Overview

Choosing the right fan cooler hinges on several critical factors:

- Fan size

- Noise levels

- Energy efficiency

- Durability

- Installation compatibility

- Advanced control features

Each of these elements plays a pivotal role in determining cooling performance and operational efficiency, ultimately influencing the effectiveness of electronic designs. By understanding how these factors interact, engineers can make informed selection decisions that optimize their designs. This article delves into each aspect, providing a comprehensive analysis that not only highlights their importance but also guides professionals toward making the best choices in their cooling solutions.

Introduction

In the realm of electronics engineering, effective cooling solutions are not merely a luxury; they are a necessity for maintaining optimal performance and longevity. Gagner-Toomey Associates stands at the forefront of this critical need, offering innovative cooling technologies specifically tailored to address the unique challenges faced by engineers. By optimizing fan sizes for enhanced airflow and ensuring minimal noise levels, the selection of cooling fans can significantly influence the efficiency of electronic designs.

This article explores the various aspects of cooling solutions, including:

- Installation simplicity

- Energy efficiency

- Advanced control features

Equipping engineers with essential insights to make informed decisions that elevate their projects to new heights. As the demand for reliable and effective cooling continues to escalate, understanding these elements becomes paramount for successful electronic design and implementation.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

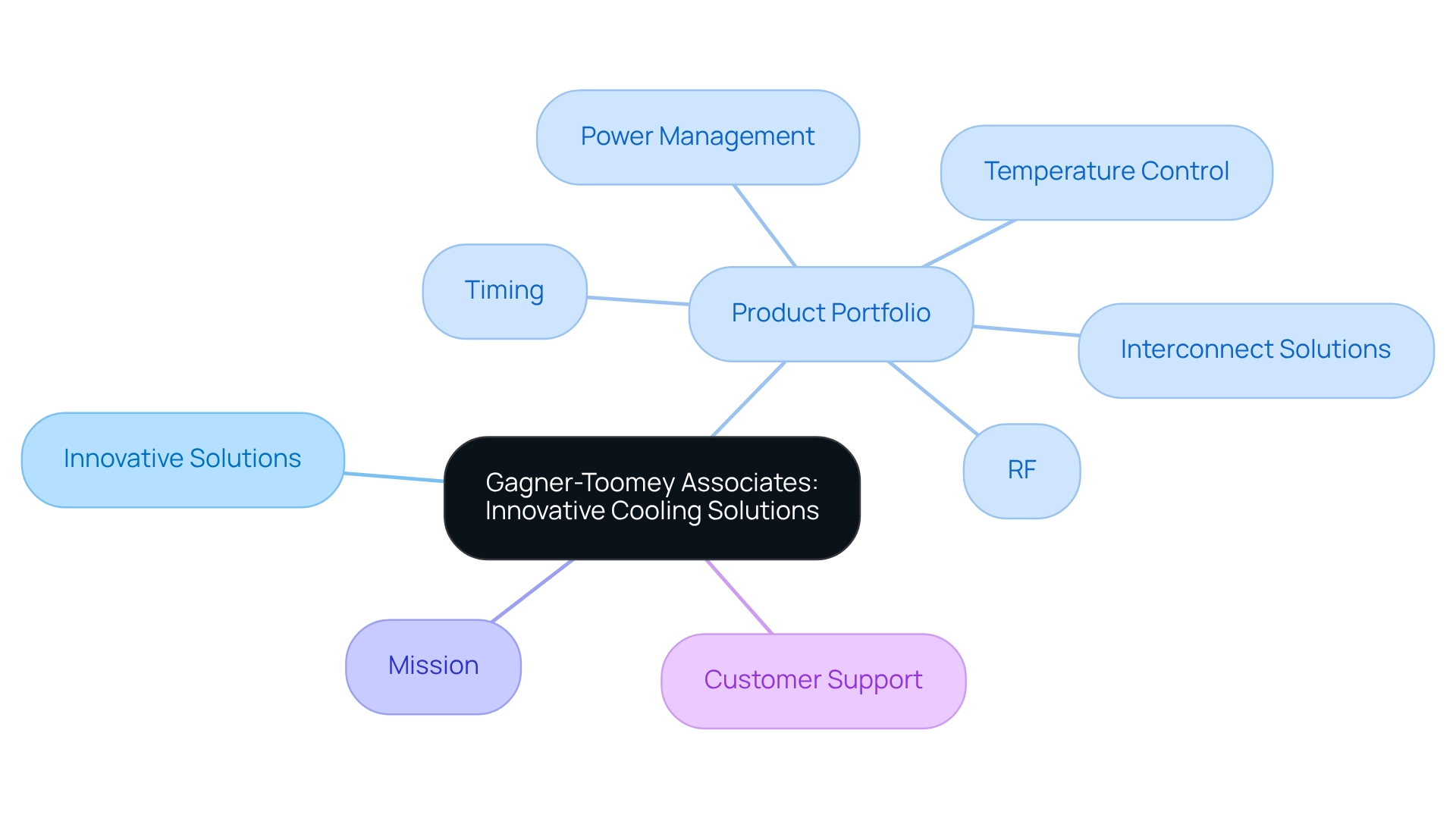

Gagner-Toomey Associates excels in delivering innovative temperature regulation solutions that address the distinct challenges faced by engineers in the electronics sector. By presenting a diverse portfolio of outstanding manufacturers, the company ensures that engineers have access to the latest advancements in temperature control, power management, timing, RF, and interconnect solutions. Their mission, ‘Helping Clients Bring World-Changing Ideas to Market,’ underscores a commitment to innovation and exceptional customer support, which is embedded in their culture. This dedication positions Gagner-Toomey Associates as an invaluable partner for engineers aiming to optimize their designs.

