Overview

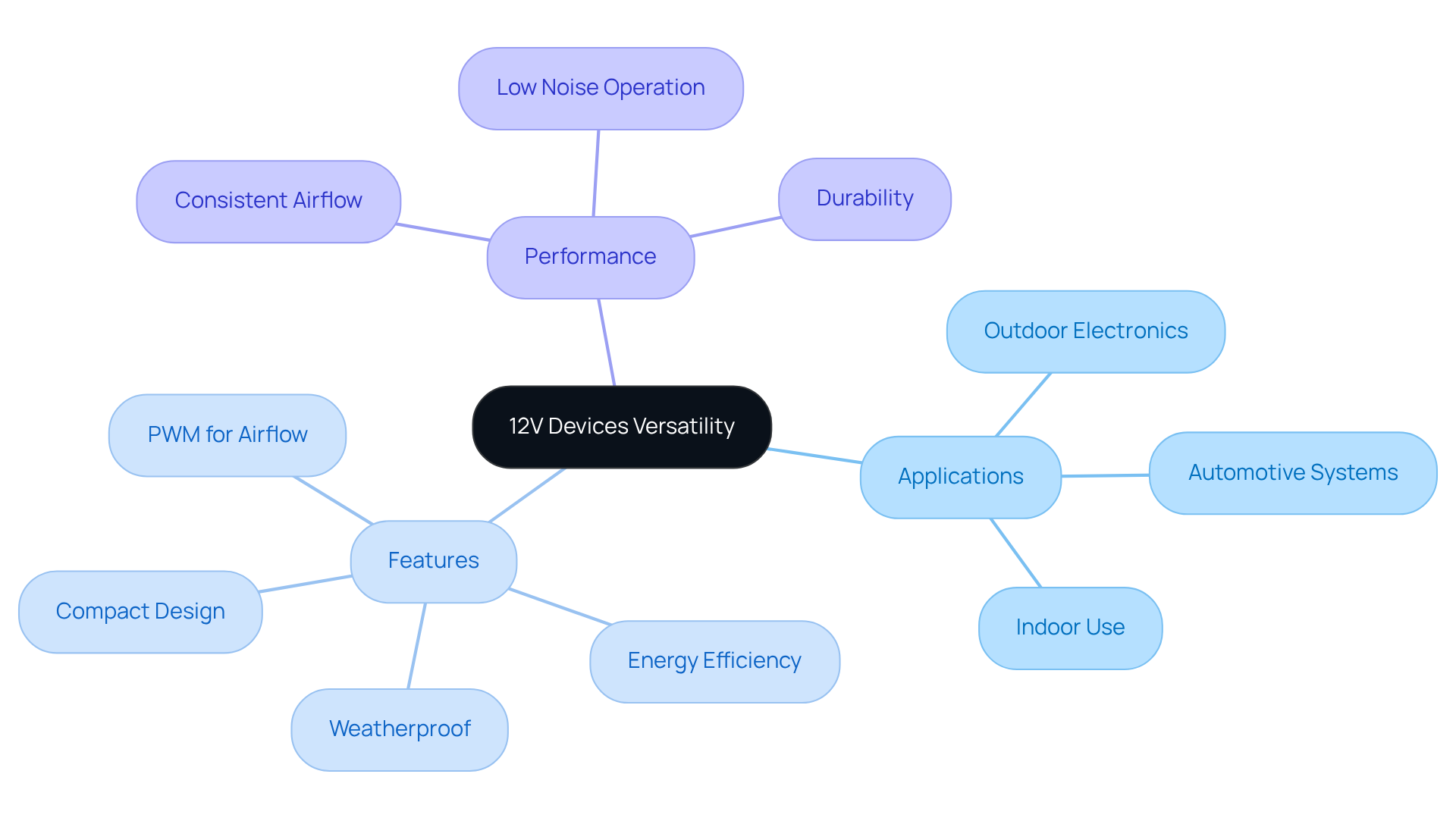

The article emphasizes the critical role of 12V fans in electronics projects, particularly in effective thermal management. These fans are characterized by several essential features:

- Low noise operation

- Energy efficiency

- Compact size

- Versatility

Together, these attributes significantly enhance the performance and reliability of electronic devices. This makes 12V fans suitable for a diverse array of applications, ensuring user comfort and extending system longevity.

Introduction

In the rapidly evolving world of electronics, effective thermal management is crucial for ensuring device performance and longevity. Among the myriad solutions available, 12V fans emerge as a versatile and efficient choice for cooling applications. This article explores nine essential features of 12V fans that not only enhance their functionality but also address the unique challenges faced by engineers across various projects.

