Overview

This article delves into the fundamentals of micro blowers, providing a comprehensive overview of their types, applications, and optimization techniques. Understanding the design and operational principles of centrifugal, axial, and diaphragm micro blowers is crucial for users aiming to select the most suitable device for specific applications. Furthermore, it underscores the significance of proper sizing, maintenance, and control systems, which are essential for enhancing efficiency and performance across various industries.

Introduction

Micro blowers have emerged as essential components across a multitude of applications, ranging from cooling electronics to enhancing airflow in medical devices. Their fundamental principles, diverse types, and optimization techniques significantly influence performance and efficiency across various industries.

However, with an array of designs and operational mechanisms available, how can engineers effectively select the right micro blower for their specific needs while maximizing its potential? This article delves into the intricacies of micro blowers, providing insights into their functionality, applications, and strategies for optimization.

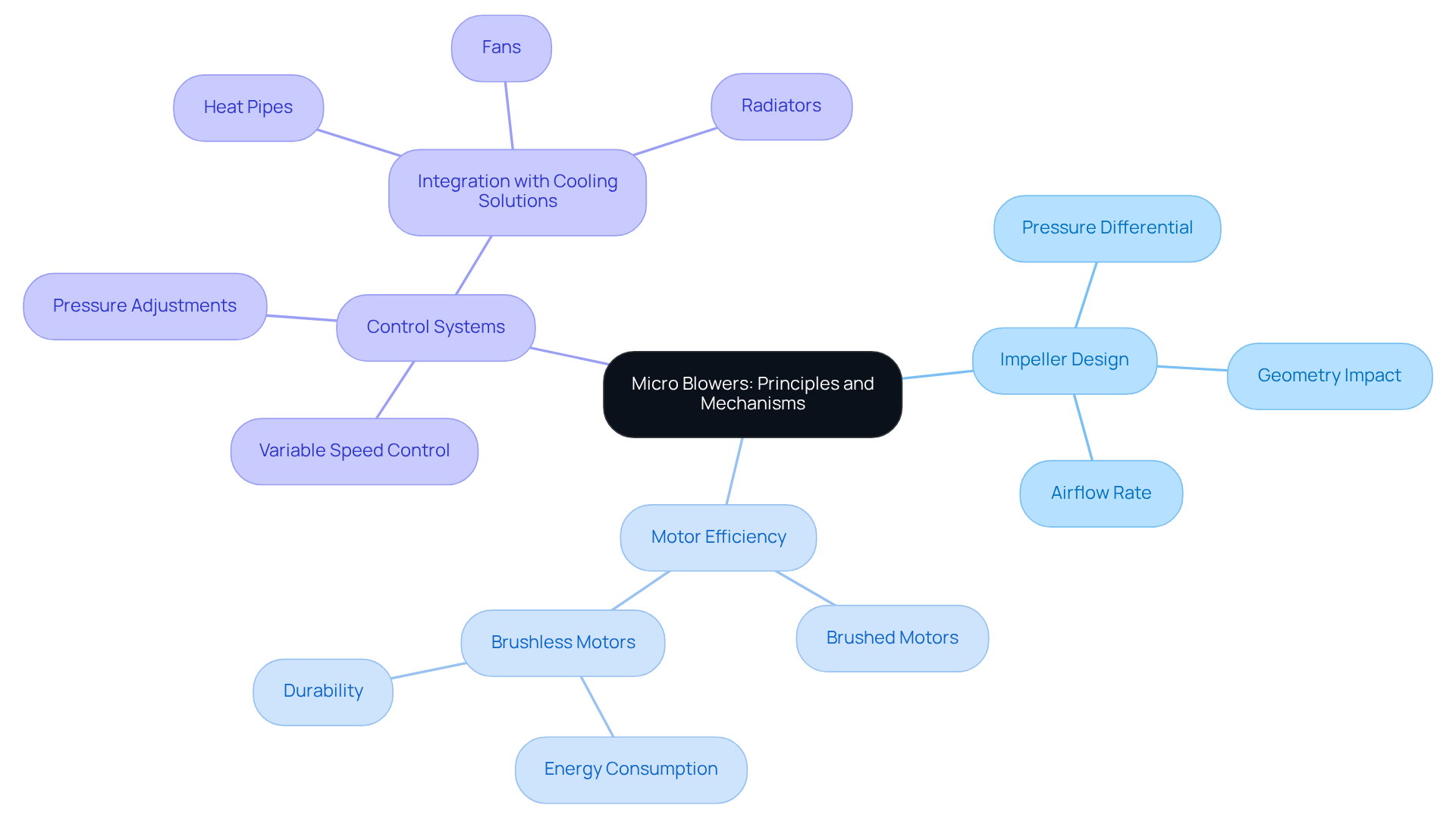

Define Micro Blowers: Principles and Mechanisms

Micro blowers are compact devices specifically designed to facilitate air movement across various applications, primarily in electronics cooling and air circulation. They operate based on fluid dynamics principles, utilizing impellers or fans to generate a pressure differential that propels air. Key mechanisms include:

- Impeller Design: The shape and size of the impeller significantly impact airflow rate and pressure. Understanding this geometry is essential for selecting the appropriate device, such as a micro blower, for specific applications. The company offers an extensive range of DC input tube axial fans and micro blowers, with sizes ranging from 15 to 280mm, alongside compact fan solutions optimized for performance and efficiency.

- Motor Efficiency: The choice of motor type (e.g., brushed versus brushless) influences energy consumption and overall performance. Brushless motors are often preferred for their effectiveness and durability, which are qualities also seen in diverse cooling solutions such as the micro blower.

- Control Systems: Advanced micro blowers may integrate electronic control systems that facilitate variable speed and pressure adjustments, optimizing their performance according to real-time demands. The company’s innovative cooling solutions incorporate a micro blower with integrated designs that combine fans, heat pipes, and radiators, ensuring effective thermal management for electronics. Furthermore, most models offer IP protection upon request, enhancing their adaptability to various environments.

By comprehending these principles and recognizing the standard and custom designs provided by the firm, users can make informed decisions when selecting and implementing micro fans in their projects.

Explore Types of Micro Blowers: Designs and Operational Principles

Micro fans are engineered in various styles, each tailored for specific applications. Gagner-Toomey Associates provides a comprehensive array of solutions, including:

-

Centrifugal Micro Blowers: These blowers leverage a rotating impeller to effectively enhance air velocity and pressure, making them ideal for high airflow applications such as cooling electronic components. Offered in dimensions from 15 to 225mm, Gagner-Toomey’s centrifugal fans excel in environments where space is at a premium, delivering significant air movement while maintaining a compact design. Importantly, these fans tend to consume more power than axial fans, a critical factor for engineers prioritizing efficiency. IP protection is available upon request for most models.

-

Axial Micro Fans: Defined by blades that push air parallel to the axis of rotation, axial fans, available in sizes from 15 to 280mm, are typically more compact and quieter than their centrifugal counterparts. This design is particularly beneficial in consumer electronics, where noise reduction and space efficiency are paramount. Their capability to operate at lower voltages further minimizes electromagnetic interference, thereby enhancing overall device performance. As highlighted by Sofasco™ International, low noise levels and extended fan life are crucial for many customers in this sector.

-

Diaphragm Micro Fans: Utilizing a diaphragm mechanism to generate airflow, these devices are ideal for applications requiring precise airflow regulation, such as medical equipment. Gagner-Toomey’s diaphragm pumps ensure consistent performance in sensitive environments, providing reliability in critical functions. Custom designs are also available to address specific requirements.

Understanding the operational principles of these designs is essential for engineers to select the most suitable fan for their needs, thereby ensuring optimal performance and efficiency. For example, centrifugal fans are frequently favored in high-pressure scenarios, while axial fans thrive in low-noise environments. This knowledge equips engineers to make informed decisions aligned with their project specifications. Furthermore, Gagner-Toomey’s extensive portfolio of thermal management solutions, which includes integrated cooling systems and custom designs, facilitates the selection process, ensuring engineers have access to innovative cooling solutions tailored to their requirements.

