Overview

This article examines various high-temperature fan solutions tailored for electronics engineers, underscoring their critical role in achieving optimal thermal management under extreme conditions. It showcases cutting-edge technologies, including DC input tube axial fans and centrifugal blowers, which significantly enhance reliability and efficiency in electronic applications. Such innovations are essential in meeting the escalating demand for effective cooling solutions across sectors like data centers and industrial environments.

Introduction

In the realm of electronics, effective heat management is not merely a necessity; it is a critical factor that determines the performance and longevity of components. As technology advances and devices grow increasingly complex, the demand for innovative cooling solutions has surged, particularly in high-temperature environments.

Gagner-Toomey Associates stands at the forefront of this challenge, offering a diverse range of advanced thermal management technologies specifically designed for extreme conditions. Their products, from high-temperature axial fans to sophisticated cooling systems, are engineered to ensure reliability and efficiency, consistently meeting rigorous industry standards.

This article explores the various cooling solutions available, underscores their importance in today’s electronics landscape, and examines future trends that promise to redefine thermal management strategies.

Gagner-Toomey Associates: Innovative Cooling Solutions for High-Temperature Applications

Gagner-Toomey Associates stands out in delivering innovative temperature regulation solutions specifically designed for applications involving a high temp fan in the electronics sector. Their comprehensive portfolio showcases advanced thermal management technologies, including an extensive range of DC input tube axial fans and centrifugal blowers, which are vital for ensuring the reliability and performance of electronic components under extreme conditions. Through strategic partnerships with leading manufacturers, Gagner-Toomey equips engineers with that comply with stringent industry standards, including IATF 16969 certification and automotive compliance.

As the demand for efficient temperature control technologies escalates—especially in data centers where uniform temperature regulation is paramount—Gagner-Toomey positions itself at the forefront, offering solutions that not only address current requirements but also anticipate future thermal management challenges. Recent studies underscore the critical need for sustainable temperature regulation solutions, emphasizing the significance of innovative designs in achieving zero emissions discharge, as highlighted by Mneimneh, Ghazzawi, and Ramakrishna.

Furthermore, the market for advanced refrigeration technologies within the electronics sector is projected to experience substantial growth by 2025, driven by the increasing complexity of electronic systems and the demand for effective thermal management. Specific data indicate that stringent environmental standards play a crucial role in fostering these sustainable temperature control solutions. Notable examples of Gagner-Toomey’s impact include the successful implementation of high temp fan systems for high-temperature refrigeration that enhance the efficiency and longevity of , reflecting their commitment to excellence and innovation in the field. Insights from the case study titled ‘Current State of Renewable Energy Technologies in Engineering’ further emphasize the necessity of integrating renewable technologies into cooling solutions, reinforcing Gagner-Toomey’s pivotal role in advancing the industry.

Cooler Guys High-Temperature Fans: Reliable Performance in Extreme Conditions

Gagner-Toomey Associates offers a comprehensive selection of meticulously engineered for reliable operation in extreme conditions. These devices, including the high temp fan, are crafted to endure high temperatures while ensuring optimal airflow and efficiency, making them essential for use in industrial environments and data centers where effective heat management is crucial. Their robust construction ensures longevity and consistent performance in demanding situations.

As the industrial ventilators and blowers market in North America witnesses substantial growth, propelled by the demand for energy-efficient and intelligent ventilation solutions—especially in manufacturing and HVAC sectors—Gagner-Toomey Associates distinguishes itself.

Rithika Thomas, a Senior Analyst at ABI Research, notes, “These firms excel by addressing modern temperature regulation challenges faced by data center operators, employing the most advanced technologies available today.”

Engineers can rely on Gagner-Toomey Associates’ units for essential temperature regulation, as evidenced by positive reviews from industry experts who commend their durability and reliability under challenging conditions. Furthermore, efficiency data indicates that these devices are adept at managing heat in areas similar to those serviced by the Cool-Space evaporative cooler, suitable for spaces up to 6,500 square feet.

With such compelling effectiveness metrics and expert insights, Gagner-Toomey Associates’ high temp fan units emerge as a premier choice for those seeking dependable temperature regulation in extreme environments.