How do these fans adeptly balance efficiency, noise reduction, and design flexibility while maintaining optimal performance? Delving into these features unveils the key to making informed decisions that can significantly influence the success of electronics projects.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Projects

stands at the forefront of providing tailored for the electronics industry. As the world’s largest producer of both standard and bespoke air-movers, their innovative solutions tackle the intricate engineers encounter, ensuring optimal functionality and reliability in electronic devices. By collaborating with leading manufacturers, Gagner-Toomey presents a comprehensive array of , featuring advanced systems with , efficiency, and low noise.

Their product line includes:

- DC input Tube Axial fans ranging from 15 to 280mm

- A complete portfolio of DC input Centrifugal Blowers from 15 to 225mm,

Importantly, Gagner-Toomey offers IP protection in most models upon request, as well as an , including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated liquid refrigeration systems

This steadfast commitment to excellence positions Gagner-Toomey as an indispensable resource for engineers in search of , particularly in a time when are crucial for sustaining system stability and longevity.

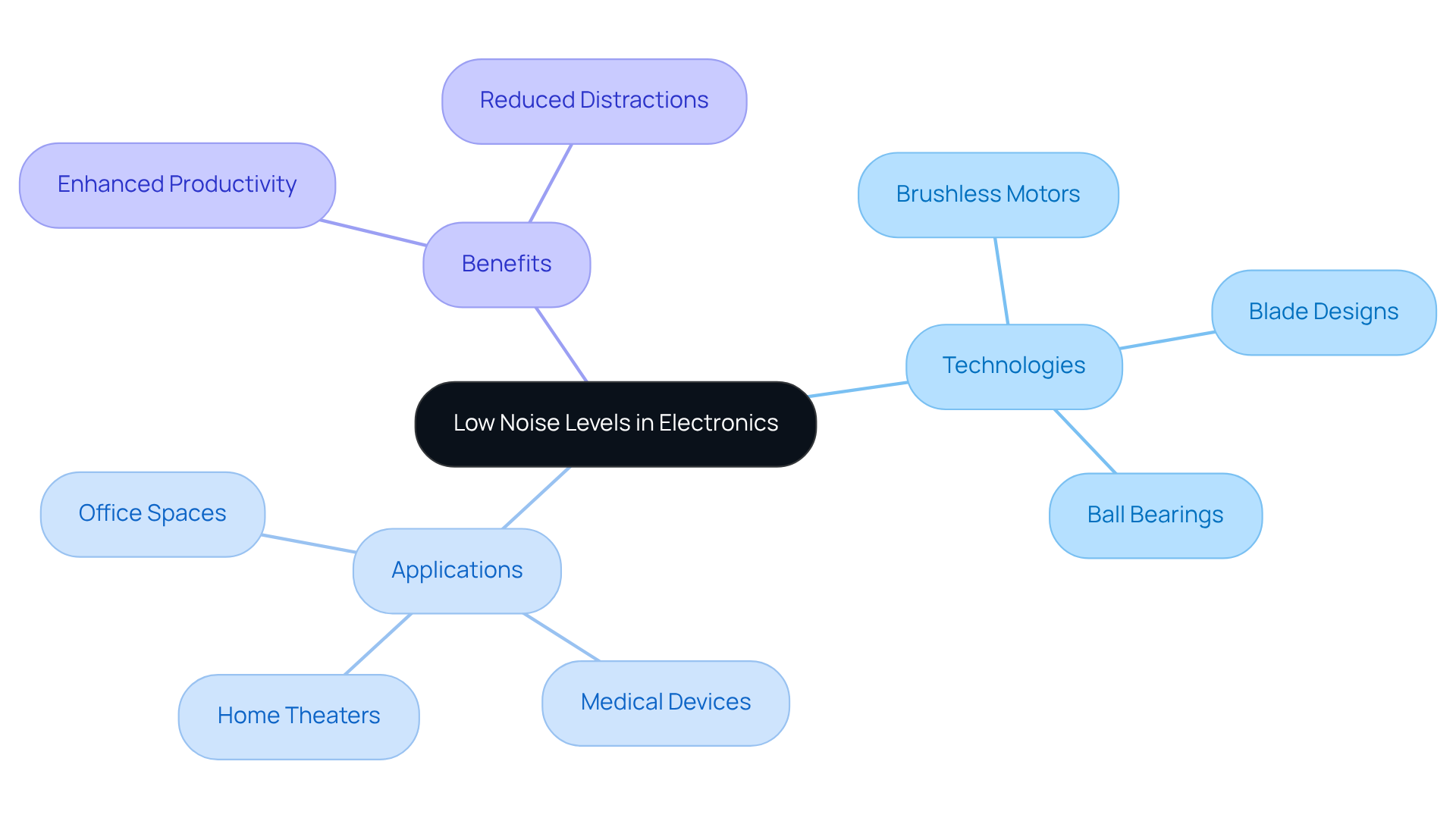

Low Noise Levels: Essential for Quiet Operation in Electronics

In the realm of electronics projects, prioritizing such as models is crucial. Advanced technologies, such as brushless motors and optimized blade designs, enable devices to operate at significantly reduced noise levels, often as low as 10-20 dBA.

