Overview

High pressure fans are pivotal in the realm of electronics cooling, offering substantial advantages such as:

- Enhanced airflow

- Optimal static pressure

- Energy efficiency

- Durability

- Cost-effectiveness

These fans play a crucial role in thermal management by effectively dissipating heat, which in turn reduces operational costs and ensures reliable performance in demanding environments. Thus, they are indispensable for contemporary electronic systems, underscoring their importance in maintaining optimal functionality and longevity.

Introduction

In the rapidly evolving landscape of electronics, effective thermal management stands as a critical factor in ensuring optimal performance and longevity of devices. As technology advances, the demand for innovative cooling solutions has surged. Companies like Gagner-Toomey Associates are at the forefront, providing high-performance cooling systems specifically tailored for the electronics industry. Their diverse portfolio, which includes high-pressure fans and advanced thermal management products, positions Gagner-Toomey to tackle the complex challenges engineers face today.

This article explores the multifaceted benefits of high-pressure fans, examining their essential role in:

- Enhancing airflow

- Ensuring durability

- Achieving energy efficiency

All while underscoring their significance in a market projected to exceed $11 billion by 2031.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates stands at the forefront of innovative temperature regulation solutions tailored for the electronics industry. By representing a diverse array of manufacturers, including leaders in high-performance thermal technologies, the company guarantees that engineers have access to state-of-the-art products designed to effectively tackle complex thermal management challenges.

The global market for is projected to reach $11,653.3 million by 2031, underscoring the growing demand for effective refrigeration methods. The integration of high pressure fans is essential for improving the efficiency and reliability of these systems, establishing Gagner-Toomey as a trusted partner for engineers seeking optimal performance in their designs.

With exclusive sales coverage in Northern California and Nevada, Gagner-Toomey Associates is dedicated to fostering growth and innovation within the industry. The company takes pride in delivering exceptional customer support, ensuring clients receive the assistance they require.

Recent partnerships, such as Gagner-Toomey Associates being selected as the sales representative for Raltron, further emphasize their commitment to enhancing customer interaction and promoting advanced temperature control solutions.

Furthermore, the market for electronics thermal management is segmented by hardware, software, services, cooling techniques, and end-users, offering a comprehensive overview of the landscape in which Gagner-Toomey operates.

Enhanced Airflow: Maximizing Cooling Efficiency with High Pressure Fans

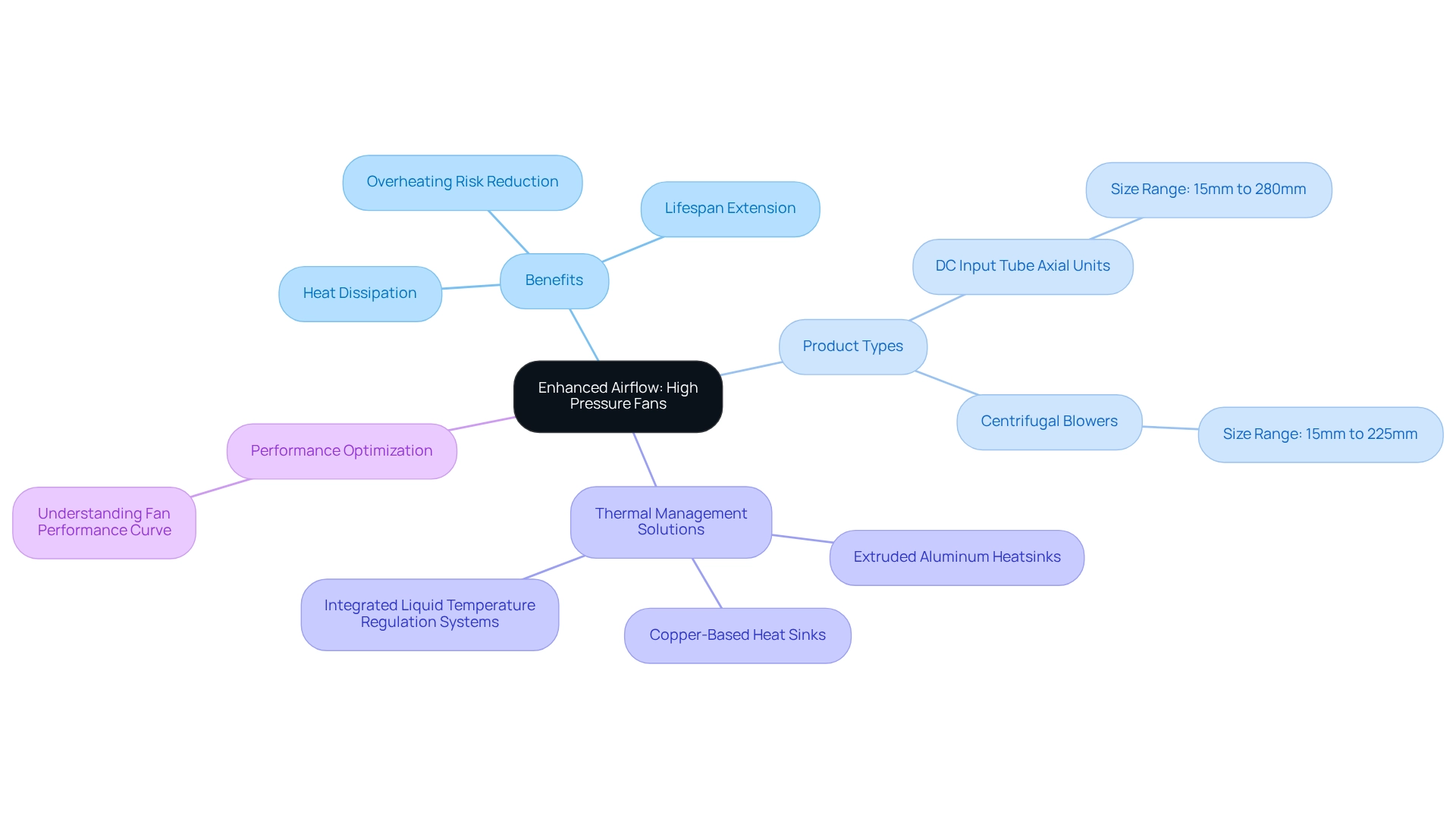

High pressure fans are engineered to produce substantial airflow, which is a critical factor in managing temperatures within electronic devices. By effectively directing air through confined spaces and around essential components, these devices promote optimal heat dissipation. This enhanced airflow not only reduces the risk of overheating but also prolongs the lifespan and reliability of electronic systems.

As we approach 2025, the benefits of high pressure fans for thermal regulation are increasingly recognized, empowering engineers to achieve exceptional temperature control in their designs. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a comprehensive range of high pressure fans and air circulators optimized for performance, efficiency, and low noise. Their innovative temperature regulation solutions are indispensable across various applications, particularly in electronics temperature management, where typical airflow rates can surpass those of conventional devices, leading to improved operational efficiency.

For instance, their DC input Tube Axial units vary from 15mm to 280mm, while Centrifugal Blowers are available in sizes from 15mm to 225mm, meticulously designed to meet the stringent demands of modern electronic devices.

Furthermore, Gagner-Toomey provides an array of thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid temperature regulation systems. Industry specialists have noted that the integration of high pressure fans significantly enhances thermal management, ensuring that electronic systems operate reliably under challenging conditions. Moreover, understanding —illustrating the aerodynamic characteristics of a fan—is crucial for optimizing their application in electronics temperature regulation.

Optimal Static Pressure: Ensuring Consistent Performance in Electronics Cooling

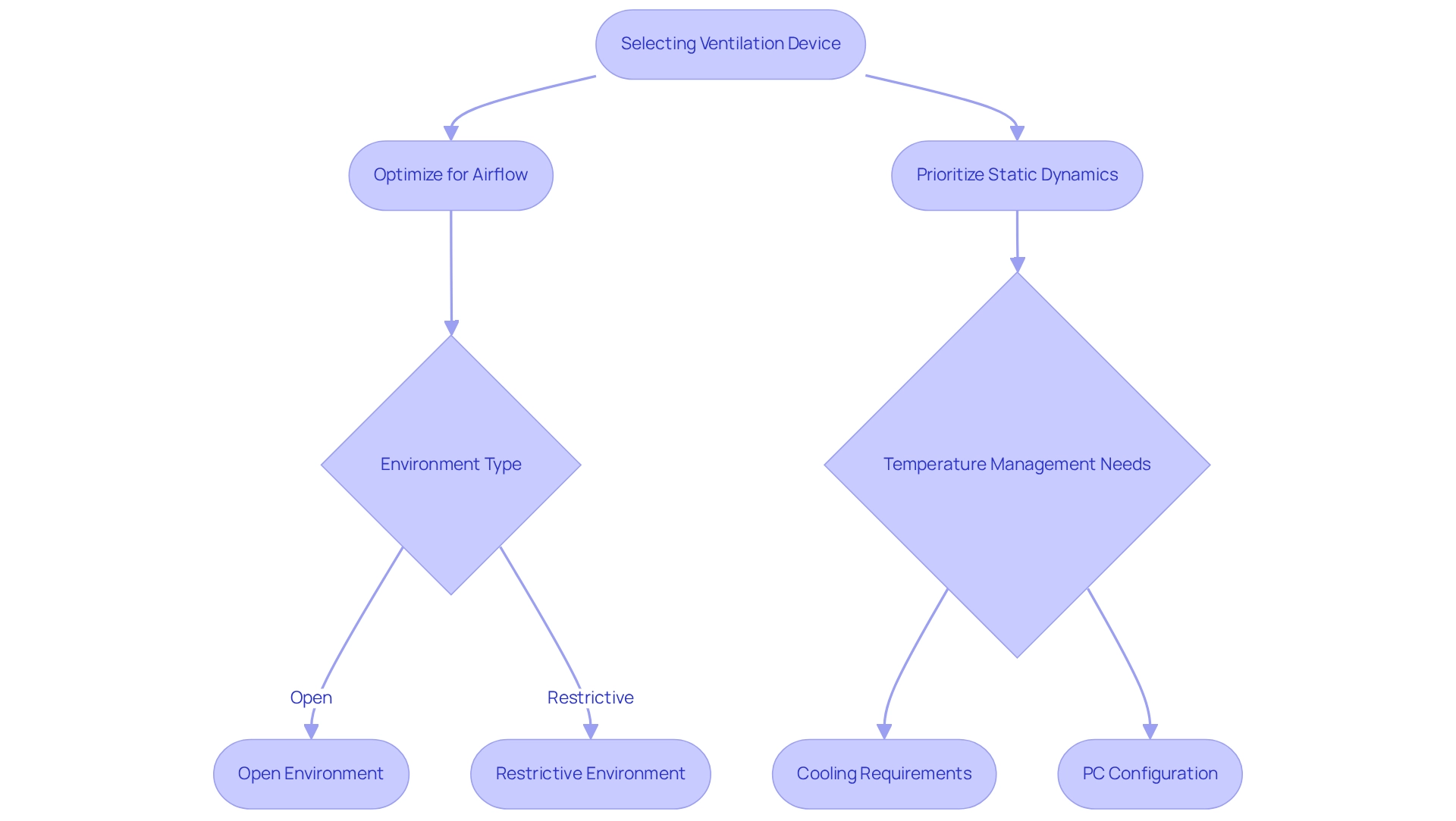

Static force plays a crucial role in the efficiency of ventilation devices, particularly in scenarios where airflow faces limitations. High pressure fans are specifically engineered as high output blowers to generate the necessary static force to navigate around barriers such as filters and heat sinks. This capability is essential for ensuring that air is efficiently directed through these components, thereby maintaining consistent temperature regulation. By selecting devices with optimal static ratings, engineers can significantly enhance the reliability of their thermal management systems, ensuring that electronic equipment remains within safe operating temperatures.

In 2025, the significance of static force in refrigeration applications cannot be overstated. Recent discussions among industry specialists emphasize that the performance of ventilation devices can vary significantly based on their design focus—some are optimized for airflow, while others prioritize static dynamics. Stahlmann, a member of the industry, asserts, “It does matter. Certain devices are enhanced for airflow, while others are designed for force.” This distinction is vital for engineers to consider when selecting devices for specific applications, particularly regarding their unique temperature management needs and PC setups.

Statistics indicate that static force is critical for ensuring in industrial ventilation systems. Case studies have demonstrated that while ventilation devices may perform well in open environments, they often struggle in restrictive settings. Conversely, high pressure fans maintain their effectiveness under stress, making them ideal for electronic heat dissipation applications. Real-world testing has shown that devices with higher static ratings consistently outperform their counterparts in challenging conditions, ensuring that electronic components remain adequately cooled.

As the electronics sector continues to advance, understanding the dynamics of static force will be essential for engineers aiming to improve temperature regulation solutions. By utilizing powerful blowers and thoroughly assessing their specific temperature control requirements, engineers can effectively address airflow limitations and enhance the overall efficiency of their systems.

Energy Efficiency: Reducing Power Consumption with High Pressure Fans

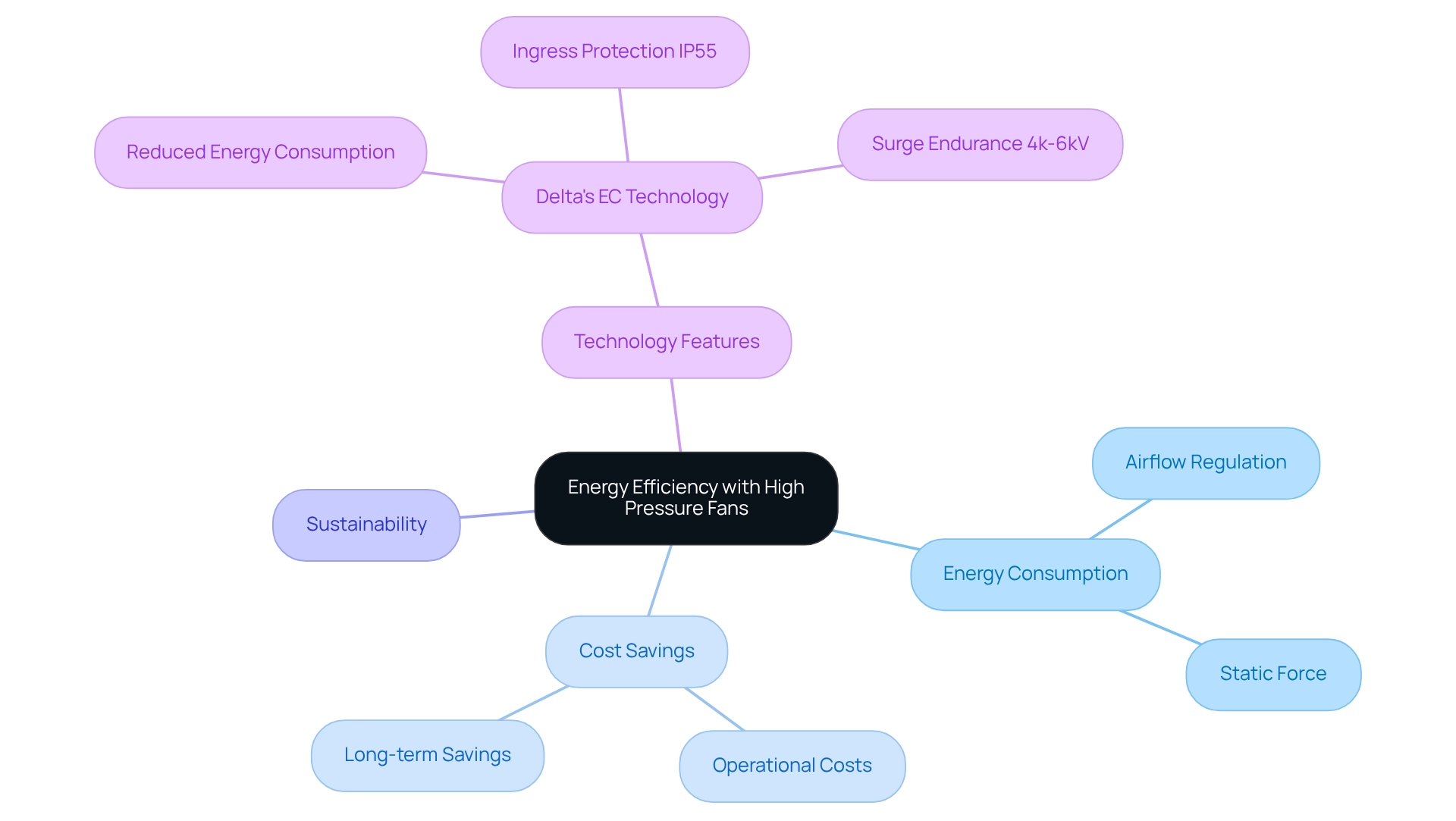

High capacity blowers are engineered for optimal efficiency, utilizing significantly less energy than conventional models while delivering enhanced cooling performance. By effectively regulating airflow and static force, these devices contribute to a reduced energy footprint for electronic systems. not only decreases operational costs but also aligns with a sustainable approach to electronics design.

In 2025, engineers can leverage high pressure fans to meet energy efficiency standards while ensuring robust thermal management. For instance, Delta’s EC technology has showcased a marked reduction in overall energy consumption, illustrating the potential for substantial savings in operational expenses. These devices achieve this by enhancing airflow while minimizing energy consumption, positioning them as superior alternatives to conventional models.