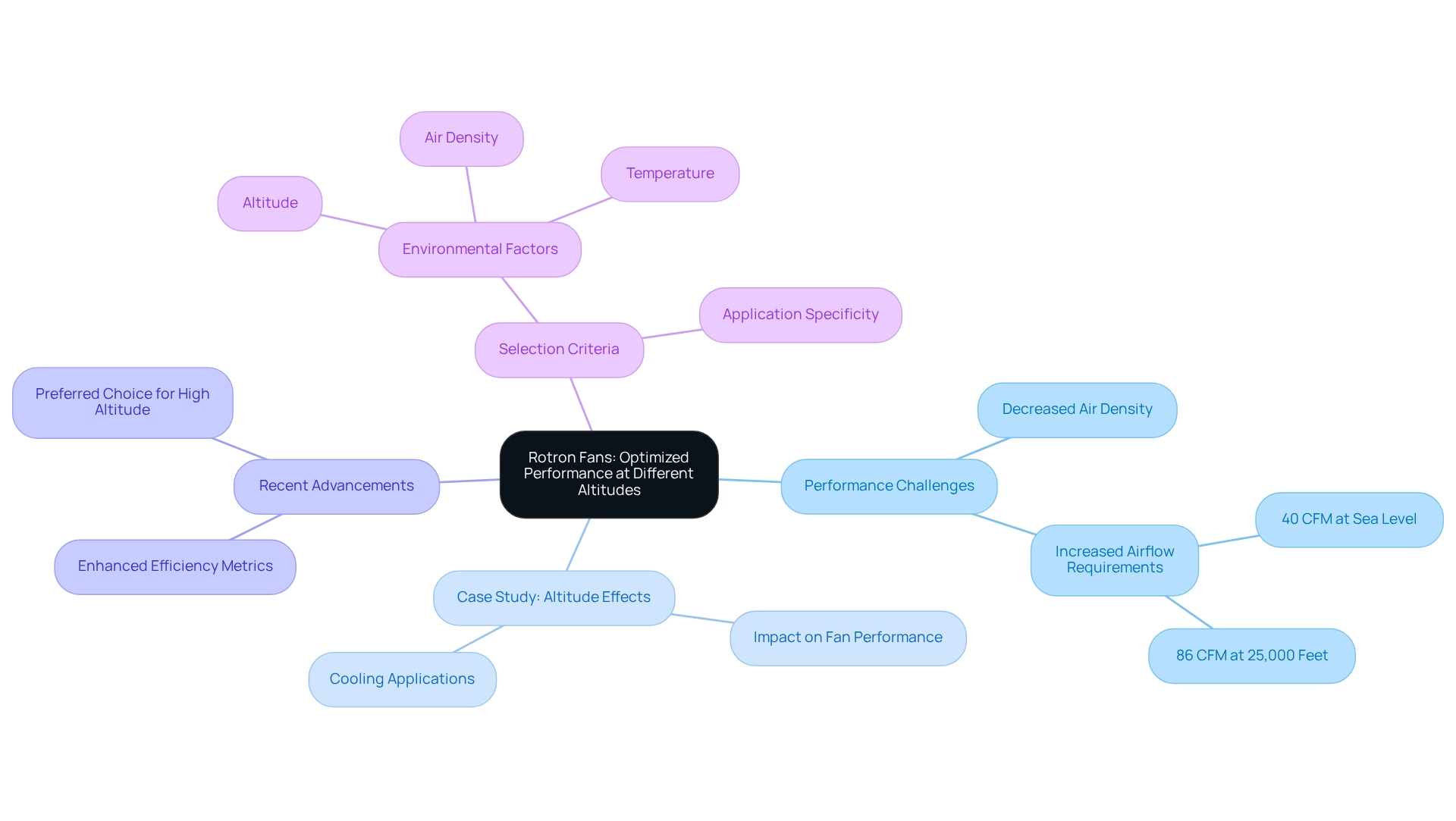

Rotron Fans: Optimized Performance at Different Altitudes

Rotron units are engineered to excel in sustaining optimal performance across varying altitudes, effectively addressing the challenges posed by decreased air density. These devices employ advanced design methodologies that guarantee steady airflow and temperature regulation, regardless of height. This capability is essential for applications in aerospace, telecommunications, and other sectors where equipment operates at high altitudes.

For instance, a case study titled ” illustrates that at 25,000 feet, the airflow requirement escalates significantly, necessitating higher CFM to cool the same heat load compared to sea level. Engineers can depend on the high temp fan by Rotron to deliver reliable temperature regulation solutions, ensuring the longevity and efficiency of their electronic systems even in demanding environments.

Recent advancements in Rotron fan technology further enhance their efficiency metrics, solidifying their status as a preferred choice for high-altitude applications. As AMETEK Rotron underscores, selecting the appropriate fan for specific applications is critical, taking into account environmental factors such as altitude, temperature, and air density. This meticulous selection process is vital for achieving optimal temperature regulation using a high temp fan.

In the words of Richard Bach, ‘He moves not through distance, but through the ranges of satisfaction that come from hauling himself up into the air with complete and utter control.’ This sentiment resonates profoundly within the engineering community, underscoring the relentless pursuit of excellence in performance.

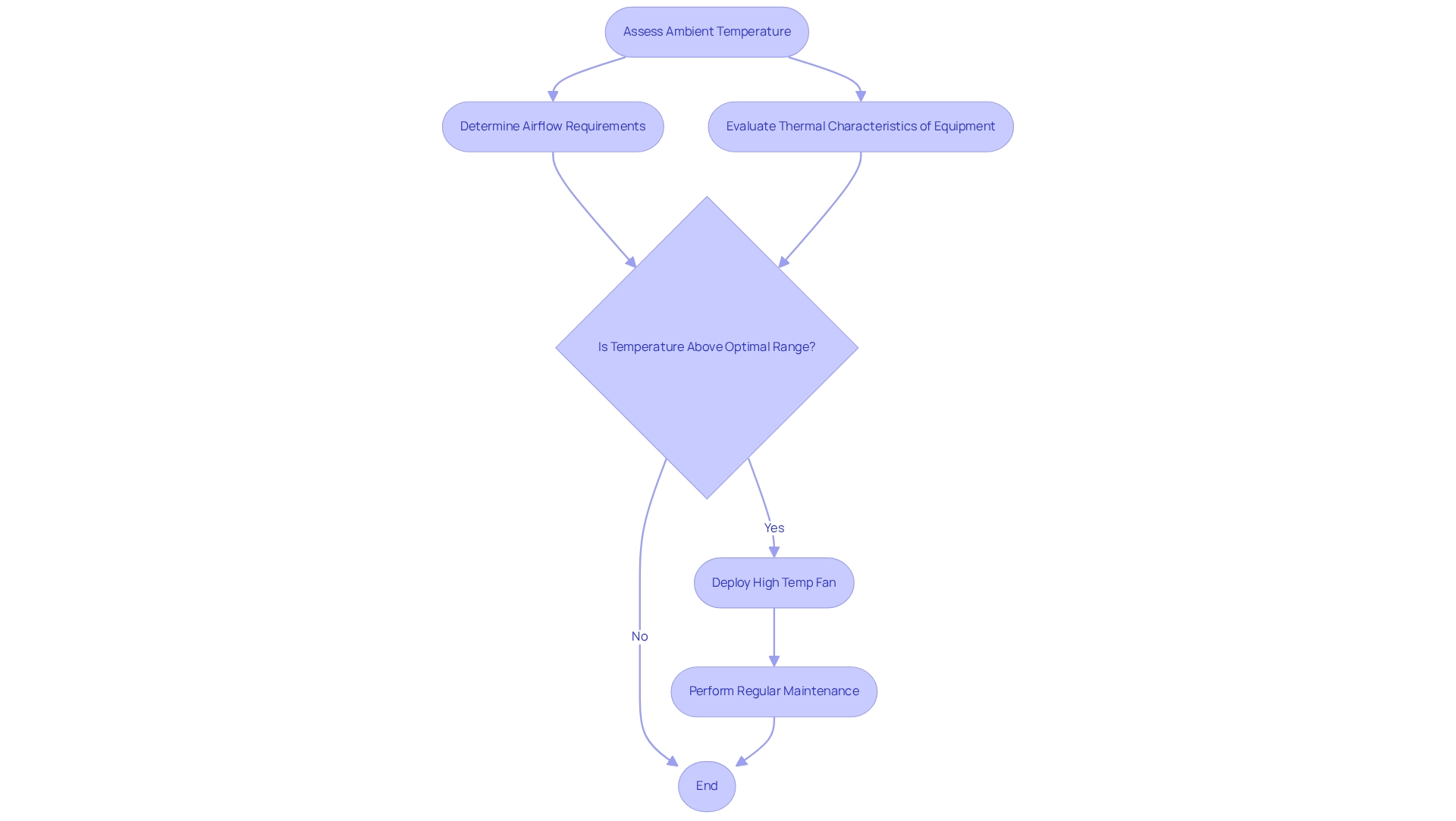

Science.org Insights: When to Use Fans in High-Temperature Scenarios

Observations from Science.org highlight the critical role of supporters, such as a high temp fan, in high-temperature environments for enhancing temperature regulation and preventing excess heat in electronic devices. Engineers must strategically employ a high temp fan, considering ambient temperature, airflow requirements, and the specific thermal characteristics of the equipment. Notably, research indicates that as surrounding temperatures rise, the effectiveness of refrigeration units can decline significantly, with climate change exacerbating discomfort by 20% across all designs. This underscores the urgent need for a proactive approach to fan deployment. By meticulously analyzing these parameters, engineers can optimize their cooling solutions, ensuring reliable operation and extending the lifespan of electronic components.

Furthermore, the case study titled ‘The Importance of Regular Maintenance for HVAC Systems‘ underscores that regular upkeep is vital for maintaining integrity and efficiency. Real-world examples demonstrate that not only enhances functionality but also mitigates risks associated with thermal stress, ultimately leading to more resilient electronic designs. As one expert noted, ‘We are not promoting them on the priciest options we provide,’ which emphasizes the importance of strategic fan usage rather than focusing solely on cost. Additionally, tools like SimScale can facilitate comprehensive evaluations of high temp fan performance in high-temperature scenarios, offering practical guidance for engineers.

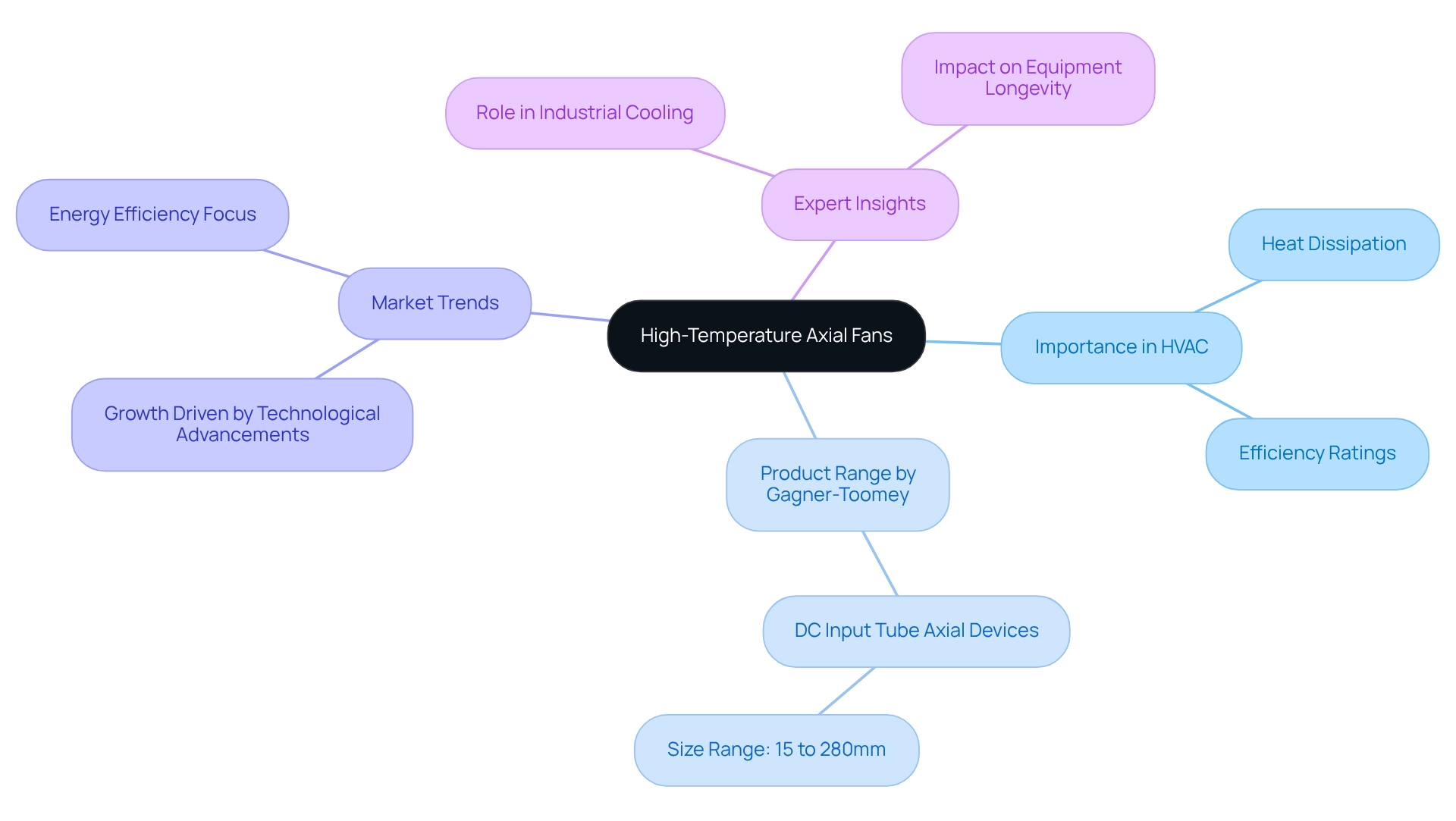

High-Temperature Axial Fans: Essential for HVAC Efficiency

High temp fans are indispensable in HVAC systems, especially in environments where efficient heat dissipation is crucial. Designed to move substantial volumes of air with exceptional efficiency, these devices are crucial in removing heat from settings such as industrial facilities, data centers, and commercial buildings. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input tube axial devices, varying from 15 to 280mm. These products are optimized for efficiency and low noise, ensuring operation at elevated temperatures without compromising effectiveness. This capability is vital for sustaining HVAC efficiency and maintaining comfort in high-heat conditions.

Recent statistics underscore that companies prioritizing energy efficiency and smart technologies are better positioned for success in the evolving market. is experiencing considerable growth, driven by technological innovations and an increasing demand for effective temperature regulation solutions. Notably, Gagner-Toomey Associates is at the forefront of this innovation, fostering a competitive landscape that promotes continuous advancement in design and functionality.

Experts in HVAC engineering emphasize the critical role of high-temperature axial blowers in sustaining optimal performance in industrial cooling setups. Their efficiency ratings in high-heat environments are essential, especially when using a high temp fan, as they directly influence the overall effectiveness of HVAC systems. Real-world applications demonstrate that these devices are not only proficient in heat dissipation but also enhance the longevity and reliability of equipment under demanding conditions. As the industry progresses into 2025, the focus on high temp fans will intensify, with both engineers and manufacturers recognizing their crucial role in achieving energy-efficient and reliable temperature regulation solutions.