For instance, devices equipped with dual ball bearings exhibit less vibration and noise compared to their sleeve bearing counterparts. This is particularly vital in environments like home theaters, medical devices, and office spaces, where excessive sound can disrupt functionality and user experience.

Moreover, and productivity by minimizing distractions. Choosing devices with , including a fan 12V, not only guarantees quieter operation but also of electronic systems, making them more suitable for sound-sensitive applications.

As Sam Pelonis aptly stated, “The bottom line is that the right fan for you will depend on your .” Furthermore, it is noteworthy that direct current devices utilize considerably less power than alternating current devices, further underscoring their efficiency in .

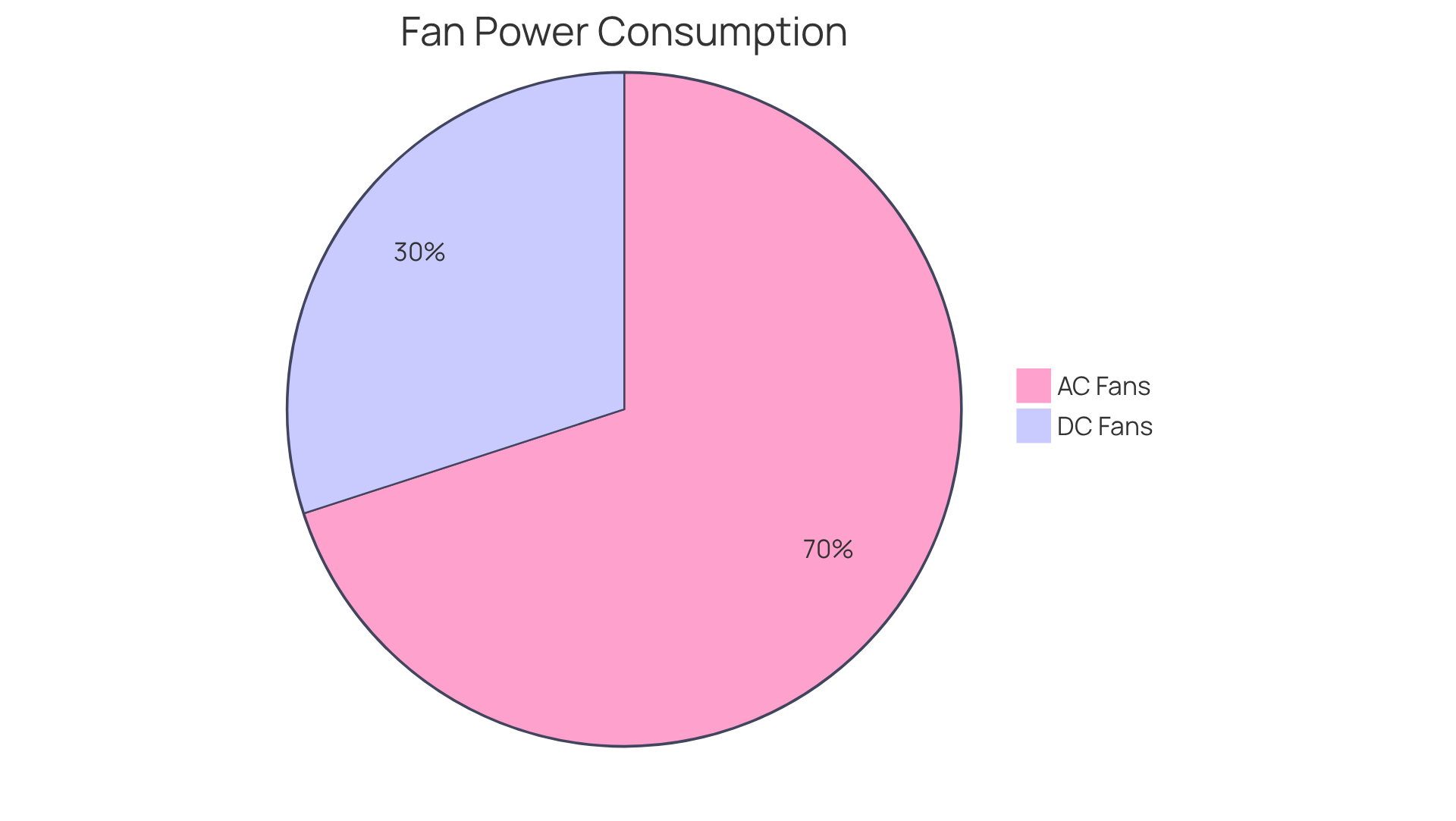

Efficient Power Usage: Maximizing Performance and Energy Savings

Efficiency in power usage is paramount when selecting a fan 12v for electronics projects. from Gagner-Toomey Associates are recognized for their exceptional , consuming up to 70% less power than conventional AC models. This translates into ; AC units can cost up to $10 for the same airflow that a $3 DC unit provides. Additionally, these DC fans produce less heat, which is crucial for maintaining optimal functionality in electronic devices.