Additionally, with upgraded ingress protection to IP55 and surge endurance ratings between 4k-6kV, these blowers are well-suited for demanding environments, reinforcing their role in energy-efficient cooling solutions. The integration of high pressure fans in electronic devices not only boosts performance but also aligns with the growing emphasis on sustainability within the sector.

Durability: Long-Lasting Performance of High Pressure Fans in Harsh Environments

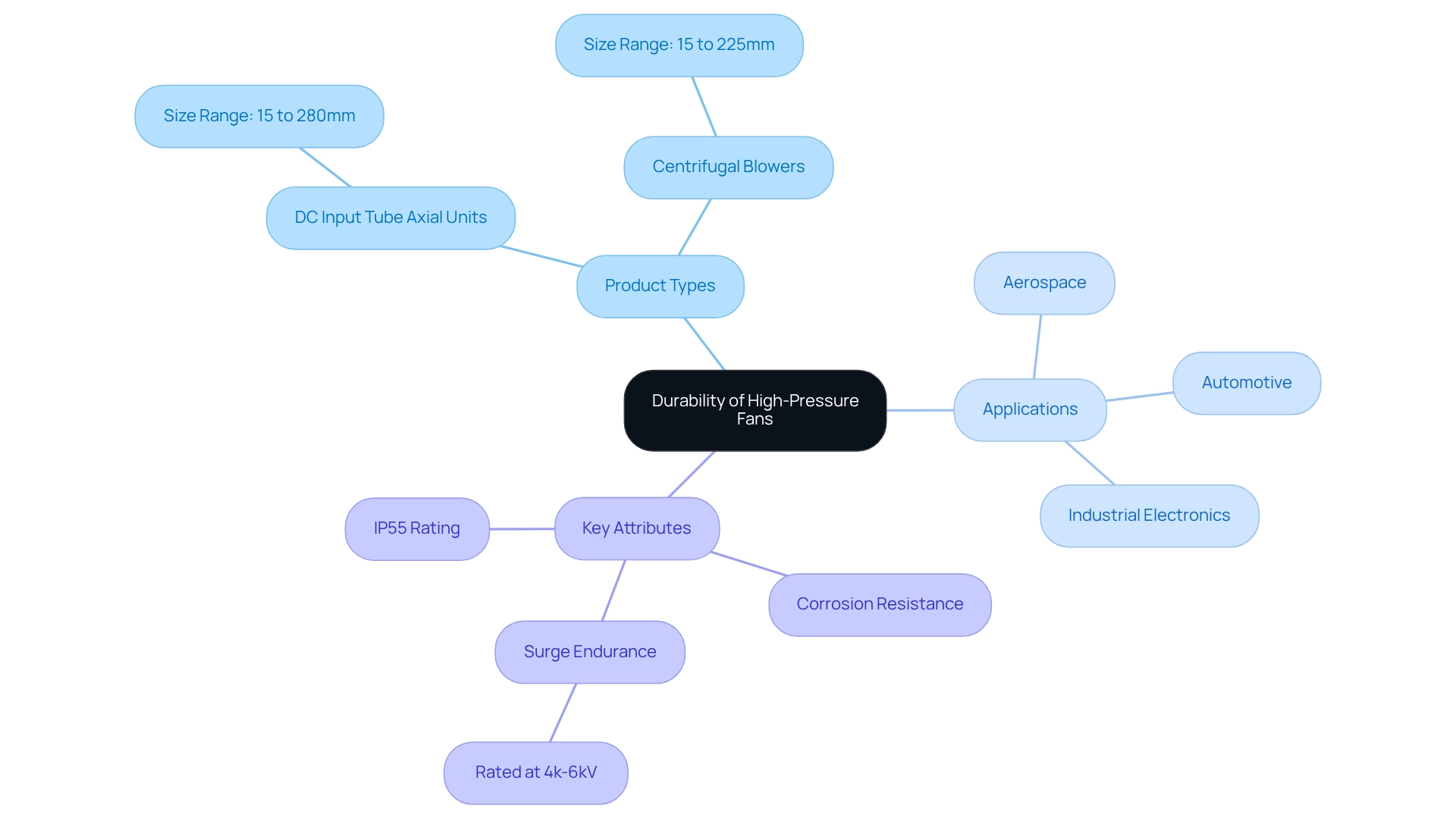

are specifically engineered to withstand demanding environments characterized by extreme temperatures, dust, and moisture. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, guarantees that their robust construction integrates corrosion-resistant materials, which significantly bolster longevity and reliability. This durability is especially critical in sectors such as aerospace, automotive, and industrial electronics, where a high pressure fan is essential for optimal equipment performance that is non-negotiable.