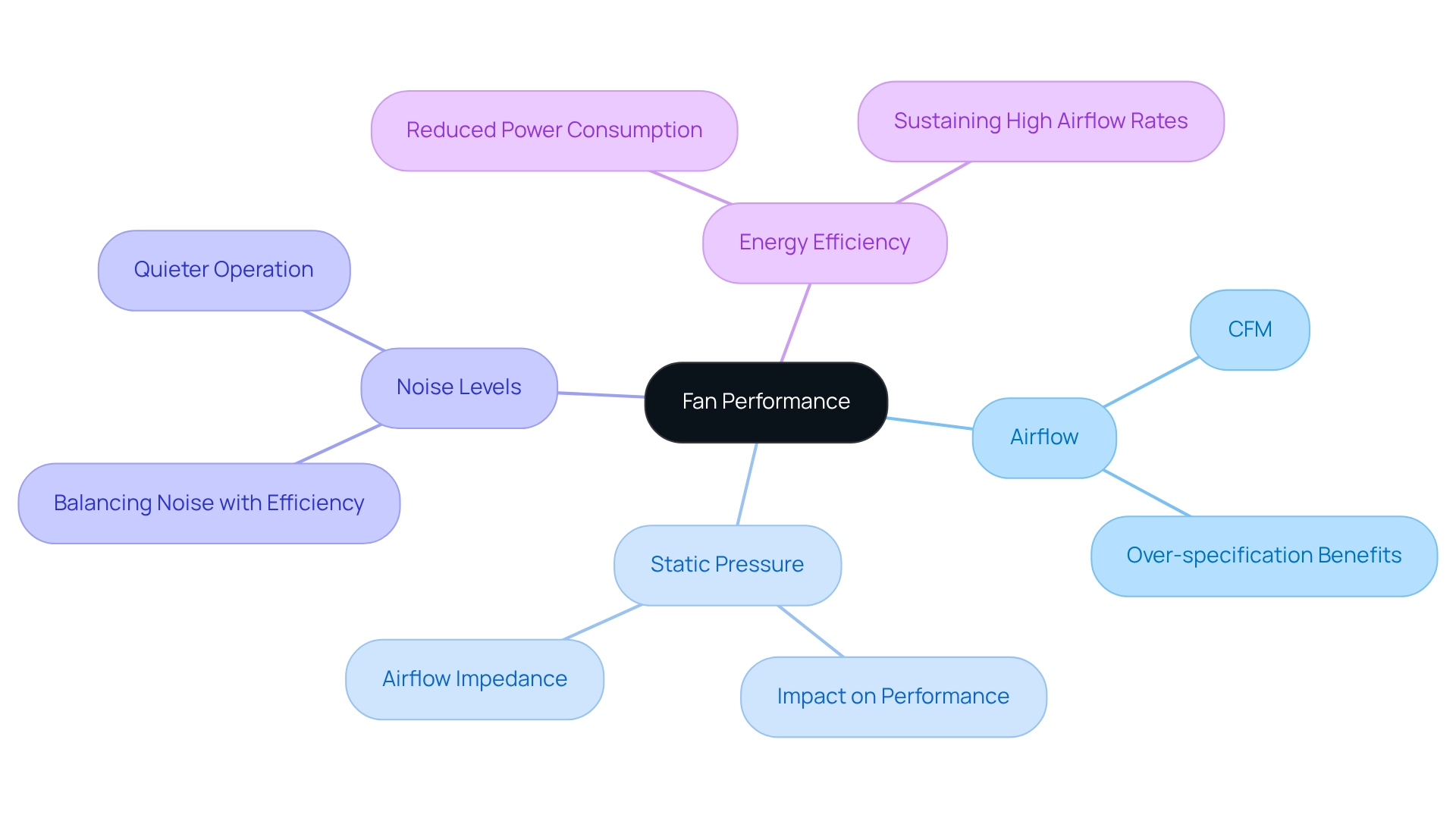

Fan Performance: Key Considerations for Electronics Cooling Systems

Creating efficient thermal management systems for electronics necessitates a comprehensive understanding of multiple essential metrics associated with the high temp fan functionality. Airflow, quantified in cubic feet per minute (CFM), is critical; over-specifying a high temp fan to achieve a maximum of 100 CFM ensures reliable performance at 75 CFM, which is essential for meeting the specific temperature regulation needs of various applications. This knowledge is crucial, as exemplified in the case study on the , where evaluating heat generation from components such as microcontrollers and processors is paramount.

Static pressure represents another vital consideration, influencing the capacity of the high temp fan to push air through restrictive environments, including densely packed electronic assemblies. Noise levels significantly affect fan selection, particularly in applications where sound is a concern. Engineers must strike a balance between the need for effective temperature regulation and the desire for quieter operation, often opting for high temp fan devices that minimize noise without sacrificing functionality. Furthermore, energy efficiency is increasingly important, with modern designs emphasizing reduced power consumption while utilizing a high temp fan to sustain high airflow rates.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a diverse array of DC input tube axial devices and centrifugal blowers, optimized for performance, efficiency, and low noise. Their solutions range from small blowers for consumer applications to larger units suitable for industrial uses, with dimensions spanning from 15 to 910mm and IP protection available upon request, ensuring that engineers have access to the appropriate tools for their specific temperature regulation requirements.

Practical evaluations of airflow and energy efficiency underscore the importance of understanding the particular needs for each application, including the use of a high temp fan. A structured approach to selecting a high temp fan highlights the necessity of assessing airflow impedance and fan types. As Jeff Smoot, VP of Engineering at Gagner-Toomey Associates, notes, “Choosing the appropriate fan is vital for guaranteeing that the ventilation setup functions effectively and efficiently.” By considering these factors, engineers can adeptly manage heat dissipation using a high temp fan, ensuring optimal operation and longevity of electronic systems.

In summary, prioritizing airflow, static pressure, noise levels, and energy efficiency empowers engineers to select the most suitable high temp fan for their ventilation solutions. To utilize these metrics effectively, engineers should conduct a comprehensive examination of their specific thermal requirements and assess the trade-offs between efficiency and operational limitations, ultimately enhancing the reliability and efficacy of their electronic designs.

Understanding Temperature Gauge Behavior: Implications for Cooling Systems

Temperature gauges play a pivotal role in monitoring the thermal behavior of electronic devices, directly influencing effective temperature regulation. Variations in gauge readings can signal changes in functionality or potential overheating, making it imperative for engineers to routinely calibrate and maintain these instruments. Accurate measurements facilitate timely adjustments to the high temp fan, which is crucial for preventing overheating and prolonging the lifespan of electronic components. Recent research underscores that the efficient operation of chillers depends on precise measurement and monitoring of temperature, pressure, and flow.

