Overview

The article outlines essential strategies for selecting the appropriate electronics cooling fan, underscoring the significance of:

- Compatibility

- Airflow requirements

- Various fan types

to achieve optimal performance and efficiency. By detailing key considerations such as:

- Fan specifications

- Strategic placement

- Ongoing maintenance

the content reinforces the assertion that meticulous selection and management of cooling fans are vital for improving the reliability and longevity of electronic devices.

Introduction

Selecting the appropriate electronics cooling fan is pivotal for the performance and longevity of electronic devices. However, the vast array of options can be daunting. Engineers and designers must navigate various specifications, types, and placement to guarantee optimal airflow and temperature regulation. This article presents essential tips that simplify the selection process while enhancing energy efficiency and operational effectiveness. By empowering readers to make informed decisions in a rapidly evolving technological landscape, we address a critical question:

- How can one effectively balance performance needs with the latest advancements in cooling technology?

Gagner-Toomey Associates: Expert Guidance for Selecting Electronics Cooling Fans

Gagner-Toomey Associates excels in providing engineers with essential tools and insights for selecting the most effective electronics cooling fans. The company’s commitment to innovative temperature control technologies positions it as a leader in the field, offering expert advice that simplifies the complexities of fan selection. This approach ensures optimal performance and energy efficiency in electronic systems.

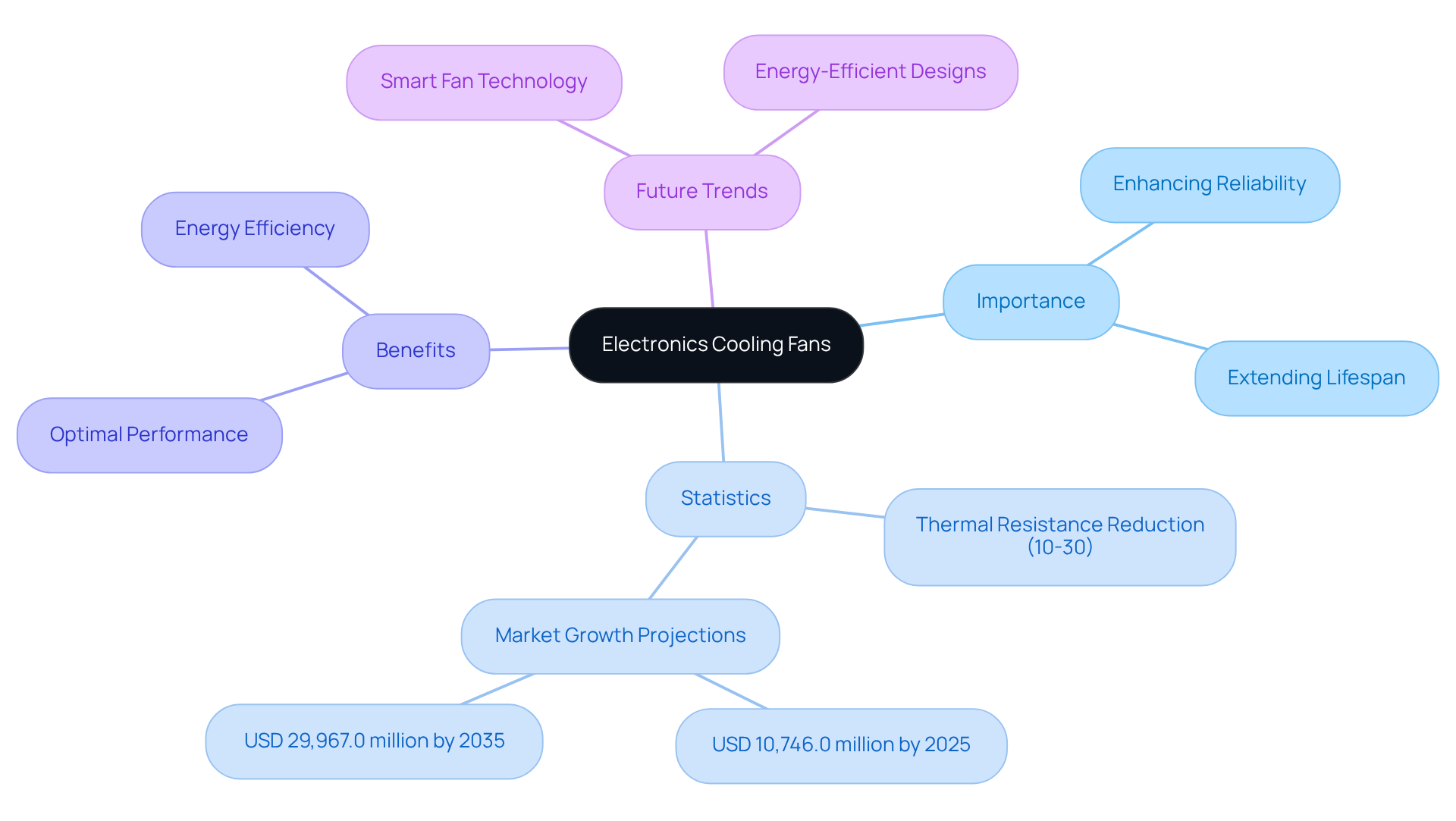

Industry leaders emphasize the critical importance of selecting the appropriate electronics cooling fan; the right choice can significantly enhance the reliability and lifespan of devices. Statistics indicate that well-chosen fans can reduce thermal resistance by 10-30%, highlighting their crucial role in thermal management. Successful implementations of advanced thermal solutions have demonstrated substantial improvements in operational efficiency, particularly in high-performance applications.

As the market evolves, trends such as the adoption of smart fan technology and energy-efficient designs are shaping the future of electronics temperature control solutions in 2025. Gagner-Toomey Associates remains at the forefront of these developments, empowering engineers to make informed choices that align with the latest advancements in temperature control technology.

Understand the Basics: What is an Electronics Cooling Fan?