Gagner-Toomey Associates offers a comprehensive product range, including:

- DC input Tube Axial units ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

This versatility showcases their adaptability across diverse applications, facilitating seamless integration of the high pressure fan into both small-scale and large industrial air management systems. Their EC fans exemplify this durability, featuring a surge endurance rating of 4k-6kV, a lighter and more compact design, and enhanced protection with an IP55 rating, making them well-suited for rigorous operational demands.

Such attributes underscore the importance of effective thermal management in maintaining the reliability of electronic devices in challenging environments. As Martin Ochs, Director of Air Cooling Systems, articulates, “Lightweight, yet durable, the solution is engineered and constructed to provide access to all components for easier maintenance.” Moreover, the MW 800 OPMi is designed for simplified upkeep, empowering engineers to significantly reduce downtime and maintenance costs, thereby enhancing overall operational efficiency.

Versatility: High Pressure Fans for Diverse Electronics Cooling Needs

are essential components in a wide range of electronic heat management applications, demonstrating remarkable adaptability. They excel in regulating high-performance computing systems and managing thermal loads in consumer electronics, seamlessly adjusting to meet specific requirements. Their design facilitates effective airflow in restrictive spaces, making them particularly well-suited for compact configurations. With proven performance across various settings, engineers can confidently incorporate high pressure fans into their projects, assured of their ability to deliver consistent and reliable temperature management.

For example, axial propellers, which move air parallel to their axis, are known for their high volume flow rates and energy efficiency, rendering them ideal for diverse applications. Recent advancements in ventilation technology, such as Delta’s 3-phase brushless DC units, further exemplify the innovative solutions available for data centers and storage servers, highlighting the ongoing evolution in temperature management for electronics design.

Moreover, the versatility of high-capacity blowers is evidenced by the latest MP4 series of military vehicle engine ventilation devices, available in diameters of 305mm, 380mm, and 475mm, effectively addressing a variety of thermal management needs. Engineers are encouraged to engage with authorized distributors for support, ensuring access to optimal solutions for their cooling challenges.

Noise Reduction: Achieving Quiet Operation with High Pressure Fans

High capacity blowers are engineered for silent operation, making them ideal for environments where sound minimization is essential. Innovations in blade design and motor optimization significantly lower noise levels while maintaining airflow and static pressure. This capability is vital in applications such as:

- Medical devices

- Home electronics

- Office spaces

Where excessive noise can hinder functionality and user experience. By selecting high pressure fans that incorporate advanced noise-reduction technologies, engineers can enhance user comfort and ensure effective temperature regulation. A recent collaboration with Silent PC Review, where Mike Chin provided Panaflo computer units for evaluation, underscored the efficacy of particular models in minimizing noise emissions, yielding valuable insights into performance.

Furthermore, of 0.08 has proven to enhance noise reduction by optimizing airflow dynamics, underscoring the importance of design in achieving quiet operation. As noise reduction technologies evolve in 2025, including strategies such as speed regulation for cooling devices, the impact of noise from these systems on user comfort remains a crucial consideration for engineers in the electronics sector. These advancements directly improve user experience in sensitive environments, ensuring that noise levels are maintained at a minimum.

Improved Thermal Management: High Pressure Fans for Effective Heat Dissipation

High-capacity blowers, such as high pressure fans, are indispensable for optimizing thermal regulation in electronic systems, ensuring efficient heat dispersal from critical components. These devices, which include a high pressure fan, generate robust airflow and maintain optimal static pressure, which is vital for effectively dissipating heat from essential areas.

In high-performance applications, where excessive heat poses risks to component reliability and efficiency, the integration of high pressure fans is non-negotiable. By employing these devices, particularly a high pressure fan, engineers can markedly enhance their thermal management strategies, guaranteeing that electronic equipment operates reliably even in demanding conditions.

It is imperative that high pressure fan specifications align with of the project, as this alignment significantly impacts heat dissipation efficacy. Recent studies indicate that effective heat dissipation can prolong the lifespan and enhance the functionality of electronic components, positioning high pressure fans as a pivotal element in modern design methodologies.

Expert Yongjie Hu emphasizes that a synergistic approach, combining both experimental and theoretical methods in selecting ventilators, can yield superior thermal management outcomes. Furthermore, data reveal that the use of a high pressure fan can lead to a substantial reduction in operating temperatures, thereby bolstering the reliability of electronic components. Engineers are urged to factor in these considerations when designing systems to ensure optimal performance.