Fan Size: Optimize Cooling Efficiency in Electronic Designs

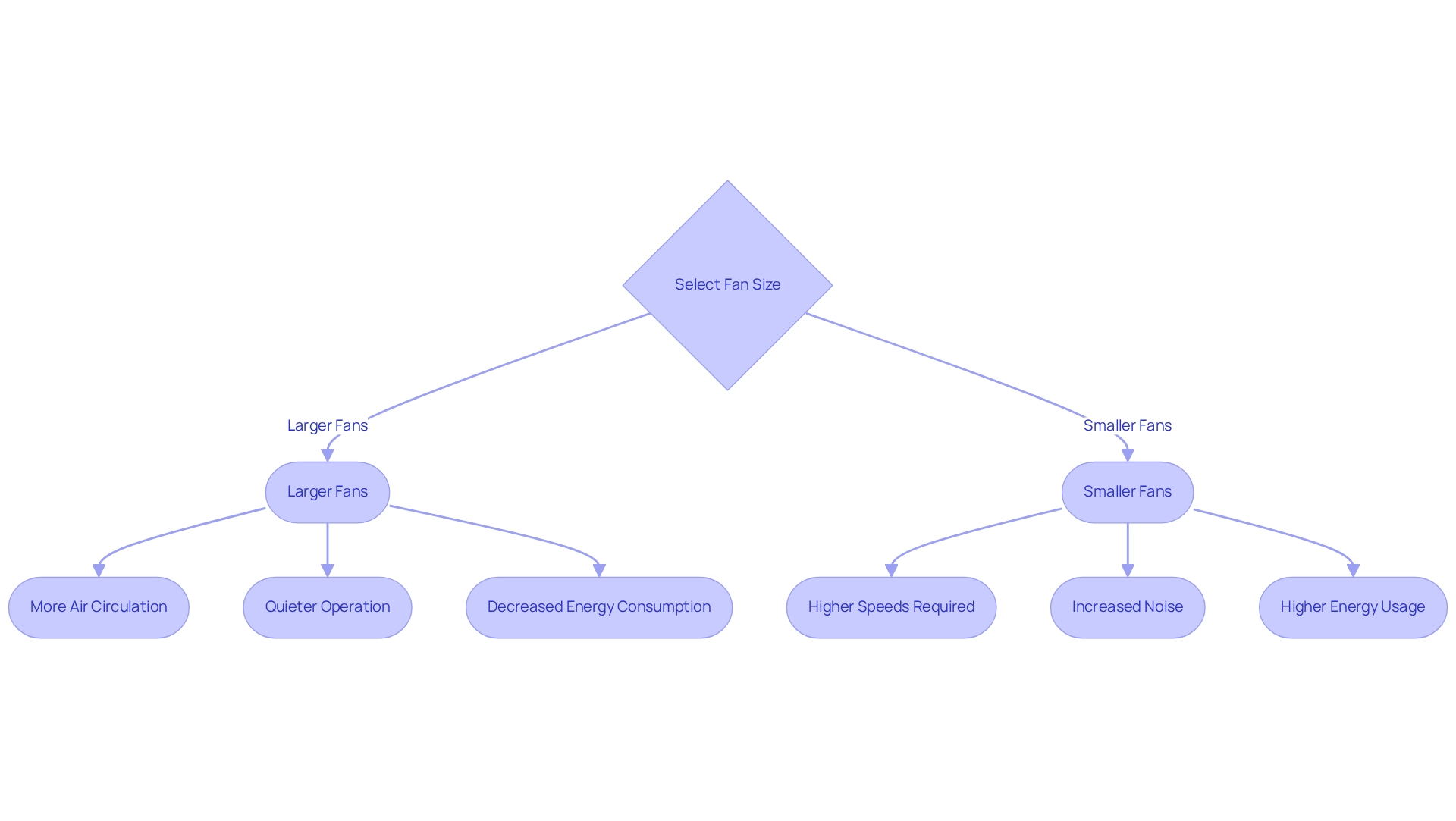

Selecting the appropriate fan cooler size is critical for maximizing cooling efficiency. Larger blowers typically circulate more air at reduced speeds, which leads to quieter operation and decreased energy consumption. Conversely, smaller devices often require higher speeds to achieve the same airflow, resulting in increased noise and energy usage. Engineers must consider the spatial limitations of their designs while ensuring that the fan cooler size aligns with the temperature management requirements of the components involved.

Noise Levels: Ensure Quiet Operation in Cooling Fans

When selecting ventilation devices, particularly a fan cooler, it is essential to emphasize noise levels, especially in environments where silent operation is paramount. Fans equipped with advanced bearing technologies, such as fluid dynamic bearings, significantly surpass standard ball bearings in noise reduction capabilities.

For example, the Fractal Design Aspect 12 Fan operates at a maximum speed of 2000 RPM, delivering an impressive airflow of up to 56 CFM while maintaining a low noise level of just 18.3 dBA. This fan cooler has received positive feedback for its silent operation and efficient airflow, making it a preferred choice for users seeking effective yet quiet air circulation solutions.

Furthermore, integrating speed control mechanisms into these devices allows for dynamic adjustments based on thermal demand, ensuring they operate only at necessary speeds. This approach not only enhances temperature regulation but also minimizes noise, aligning with recommendations from organizations such as the US EPA and BCCDC, which advocate for the use of certified devices to mitigate fire hazards in DIY air purifiers.

As Hartzell Air Movement articulates, ‘We take pride in the recognition bestowed upon us by renowned organizations, further reinforcing our commitment to excellence.’

As the industry progresses, innovations in low-noise thermal technologies continue to surface, underscoring the critical role of noise levels in the selection of fan coolers for electronics. Additionally, commercial units can automatically increase fan speed in response to elevated PM levels, further highlighting the significance of effective fan design in maintaining operational efficiency.

