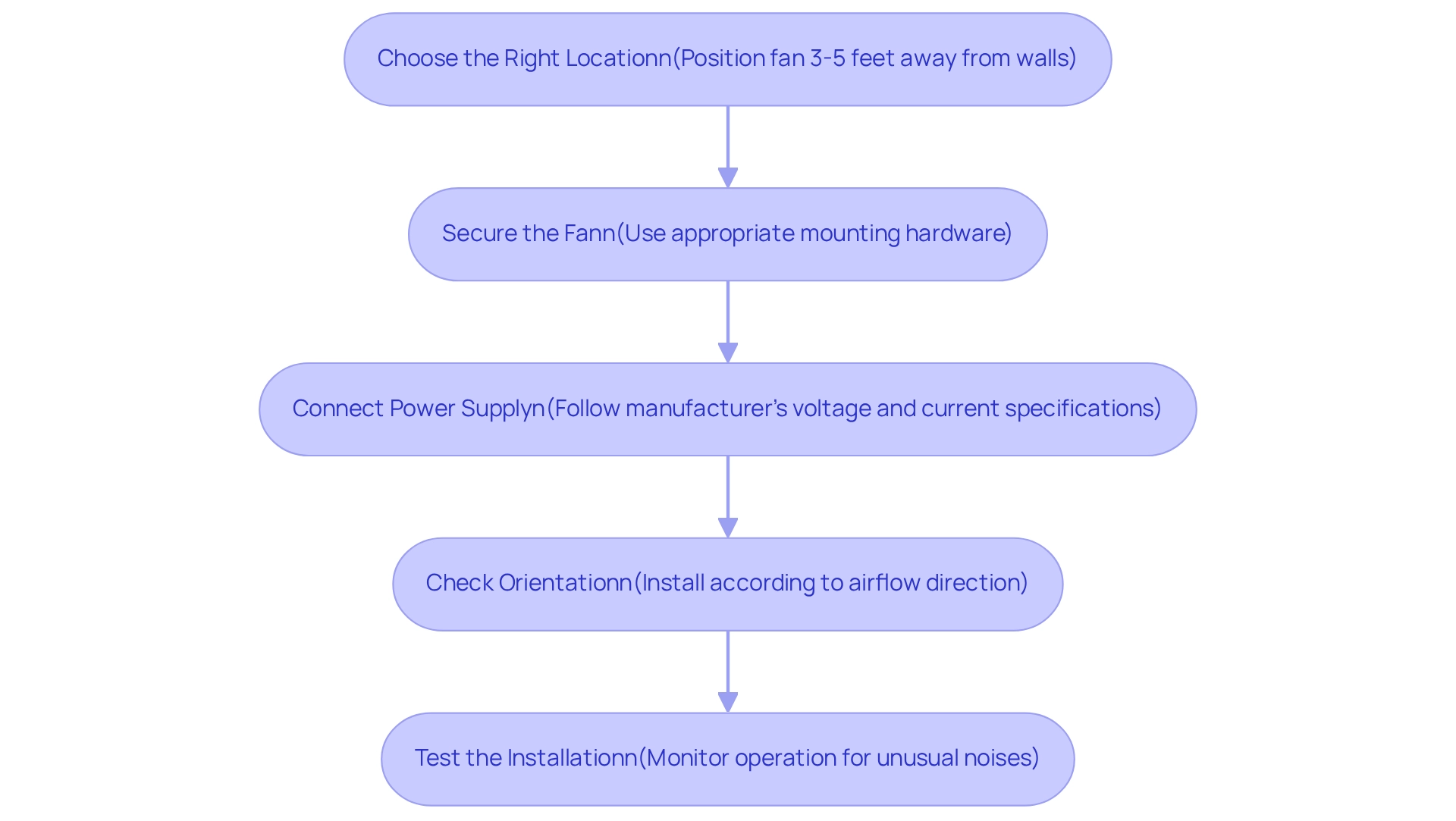

To ensure optimal performance of high-power fans, it is essential to adhere to the following installation steps:

- Choose the Right Location: Position the fan at least 3-5 feet away from walls or other structures to enhance circulation. This distance prevents obstructions that can hinder air circulation and performance.

- Secure the Fan: Utilize appropriate mounting hardware to firmly secure the fan, ensuring it remains stable and free from vibrations that could affect performance.

- Connect Power Supply: Connect the fan to a suitable power source, strictly following the manufacturer’s specifications for voltage and current to avoid operational issues.

- Check Orientation: Install the fan according to the airflow direction indicated on the casing. Typically, the intake side should face the cooler air source to improve cooling performance.

- Test the Installation: After installation, power on the fan and monitor its operation. Listen for any unusual noises or vibrations, which may indicate installation errors.

By adhering to these guidelines, engineers can prevent typical installation errors that adversely affect the performance of a high power fan. For instance, improper fan placement can lead to increased energy consumption, underscoring the importance of adhering to best practices. Furthermore, selecting devices based on the lowest operating power and ensuring they meet performance standards can significantly contribute to energy savings in commercial applications. Regular maintenance, such as tightening loose fasteners, is also crucial for maintaining optimal performance over time.

As noted by Michael Wolf, PE, “The term sheet was submitted to the DOE in September 2015,” highlighting the importance of regulatory compliance in fan installation. Additionally, the case study named ‘Role of Engineers and Contractors in Fan Selection’ emphasizes that engineers and contractors ought to select fans according to operating power and confirm they satisfy performance standards to enhance energy conservation. Statistics show that improper installation of a high power fan can lead to substantial performance losses, making it essential to follow the outlined steps. Frequent errors involve overlooking correct fan positioning and not fastening the fan properly; steering clear of these traps is crucial for attaining optimal performance.

Control Fan Speed and Airflow for Optimal Cooling Performance

To achieve optimal cooling performance, it is essential to consider various methods for controlling fan speed and airflow:

- PWM Control: Pulse Width Modulation (PWM) represents a cutting-edge technology that facilitates precise fan speed adjustments based on real-time temperature readings from sensors. This approach enhances temperature regulation while simultaneously reducing energy usage and noise levels, making it particularly suitable for systems utilizing a high power fan. Notably, energy consumption varies significantly with traffic allocation strategies and virtual CPU affinity conditions in virtual machines, underscoring the efficiency of PWM control.

- Voltage Control: Adjusting the voltage supplied to the fan can regulate its speed; however, this method is generally less efficient compared to PWM. It may result in increased energy usage and noise, especially in high-demand environments.

- Thermal Sensors: By integrating thermal sensors into your system, you enable automatic adjustments of fan speed in response to the temperature of critical components. This proactive strategy ensures that temperature regulation is optimized without manual intervention, thereby enhancing system reliability.

- Manual Control: For systems that lack automated controls, a manual fan controller can be employed. This allows for real-time modifications based on recorded temperatures, providing adaptability in temperature management.

Implementing these control strategies can significantly enhance the cooling efficiency of a high power fan and prolong the lifespan of electronic components. PWM devices have demonstrated their effectiveness in high-performance computing environments, such as gaming PCs and workstations, where a high power fan is essential for maintaining optimal temperatures to prevent thermal throttling and ensure system reliability during demanding tasks. As noted by Annie Chan, Account Manager of CCHV and EAGLE fan, “In the past 17 years, we have helped 32 countries and 400+ Clients like home appliances, car headlamps, power supplies, commercial lighting, etc.” This statement underscores the widespread application and benefits of PWM technology. Furthermore, the case study titled “Benefits of PWM Control in High-Performance Systems” illustrates how PWM devices assist in maintaining optimal temperatures, reinforcing the claims made regarding their effectiveness. As the industry continues to evolve, adopting advanced fan speed control methods will be essential for achieving optimal cooling performance in 2025 and beyond, particularly in light of emerging trends in fan speed control technologies.

Maintain High Power Fans for Long-Term Reliability

To ensure the long-term reliability of high power fans, it is essential to implement a comprehensive maintenance strategy that encompasses several key practices:

- Regular Cleaning: Accumulated dust and debris on fan blades and housing can significantly reduce efficiency. It is recommended to clean ventilators consistently with a gentle brush or compressed air to ensure optimal circulation.

- Inspect Components: Conduct periodic inspections for wear and tear on critical components such as bearings, belts, and electrical connections. Promptly replacing any worn parts can prevent larger issues and extend the fan’s lifespan.