Cost-Effectiveness: High Pressure Fans as a Budget-Friendly Cooling Solution

High-capacity blowers present a compelling economical choice for electronics cooling, delivering exceptional value through their performance and longevity. While the initial investment may exceed that of conventional models, the long-term savings from reduced energy consumption and lower maintenance costs position them as a prudent option.

With access to a 3D printer, engineers can swiftly prototype and assess various design concepts, enhancing the efficiency and adaptability of high-pressure devices during the design process. The high pressure fan is particularly beneficial in situations involving significant heat generation and system resistance, where its efficiency can substantially bolster system reliability.

User testimonials regarding Hongguan’s inline devices reveal high satisfaction levels, with users commending their durability, efficiency, and effectiveness across diverse applications. This reliability translates into fewer failures and replacements, further amplifying cost savings over time.

As James emphasizes, regular maintenance—such as inspecting and cleaning and housing—is essential to prevent dust accumulation that can impair performance. For engineers, selecting high-capacity blowers not only aligns with performance goals but also considers financial implications, ensuring a sustainable approach to temperature control solutions.

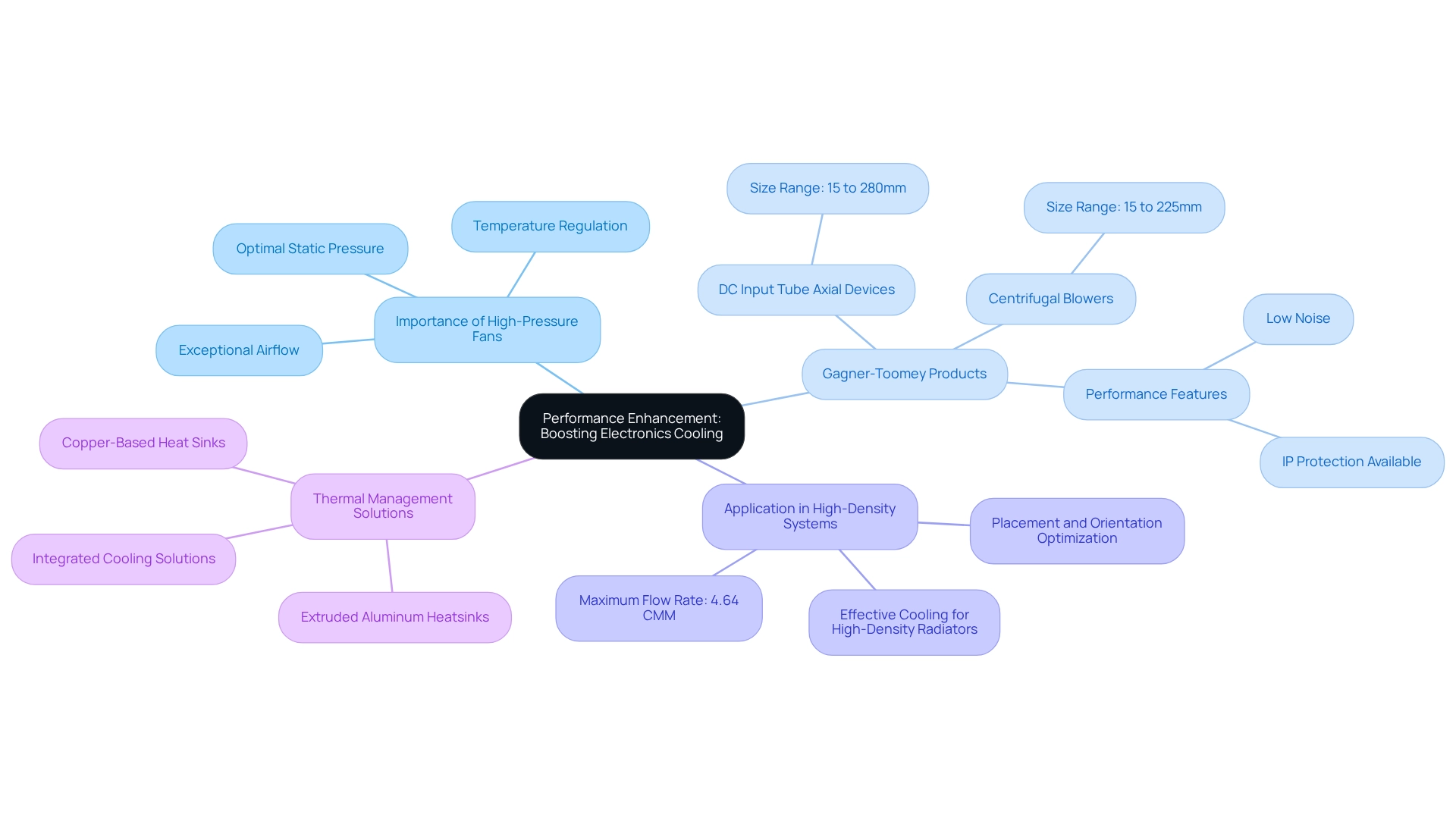

Performance Enhancement: Boosting Electronics Cooling with High Pressure Fans

Powerful blowers are crucial for enhancing the efficiency of electronic cooling systems. By delivering exceptional airflow and sustaining optimal static pressure, these devices adeptly manage heat, allowing electronic components to function at peak efficiency.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive array of DC input tube axial devices, ranging from 15 to 280mm, alongside centrifugal blowers from 15 to 225mm. These products are optimized for performance, efficiency, and low noise, with IP protection available in most models upon request.

This enhancement in performance is particularly vital in high-density applications, where effective temperature regulation is essential for ensuring stability and reliability. Engineers can harness the capabilities of high-capacity blowers, which achieve maximum flow rates of up to 4.64 CMM, to cool components effectively, even under challenging conditions with high-density radiators and heatsinks.

By integrating these units into their systems, engineers can significantly improve temperature regulation, ultimately extending the lifespan and reliability of electronic devices. To fully capitalize on the advantages of high pressure fans, engineers should optimize their placement and orientation within designs to guarantee optimal airflow dynamics.

Gagner-Toomey’s comprehensive portfolio also features innovative thermal management solutions, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

These further enhance the cooling capabilities for electronics.

Conclusion

The exploration of high-pressure fans underscores their indispensable role in electronics cooling, where effective thermal management is crucial. These fans not only enhance airflow but also ensure optimal heat dissipation, significantly contributing to the longevity and reliability of electronic devices. Their capacity to generate essential static pressure enables high-pressure fans to navigate obstacles efficiently, maintaining consistent cooling performance even in restrictive environments.