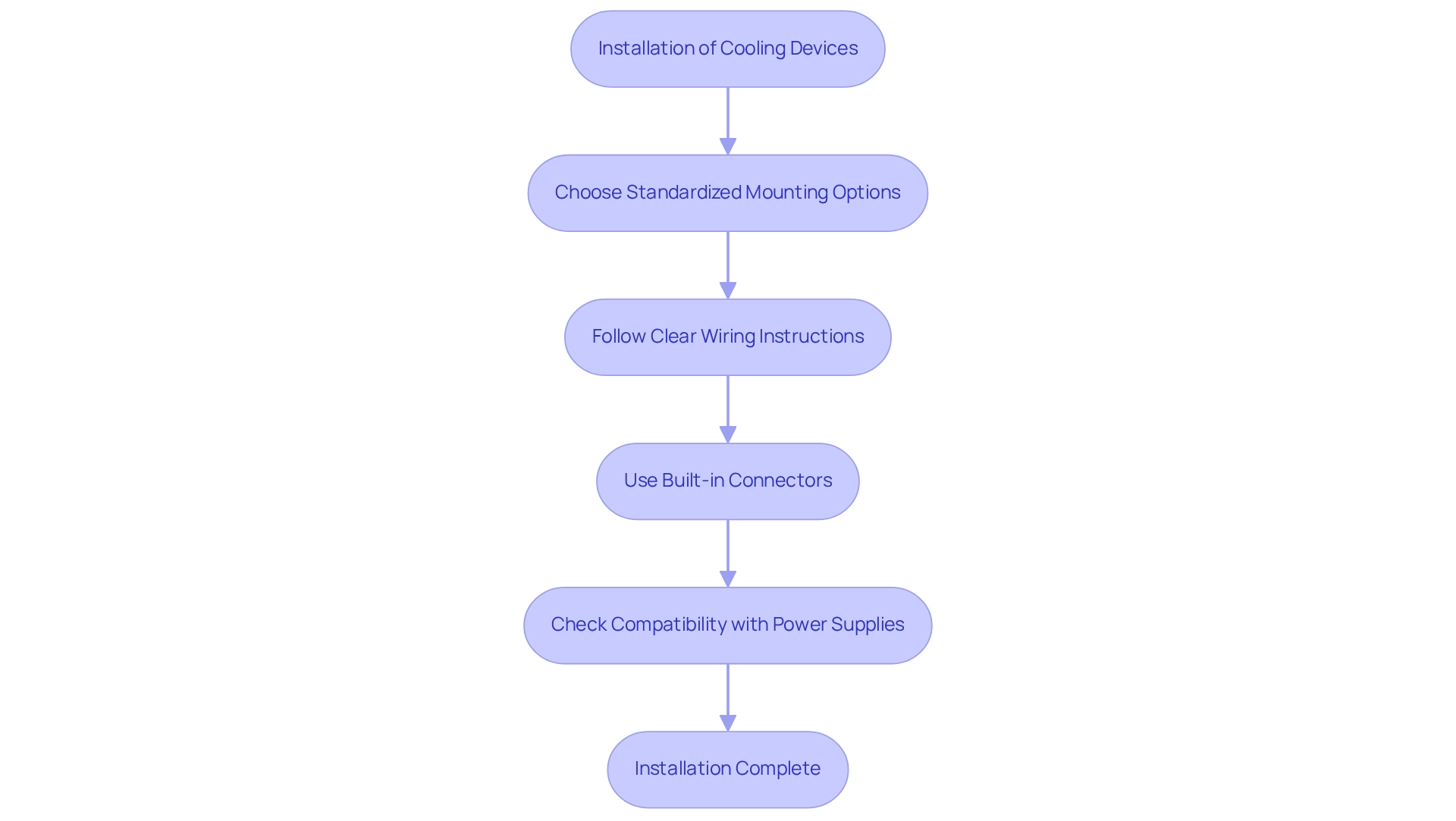

Installation and Connectivity: Simplify Fan Cooler Integration

The installation procedure for cooling devices must be straightforward to minimize downtime and reduce errors. Prioritize devices that offer standardized mounting options and clear wiring instructions. Additionally, fans equipped with built-in connectors can significantly streamline the connection process, facilitating quicker integration into existing setups. Ensuring compatibility with standard power supplies and control systems will further enhance the installation experience, making it both efficient and effective.

