Overview

Frameless BLDC motors stand out due to their compact design and high efficiency, making them exceptionally suitable for applications in robotics, medical devices, and consumer electronics. Their unique structure not only allows for significant space savings but also enhances performance, effectively addressing the increasing demand for innovative and efficient solutions in contemporary engineering. This evolution in motor technology exemplifies the drive towards more effective and space-conscious designs, paving the way for future advancements in various high-tech industries.

Introduction

Frameless BLDC motors are emerging as a pivotal innovation in electronics engineering, delivering unmatched efficiency and a compact design that meets the demands of contemporary technology. As industries increasingly pursue cutting-edge solutions for applications spanning robotics to medical devices, it becomes imperative for engineers to grasp the complexities of these motors to maintain a competitive edge.

However, what challenges and opportunities await in fully leveraging the capabilities of frameless BLDC technology? This article explores ten essential insights that illuminate the transformative influence of these motors on engineering practices and their crucial role in shaping the future of electronic devices.

Gagner-Toomey Associates: Pioneering Solutions for Frameless BLDC Motor Applications

Gagner-Toomey Associates is at the forefront of the borderless BLDC technology sector, delivering engineers cutting-edge solutions that address the evolving demands of contemporary electronics. Their diverse portfolio encompasses advanced cooling and power management technologies, which significantly enhance the performance and reliability of edge-less drives. By collaborating with leading producers, Gagner-Toomey provides engineers access to the latest technological advancements related to engines, including breakthroughs in miniaturization and energy efficiency. This commitment facilitates the creation of high-performance applications across various sectors, such as industrial automation, medical devices, and aerospace.

The frameless BLDC device market is projected to grow at a CAGR of 3.2% by 2034, driven by the increasing demand for compact and efficient solutions. Successful implementations of these devices in collaborative robots and medical robotics underscore their versatility and efficacy in contemporary electronics, paving the way for future innovations.

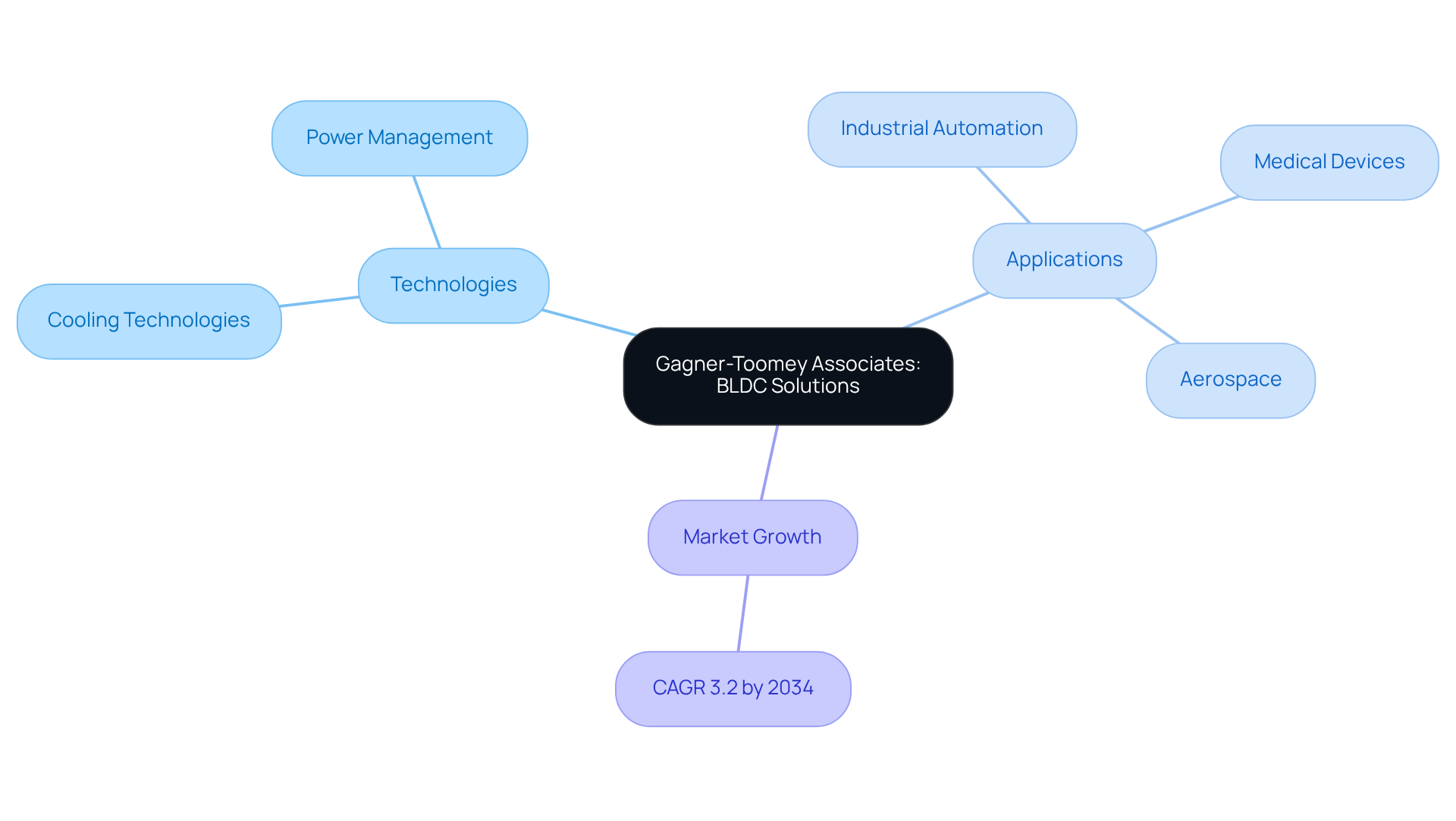

Frameless BLDC Motor Structure: Compact Design for Enhanced Performance

Frameless BLDC devices showcase an innovative design that consists solely of a rotor and stator, without a traditional casing. This unique configuration results in significant space savings, particularly advantageous in applications where size and weight are critical factors. The absence of a frame in the frameless BLDC design not only reduces the engine’s weight but also decreases inertia, facilitating faster response times and enhanced efficiency. Engineers can seamlessly integrate these devices into their systems, thereby boosting efficiency while preserving a compact footprint. The lightweight nature of borderless engines proves especially beneficial in robotics, enabling precise movements within constrained spaces, thus elevating overall system efficiency. Furthermore, the compact design promotes optimized thermal management and diminishes cogging, contributing to smoother motion and increased operational efficiency.

As Delta Line asserts, “These new sizes and configurations will allow us to offer even greater flexibility and customization options to our clients.”

As industries such as aerospace, medical devices, and automotive progressively adopt frameless BLDC systems, their role in advancing technology across these sectors becomes increasingly vital. Notably, borderless engines deliver high torque density, making them indispensable in specialized applications.

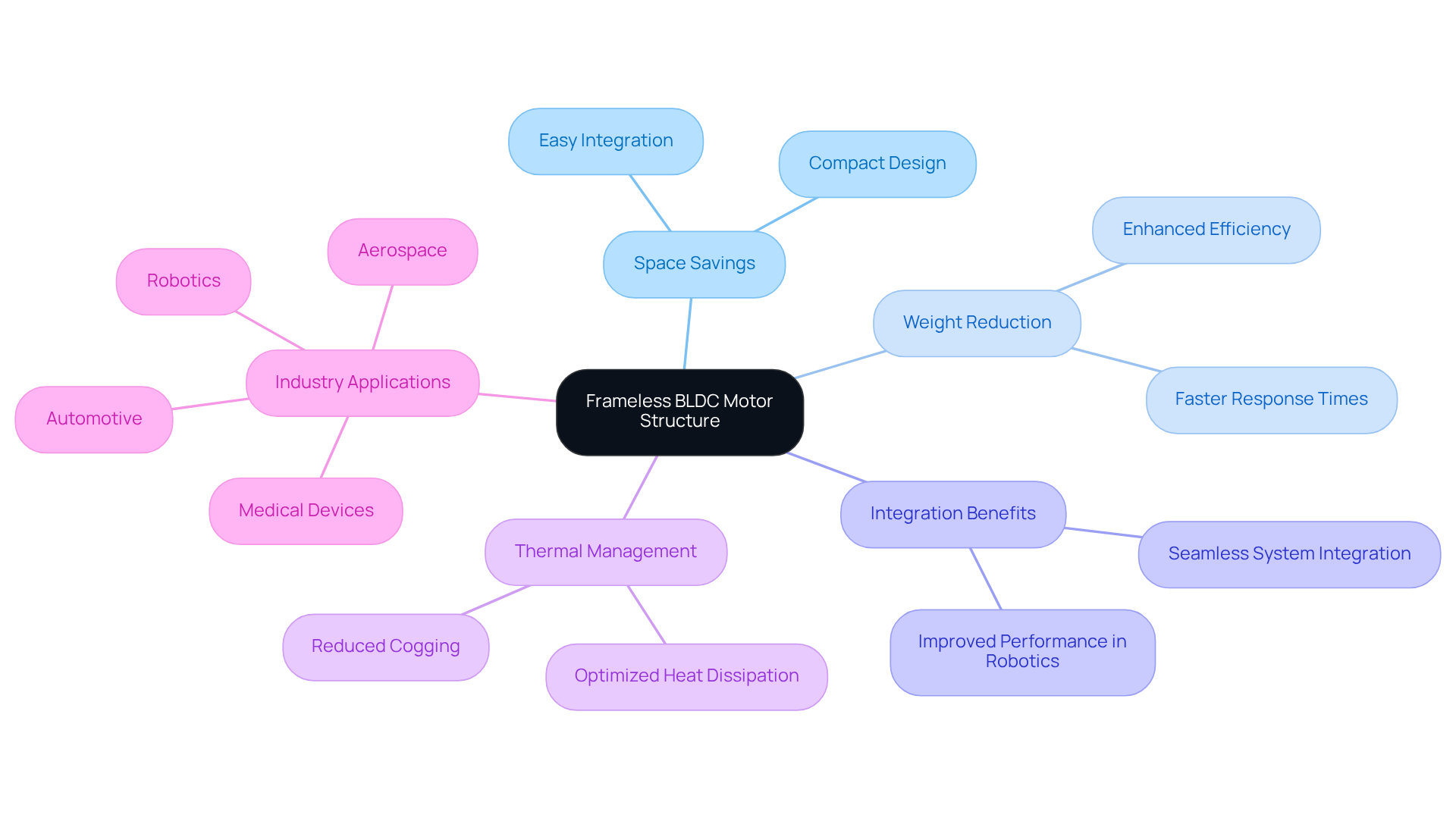

How Frameless BLDC Motors Work: Efficiency and Precision in Motion

Frameless BLDC devices operate on the principle of electromagnetic induction, where the interaction between the rotor’s permanent magnets and the stator’s coils in the frameless BLDC design generates motion. This innovative design eliminates the need for brushes, resulting in lower friction and heat generation, thus enhancing overall efficiency.

According to Mosrac Application Engineers, direct drive units are termed as such because the load connects directly with the device without any shaft, gearing, or pulley. This configuration minimizes backlash and enhances precision. Advanced electronic commutation methods facilitate precise control over the machine’s speed and torque, enabling smooth and accurate motion control.

This efficiency renders frameless BLDC machines suitable for high-performance applications in robotics, medical equipment, and automation. For instance, they are utilized in MRI scanners for silent operation and in robotic joints for precise positioning. The global market for frameless BLDC devices is projected to reach $3.26 billion by 2033, underscoring the growing significance of this technology across various sectors.

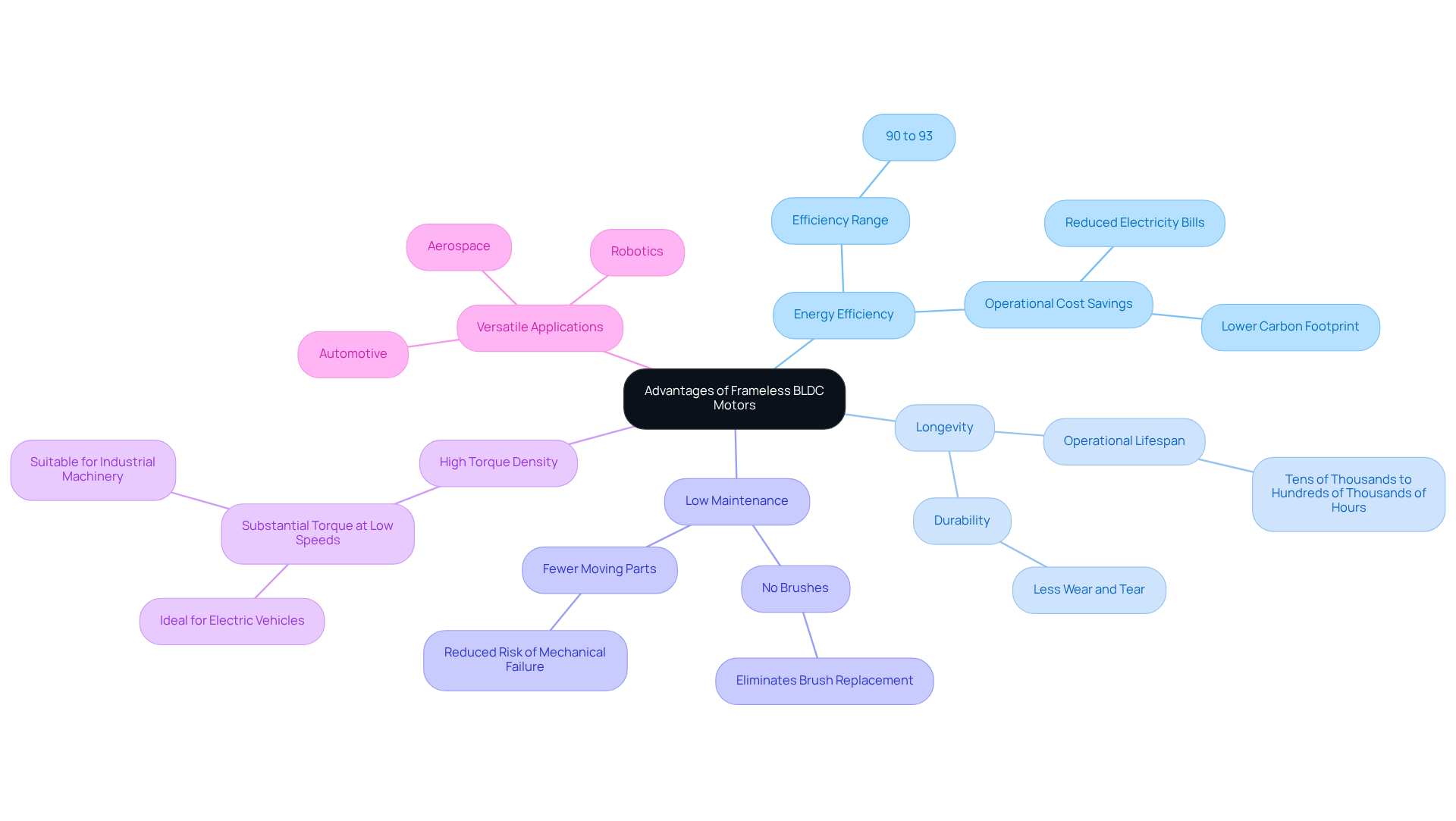

Advantages of Frameless BLDC Motors: Superior Performance and Flexibility

Frameless BLDC devices are distinguished by their exceptional energy efficiency, achieving efficiencies between 90% and 93%. This remarkable performance significantly reduces electricity consumption and operational costs. Such efficiency is particularly beneficial in sectors like robotics and aerospace, where precise control and reliability are critical. The compact design of these devices allows for seamless integration into diverse systems, enabling engineers to develop innovative solutions tailored to specific requirements.

Moreover, the absence of brushes in frameless BLDC devices not only enhances their longevity but also minimizes the need for maintenance. This leads to lower operational costs compared to conventional machines, which often necessitate regular brush replacements. Notably, borderless engines can operate for tens of thousands to hundreds of thousands of hours without significant performance decline, underscoring their cost-efficiency.

Another vital advantage of frameless BLDC is their high torque density, which makes them ideal for demanding applications. They provide substantial torque even at low speeds, a critical requirement for electric vehicles and industrial machinery. This capability guarantees robust performance while preserving efficiency across varying loads, thereby supporting sustainability objectives and reducing the overall carbon footprint. As industries increasingly adopt automation and advanced manufacturing techniques, the demand for these high-performance engines continues to grow.

Applications of Frameless BLDC Motors: From Robotics to Consumer Electronics

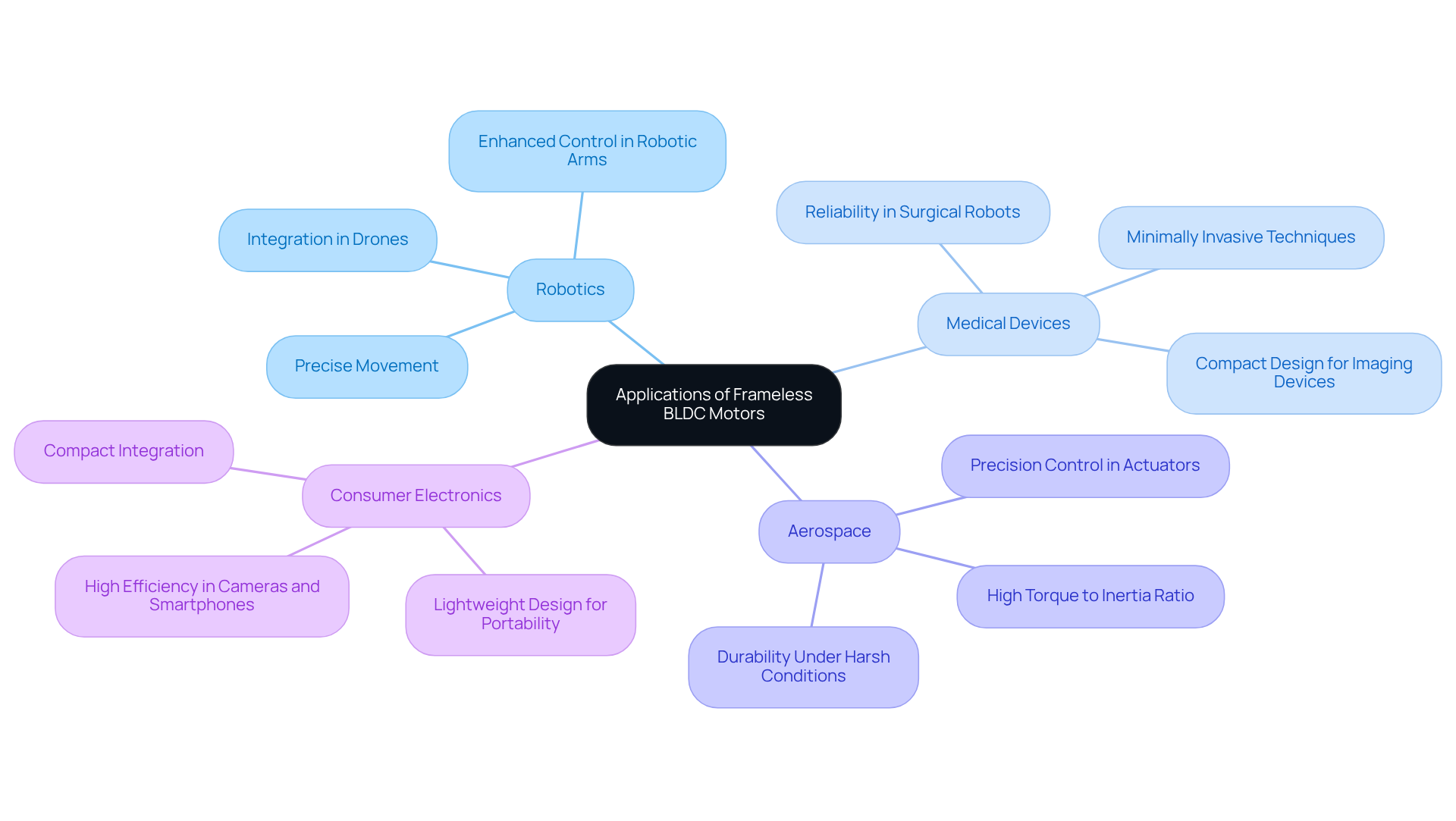

Frameless BLDC units exhibit remarkable versatility, finding applications across a broad spectrum of fields, including:

- Robotics

- Medical devices

- Aerospace

- Consumer electronics

In the realm of robotics, these devices enable precise movement and control in robotic arms and drones, significantly enhancing their operational capabilities. Within medical technology, frameless BLDC engines are essential for surgical robots and imaging devices, where reliability and accuracy are crucial for patient safety and operational effectiveness. Their compact design not only allows for seamless integration into medical devices but also meets the stringent demands of the industry, ensuring high functionality in space-constrained environments.

Notably, frameless BLDC engines operate efficiently in environments with elevated surrounding temperatures and are increasingly utilized in surgical robotics, contributing to the advancement of minimally invasive techniques and improving recovery times for patients. Additionally, their lightweight and efficient characteristics render them ideal for consumer electronics, such as cameras and smartphones, where performance is critical despite spatial limitations.

As the demand for frameless BLDC engines in medical devices continues to rise, their role in enhancing the functionality and reliability of sophisticated medical equipment becomes increasingly vital. Furthermore, frameless engines can be integrated into devices operating under challenging conditions without incurring significant financial burdens, underscoring their durability and versatility across numerous applications.

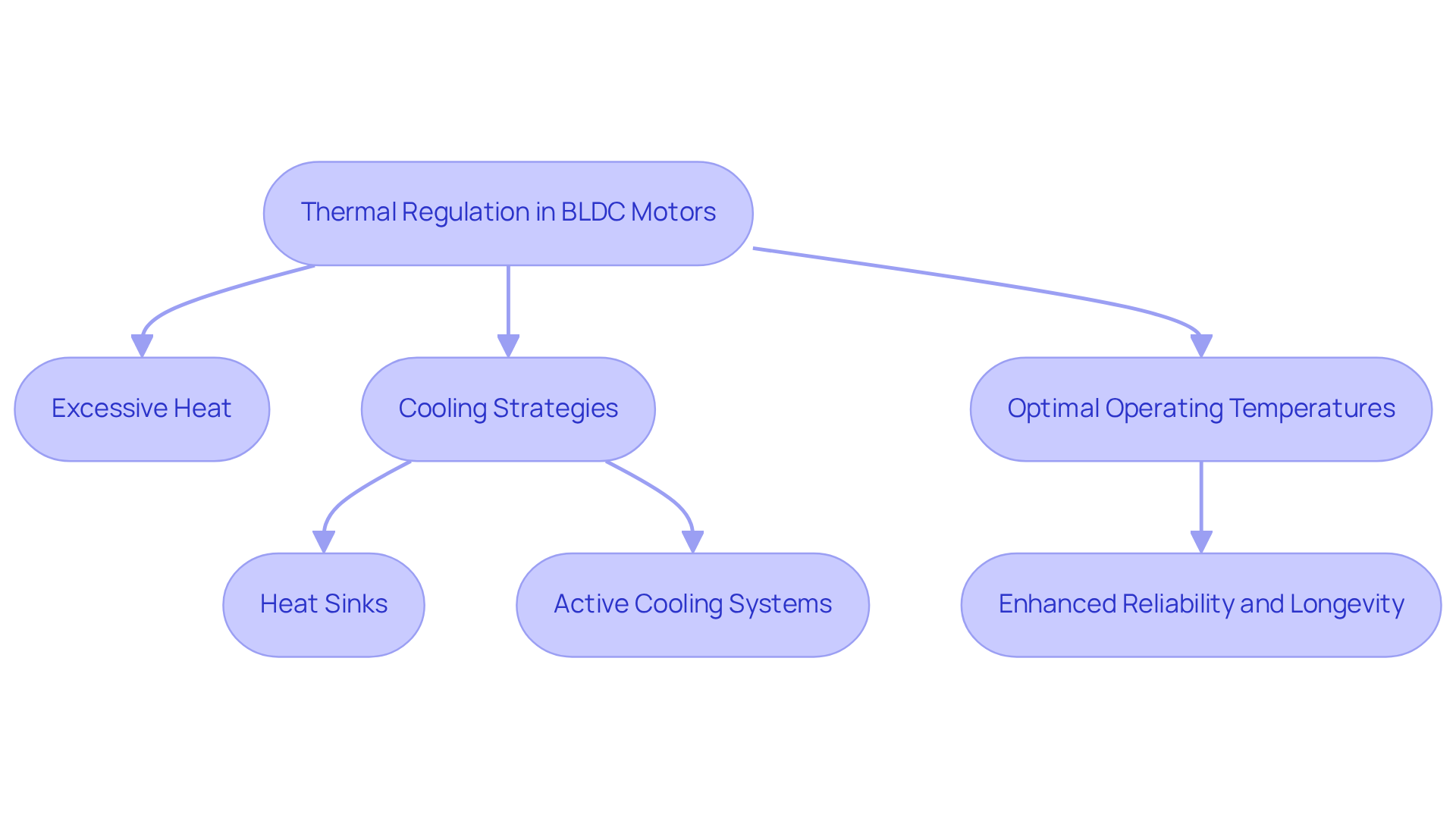

Thermal Management in Frameless BLDC Motors: Ensuring Reliability and Longevity

Thermal regulation stands as a critical component of borderless BLDC design; excessive heat can lead to a decline in efficiency and potential breakdowns. Engineers are tasked with implementing robust cooling strategies—such as heat sinks or active cooling systems—to effectively dissipate the heat generated during operation. The compact design of frameless BLDC devices facilitates the integration of innovative cooling solutions directly into the system. By maintaining optimal operating temperatures, engineers can significantly enhance the reliability and longevity of these devices, ensuring consistent functionality even in challenging environments.

Customized Solutions for Frameless BLDC Motors: Meeting Specific Engineering Needs

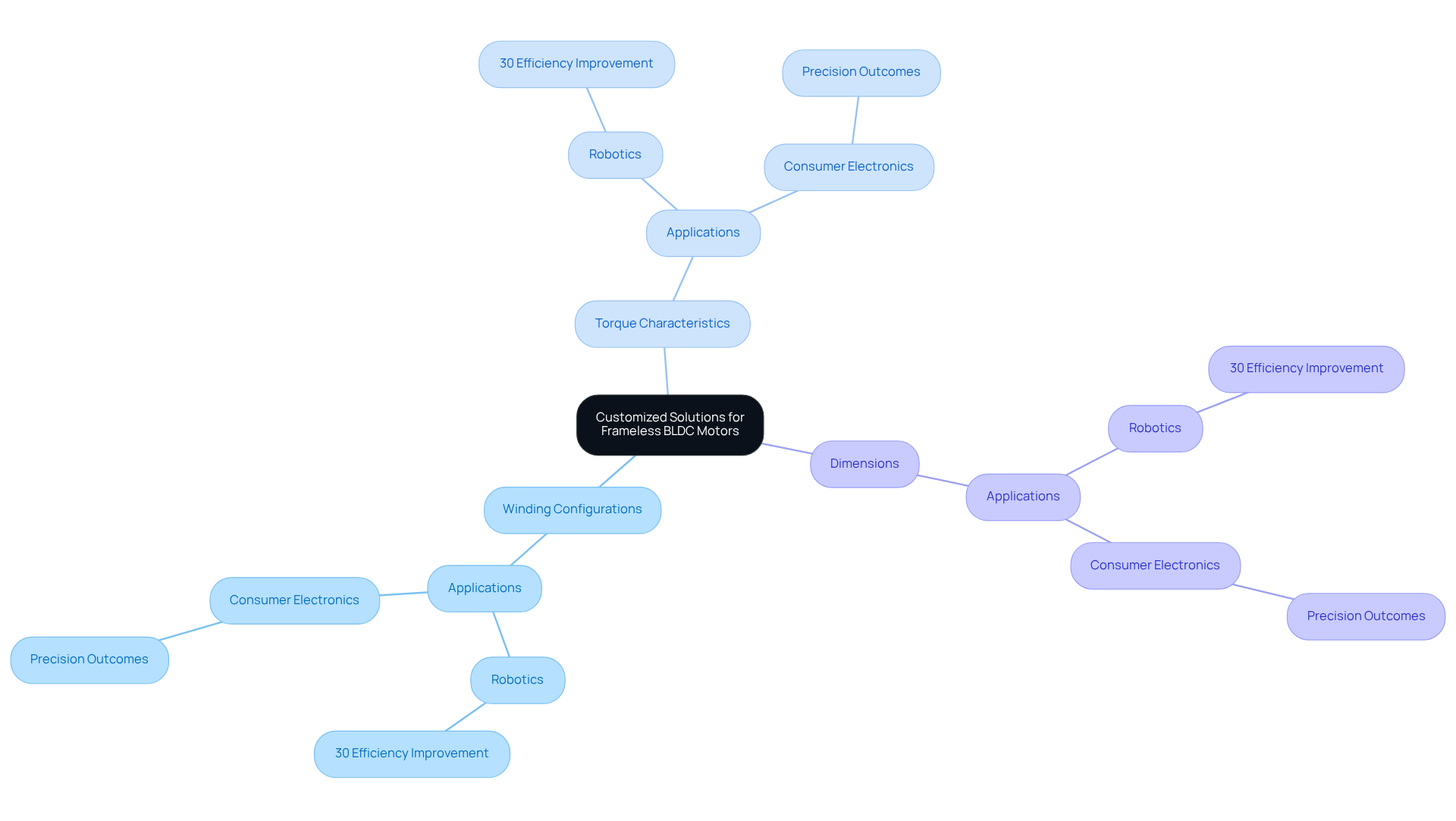

Frameless BLDC devices offer significant advantages through their customization options, which allow producers to adjust various parameters such as winding configurations, torque characteristics, and dimensions to meet specific engineering requirements. This tailored approach not only enhances effectiveness and efficiency but also facilitates seamless integration into diverse systems.

In specialized robotics applications, for instance, customized drives can lead to remarkable improvements in operational efficiency, with reports indicating performance enhancements of up to 30% when drives are optimized for particular tasks. Likewise, unique designs in consumer electronics benefit from this flexibility, empowering engineers to achieve precise outcomes that align with their innovative aspirations.

Thus, the ability to customize frameless BLDC devices stands as a crucial advantage in advancing engineering solutions across multiple sectors.

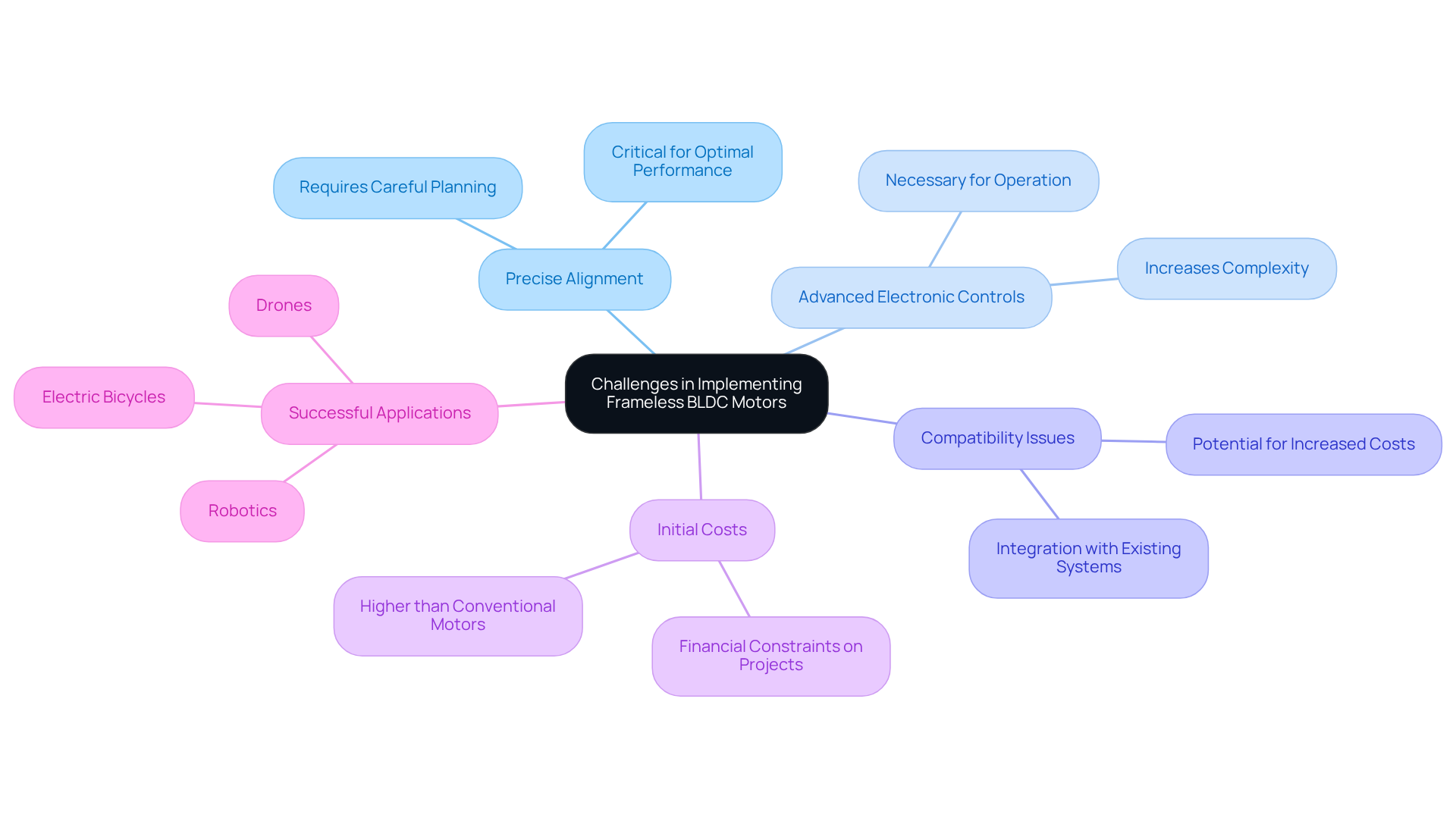

Challenges in Implementing Frameless BLDC Motors: Key Considerations for Engineers

Frameless BLDC devices offer a range of benefits, but they also introduce specific challenges that engineers must navigate during the execution of frameless BLDC technology. A critical consideration is the need for precise alignment during installation, which is essential for achieving optimal performance. The absence of a housing, shaft, and bearings in frameless BLDC systems necessitates advanced electronic control systems to manage their operation efficiently. When integrating borderless engines into existing systems, engineers may encounter compatibility issues, underscoring the importance of meticulous planning to ensure seamless integration with other components.

Moreover, the initial costs associated with borderless engines typically exceed those of conventional engines, potentially imposing financial constraints on projects. Engineers are advised to conduct comprehensive assessments and strategic planning to address these challenges, thereby facilitating a smooth integration process. Successful applications of frameless BLDC devices can be found in specialized sectors such as robotics, drones, and electric bicycles, where their compact design and high torque density provide significant advantages. By comprehensively understanding these factors, engineers can make informed decisions that enhance the effectiveness and efficiency of their projects.

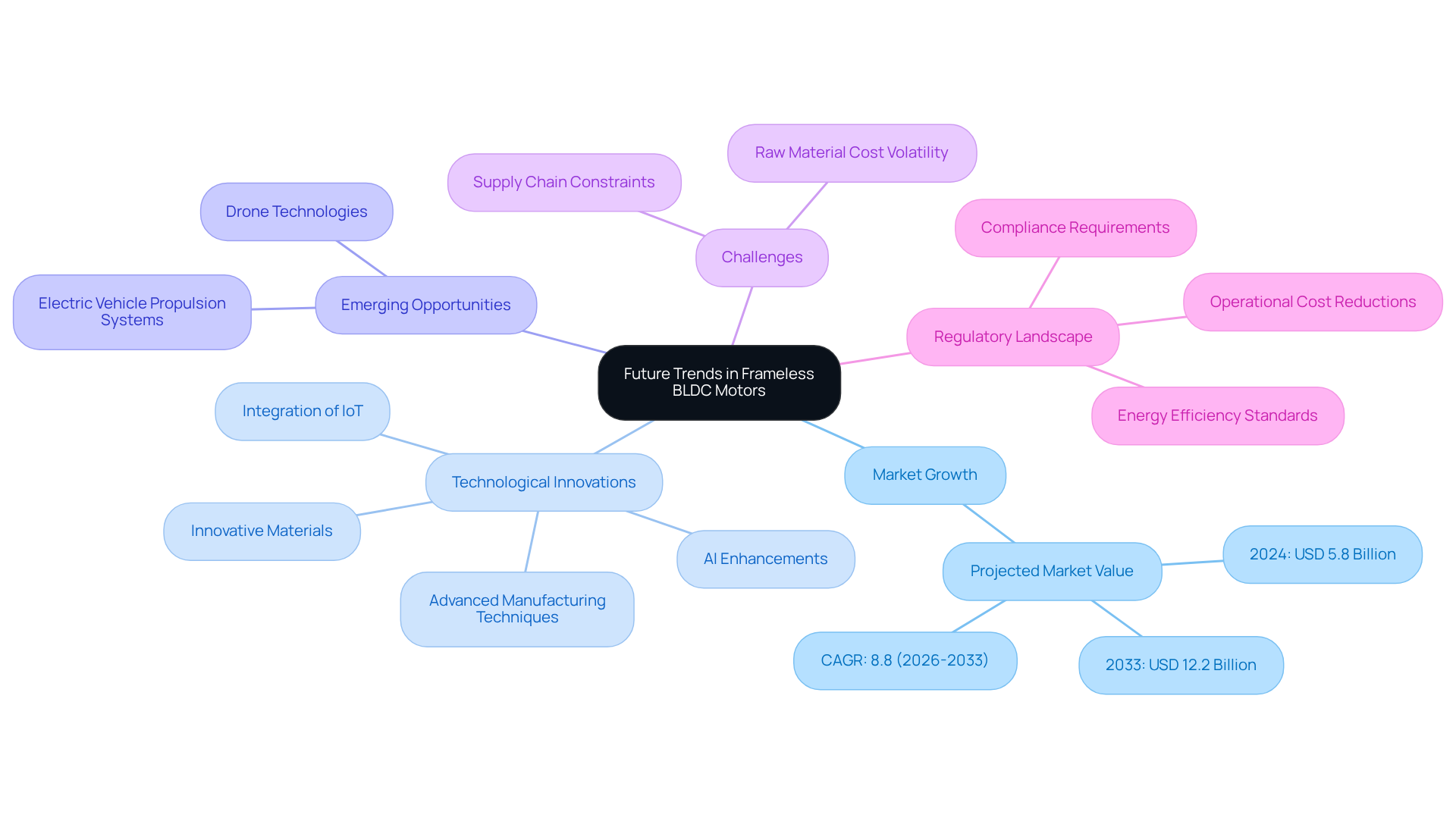

Future Trends in Frameless BLDC Motors: Innovations Shaping Electronics Engineering

The borderless brushless direct current device market is poised for significant growth, with an expected market value of USD 5.8 billion in 2024, projected to reach USD 12.2 billion by 2033, reflecting a CAGR of 8.8% from 2026 to 2033. This expansion is fueled by technological advancements and a rising demand for compact, efficient solutions.

Future trends indicate a shift towards the integration of intelligent technologies, including IoT and AI, which will enhance performance and enable real-time monitoring and control. Furthermore, ongoing research into innovative materials and manufacturing techniques is set to improve efficiency and lower costs.

Emerging opportunities in electric vehicle propulsion systems and drone technologies underscore the relevance of these innovations in current industry trends. However, the market is confronted with challenges such as supply chain constraints and raw material cost volatility, which can influence pricing strategies and market penetration.

Additionally, the regulatory landscape is impacting the adoption of frameless bldc devices, compelling OEMs to integrate advanced solutions to ensure compliance and achieve operational cost reductions. As these innovations unfold, engineers will gain access to increasingly powerful and versatile drive solutions, further expanding the scope of their applications.