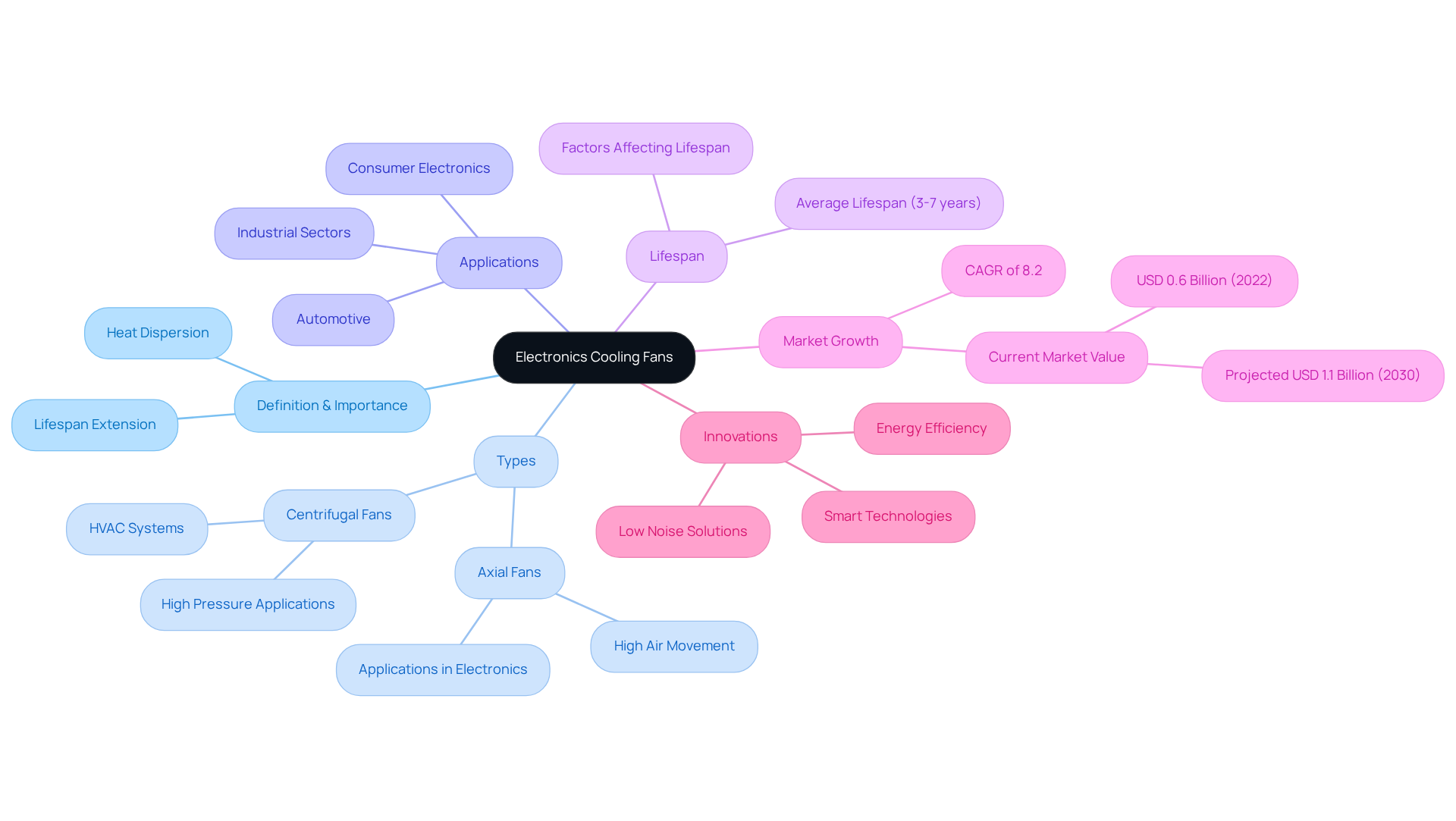

Electronics cooling fans are essential cooling devices for equipment designed to facilitate airflow over components, effectively dispersing heat and preventing overheating. By maintaining optimal operating temperatures, these units significantly extend the lifespan of electronic devices. Gagner-Toomey Associates emerges as the world’s largest manufacturer of both standard and custom air-movers, presenting an extensive product line of DC input tube axial units and centrifugal blowers optimized for performance, efficiency, and low noise. Their solutions serve a diverse range of applications, including electronics, automotive, and industrial sectors.

Two primary categories of cooling devices exist: axial and centrifugal. Axial blowers, which propel air parallel to the axis, are commonly employed in applications requiring high air movement rates, such as data centers and consumer electronics. Conversely, centrifugal blowers, which direct air at right angles to the intake, are typically utilized in scenarios demanding higher pressure, such as HVAC systems.

Engineers emphasize the critical importance of air movement in electronic devices, noting that an electronics cooling fan is essential for adequate temperature regulation to prevent performance degradation and potential malfunction. The average lifespan of electronic ventilation devices generally ranges from 3 to 7 years, contingent upon usage and environmental conditions. For example, axial blowers are frequently found in laptops and gaming consoles, while centrifugal models are favored in industrial settings where space limitations and high airflow requirements prevail.

As technology advances, the demand for effective temperature regulation solutions continues to rise, with innovations in the design and materials of electronics cooling fans enhancing both performance and energy efficiency. Gagner-Toomey Associates provides a comprehensive portfolio of DC input tube axial fans, available in sizes from 15 to 280mm, alongside centrifugal blowers ranging from 15 to 225mm, with IP protection offered in most models upon request. The North America DC Fans for Electronic Cooling Market, valued at USD 0.6 Billion in 2022, is projected to escalate to USD 1.1 Billion by 2030, reflecting a CAGR of 8.2%. This growth underscores the increasing necessity for effective thermal management solutions across various sectors, particularly in consumer electronics, where electronics cooling fans are essential to address challenges such as space constraints and cost pressures. Moreover, Gagner-Toomey Associates’ dedication to delivering innovative cooling solutions, including integrated custom designs and a robust portfolio of thermal management products, positions them as a pivotal player in addressing the trend toward energy-efficient and low-noise solutions, which are becoming increasingly vital in meeting consumer expectations.

Determine Airflow Needs: Assessing Cooling Requirements for Your Electronics

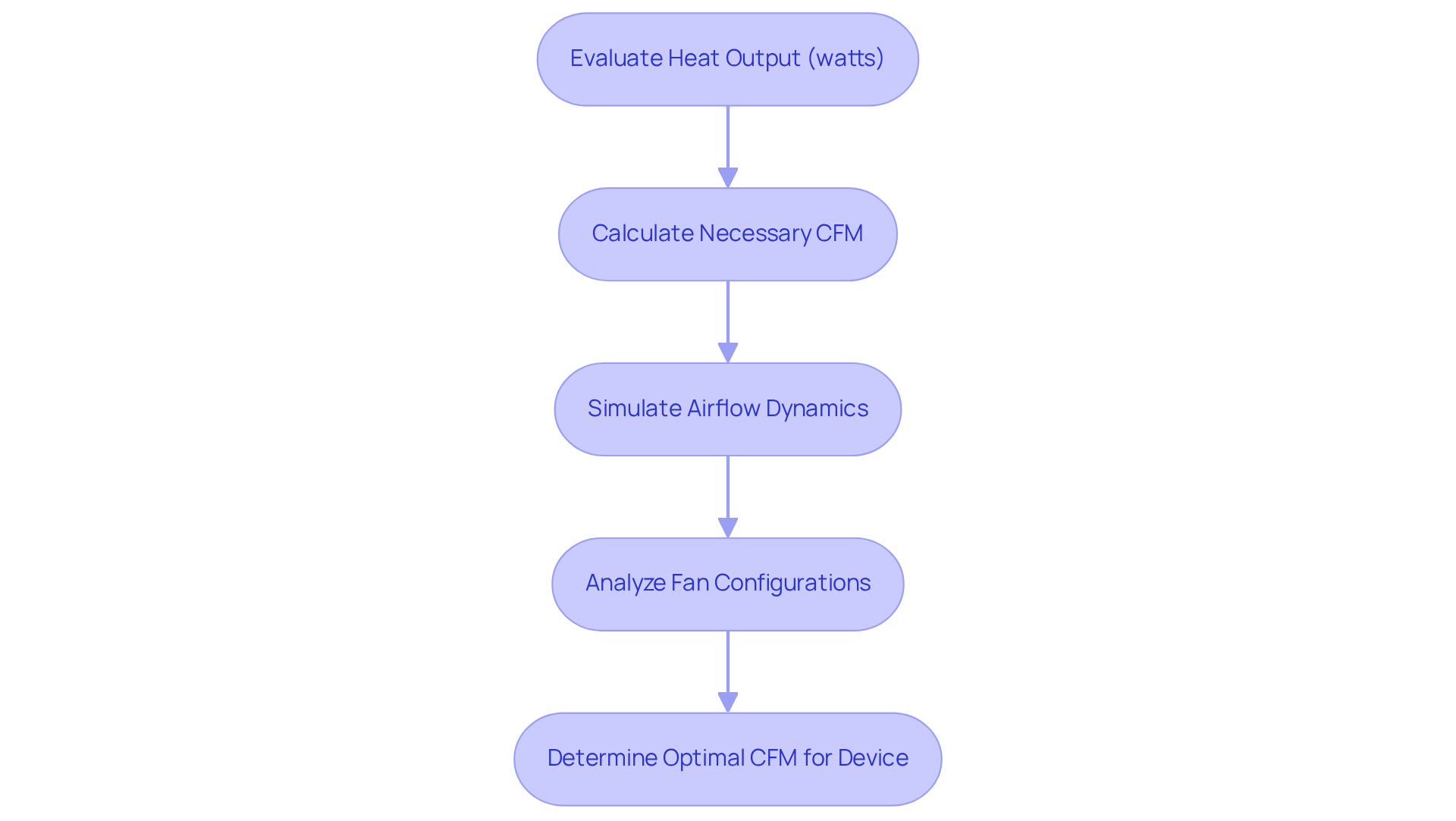

To accurately assess the ventilation needs for your electronics, begin by evaluating the heat output of the components, typically measured in watts. The necessary air movement is quantified in cubic feet per minute (CFM). A widely accepted guideline suggests that the fan’s ventilation capacity should exceed the heat output to ensure safe operating temperatures.

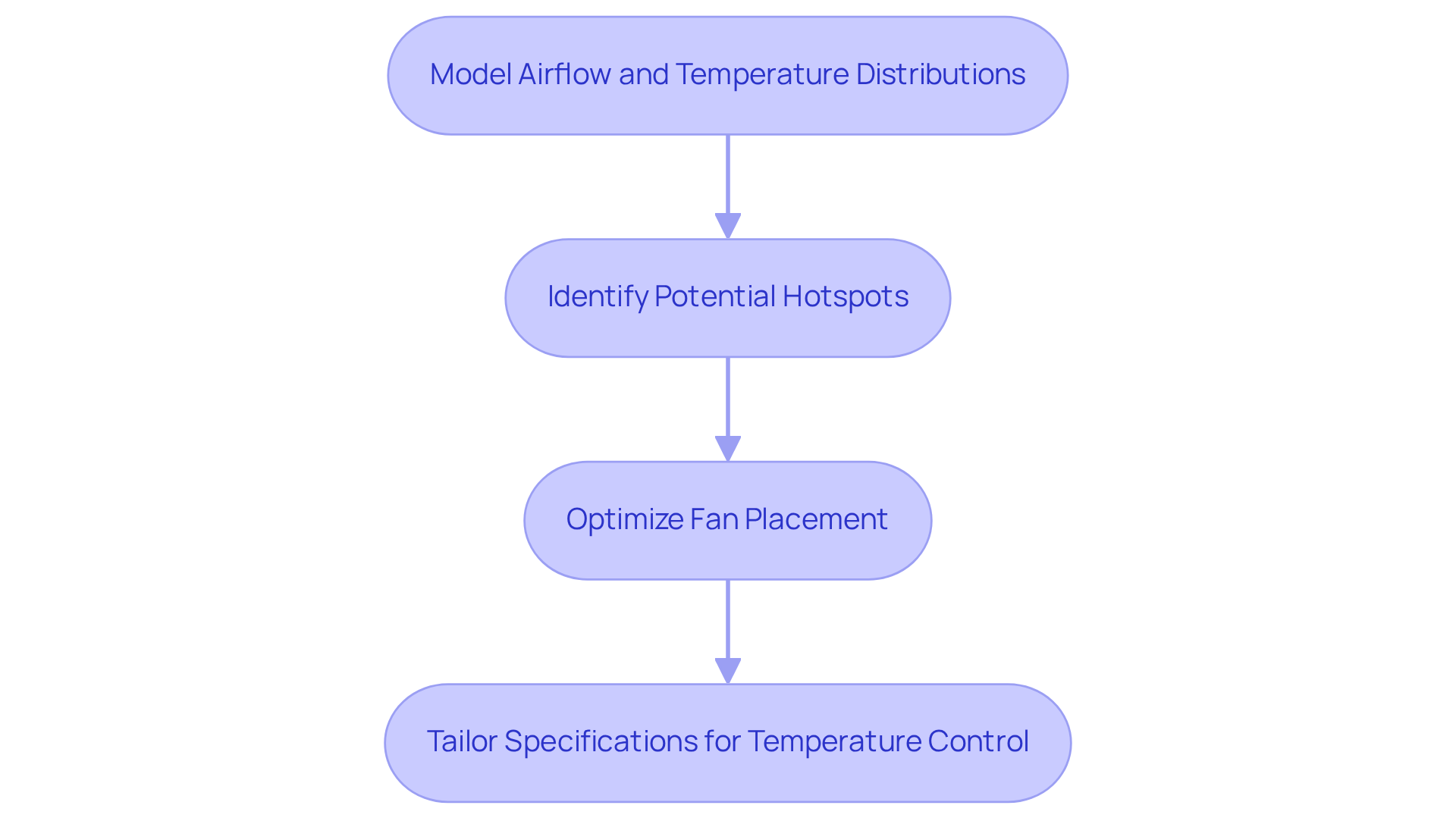

For instance, if a CPU consumes 3 watts, the appropriate CFM must be calculated to guarantee efficient temperature regulation. Thermal simulations can play a crucial role in this evaluation, facilitating precise modeling of airflow dynamics and temperature distributions within the system.

By employing tools that simulate various operating conditions, engineers can visualize the impact of different fan configurations on cooling efficiency. A simulation might reveal that a fan with a CFM rating of 50 is optimal for a specific device, ensuring effective heat dispersion.

Additionally, understanding the CFM specifications for different devices is vital; smaller chips may require less ventilation compared to high-performance CPUs, which generate more heat. This tailored approach to calculating airflow needs is essential for maintaining the reliability and performance of electronic systems.

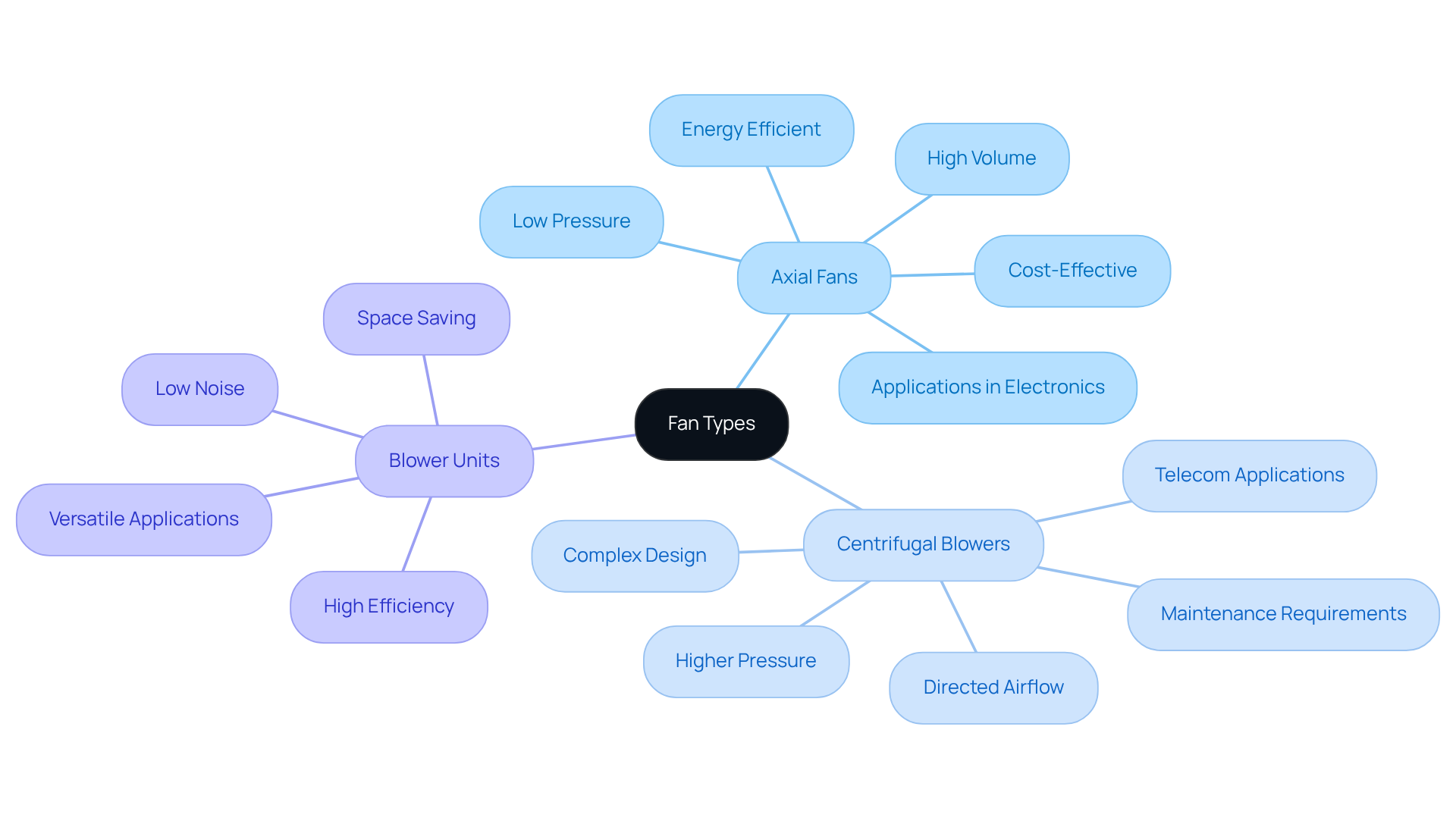

Explore Fan Types: Choosing Between Axial, Centrifugal, and Blower Fans

When selecting a fan, it is essential to consider the type that best suits your application. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive product range that includes:

- DC input Tube Axial units, spanning from 15 to 280mm

- Centrifugal Blowers, available in sizes from 15 to 225mm

All optimized for performance and efficiency.

- Axial blowers excel in delivering high volume movement at low pressure, making them ideal for general cooling applications where an electronics cooling fan is needed in the electronics and automotive sectors.

- Conversely, centrifugal blowers generate higher pressure, making them more suitable for scenarios requiring directed airflow, such as in telecom and industrial environments.

- Additionally, Gagner-Toomey Associates’ blower units are an excellent choice for specific setups where space is limited.

- Most models also provide low noise operation and IP protection upon request.

Each type presents distinct advantages; therefore, it is crucial to choose based on your system’s specific requirements.

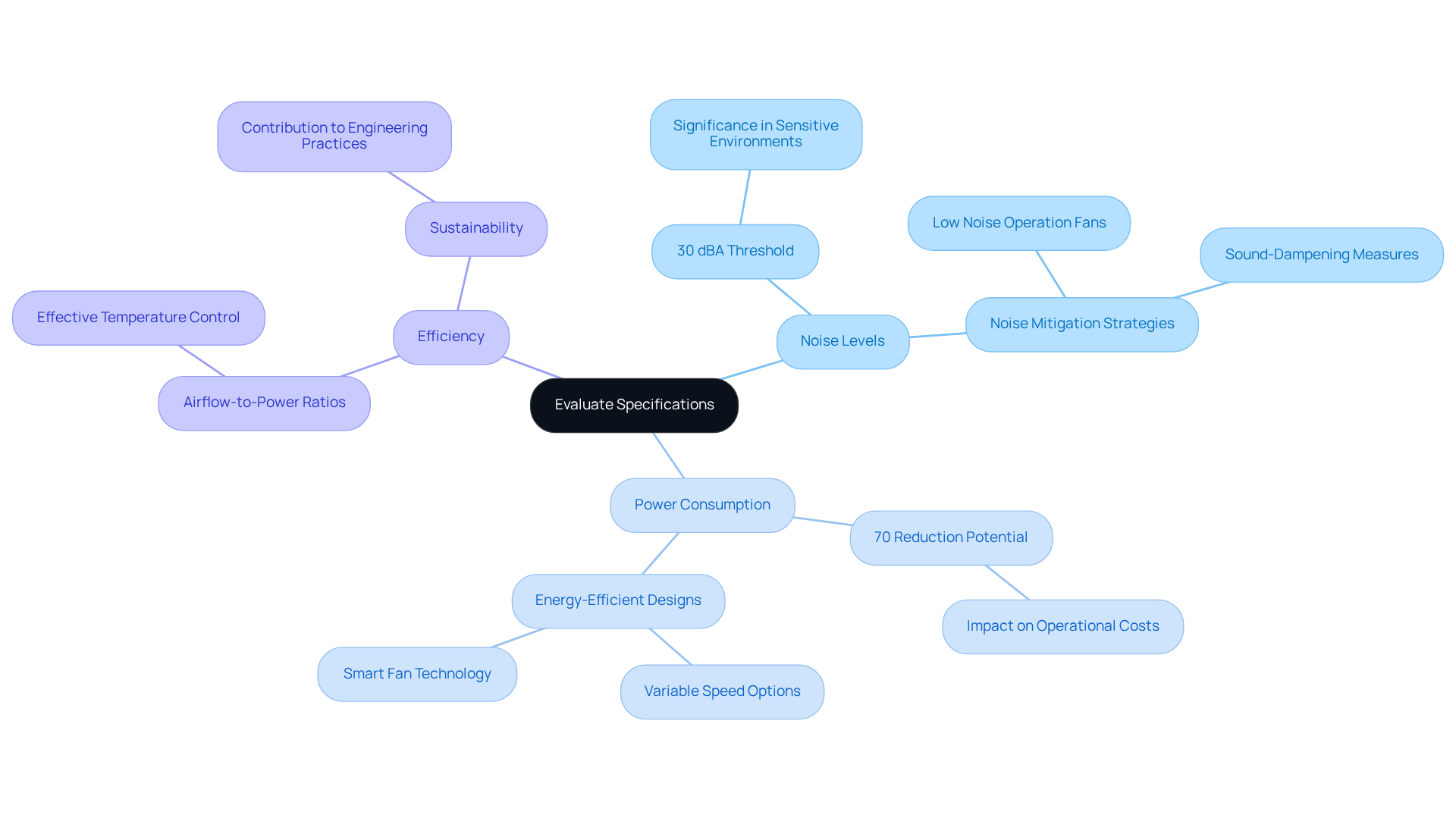

Evaluate Specifications: Noise Levels, Power Consumption, and Efficiency

When selecting electronics cooling fans, it is crucial to evaluate specifications such as noise levels, power consumption, and efficiency ratings. Noise levels are particularly significant in environments where sound sensitivity is critical, such as offices and residential areas. Engineers typically seek devices that operate below 30 dBA to minimize disruption. Furthermore, power consumption has a direct effect on operational costs; therefore, choosing models equipped with an electronics cooling fan can lead to substantial savings. For instance, energy-efficient devices can achieve up to a 70% reduction in power consumption compared to conventional air conditioning units. It is advisable to look for devices that include an electronics cooling fan providing high airflow-to-power ratios, as these ensure effective temperature control while decreasing energy usage. With the ventilation fan market anticipated to grow significantly, focusing on these specifications will not only enhance performance but also contribute to sustainability within engineering practices.