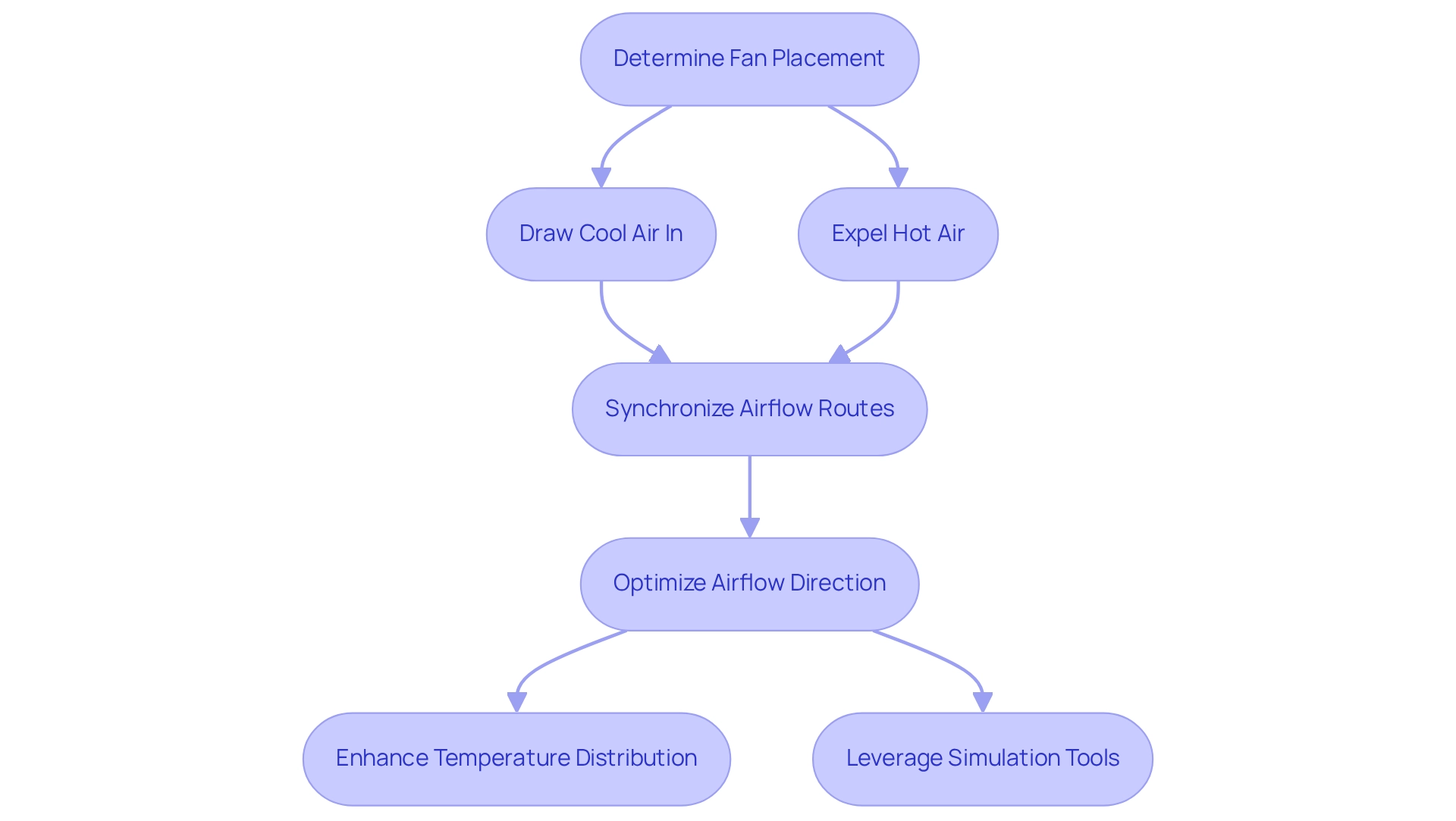

Airflow Direction: Enhance Cooling Performance with Proper Orientation

Correct positioning of the fan cooler is essential for optimizing temperature management in electronic devices. Fan coolers must be strategically placed to draw cool air into the setup while effectively expelling hot air. When multiple fan coolers are utilized, it is crucial to ensure that their airflow routes are synchronized to prevent turbulence, as this can significantly diminish their effectiveness.

Research indicates that optimizing airflow direction can enhance temperature distribution uniformity by over 18.36% with a discontinuous transpiration surface length of 1 mm, underscoring the importance of precise fan placement. Engineers can leverage airflow simulation tools to visualize and refine fan configurations, ensuring that designs meet the temperature requirements of complex systems.

As Yuyang Bian notes, “The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper,” highlighting the integrity of the research in this domain.

Furthermore, findings from the case study titled ‘Thermal Insulation Effects in Transpiration Cooling’ reveal that greater injection ratios improve thermal insulation, facilitating enhanced temperature regulation under varying operational conditions. This emphasizes the necessity for meticulous consideration in fan cooler placement strategies to maintain optimal functioning and temperature control.

Energy Efficiency: Reduce Power Consumption in Cooling Systems

Energy-efficient ventilation units are designed to minimize power consumption while delivering optimal performance. Seek out devices that incorporate brushless DC motors, renowned for their exceptional efficiency and durability. Moreover, the implementation of variable speed controls allows for the adjustment of the fan cooler speeds in response to real-time thermal demands, further curtailing energy usage. By emphasizing energy efficiency, engineers can play a pivotal role in fostering more sustainable electronic designs.

