Overview

This article provides engineers with comprehensive, step-by-step instructions for wiring PWM fans, underscoring the critical importance of understanding Pulse Width Modulation (PWM) for effective fan speed control. It outlines the necessary tools, detailed wiring steps, and essential troubleshooting tips, illustrating how proper implementation can significantly enhance cooling efficiency and overall system performance.

Introduction

Mastering the intricacies of Pulse Width Modulation (PWM) fan wiring is crucial for engineers aiming to optimize their cooling systems. This guide explores the fundamental principles of PWM, offering step-by-step instructions that enable professionals to control fan speed with precision and efficiency.

However, the potential for common wiring pitfalls and the complexity of electrical connections raises an important question: how can engineers guarantee that their installations are both effective and reliable?

By understanding these principles and applying best practices, engineers can significantly enhance the performance and reliability of their cooling systems.

Understand Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) fan wiring represents a critical technique for controlling power delivery to electrical devices, particularly in regulating fan speed. By varying the width of the pulses in a waveform, the PWM fan wiring effectively adjusts the average voltage and current supplied to the fan. The duty cycle, which indicates the percentage of time the signal is ‘on’ versus ‘off’, is crucial in PWM fan wiring as it determines the fan speed.

For instance, a 50% duty cycle implies that the fan is powered half the time, resulting in a moderate speed, whereas a 100% duty cycle operates the fan at full capacity. Mastering these principles is essential for engineers who aim to optimize cooling solutions through PWM fan wiring.

As Aristotle noted, ‘Excellence is a habit’; thus, understanding PWM serves as a foundational step in achieving excellence in electronic design, necessitating consistent practice and precision in implementation. Moreover, as Nikola Tesla emphasized, focusing on originality in engineering solutions can lead to innovative cooling strategies that enhance performance and efficiency. This originality is vital for developing unique PWM applications that can significantly improve system cooling.

Additionally, as Henry Ford stated, ‘Quality means doing it right when no one is looking,’ underscoring the importance of meticulous attention to detail in PWM implementation. Such diligence ensures that engineers achieve optimal performance in their designs.

Gather Necessary Tools and Components

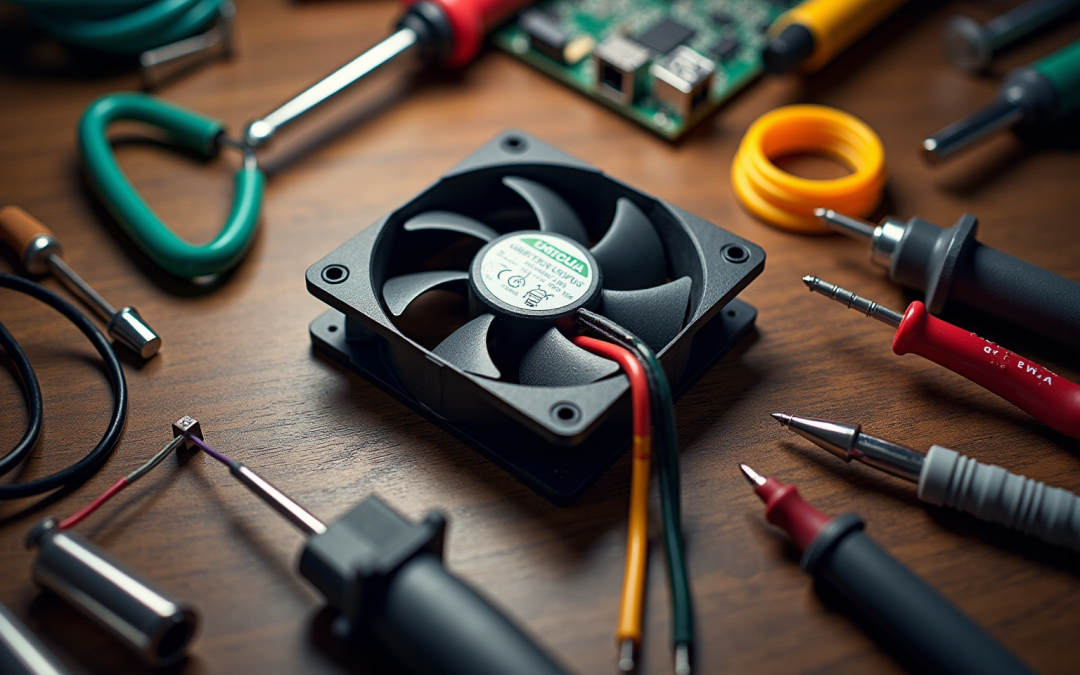

Before embarking on the wiring process, it is essential to gather the following tools and components to ensure a successful PWM fan installation:

- PWM Fan: Select a fan equipped with a 4-pin connector for effective PWM control.

- Power Supply: A 12V DC power supply is typically required for most PWM fans, ensuring compatibility and optimal performance.

- Wires: Use appropriately gauged wires to handle the current load, which is crucial for maintaining system stability.

- Soldering Iron and Solder: These are necessary for making secure and reliable connections, which are vital for long-term functionality.

- Heat Shrink Tubing: This is used to insulate soldered connections, preventing short circuits and enhancing safety.

- Multimeter: A multimeter is indispensable for testing voltage and continuity, helping to troubleshoot any issues that may arise during installation. As one engineer humorously noted, “I trust my multimeter more than my emotions – at least it gives me accurate resistance.”

- Wire Strippers: These tools prepare wires for connections, ensuring clean and effective joins.

- Breadboard (optional): For those looking to prototype and test connections before finalizing, a breadboard can be a valuable asset.