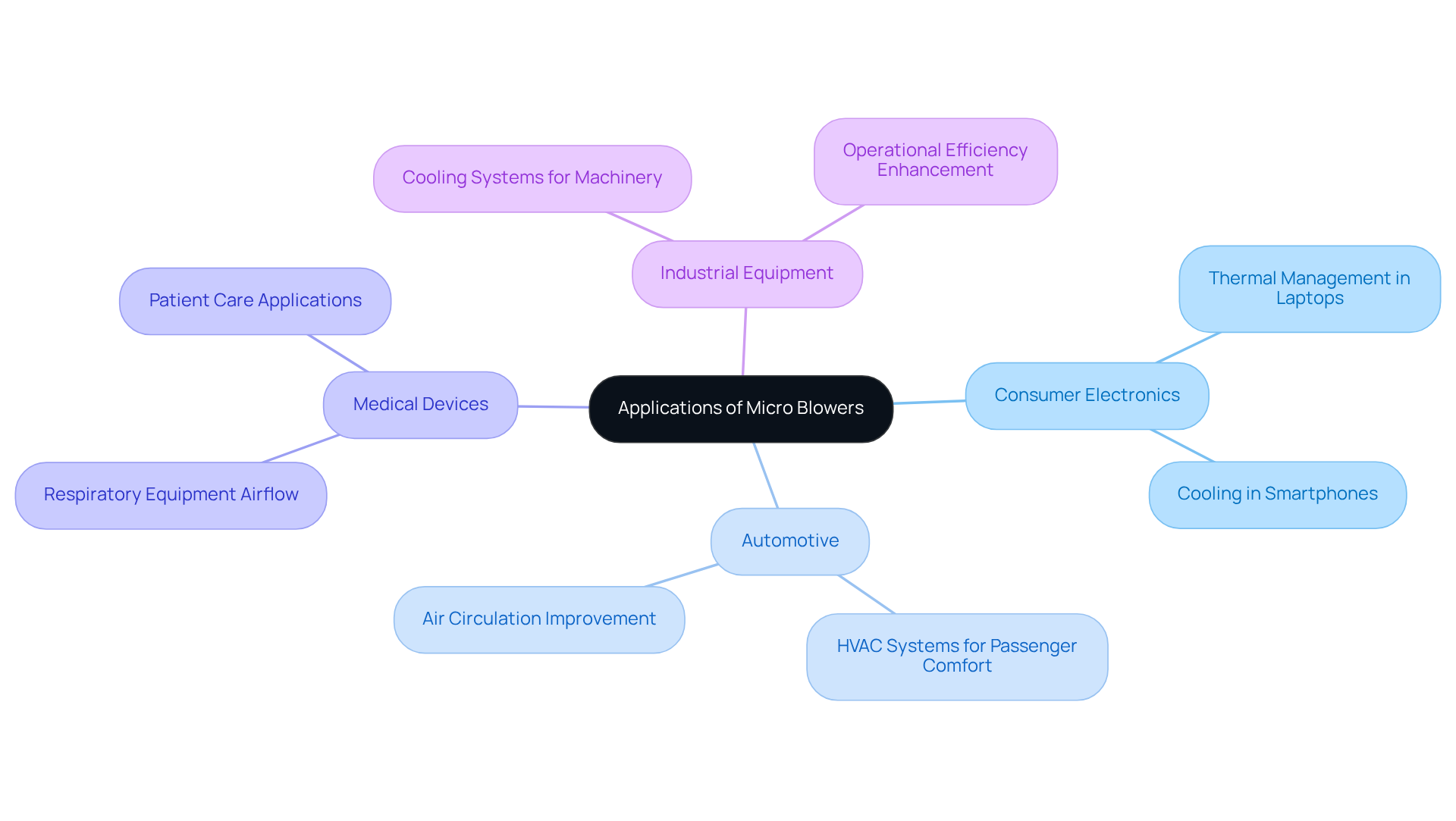

Examine Applications of Micro Blowers: Industry Use Cases

The remarkable versatility of micro blowers is showcased through their employment across a diverse range of industries. Notable applications include:

- Consumer Electronics: These devices are integral in laptops and smartphones for thermal management, ensuring that devices operate within safe temperature ranges.

- Automotive: In HVAC systems, the use of micro blowers enhances passenger comfort and improves air circulation within vehicles.

- Medical Devices: They play a critical role in respiratory equipment, where a micro blower is essential for ensuring precise airflow in patient care.

- Industrial Equipment: A micro blower is utilized in cooling systems for machinery, preventing overheating and ensuring operational efficiency.

These examples underscore the essential function of micro fans in enhancing performance and reliability across various sectors.