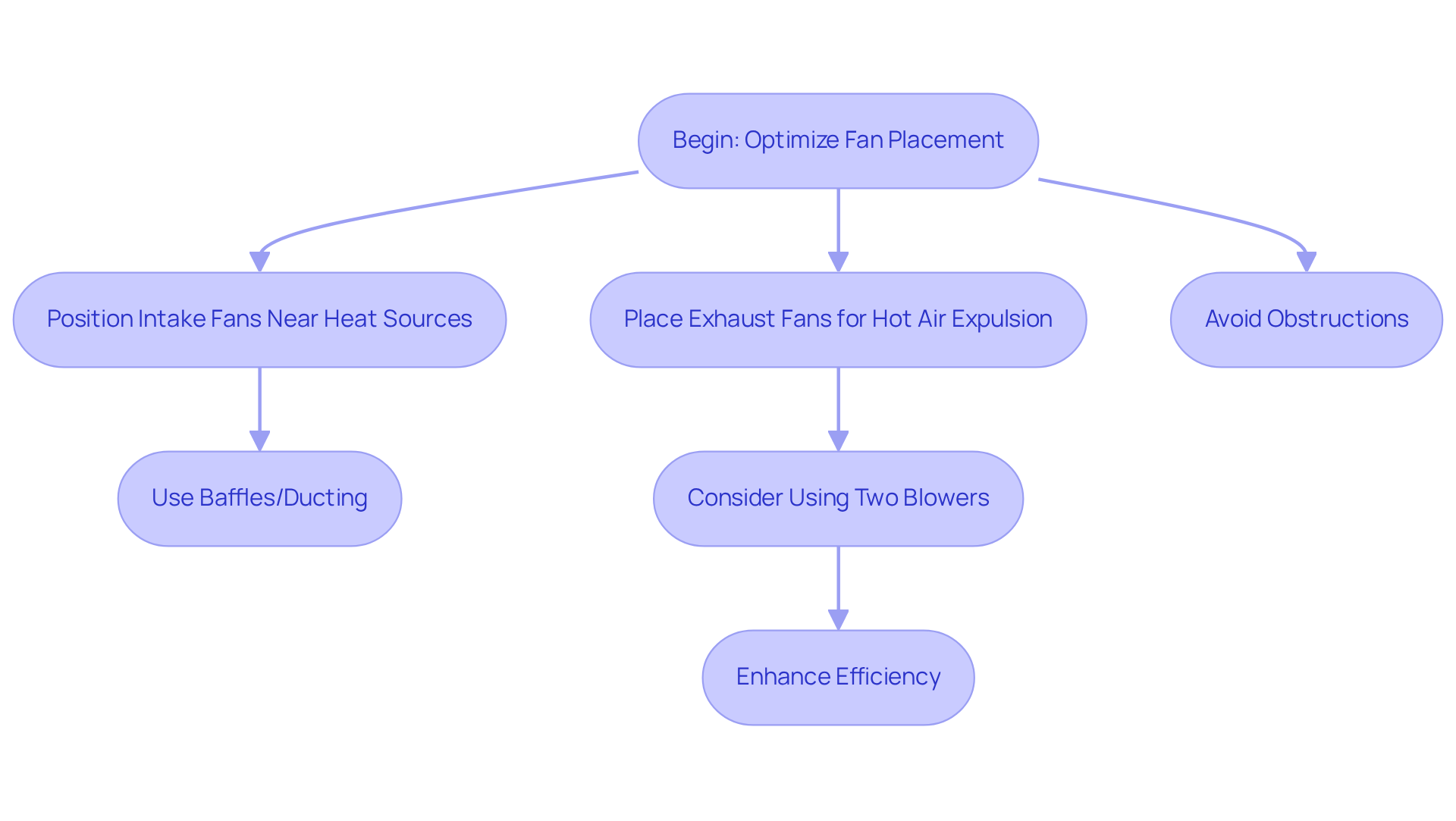

Optimize Placement: Strategic Fan Positioning for Maximum Cooling

To achieve optimal temperature regulation in electronic systems, it is imperative to strategically position ventilators to facilitate efficient air movement routes. Intake fans should be situated near heat-generating components to draw in cooler air, while exhaust fans must be positioned to effectively expel hot air. It is crucial to avoid any obstructions that could hinder air movement; even minor barriers can significantly diminish cooling effectiveness. The use of baffles or ducting can further enhance airflow direction within the enclosure, ensuring that cool air reaches critical components while hot air is effectively removed.

For instance, a recent case study demonstrated that a distribution center improved internal temperatures by strategically placing high-speed air circulators at regular intervals, thereby significantly reducing heat-related complaints. HVAC experts emphasize that proper fan placement not only enhances air quality but also reduces energy costs, making it a vital consideration in thermal management. Furthermore, employing two blowers instead of a single unit can create a more substantial chilling effect, enhancing overall efficiency. Al Fouz, an HVAC specialist, notes that for ceiling devices, adjusting the blades to spin counterclockwise in summer can generate a refreshing breeze. By adhering to these recommendations and utilizing ventilators for peak performance, engineers can significantly enhance thermal efficiency and maintain ideal operating conditions for devices.

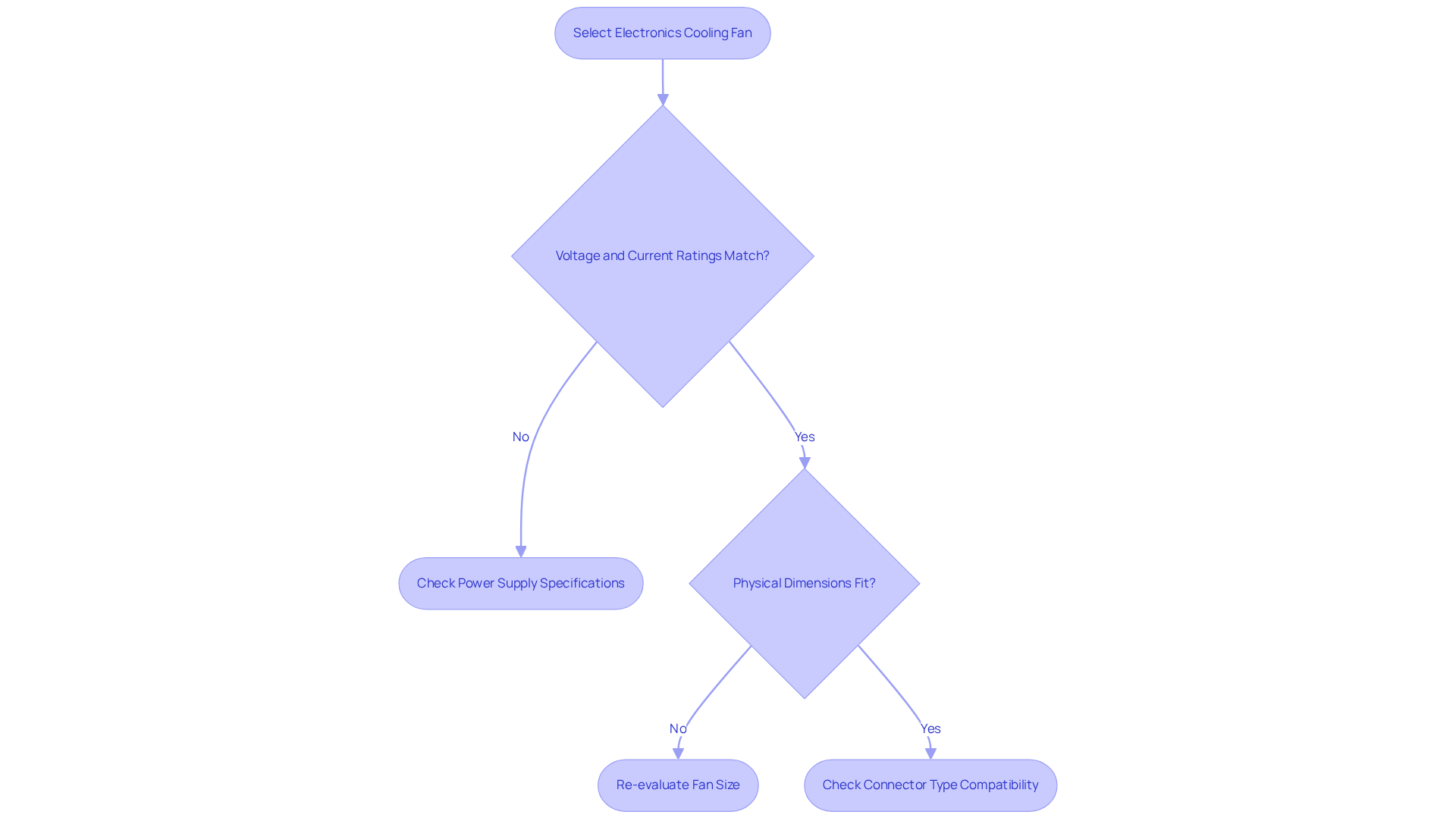

Ensure Compatibility: Matching Fans with Your Electronics Systems

Selecting the right electronics cooling fan for your devices requires thorough consideration of compatibility. Start by confirming that the fan’s voltage and current ratings correspond with your power supply specifications. A typical 12V DC fan operates at a nominal current rating of 0.2A, consuming approximately 2.4 watts. It is essential that your power supply exceeds these requirements to avoid underperformance or potential damage.

Equally critical are the physical dimensions; the fan must fit within the designated space of your device. Moreover, connector types should be compatible to ensure seamless installation and operation. Engineers emphasize that mismatched specifications can lead to inefficiencies, with over 70% of electronics engineers incorporating electronics cooling fans and PWM cooling devices in their designs to improve thermal management.

Successful integration cases highlight the necessity of aligning fan specifications with technological systems. For example, projects utilizing DC blowers have shown energy savings of up to 70% compared to traditional AC models, illustrating the advantages of selecting the appropriate equipment for specific applications. By prioritizing these factors, you can significantly improve the performance and longevity of your electronics cooling fan and enhance the overall effectiveness of your electronic devices.