- Lubricate Moving Parts: Proper lubrication of bearings is crucial to minimize friction and wear. Regularly check and apply lubricant to ensure smooth operation and reduce the risk of mechanical failure.

- Monitor Performance: Keep track of performance metrics, including noise levels and airflow rates. Significant changes in these metrics may indicate underlying maintenance needs that should be addressed immediately.

- Schedule Routine Inspections: Create a proactive maintenance timetable for regular checks and servicing of ventilation systems. This method not only improves efficiency but also reduces safety hazards linked to inadequately maintained units, such as accidents or electrical fires caused by loose blades or defective wiring. A case study titled “Enhances Safety” highlights that inadequately maintained ventilation systems can pose safety risks, including accidents or electrical fires due to loose blades, faulty wiring, or worn-out motors. Routine upkeep guarantees that ventilation devices are secure for operation, safeguarding households and loved ones from possible dangers.

Regular upkeep is not merely a best practice; it is essential for ensuring the safety and efficiency of high power fans. Statistics indicate that properly maintained units can function significantly longer and more efficiently, ultimately leading to reduced downtime and operational expenses. As maintenance experts highlight, “By adhering to these five crucial upkeep suggestions, you can minimize downtime, prolong the lifespan of your industrial equipment, and guarantee they keep delivering dependable circulation and ventilation for your facility.” By following these maintenance tips, engineers can ensure their high power fans consistently provide reliable airflow and cooling solutions for years to come.

Conclusion

High power fans are integral to the effective cooling of electronic devices, ensuring optimal performance and reliability in an increasingly power-hungry technological landscape. By understanding the various types of fans—axial, centrifugal, and mixed-flow—and their specific applications, engineers can make informed decisions that align with the cooling requirements of their systems. When the installation process is executed correctly, it maximizes efficiency and prevents common pitfalls that could lead to operational issues.

Control methods such as Pulse Width Modulation (PWM) and the integration of thermal sensors significantly enhance cooling performance by allowing dynamic adjustments based on real-time conditions. This proactive approach not only improves energy efficiency but also extends the lifespan of critical electronic components. Regular maintenance practices, including cleaning, inspection, and lubrication, are imperative for sustaining the long-term reliability of high power fans, ultimately reducing downtime and operational costs.

In conclusion, the strategic application of high power fans, grounded in a comprehensive understanding of their functionality, installation, control, and maintenance, is essential for optimizing cooling solutions in electronic systems. By prioritizing these factors, engineers can significantly enhance the performance and reliability of their designs, ensuring they meet the demands of modern technology both now and in the future.

Frequently Asked Questions

Why are powerful ventilators important for electronic devices?

Powerful ventilators are essential for regulating temperatures in electronic devices as they facilitate air circulation and effectively dissipate heat generated by high-density components, which is vital for enhancing performance and reliability.

What types of applications benefit from high power fans?

High power fans are utilized in various applications including automotive, telecom, and IT sectors.

How can engineers improve thermal management solutions?

Engineers can enhance thermal management by understanding air movement dynamics and strategically positioning high power fans to create efficient circulation patterns, ensuring hot air is expelled and cool air is drawn in.

What recent advancements have been made in high power fan technology?

Recent advancements include extruded aluminum heatsinks, copper-based heat sinks, and integrated thermal systems that improve efficiency and reduce noise, making fans more suitable for sensitive electronic environments.

What are the different types of high power fans available?

The main types of high power fans are: – Axial Units: Move air along their axis and are ideal for high air movement at low pressure. – Centrifugal Devices: Draw air into the center and expel it at a right angle, excelling in high-pressure applications. – Mixed-Flow Devices: Combine features of both axial and centrifugal designs, offering versatility for various pressure conditions.

What factors should be considered when selecting a fan type?

When choosing a fan type, it is crucial to consider the required airflow, pressure, and the specific operational environment, along with a comprehensive understanding of the system’s thermal dynamics.

What role do high power fans play in the manufacturing sector?

High power fans and blowers are critical for maintaining optimal airflow and temperature regulation, which is essential for the reliability of electronic devices in manufacturing environments.