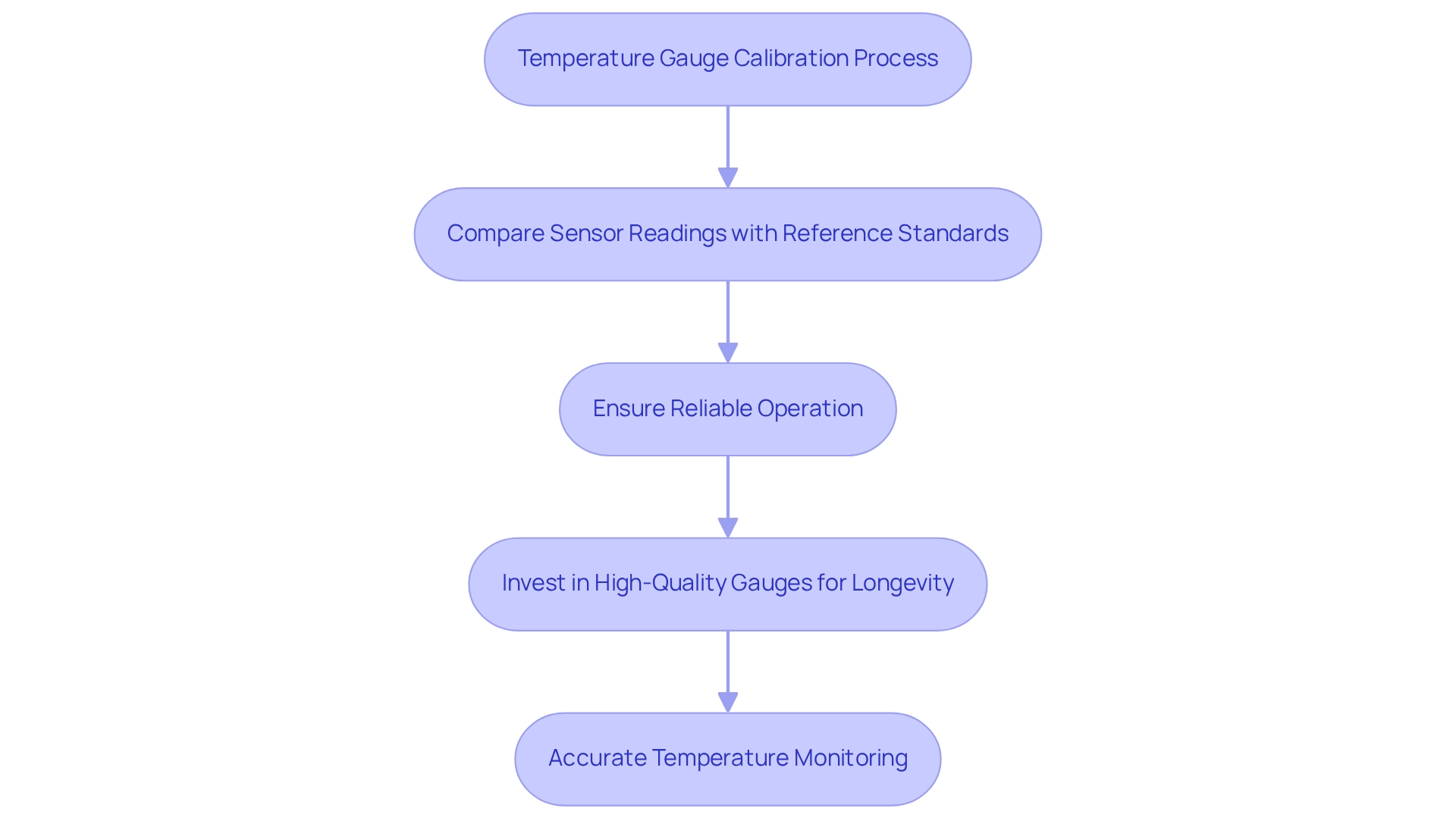

As outlined in a standard calibration process:

- Comparing sensor readings with reference standards is essential for ensuring reliable operation.

As Dan Holohan aptly stated, “You’re not rich enough to afford cheap stuff,” highlighting the necessity of investing in high-quality temperature gauges. Moreover, Don Clark, who brings over 24 years of experience in , emphasizes that effective thermal performance monitoring has led to significant enhancements in system reliability and longevity. This reinforces the critical role of temperature gauges in modern electronic temperature regulation solutions.

Challenges in High-Temperature Cooling: Solutions for Electronics Engineers

High-temperature refrigeration presents considerable challenges for electronics engineers, including material degradation, reduced efficiency of the high temp fan, and increased thermal stress on components. These factors can lead to a decline in the performance and reliability of electronic devices. To address these challenges, engineers can implement several effective strategies:

- Material Selection: Selecting high-temperature-rated materials is essential. These materials are designed to withstand extreme conditions, thereby reducing degradation rates and extending the lifespan of components.

- Advanced Thermal Technologies: The adoption of can significantly improve thermal management. While the initial investment may exceed that of traditional air systems, the long-term benefits include enhanced efficiency and sustainability, particularly in data center environments. This investment is justified by the potential for improved efficiency and lower operational costs over time, especially with the implementation of a high temp fan for optimizing airflow, which is critical for regulating component temperatures. Engineers should design structures that facilitate efficient airflow, thereby minimizing hotspots and enhancing .