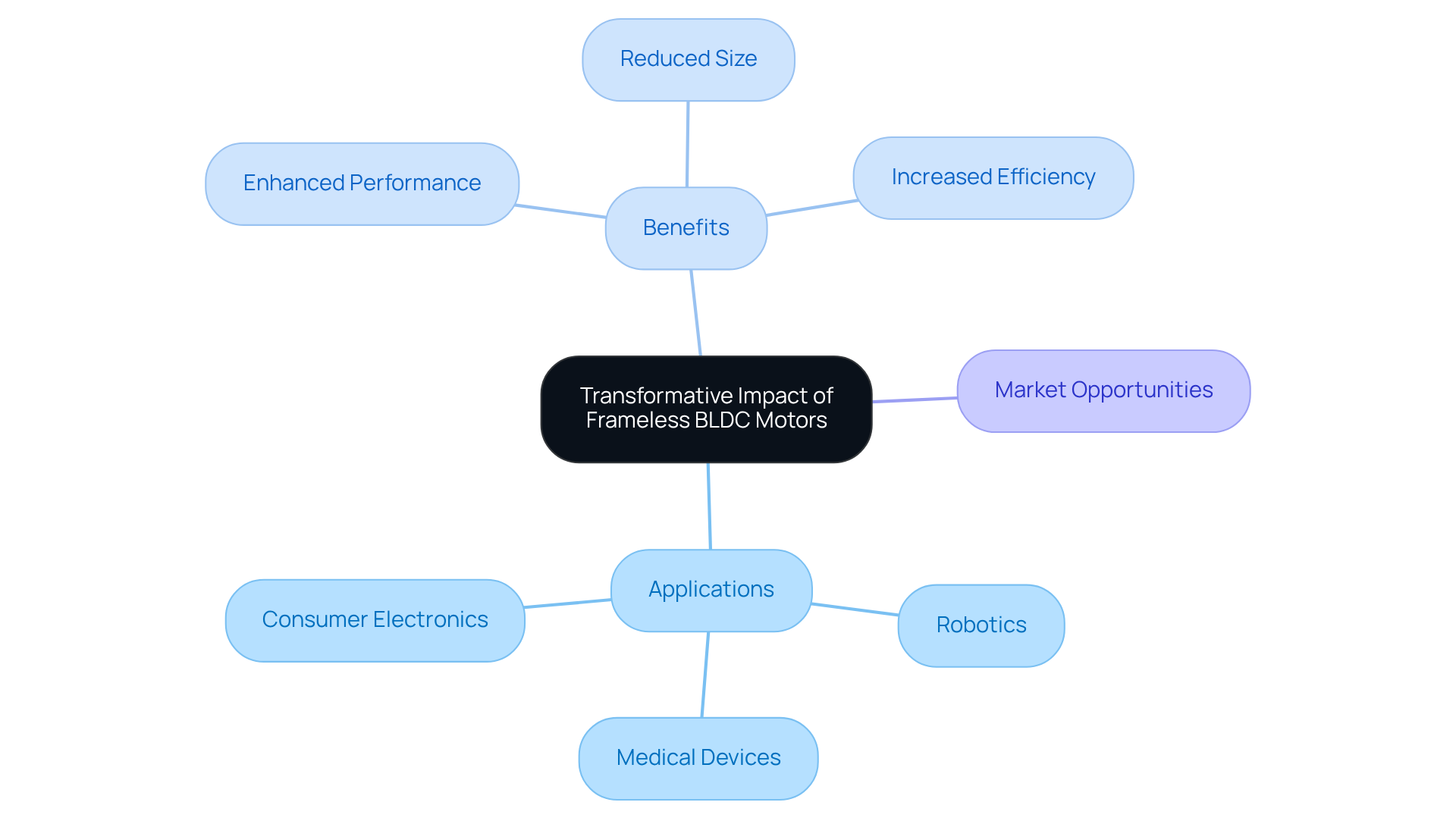

Transformative Impact of Frameless BLDC Motors: Revolutionizing Electronics Engineering

Frameless bldc devices are revolutionizing electronics engineering by providing unprecedented levels of capability, efficiency, and design adaptability. Their compact structure and high torque density facilitate innovative applications in robotics, medical devices, and consumer electronics, thereby expanding the boundaries of what is achievable in these fields.

As engineers increasingly adopt frameless BLDC drive technology, they unlock new opportunities to develop advanced systems that align with the evolving demands of the market. The transformative impact of these motors is manifested in their ability to enhance product performance while simultaneously reducing size and weight, ultimately resulting in more efficient and effective engineering solutions.

Conclusion

Frameless BLDC motors signify a pivotal advancement in electronics engineering, delivering unmatched efficiency, a compact design, and versatility across diverse applications. By removing conventional casings and integrating cutting-edge technologies, these motors not only elevate performance but also address the increasing demand for smaller and more efficient solutions in sectors such as robotics, medical devices, and aerospace.

Key insights into frameless BLDC motors highlight their exceptional energy efficiency, high torque density, and adaptability to specific engineering requirements. The capability to customize these motors empowers engineers to optimize performance for specialized applications, while their thermal management features ensure reliability and longevity. Although challenges such as installation precision and initial costs exist, the advantages of frameless BLDC technology are propelling its adoption and integration into advanced systems.

As the market for frameless BLDC motors continues to grow, engineers are urged to investigate these innovative solutions to enhance their projects. Embracing the transformative potential of frameless BLDC technology not only unlocks new possibilities but also aligns with sustainability objectives, paving the way for a more efficient and effective future in electronics engineering.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for pioneering solutions in the borderless BLDC technology sector, providing engineers with advanced cooling and power management technologies that enhance the performance and reliability of frameless BLDC motors.

What are frameless BLDC motors?

Frameless BLDC motors are designed without a traditional casing, consisting solely of a rotor and stator. This design allows for significant space savings, reduced weight, decreased inertia, and improved efficiency, making them ideal for applications where size and weight are critical.

How do frameless BLDC motors operate?

Frameless BLDC motors operate on the principle of electromagnetic induction, where the interaction between the rotor’s permanent magnets and the stator’s coils generates motion. Their brushless design reduces friction and heat, enhancing efficiency.

What are the benefits of using frameless BLDC motors in robotics?

The lightweight and compact design of frameless BLDC motors allows for precise movements in constrained spaces, improving overall system efficiency and enabling applications in robotics, medical devices, and automation.

What industries are adopting frameless BLDC systems?

Industries such as aerospace, medical devices, and automotive are progressively adopting frameless BLDC systems due to their high torque density and flexibility, which are essential for specialized applications.

What is the projected growth of the frameless BLDC device market?

The frameless BLDC device market is projected to grow at a compound annual growth rate (CAGR) of 3.2% by 2034, driven by the increasing demand for compact and efficient solutions.

What are some applications of frameless BLDC motors?

Frameless BLDC motors are utilized in various high-performance applications, including collaborative robots, medical robotics, MRI scanners for silent operation, and robotic joints for precise positioning.

What is the projected market value for frameless BLDC devices by 2033?

The global market for frameless BLDC devices is projected to reach $3.26 billion by 2033, highlighting the growing significance of this technology across various sectors.