Durability and Material Quality: Ensure Long-lasting Cooling Solutions

Durability stands as a critical factor when selecting a fan cooler, particularly as it must endure a variety of operating conditions. Fans constructed from high-quality materials, such as reinforced plastics and metals, demonstrate significantly reduced failure rates under stress.

For example, the implementation of sealed bearings effectively protects against dust and moisture, thereby prolonging the operational lifespan of the fan. Engineers must meticulously assess the environmental conditions in which the fan cooler will operate, ensuring that the selected model meets durability standards.

Recent innovations, such as the Fantech Rn4-4EC fan, illustrate how cutting-edge designs can facilitate installation while efficiently utilizing just 4.5 watts of electricity. This fan not only boosts performance by moving over 500 cfm but also lowers labor costs, positioning it as an optimal choice for new mitigators.

Jesse Green, a professional in the field, remarked, “It’s so nice to just install and dial it in. No need to interchange between different devices. It costs more, but my labor is cut down. These would be very beneficial for new mitigators who simply want to carry two blowers and don’t comprehend airflow curves or all the various blower models. The two EC supporters have you covered. We fixed a house using only 4.5 watts of electricity!”

Furthermore, data indicate that fan coolers crafted from premium materials can achieve lifespans exceeding 50,000 hours under ideal conditions, emphasizing the critical role of material selection in achieving durable performance.

System Compatibility: Guarantee Versatile Cooling Solutions

Ensuring compatibility with the overall structure is vital when selecting a fan cooler for ventilation. Engineers must verify that the fan’s voltage and current ratings align with the application’s requirements; mismatches can lead to inefficiencies or failures. Additionally, the connector types must be compatible to facilitate seamless integration. Physical dimensions are another critical factor; the fan must fit within the designated space without obstructing other components.

Modular fan designs present considerable benefits, offering adaptability that enables straightforward upgrades or replacements as requirements change. This adaptability is particularly beneficial in dynamic environments where technology rapidly advances. By selecting modular solutions, engineers can improve longevity and performance, ensuring that cooling solutions remain effective even as configurations vary. The capability to swiftly replace components without significant alterations can conserve time and resources, rendering modular designs a wise option for contemporary electronic setups.

A case study titled ‘Lessons Learned for Future Deployments’ emphasizes the significance of ensuring compatibility in designs, showcasing key challenges and solutions for future electric bus implementations. This real-world context underscores the necessity of addressing compatibility issues to avoid potential failures. As Brian Foulds, an electric technology champion for Concord, stated, “Everything is operating as expected,” reflecting the positive outcomes of meticulous planning and compatibility checks. Moreover, data suggests that compatibility problems can greatly affect the efficiency of ventilation devices, including fan coolers, in electronic systems, emphasizing the necessity for engineers to focus on these factors in their designs.

Advanced Control Features: Optimize Fan Performance and Adaptability

Contemporary ventilation devices are increasingly equipped with advanced control features that allow for dynamic adjustments based on real-time temperature readings. Pulse-width modulation (PWM) technology emerges as a pivotal innovation, enabling devices to function at variable speeds. This functionality not only reduces noise but also significantly cuts energy consumption when full power is not required.

Furthermore, many modern devices incorporate thermal sensors that automatically modulate their speed in response to fluctuating thermal loads, thereby ensuring optimal cooling efficiency at all times. The uptake of these sophisticated features is growing, with research indicating that systems employing PWM technology can achieve energy savings of up to 30% compared to conventional fan designs.

For instance, the ROG Crosshair X870E Hero motherboard features dual ProCool connectors, which enhance power delivery stability and reliability under load, thus supporting the operation of PWM-enabled fans. Additionally, Q-Fan Control amplifies PWM technology by permitting manual or pre-set fan speed configurations according to temperature, further boosting efficiency.

As the electronics industry advances, the importance of such technologies in improving the efficiency of fan coolers and promoting energy conservation cannot be overstated. As noted by Alza.sk, the ASUS ROG CROSSHAIR X870E HERO is recognized for its capability to handle intensive tasks, including overclocking, underscoring the necessity of effective thermal management in high-performance environments.