Recent metrics for evaluating efficiency in liquid refrigeration systems, such as Coefficient of Performance (CoP) and Power Usage Effectiveness (PUE), provide valuable insights for data center operators regarding the temperature control achieved per unit of energy consumed. These metrics assist engineers in refining their temperature regulation strategies.

Expert insights highlight that maintaining components at optimal temperatures not only boosts efficiency but also extends their lifespan. By addressing these challenges, engineers can significantly enhance the reliability and functionality of their electronic devices in demanding thermal environments.

Power Management Strategies: Enhancing Cooling Efficiency in Electronics

Effective power management strategies are essential for enhancing temperature control efficiency in electronic systems. By focusing on reducing power consumption and minimizing heat generation, engineers can significantly improve the effectiveness of temperature regulation solutions. Techniques such as dynamic voltage scaling and load balancing are crucial in managing thermal output. For instance, dynamic voltage scaling adjusts the voltage supplied to components based on their workload, which not only conserves energy but also reduces heat production, thereby enhancing temperature management.

Moreover, integrating power management with temperature regulation systems enables real-time adjustments based on current thermal conditions. This synergy ensures that temperature regulation resources are utilized efficiently, adapting to varying demands. Gagner-Toomey Associates offers a comprehensive range of high temp fans and blowers, optimized for effectiveness and efficiency, which are vital for maintaining adequate temperature control in electronic applications. Data indicates that refrigeration units must maintain 10 to 15% greater supply airflow than demand airflow, underscoring the importance of precise power management in achieving optimal temperature regulation.

Real-world applications illustrate the effectiveness of these strategies. For example, distributing load across multiple temperature control units can lead to significant energy savings while ensuring adequate temperature regulation. A notable case is Infineon’s , showcasing how innovative power management can enhance thermal efficiency by substantially reducing power loss and improving overall system performance.

As Gordon Johnson, Senior CFD Manager, states, “Discover how to reduce data center energy expenses with .” This perspective highlights the critical role of efficient temperature regulation strategies within power management. As the electronics sector evolves, it remains imperative for engineers to stay informed about the latest power management techniques and their impact on temperature regulation, striving to develop innovative and sustainable solutions. Furthermore, Gagner-Toomey Associates’ advanced solenoid and rotary boost pumps exemplify the integration of cutting-edge features for fluid management, enhancing the overall performance of refrigeration systems.

Integrating Cooling Technologies: Best Practices for Electronics Engineers

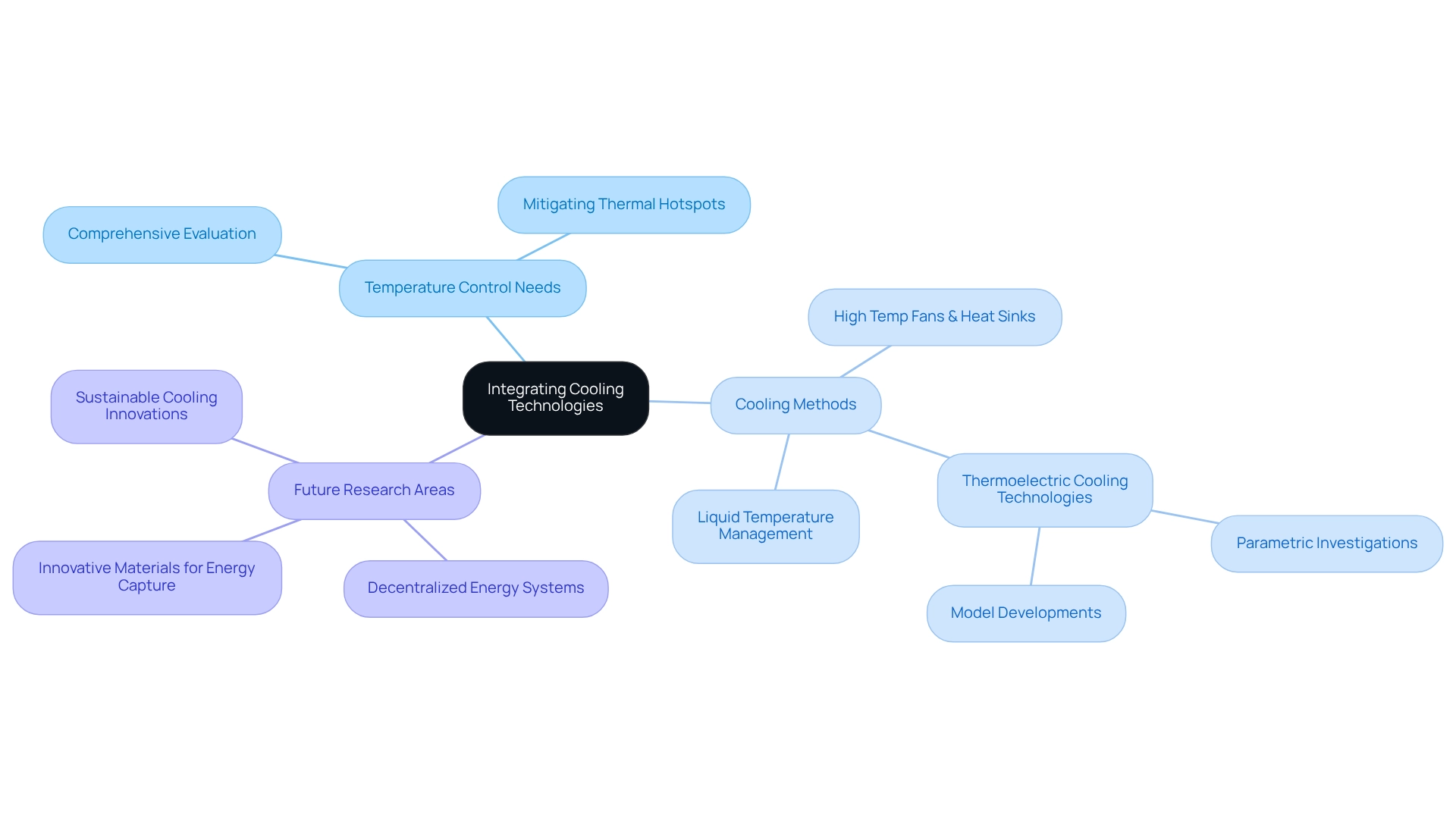

Incorporating various temperature control technologies is essential for enhancing thermal management in electronic devices. The optimal methods begin with a comprehensive evaluation of the specific temperature control needs for each application. Engineers must select complementary temperature regulation methods, such as:

- Utilizing a high temp fan paired with heat sinks

- Employing liquid temperature management alternatives

to maximize efficiency. Proper airflow management is critical; this includes strategically positioning components to mitigate thermal hotspots and enhance heat dissipation. Recent advancements in microfluidics have demonstrated the potential to surpass conventional temperature regulation techniques, with research indicating that these approaches can achieve higher efficiency than existing solutions. Furthermore, Emmanuel Augustine Etukudoh emphasizes the ongoing shift towards decentralized energy frameworks and the exploration of innovative materials for energy capture and storage as vital areas for future research. By adhering to these best practices, engineers can formulate effective temperature management strategies that significantly enhance the performance and reliability of electronic systems. Real-world examples illustrate that a combination of temperature control technologies not only meets the escalating demands of the industry but also paves the way for future advancements in electronic temperature management. Additionally, advancements in thermoelectric cooling technologies, as highlighted in recent case studies, underscore their applicability and potential improvements for electronic thermal management, reinforcing the necessity of integrating .

Conclusion

Innovative cooling solutions are indispensable for the performance and longevity of electronic components, particularly in high-temperature environments. Gagner-Toomey Associates distinguishes itself in the marketplace with a comprehensive array of advanced thermal management technologies, including high-temperature axial fans and centrifugal blowers. These innovations are essential for satisfying the stringent demands of industries such as data centers and manufacturing, where effective heat management is paramount.

The increasing complexity of electronic systems necessitates a proactive approach to cooling, integrating diverse technologies to optimize thermal management. By implementing strategies like dynamic voltage scaling and efficient airflow management, engineers can markedly enhance cooling efficiency, ensuring reliable operation while extending the lifespan of critical components. The trend towards sustainable solutions is also apparent, as companies increasingly emphasize energy-efficient cooling options that adhere to rigorous environmental standards.

As the market for advanced cooling technologies continues to grow, propelled by the demand for enhanced performance and sustainability, Gagner-Toomey Associates remains steadfast in its commitment to innovation. Their products not only tackle current challenges but also anticipate future requirements within the electronics landscape. By adopting best practices in cooling technology integration, engineers can lay the groundwork for improved reliability and performance in electronic systems, ultimately contributing to a more efficient and sustainable future.

Frequently Asked Questions

What type of solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates delivers innovative temperature regulation solutions designed for high temp fan applications in the electronics sector, featuring advanced thermal management technologies.

What products are included in Gagner-Toomey’s portfolio?

Their portfolio includes a range of DC input tube axial fans and centrifugal blowers essential for ensuring the reliability and performance of electronic components under extreme conditions.

How does Gagner-Toomey ensure compliance with industry standards?

Gagner-Toomey partners with leading manufacturers to equip engineers with thermal management solutions that comply with stringent industry standards, including IATF 16969 certification and automotive compliance.

Why is temperature regulation important in data centers?

Uniform temperature regulation is crucial in data centers to maintain the efficiency and performance of electronic systems, especially as the demand for effective temperature control technologies increases.

What is the projected market trend for refrigeration technologies in the electronics sector?

The market for advanced refrigeration technologies within the electronics sector is expected to experience substantial growth by 2025, driven by the increasing complexity of electronic systems and the need for effective thermal management.

What are the benefits of Gagner-Toomey’s high temp fan systems?

Gagner-Toomey’s high temp fan systems enhance the efficiency and longevity of essential electronic components, making them integral to high-temperature refrigeration applications.

How do Gagner-Toomey’s products contribute to sustainability?

Their innovative designs aim to achieve zero emissions discharge, aligning with the growing emphasis on sustainable temperature regulation solutions.

What feedback do engineers provide about Gagner-Toomey’s high temp fans?

Engineers commend Gagner-Toomey’s high temp fans for their durability and reliability under challenging conditions, making them a preferred choice for dependable temperature regulation.

What specific applications benefit from Rotron fan technology?

Rotron fans are designed to perform optimally across varying altitudes, making them suitable for applications in aerospace, telecommunications, and other sectors where equipment operates at high altitudes.

Why is selecting the appropriate fan critical for performance?

Choosing the right fan is essential for achieving optimal temperature regulation, as it must consider environmental factors such as altitude, temperature, and air density to ensure steady airflow and efficiency.