Furthermore, the energy efficiency of these fans aligns seamlessly with the industry’s increasing focus on sustainability. By reducing power consumption while maximizing cooling capabilities, high-pressure fans lower operational costs and support eco-friendly design practices. Their durability further enhances their appeal; robust construction allows them to withstand harsh conditions, making them suitable for diverse applications across various sectors.

As technology advances, the versatility and effectiveness of high-pressure fans will remain critical in addressing the evolving needs of engineers and designers. Their ability to deliver exceptional performance in compact configurations while minimizing noise and maintenance costs solidifies their status as a preferred choice in the electronics industry. Given these advantages, investing in high-pressure fans represents a strategic decision for those aiming to achieve optimal thermal management and operational efficiency in their electronic systems.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for its innovative temperature regulation solutions tailored for the electronics industry, representing a variety of manufacturers specializing in high-performance thermal technologies.

What is the projected market size for electronics thermal management solutions by 2031?

The global market for electronics thermal management solutions is projected to reach $11,653.3 million by 2031.

How do high pressure fans contribute to thermal management?

High pressure fans produce substantial airflow, which is crucial for managing temperatures in electronic devices. They effectively direct air through confined spaces, promoting optimal heat dissipation, reducing the risk of overheating, and prolonging the lifespan of electronic systems.

What are some examples of high pressure fans offered by Gagner-Toomey?

Gagner-Toomey offers a range of high pressure fans, including DC input Tube Axial units ranging from 15mm to 280mm and Centrifugal Blowers available from 15mm to 225mm.

What additional thermal management solutions does Gagner-Toomey provide?

Gagner-Toomey provides various thermal management solutions such as extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid temperature regulation systems.

Why is static force important in ventilation devices?

Static force is crucial for the efficiency of ventilation devices, especially in scenarios with airflow limitations. High pressure fans are designed to generate the necessary static force to navigate barriers like filters and heat sinks, ensuring efficient air direction and consistent temperature regulation.

What should engineers consider when selecting ventilation devices for specific applications?

Engineers should consider the design focus of ventilation devices—whether they are optimized for airflow or static dynamics—based on the unique temperature management needs of their applications.

How do high pressure fans perform in restrictive environments compared to other ventilation devices?

High pressure fans maintain their effectiveness under stress in restrictive settings, consistently outperforming other devices with lower static ratings, ensuring adequate cooling of electronic components.