Maintenance Requirements: Ensure Optimal Performance of Cooling Fans

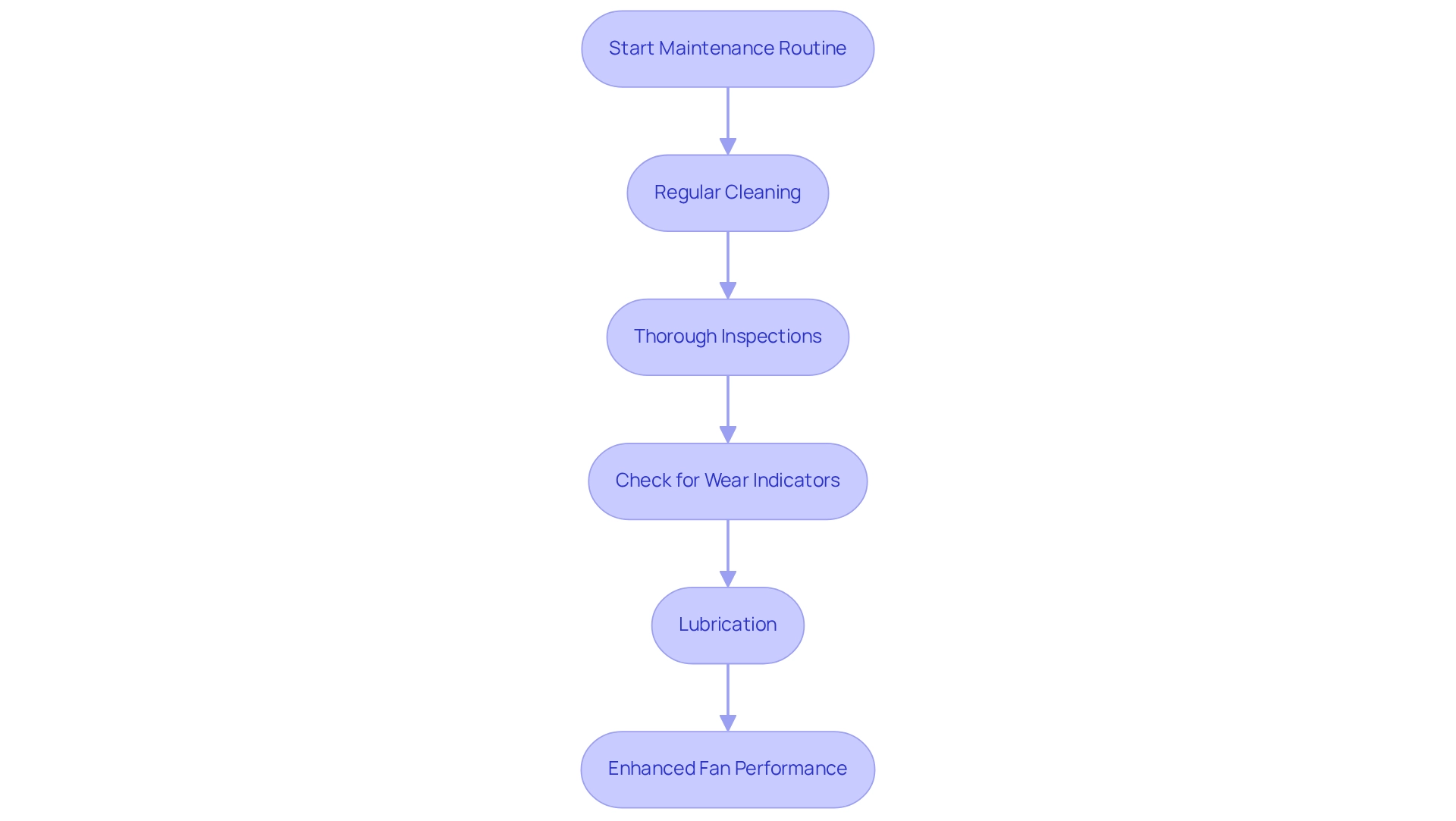

To ensure peak operation, ventilation devices necessitate a structured maintenance routine that encompasses regular cleaning and thorough inspections. Dust accumulation can significantly obstruct airflow and increase noise levels, making periodic cleaning vital for sustaining efficiency. A clearly defined maintenance schedule not only prolongs the lifespan of cooling devices but also bolsters overall system reliability.