Having these tools ready not only streamlines the PWM fan wiring process but also helps avoid common pitfalls, ensuring a smoother installation experience. As noted in various electronics projects, the right tools can significantly impact the success of your work, turning potential challenges into manageable tasks. For instance, PWM fan controllers can significantly reduce noise levels by dynamically adjusting fan speed, making them ideal for noise-sensitive environments. Additionally, case studies have shown that implementing PWM technology in thermal management can lead to substantial energy efficiency improvements.

Wire the PWM Fan: Step-by-Step Instructions

To wire your PWM fan correctly, adhere to the following detailed steps:

-

Identify the Wires: A standard 4-pin PWM fan typically includes:

- Black: Ground

- Red: Power (+12V)

- Yellow: Tachometer signal (RPM feedback)

- Green or Blue: PWM control signal

-

Connect the Ground Wire: Begin by attaching the black wire to the ground terminal of your power supply.

-

Connect the Power Wire: Next, link the red wire to the positive terminal of your power supply (+12V).

-

Connect the Tachometer Wire: For monitoring fan speed, connect the yellow wire to the designated input on your microcontroller or monitoring device.

-

Connect the PWM Control Wire: Attach the green or blue wire to the PWM output pin of your microcontroller or fan controller.

-

Secure Connections: Utilize solder and heat shrink tubing to secure and insulate all connections, ensuring that no exposed wires remain.

-

Test the Connections: Prior to powering on, verify all connections for accuracy and security.

-

Power On: After confirming all connections, power on the system and test the fan operation by adjusting the PWM signal to observe changes in speed.

Typical electrical errors in PWM fan wiring often involve reversing the power and ground connections, which can lead to fan malfunction or damage. According to industry statistics, improper connections can result in a 30% increase in fan failure rates, underscoring the importance of proper installation practices. Ensuring correct connections is crucial for optimal fan performance and longevity. As noted by engineers in the field, “Attention to detail in connections can prevent many common issues that arise during fan installation.

Troubleshoot Common Wiring Issues

When troubleshooting PWM fan wiring issues, it is essential to follow these steps to effectively diagnose and resolve common problems:

-

Fan Not Spinning: First, ensure all connections are secure and verify that the power supply is operational, delivering the correct voltage. A steady voltage of 12V is typically required for proper fan function.

-

Fan Operates at Maximum Velocity: This situation may indicate a disconnection of the PWM control wire or a continuous high input being received. It is crucial to verify that the PWM output is being produced accurately; erratic waves can lead to inconsistent fan behavior.

-

Inconsistent Fan Speed: If the fan speed varies unexpectedly, check the stability of the PWM output. Utilize a multimeter to measure the duty cycle, ensuring it aligns with your intended settings. Research suggests that a properly calibrated PWM output can lead to an estimated 20% reduction in total energy use, significantly enhancing fan performance and energy efficiency.

-

No RPM Feedback: If the tachometer signal fails to provide feedback, verify the connection of the yellow wire. Ensure it is correctly linked to the appropriate input on your monitoring device, as accurate RPM feedback is crucial for effective fan management.

-

Overheating: If the fan or components are overheating, check for short circuits or improper connections. Confirm that the fan is rated for the supplied voltage; improper voltage can lead to overheating and potential failure.

By adhering to these troubleshooting steps, engineers can effectively diagnose and resolve common issues related to PWM fan wiring, ensuring optimal performance and longevity of their cooling systems. The integration of PWM technology has been shown to reduce power consumption by up to 30% in fan systems, making it essential for efficient thermal management in high-performance environments. As noted by industry experts, “the accuracy of PWM devices enables engineers to enhance temperature management strategies efficiently, which is crucial in high-performance settings.

Conclusion

Mastering PWM fan wiring is crucial for engineers aiming to optimize cooling solutions and enhance performance in electronic designs. This guide has offered a thorough overview of the principles of Pulse Width Modulation, the essential tools and components for effective installation, and a detailed step-by-step approach to wiring PWM fans. By grasping the intricacies of PWM, engineers can achieve precise control over fan speeds, resulting in improved energy efficiency and system stability.

Key insights discussed emphasize the significance of the duty cycle in regulating fan speed, the necessity of secure connections, and effective troubleshooting techniques for common wiring issues. Each outlined step empowers engineers to navigate the installation process with confidence, minimizing errors while maximizing the longevity and efficiency of their cooling systems. The integration of PWM technology not only enhances performance but also contributes to substantial energy savings, making it an essential consideration in modern electronic engineering.

In summary, the knowledge and skills acquired from this PWM fan wiring guide are invaluable for engineers striving to advance thermal management. As technology continues to evolve, embracing innovative solutions like PWM will be critical in developing efficient and effective cooling strategies. Engineers are urged to diligently apply these principles and explore unique applications of PWM to further elevate their designs.

Frequently Asked Questions

What is Pulse Width Modulation (PWM) in fan wiring?

Pulse Width Modulation (PWM) in fan wiring is a technique used to control power delivery to electrical devices, particularly for regulating fan speed by varying the width of the pulses in a waveform.

How does PWM affect fan speed?

PWM affects fan speed by adjusting the duty cycle, which is the percentage of time the signal is ‘on’ versus ‘off’. A 50% duty cycle means the fan is powered half the time, resulting in moderate speed, while a 100% duty cycle operates the fan at full capacity.

Why is understanding PWM important for engineers?

Understanding PWM is essential for engineers as it helps them optimize cooling solutions in electronic design, allowing for better performance and efficiency.

What does the article suggest about originality in engineering solutions?

The article emphasizes that focusing on originality in engineering solutions can lead to innovative cooling strategies, which are crucial for developing unique PWM applications.

What is the significance of attention to detail in PWM implementation?

Attention to detail in PWM implementation is important to ensure optimal performance in designs, as highlighted by the quote from Henry Ford about quality and diligence.