Gagner-Toomey Associates offers an extensive selection of and centrifugal blowers, , ensuring engineers have access to . Furthermore, allow users to dynamically adjust fan speeds, optimizing energy savings while ensuring adequate cooling as required.

For example, a standard fan 12v typically operates at around 2.4 watts, illustrating its efficiency in delivering effective airflow with minimal energy consumption. As trends in power usage evolve, the adoption of from Gagner-Toomey Associates continues to gain momentum, further enhancing the performance and sustainability of electronic systems.

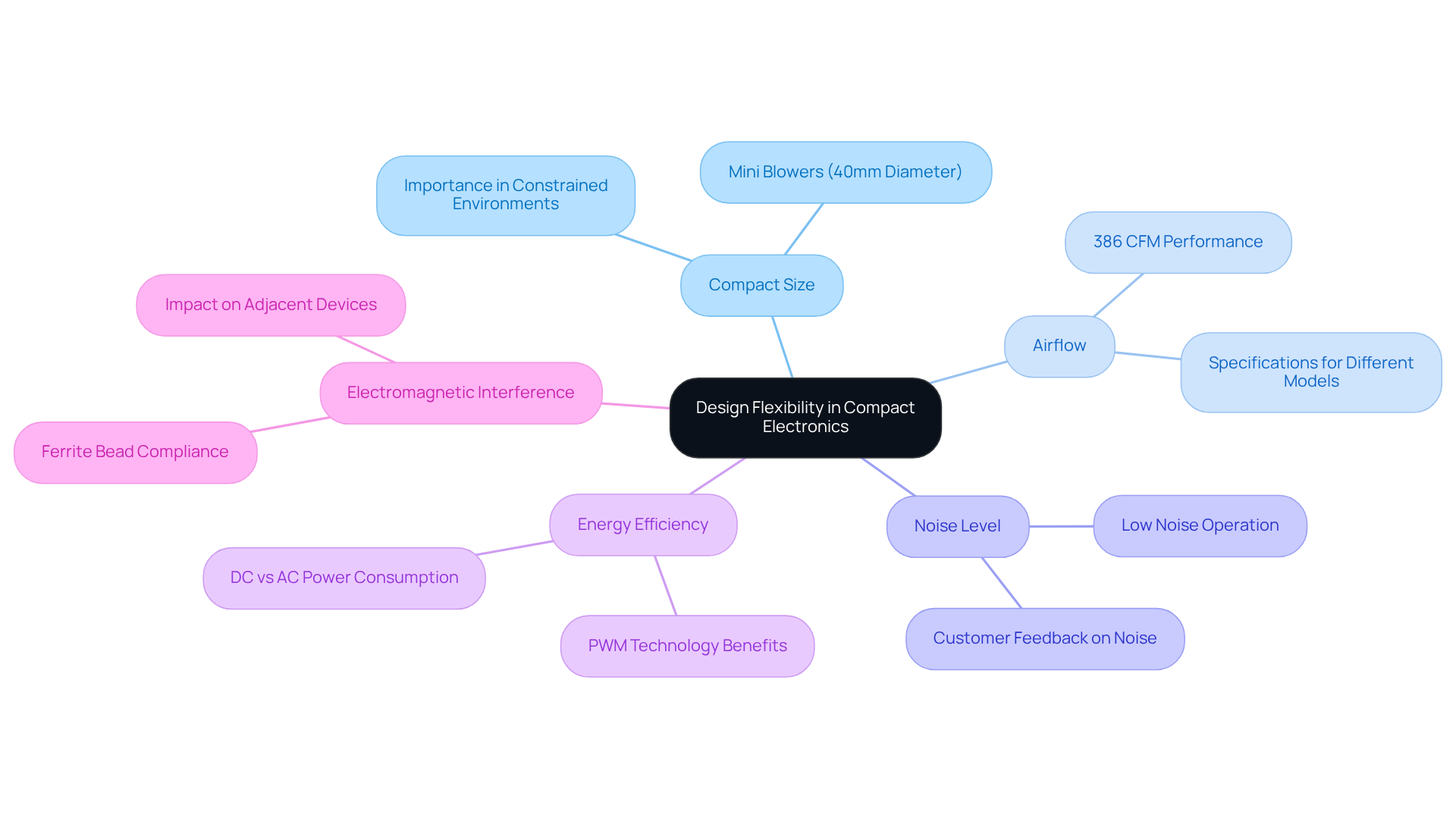

Compact Size and Portability: Key Considerations for Design Flexibility

In the realm of electronics, the significance of is paramount. Numerous , including options, are meticulously designed to be lightweight and compact, rendering them ideal for constrained environments such as computer cases, control panels, and portable gadgets.