For example, conducting regular checks for wear indicators—such as unusual noises or vibrations—can facilitate the early detection of potential issues, thereby averting costly failures. Data suggests that establishing a consistent maintenance routine, which includes cleaning, lubrication, and inspections, can markedly improve fan performance.

A case study focusing on the longevity of fans in electronic applications demonstrates that adherence to manufacturer guidelines and the maintenance of optimal operating conditions can yield considerable enhancements in reliability and efficiency. Regular maintenance practices are not merely advantageous; they are essential for preserving the effectiveness of fan cooler solutions in electronics.

As noted by Bassett, “We lowered the fan load needed, reducing our electrical bill by $1,400 per unit for the year. We reduced our chilled water flow by 60%, significantly reducing our energy bill.” This highlights the tangible benefits of diligent maintenance, reinforcing its critical role in operational efficiency.

Conclusion

Selecting the right cooling solutions is essential for engineers tasked with optimizing electronic designs. By carefully considering fan size, noise levels, installation simplicity, airflow direction, energy efficiency, durability, system compatibility, advanced control features, and maintenance requirements, engineers can significantly enhance the performance and longevity of their projects. Each of these elements plays a critical role in creating efficient cooling systems that not only meet operational demands but also contribute to sustainability goals.

As technology advances and the challenges in electronics design become more intricate, the importance of effective cooling solutions cannot be overstated. Innovations from companies like Gagner-Toomey Associates provide engineers with the tools and insights necessary to navigate these complexities. By prioritizing the integration of advanced cooling technologies, engineers can ensure that their designs remain competitive and reliable in an ever-evolving landscape.

In conclusion, understanding and implementing effective cooling strategies is not just a technical necessity but a pivotal factor in the success of electronic designs. By making informed decisions regarding cooling solutions, engineers can elevate their projects, ensuring optimal performance, reduced energy consumption, and enhanced system reliability. Embracing these principles will undoubtedly lead to more innovative and sustainable electronic designs, positioning engineers to meet the demands of the future.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative temperature regulation solutions for engineers in the electronics sector, providing access to advancements in temperature control, power management, timing, RF, and interconnect solutions.

What is the mission of Gagner-Toomey Associates?

Their mission is “Helping Clients Bring World-Changing Ideas to Market,” reflecting their commitment to innovation and exceptional customer support.

Why is selecting the appropriate fan cooler size important?

Selecting the right fan cooler size is critical for maximizing cooling efficiency. Larger blowers circulate more air at reduced speeds, leading to quieter operation and decreased energy consumption, whereas smaller devices require higher speeds, resulting in increased noise and energy usage.

What should engineers consider when choosing fan cooler sizes?

Engineers must consider both the spatial limitations of their designs and ensure that the fan cooler size aligns with the temperature management requirements of the components involved.

How do noise levels affect the selection of ventilation devices?

Noise levels are crucial when selecting ventilation devices, especially in environments where silent operation is essential. Fans with advanced bearing technologies, like fluid dynamic bearings, offer better noise reduction compared to standard ball bearings.

Can you provide an example of a fan cooler known for its quiet operation?

The Fractal Design Aspect 12 Fan is an example; it operates at a maximum speed of 2000 RPM, delivers airflow up to 56 CFM, and maintains a low noise level of just 18.3 dBA, making it a preferred choice for users seeking effective yet quiet air circulation solutions.

What role do speed control mechanisms play in fan coolers?

Speed control mechanisms allow for dynamic adjustments based on thermal demand, ensuring fans operate only at necessary speeds. This enhances temperature regulation and minimizes noise.

What do organizations like the US EPA and BCCDC recommend regarding fan coolers?

They advocate for the use of certified devices to mitigate fire hazards in DIY air purifiers, emphasizing the importance of effective fan design in maintaining operational efficiency.

How are innovations in low-noise thermal technologies impacting the industry?

Innovations in low-noise thermal technologies are increasingly important, highlighting the critical role of noise levels in selecting fan coolers for electronics, as well as the ability of commercial units to automatically increase fan speed in response to elevated PM levels.