Consider Maintenance: Ensuring Longevity and Reliability of Cooling Fans

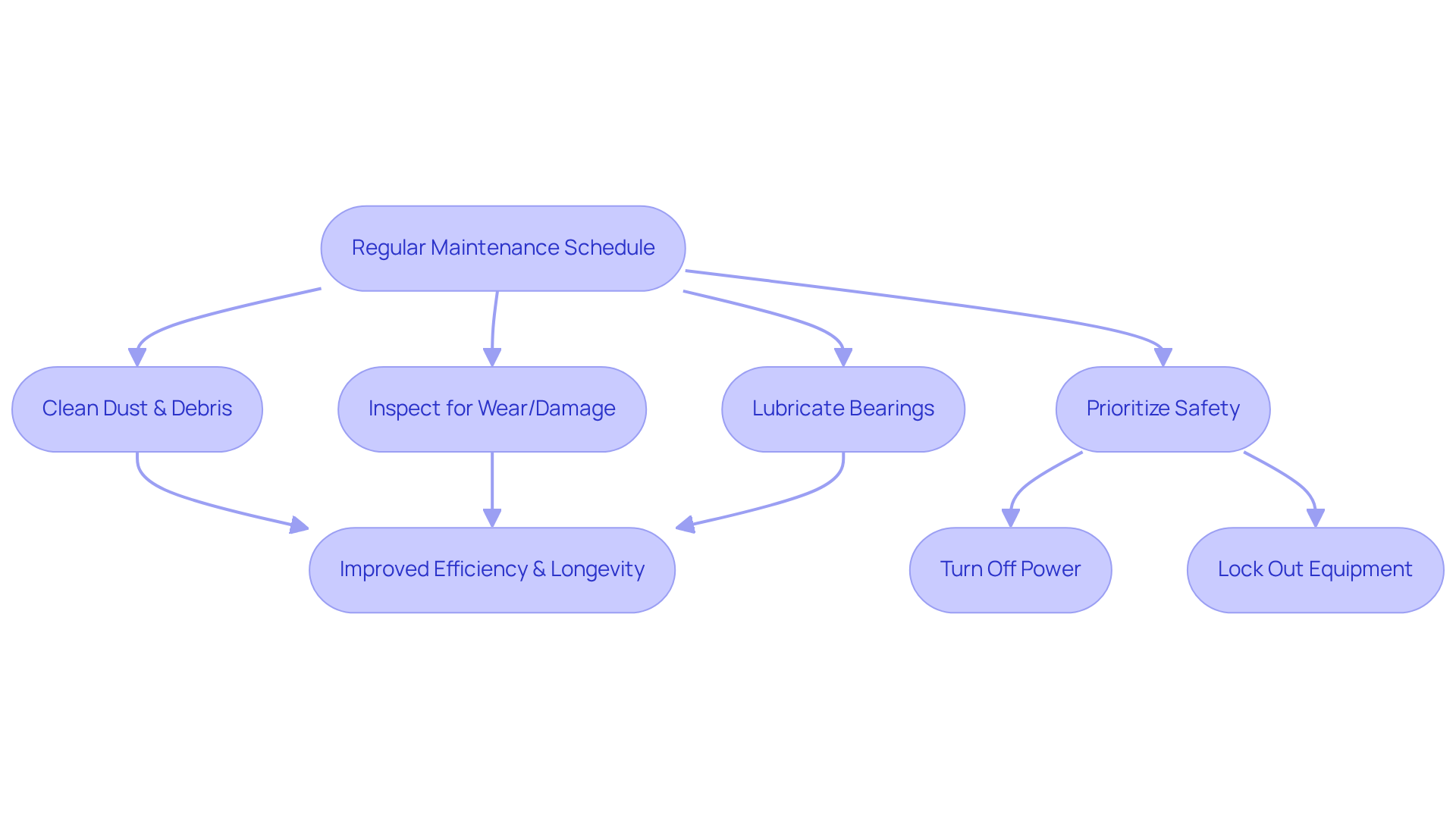

To enhance the longevity and reliability of the electronics cooling fan, implementing a regular maintenance schedule is essential. This routine should encompass:

- Cleaning dust and debris from the electronics cooling fan blades and housing

- Inspecting the electronics cooling fan for signs of wear or damage

- Lubricating bearings as needed

Prioritizing safety during maintenance is crucial; always turn off power sources and lock out equipment before conducting any maintenance tasks. Regular monitoring of the electronics cooling fan’s performance and noise levels can help detect potential issues early, preventing costly failures.

According to maintenance experts, properly cared-for appliances can last between 7 to 15 years, while disregarded units may only endure 3 to 5 years. Consistent upkeep can prolong the lifespan of industrial blowers by 30-50%. Adopting these best practices not only improves efficiency but also greatly prolongs the operational lifespan of ventilation units, decreasing the chances of unexpected outages by as much as 66%.

Additionally, keeping detailed records of all maintenance activities aids in planning future upkeep. By prioritizing maintenance, you ensure that your temperature control systems, such as the electronics cooling fan, operate at peak performance, ultimately leading to improved reliability and reduced operational costs.

Utilize Thermal Simulations: Predicting Fan Performance in Real-World Scenarios

Utilizing thermal simulations is pivotal in forecasting the operational performance of fans in real-world scenarios. By meticulously modeling airflow and temperature distributions, engineers can pinpoint potential hotspots and optimize fan placement and specifications accordingly. This proactive approach not only fosters enhanced design choices but also ensures that temperature control solutions are precisely tailored to meet specific thermal management requirements.

Stay Informed: Keeping Up with Innovations in Electronics Cooling Technologies

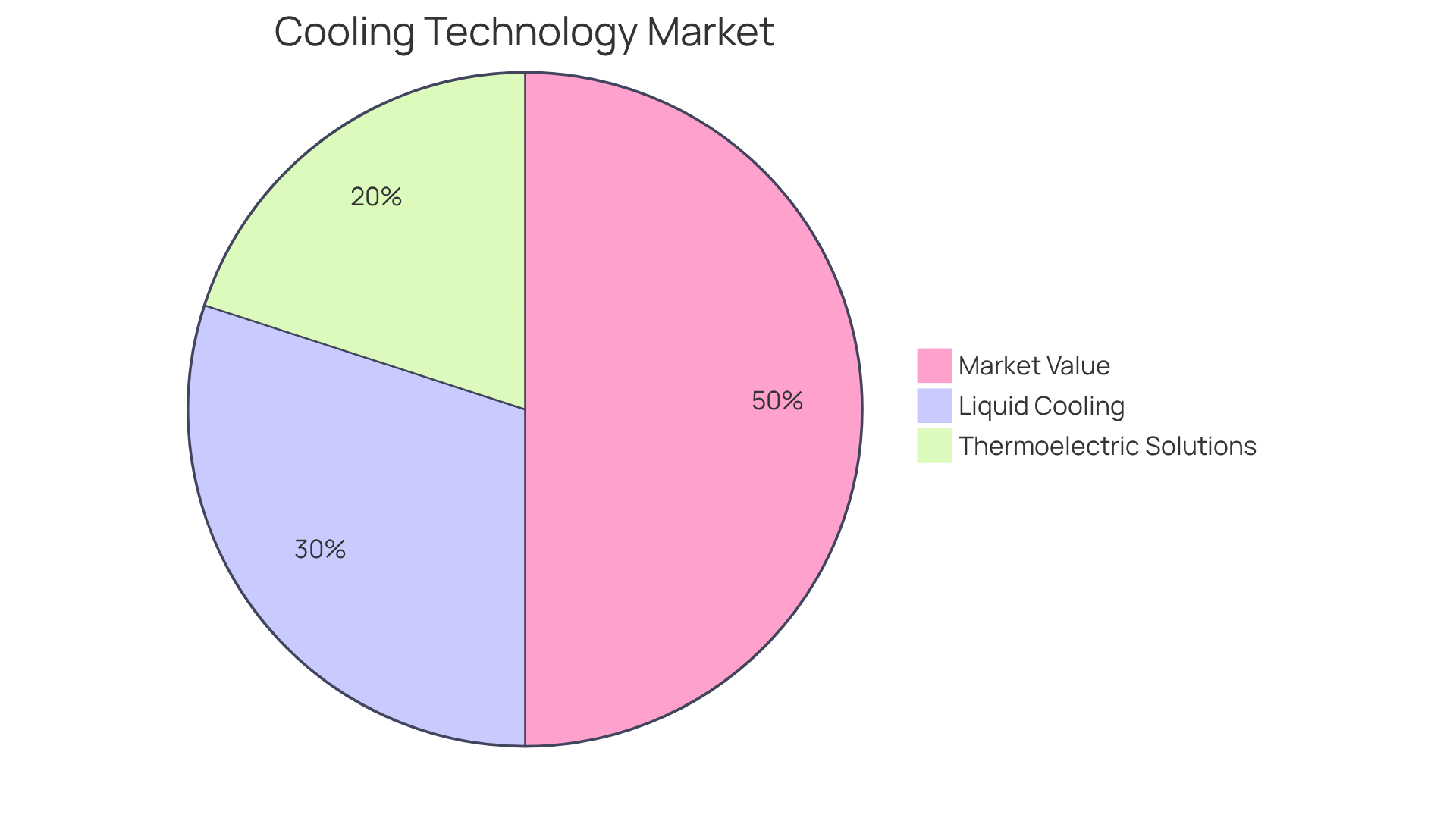

The landscape of electronics temperature regulation is undergoing a rapid transformation, propelled by the demand for more efficient thermal management solutions. Recent statistics reveal that the global market for innovative electronic temperature regulation technologies is anticipated to grow significantly, reaching USD 5.07 billion by 2033, with a compound annual growth rate (CAGR) of 9.85% from 2026 to 2033.

To maintain a competitive edge, engineers must actively engage with industry publications, attend pertinent conferences, and participate in professional networks. Insights from industry leaders underscore the importance of innovation in temperature regulation solutions, particularly as AI workloads and data center demands escalate.

Noteworthy trends, such as liquid cooling systems and thermoelectric solutions, are gaining traction due to their effectiveness in managing heat within high-density environments. By staying informed about these advancements, engineers can make educated decisions that enhance the performance and reliability of their electronic systems.

Conclusion

Selecting the appropriate electronics cooling fan is vital for ensuring optimal performance and longevity of electronic devices. This selection process requires a thorough understanding of the various types of fans, an assessment of airflow needs, and a careful evaluation of specifications, all while considering the specific requirements of the application. By making informed decisions, engineers can significantly enhance thermal management and overall efficiency in their systems.

Key insights from this guide underscore the significance of:

- Proper fan placement

- Compatibility with electronic systems

- The necessity of regular maintenance

Assessing airflow needs based on heat output, choosing between axial and centrifugal fans, and prioritizing noise levels alongside energy efficiency are all essential steps toward achieving effective cooling solutions. Moreover, leveraging thermal simulations can facilitate better design choices that align with real-world performance.

Ultimately, staying informed about the latest innovations in cooling technologies and trends empowers engineers to make educated decisions that not only meet current demands but also anticipate future challenges. Embracing these strategies will enhance device reliability and contribute to sustainable engineering practices, ensuring that electronic systems remain efficient and effective in a rapidly evolving technological landscape.

Frequently Asked Questions

What is the role of Gagner-Toomey Associates in electronics cooling fan selection?

Gagner-Toomey Associates provides engineers with essential tools and insights for selecting effective electronics cooling fans, ensuring optimal performance and energy efficiency in electronic systems.

Why is selecting the right electronics cooling fan important?

Choosing the appropriate electronics cooling fan can significantly enhance the reliability and lifespan of devices, with statistics indicating that well-chosen fans can reduce thermal resistance by 10-30%.

What are electronics cooling fans used for?

Electronics cooling fans facilitate airflow over components to disperse heat and prevent overheating, thereby maintaining optimal operating temperatures and extending the lifespan of electronic devices.

What types of cooling fans does Gagner-Toomey Associates manufacture?

Gagner-Toomey Associates manufactures both standard and custom air-movers, including DC input tube axial units and centrifugal blowers optimized for performance, efficiency, and low noise.

What are the two primary categories of cooling devices?

The two primary categories are axial blowers, which propel air parallel to the axis for high air movement rates, and centrifugal blowers, which direct air at right angles to the intake for higher pressure applications.

How long do electronics cooling fans typically last?

The average lifespan of electronic ventilation devices generally ranges from 3 to 7 years, depending on usage and environmental conditions.

How do you assess the airflow needs for electronics cooling?

To assess airflow needs, evaluate the heat output of components in watts and ensure the fan’s ventilation capacity in cubic feet per minute (CFM) exceeds this heat output for safe operating temperatures.

What tools can help in assessing cooling requirements?

Thermal simulations can help model airflow dynamics and temperature distributions, allowing engineers to visualize the impact of different fan configurations on cooling efficiency.

What is the projected growth of the North America DC Fans for Electronic Cooling Market?

The market, valued at USD 0.6 Billion in 2022, is projected to grow to USD 1.1 Billion by 2030, reflecting a CAGR of 8.2%.

What trends are shaping the future of electronics temperature control solutions?

Trends such as the adoption of smart fan technology and energy-efficient designs are shaping the future of electronics temperature control solutions.