For instance, can effectively cool components without consuming precious space. This design flexibility empowers engineers to integrate into their projects without compromising functionality or aesthetics.

When , it is essential to consider the with the project’s spatial constraints, thereby optimizing the overall design. Furthermore, factors such as airflow, noise level, and , as DC devices utilize up to 70% less power compared to their AC counterparts, making them suitable for sensitive electronic applications.

Moreover, engineers must remain vigilant regarding potential , which can impact the functionality of adjacent electronic devices.

Year-Round Use: Versatility in Various Electronics Applications

, offering versatile solutions across a broad spectrum of electronics applications. These devices perform exceptionally in both summer heat and winter chill, guaranteeing for sensitive components.

For example, in outdoor electronics and automotive systems, must endure while delivering consistent airflow. By selecting devices crafted from robust materials with weatherproof characteristics, users can ensure reliability in diverse environments, making them suitable for both indoor and outdoor applications.

Furthermore, the facilitates seamless integration into tight spaces, while their minimizes power consumption and environmental impact. Many models also feature for variable airflow, enhancing adaptability across different conditions. Their capability to function effectively under varying circumstances underscores their critical role in preserving the performance and extending the lifespan of electronic devices.

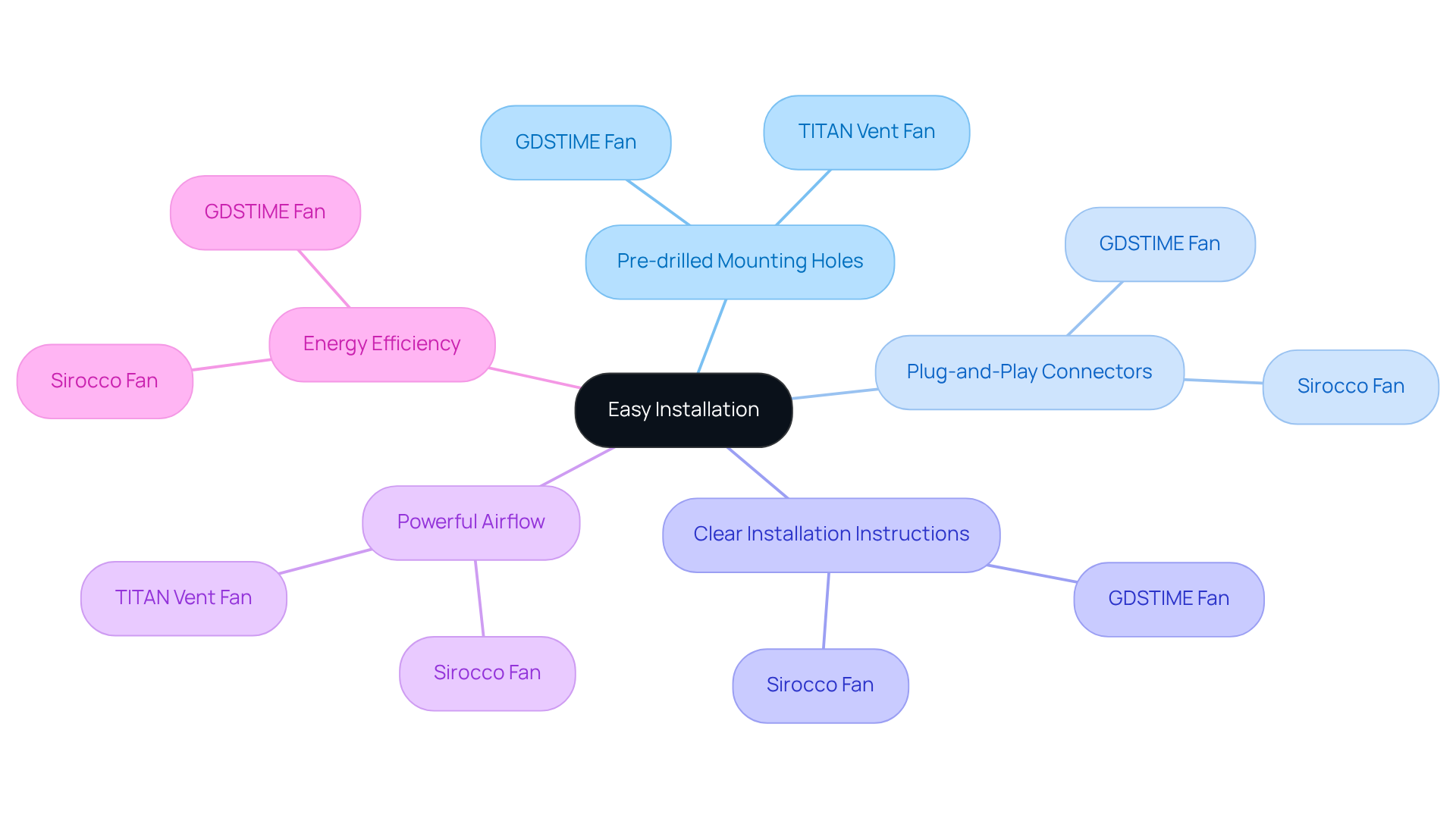

Easy Installation: Streamlining Setup for Electronics Projects

Selecting a that ensures is crucial for streamlining the setup process in electronics projects. Many feature user-friendly attributes, including:

- Pre-drilled mounting holes

- Plug-and-play connectors

- Clear installation instructions

For instance, the operates at a low noise level of 31 dB, is compact, and is designed for seamless integration into various applications. Additionally, that simplify the . The , recognized for its powerful airflow and energy efficiency, can be installed in under 30 minutes, making it a practical choice for expedited setups.

Furthermore, devices with standardized sizes and connectors can easily replace existing units, thereby reducing downtime and enhancing project efficiency. Ensuring compatibility of the chosen fan with the project’s design is essential for facilitating a smoother . As Joseph Ciravola noted, ‘The fan was a fairly easy install; the only issue is the temperature sensor is attached to the controller, not through a connector,’ underscoring the significance of intuitive design in optimizing project outcomes.

Quality and Price Balance: Ensuring Value in Fan Selection

Selecting a necessitates a careful balance between quality and price. While the allure of the least expensive option is strong, investing in a leads to . Look for devices that come with warranties, , and certifications that attest to their reliability. Notably, products from often include reliability assurances and are engineered to withstand demanding usage.

For instance, the MaxxFan Deluxe is recognized for its and is backed by a robust warranty, positioning it as a trustworthy choice for engineers. By meticulously comparing specifications—such as the rated voltage of a [fan 12v](https://gagner-toomey.com/?p=8750) and a —alongside pricing, engineers can identify devices that fulfill their performance requirements without straining their budgets.

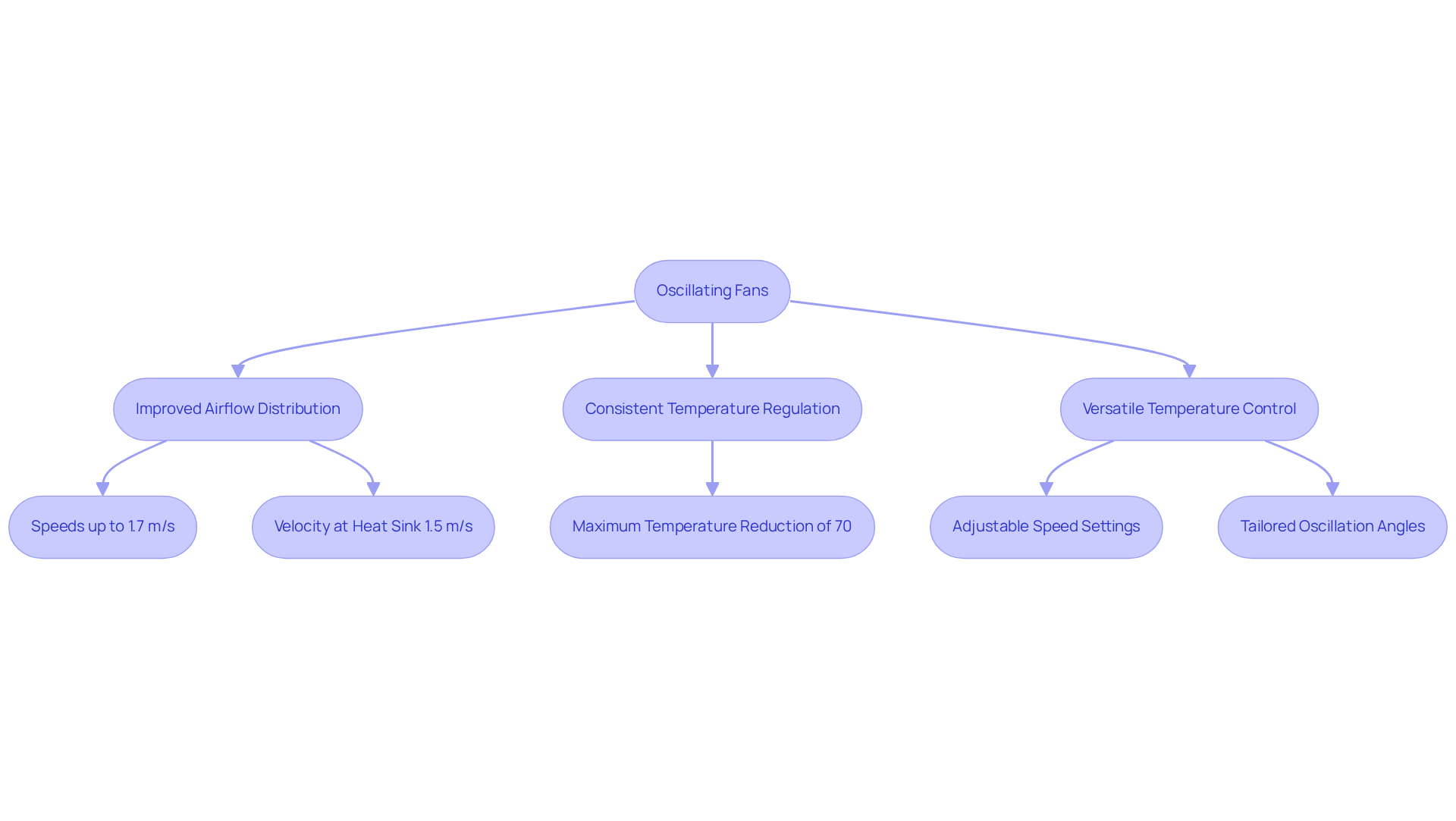

Oscillating Fans: Enhancing Airflow in Electronics Environments

present a compelling solution for . Their ability to pivot back and forth allows for more uniform air distribution across larger areas, effectively mitigating hotspots and ensuring consistent temperature regulation. This characteristic is particularly vital in environments where multiple components generate heat, such as server rooms and high-performance computing setups.

Research shows that oscillating devices can significantly improve airflow distribution, achieving speeds of up to 1.7 m/s under optimal conditions. Additionally, velocities at the heat sink can reach approximately 1.5 m/s, demonstrating their efficacy in . Furthermore, these devices can be tailored to focus on specific areas, providing versatility in .

For instance, in server rooms, can help maintain an airflow speed exceeding 1.2 m/s in critical zones, which is essential for . Research indicates that oscillating devices can achieve a compared to natural convection, underscoring their effectiveness.

When selecting a , engineers should consider features such as and oscillation angles to maximize functionality and efficiency. As noted by James Petroski, a piezofan system can attain a coefficient of performance (COP) five times that of conventional natural convection methods, further validating the advantages of utilizing oscillating devices in temperature regulation strategies.

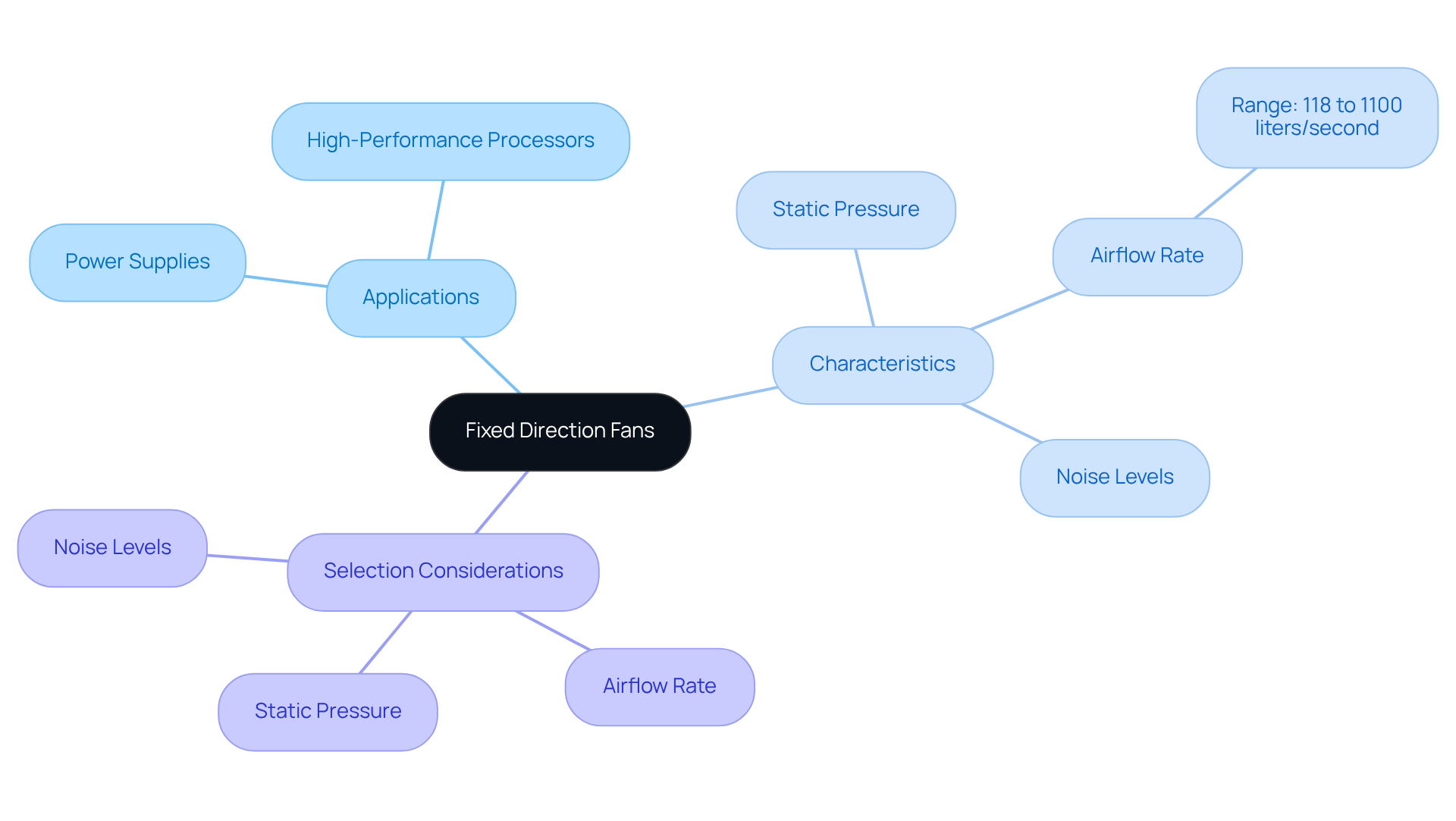

Fixed Direction Fans: Targeted Airflow for Specific Applications

Fixed direction blowers are engineered to deliver focused air movement, making them ideal for applications requiring . These devices excel in scenarios where components, such as power supplies and , necessitate direct airflow to effectively dissipate heat and sustain optimal operating temperatures.

Bill Schweber observes, “Depending on the physical arrangement of the fan and air movement path, when air is pushed in by a fan at the front end, dust will accumulate significantly on the filter’s screen and to a lesser degree on the blades,” underscoring the in operational efficiency.

For instance, can achieve flow rates ranging from 118 to 1100 liters per second, contingent on their size and design, thereby ensuring adequate for even the most demanding electronic systems.

When selecting a with a fixed direction, it is imperative to consider the , static pressure, and noise levels to align with the specific temperature regulation requirements of the application. This targeted approach not only enhances but also bolsters the longevity and reliability of electronic components.

Furthermore, case studies on fan placement within thermal management underscore the practical implications of fan configuration decisions, reinforcing the necessity of .

Conclusion

In summary, the selection of the appropriate 12V fan for electronics projects is critical, hinging on several essential features that significantly enhance performance and usability. Low noise levels, efficient power usage, compact size, and ease of installation are paramount, all contributing to the overall effectiveness of cooling solutions in electronic applications. By grasping these key characteristics, engineers can make informed decisions that optimize their designs and ensure reliable operation.

Key insights discussed include the advantages of utilizing advanced technologies, such as brushless motors, which facilitate quieter operation. The energy savings achieved with DC fans compared to AC models further highlight their efficiency, while the versatility offered by compact designs allows for integration into tight spaces. Moreover, the value of oscillating and fixed direction fans is emphasized, as they provide tailored airflow, ensuring optimal thermal management across various environments.

Ultimately, the significance of selecting high-quality fans cannot be overstated. Investing in reliable cooling solutions not only enhances the longevity and performance of electronic systems but also leads to improved user experiences. As technology continues to evolve, embracing innovative fan technologies will be crucial for engineers aiming to advance their projects and meet the demands of modern electronics.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative temperature control solutions tailored for the electronics industry, focusing on thermal management challenges to ensure optimal functionality and reliability in electronic devices.

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers a range of products, including DC input Tube Axial fans ranging from 15 to 280mm and DC input Centrifugal Blowers from 15 to 225mm.

Can Gagner-Toomey fans be customized for specific needs?

Yes, Gagner-Toomey offers IP protection in most models upon request, allowing for customization to meet specific requirements.

What additional temperature management solutions does Gagner-Toomey provide?

In addition to fans, Gagner-Toomey provides extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid refrigeration systems.

Why are low noise levels important in electronics?

Low noise levels are crucial in electronics to minimize distractions, particularly in sensitive environments like home theaters and medical devices, enhancing user experience and workplace productivity.

What technologies help reduce noise levels in Gagner-Toomey fans?

Advanced technologies such as brushless motors and optimized blade designs help reduce noise levels, often achieving sound levels as low as 10-20 dBA.

How do DC fans compare to AC fans in terms of power usage?

DC fans from Gagner-Toomey are recognized for their exceptional energy efficiency, consuming up to 70% less power than conventional AC models, which leads to lower operational costs.

What is the impact of using DC fans on heat production?

DC fans produce less heat compared to AC fans, which is essential for maintaining optimal functionality in electronic devices.

What is Pulse Width Modulation (PWM) control in fans?

PWM control allows users to dynamically adjust fan speeds, optimizing energy savings while ensuring adequate cooling as needed.

What is the typical power consumption of a standard fan 12V?

A standard fan 12V typically operates at around 2.4 watts, demonstrating its efficiency in providing effective airflow with minimal energy consumption.