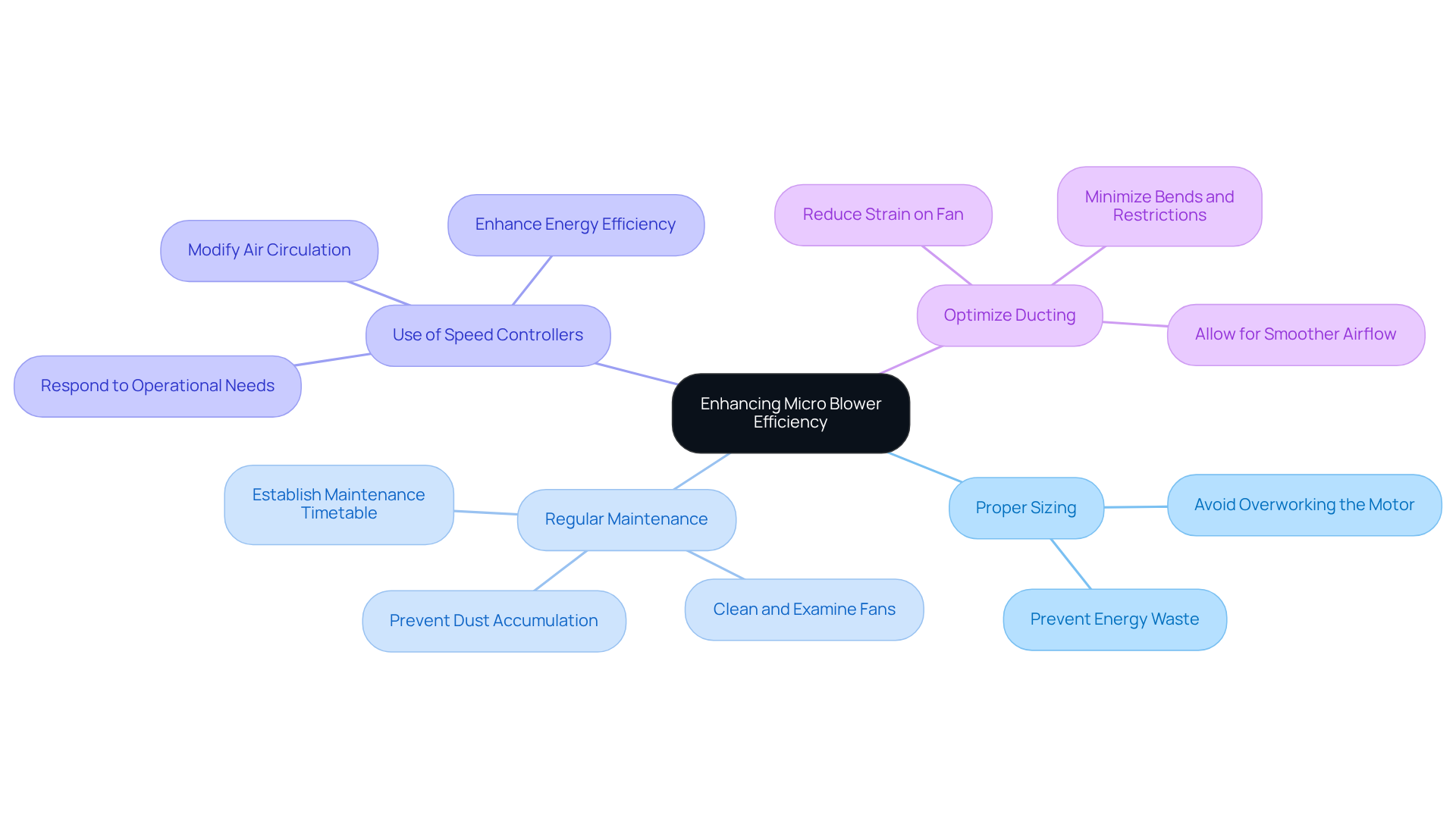

Optimize Performance: Techniques for Enhancing Micro Blower Efficiency

To enhance the efficiency of micro blowers, it is essential to consider the following techniques:

- Proper Sizing: Ensure the blower is appropriately sized for the application. This avoids overworking the motor and wasting energy, which can lead to decreased performance.

- Regular Maintenance: Establish a maintenance timetable to clean and examine fans. This practice prevents dust accumulation that can obstruct performance and prolongs the lifespan of the system.

- Use of Speed Controllers: Integrate electronic speed controllers to modify air circulation based on real-time requirements. This adjustment significantly enhances energy efficiency and responsiveness to varying operational needs.

- Optimize Ducting: Design ducting systems to minimize bends and restrictions. This approach allows for smoother airflow, reducing the strain on the fan and improving overall system performance.

By applying these techniques, users can significantly enhance the performance and lifespan of their micro blower systems, ensuring optimal operation and energy efficiency.

Conclusion

Micro blowers play a critical role in numerous industries, facilitating efficient air movement and cooling. Understanding essential principles such as impeller design, motor efficiency, and advanced control systems is fundamental to their effectiveness. By grasping these concepts, users can select the appropriate micro blower for specific applications, thereby ensuring optimal performance and energy efficiency.

This article explores the various types of micro blowers, including:

- Centrifugal fans

- Axial fans

- Diaphragm fans

Each designed to meet distinct operational needs. Their applications span consumer electronics, automotive, medical devices, and industrial equipment, underscoring their versatility and crucial role in enhancing performance and reliability.

Furthermore, the importance of optimizing micro blower efficiency through proper sizing, maintenance, speed control, and ducting design is highlighted as vital for maximizing lifespan and operational effectiveness.

Ultimately, a comprehensive understanding of micro blower fundamentals, types, applications, and optimization techniques is essential for engineers and designers. By leveraging this knowledge, stakeholders can make informed decisions that enhance device performance and energy efficiency, contributing to more reliable and effective systems across various industries. