Overview

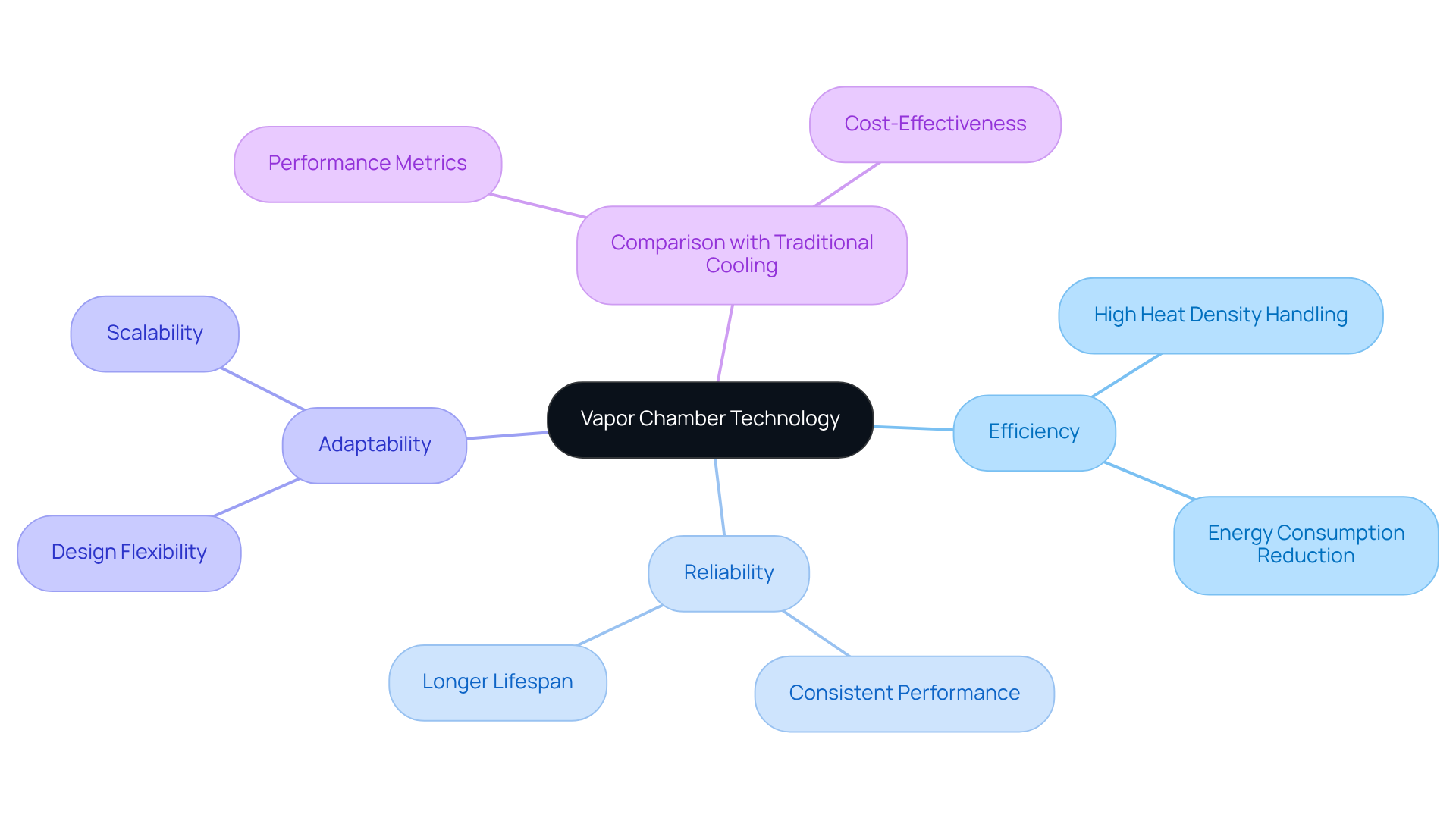

Engineers can reap significant benefits from vapour chamber technology, including:

- Efficient thermal management

- Design flexibility

- Enhanced reliability for electronic devices

Vapour chambers distinctly outperform traditional cooling methods by:

- Delivering superior heat distribution

- Effectively adapting to specific design requirements

- Extending the lifespan of components

This technology addresses the evolving demands of high-performance electronics, urging engineers to consider its advantages for their designs.

Introduction

Vapor chamber technology is revolutionizing thermal management in electronics, effectively addressing the urgent demand for efficient cooling solutions in an age of increasingly powerful devices. Engineers are now presented with a significant opportunity to explore the extensive benefits of this innovative technology, which promises to enhance performance, reliability, and design flexibility.

However, as they investigate the advantages of vapor chambers, critical questions emerge:

- What challenges must be navigated to fully harness their potential?

- How do these systems compare to traditional cooling methods?

Gagner-Toomey Associates: Leading Provider of Innovative Cooling Solutions

Gagner-Toomey Associates stands out as a premier provider of in the electronics industry. Recognized for its advanced technologies, the company specializes in helping engineers tackle complex . Their expertise in vapor technology, especially in the development of s, underscores a commitment to delivering that enhance the reliability and efficiency of electronic devices.

By representing a diverse portfolio of manufacturers, Gagner-Toomey ensures engineers have access to an extensive range of cutting-edge tailored to their specific needs. Furthermore, Gagner-Toomey Associates emphasizes a consultative approach, valuing the time and requirements of its customers. This dedication reinforces their commitment to responsive, within the electronics sector.

Understanding Vapor Chamber Technology: Principles of Operation

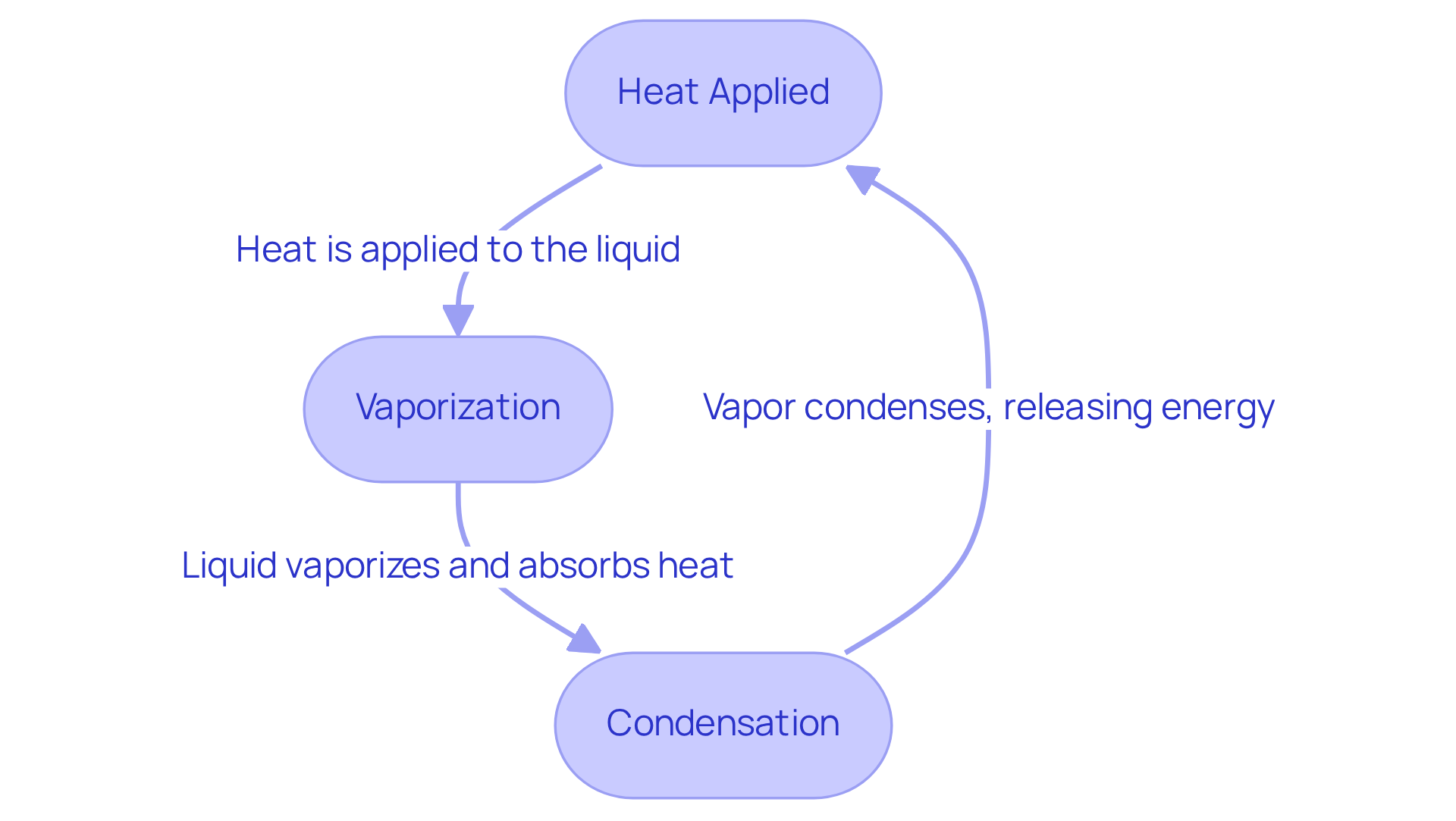

Vapor technology operates on the principles of , presenting a compelling solution for efficient . A steam enclosure consists of a sealed vessel filled with a working liquid, typically water. When heat is applied to one side of the enclosure, the liquid undergoes , absorbing energy in the process. Subsequently, the vapor migrates to the cooler side of the enclosure, where it condenses back into liquid, releasing the stored energy. This continuous cycle facilitates effective within the enclosure, making it adept at managing substantial temperature loads in confined spaces.

Vapor Chambers vs. Traditional Cooling Methods: Key Advantages

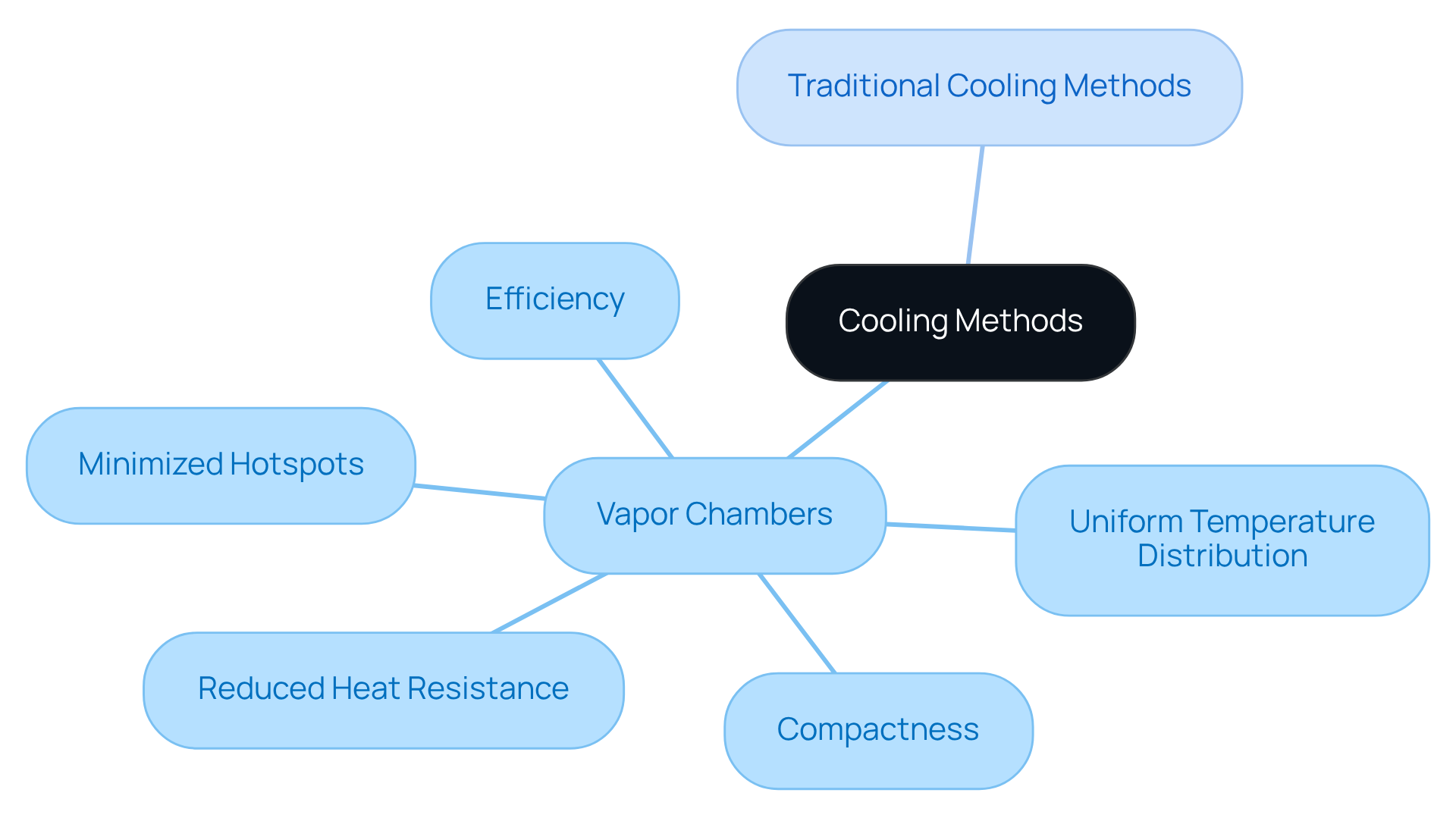

, such as , offer significant advantages over like sinks and pipes. Unlike thermal sinks that rely on air convection, phase change devices utilize state transitions to transfer energy with greater efficiency. This results in a more uniform and reduced heat resistance. Additionally, a is capable of managing while being more compact, making it particularly suitable for applications with limited space. Their ability to distribute heat across a larger surface area minimizes hotspots, thereby enhancing overall performance in .

Enhancing Thermal Performance: Benefits of Vapor Chamber Cooling

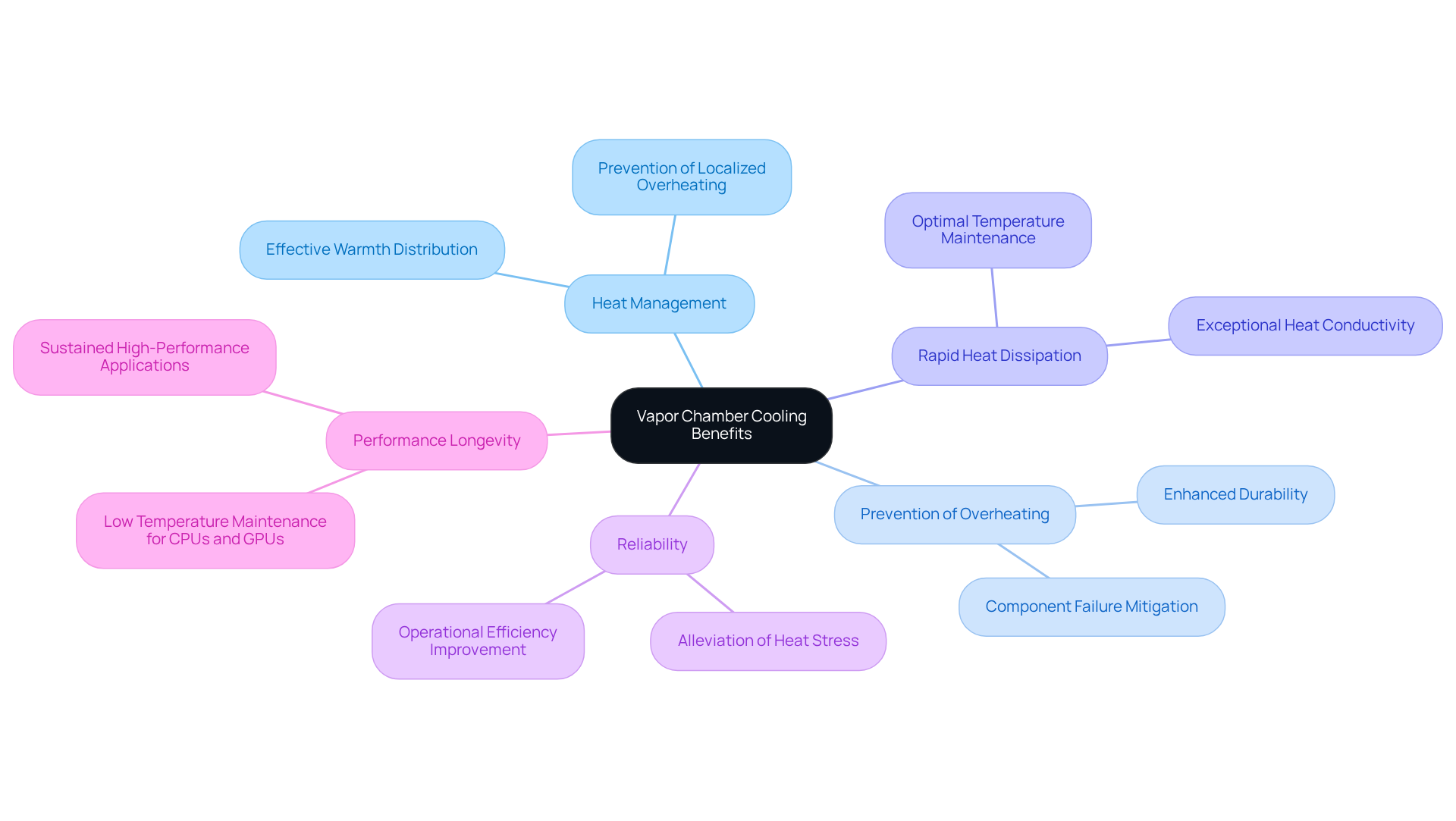

The cooling system significantly enhances in . By effectively distributing warmth, these systems prevent localized overheating, a condition that can lead to . Their exceptional facilitates rapid heat dissipation via the vapour chamber, ensuring that devices function within optimal temperature ranges. This capability is especially advantageous in such as CPUs and GPUs, where a vapour chamber is essential for maintaining low temperatures crucial for both performance and longevity. Furthermore, gas-filled units can bolster the overall reliability of electronic systems by alleviating heat stress on components, thereby enhancing their durability and operational efficiency.

Design Flexibility: Customizing Vapor Chamber Solutions for Electronics

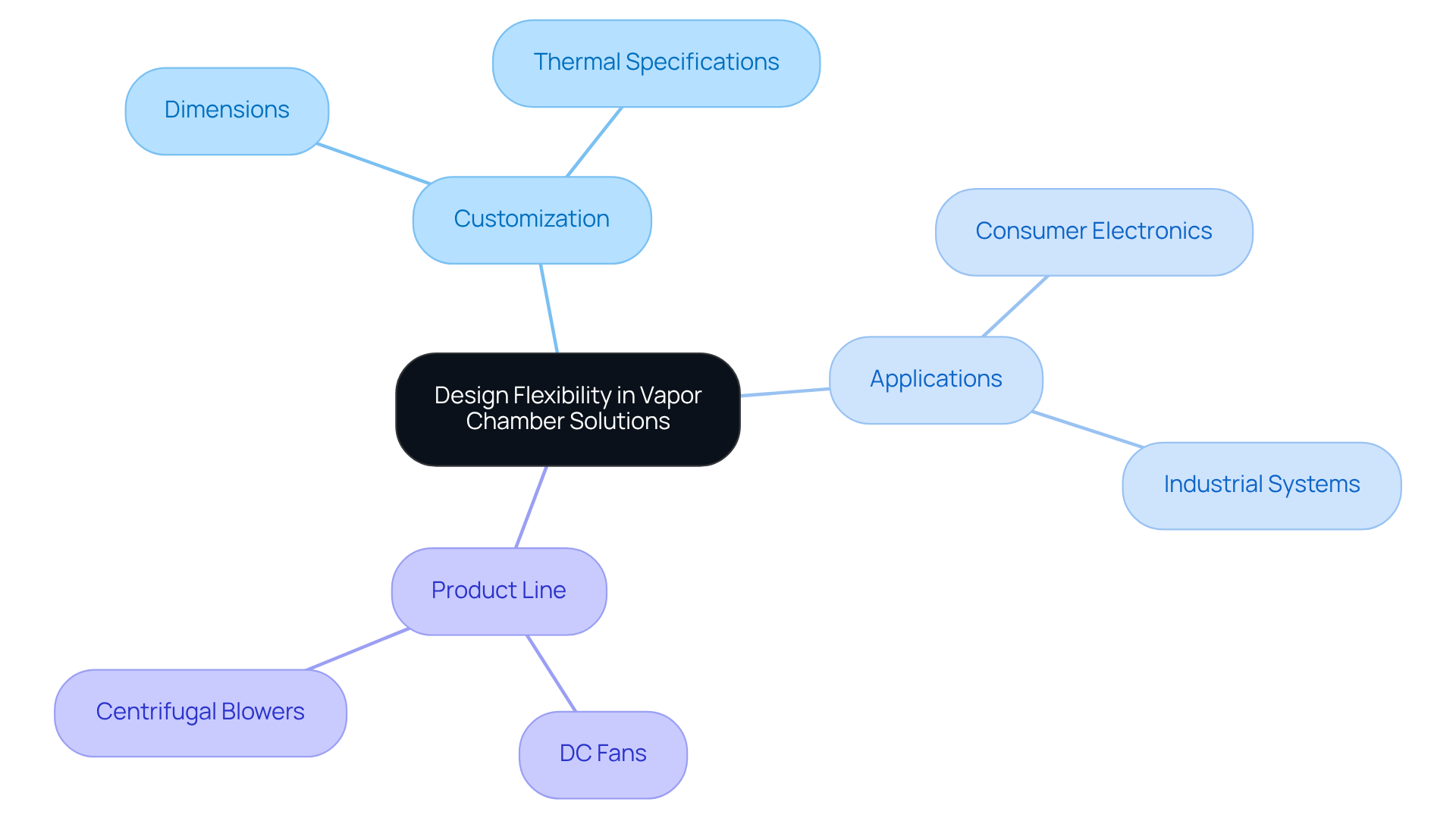

One of the most significant features of is its design adaptability. Gagner-Toomey Associates, the world’s largest supplier of for electronics cooling, empowers engineers to customize to meet specific dimensions and . This adaptability renders them suitable for a diverse array of applications, ranging from compact consumer electronics to larger industrial systems.

Vapor devices can be engineered to incorporate a vapour chamber, while maintaining a sleek profile, thereby improving temperature regulation without compromising space or efficiency. Furthermore, Gagner-Toomey Associates provides an extensive product line, including:

- Centrifugal blowers

This ensures comprehensive cooling solutions tailored to various requirements.

Longer Product Lifetimes: Reliability of Vapor Chamber Technology

Vapor compartment technology stands out for its and longevity. By effectively controlling heat, play a crucial role in , significantly extending the lifespan of . The absence of moving parts in vapour chamber systems minimizes the risk of , making them a reliable choice for . Furthermore, their ability to maintain consistent temperature performance over time ensures that devices remain operational even under challenging conditions, thereby enhancing their reliability.

High Efficiency: Vapor Chambers for High Heat Density Applications

Vapor devices excel in , where often struggle, particularly when utilizing a . Their innovative design facilitates rapid temperature transfer across a broad surface area, making them ideal for addressing the , GPUs, and densely packed electronic components.

By efficiently dispersing heat, fluid containers play a crucial role in , preventing overheating, and ensuring reliable performance. This efficiency is particularly critical in scenarios where space is limited and thermal output is substantial, such as in mobile devices and .

Types of Vapor Chambers: Choosing the Right Solution for Your Needs

Gagner-Toomey Associates offers a diverse range of thermal enclosures, each meticulously designed to meet specific temperature regulation needs. Flat thermal devices are particularly suited for compact applications, whereas 3D thermal structures enhance temperature distribution capabilities. Additionally, ultra-slim heat exchangers are ideal for scenarios where space constraints are critical.

When selecting a , engineers must consider factors such as:

- Heat load

- Available space

- Integration requirements

to guarantee optimal performance. With Gagner-Toomey Associates’ comprehensive portfolio of innovative cooling solutions—including integrated custom cooling systems and various —engineers can identify the perfect heat transfer device tailored to their unique specifications.

Challenges of Vapor Chamber Technology: Considerations for Implementation

While offers numerous advantages, it also presents certain challenges that must be addressed during implementation. A primary concern is the complexity of manufacturing, which can result in elevated costs compared to . Furthermore, gas-filled enclosures necessitate precise design and integration for , demanding extensive planning and . Engineers must also take into account the employed, as these significantly impact overall temperature performance. Understanding these challenges is crucial for effective implementation and for maximizing the benefits of this technology.

Transforming Electronics Cooling: The Impact of Vapor Chamber Technology

Vapor containment technology is revolutionizing by offering efficient, reliable, and adaptable . As electronic devices evolve and demand greater efficiency, emerge as a compelling alternative to traditional cooling techniques. Their capability to handle high heat densities, combined with design flexibility and enhanced reliability, positions them as essential components in the advancement of . By integrating , engineers can effectively address the of both today and tomorrow.

Conclusion

Vapor chamber technology signifies a remarkable advancement in thermal management for engineers, seamlessly combining efficiency, reliability, and adaptability to satisfy the escalating demands of modern electronics. By harnessing the principles of phase change thermal transfer, vapor chambers present a superior alternative to conventional cooling methods, adeptly managing heat in compact and high-performance applications. This innovation not only boosts the operational efficiency of electronic devices but also prolongs their lifespan, rendering it an essential consideration for engineers in their designs.

The article underscores several key advantages of vapor chamber technology, including:

- Enhanced thermal performance

- Customizable design options

- Exceptional reliability

These benefits position vapor chambers as the optimal choice for high-density electronic applications, where effective heat management is crucial. Moreover, the capacity to tailor these solutions to specific requirements highlights the versatility and efficacy of vapor chambers across various engineering contexts.

As the electronics landscape continues to evolve, adopting vapor chamber technology is imperative for engineers aiming to expand the frontiers of performance and reliability. By integrating these advanced cooling solutions, engineers can not only tackle the thermal challenges of the present but also prepare for the demands of future innovations. The influence of vapor chamber technology on electronics cooling is profound—it is a transformative approach that paves the way for more efficient, durable, and high-performing electronic systems.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of innovative cooling solutions in the electronics industry, specializing in advanced technologies for heat management challenges.

What specific technology does Gagner-Toomey Associates focus on?

The company specializes in vapor technology, particularly in the development of vapor chambers, which are designed to enhance the reliability and efficiency of electronic devices.

How does Gagner-Toomey Associates support engineers?

Gagner-Toomey represents a diverse portfolio of manufacturers, providing engineers with access to a wide range of cutting-edge thermal management products tailored to their specific needs.

What type of approach does Gagner-Toomey Associates take with its customers?

Gagner-Toomey emphasizes a consultative approach, prioritizing the time and requirements of its customers to ensure responsive, customer-centric service.

What is vapor chamber technology?

Vapor chamber technology operates on the principles of phase change thermal transfer, using a sealed vessel filled with a working liquid, typically water, to efficiently manage thermal distribution.

How does vapor chamber technology work?

When heat is applied to one side of the vapor chamber, the liquid vaporizes, absorbing energy. The vapor then migrates to the cooler side, where it condenses back into liquid, releasing stored energy, creating a continuous cycle for effective thermal management.

What advantages do vapor chambers have over traditional cooling methods?

Vapor chambers offer significant advantages, including greater energy transfer efficiency, more uniform temperature distribution, reduced heat resistance, and the ability to manage higher thermal fluxes in a compact design.

Why are vapor chambers suitable for applications with limited space?

Their compact nature and ability to distribute heat across a larger surface area minimize hotspots, making them particularly effective for temperature management in confined spaces.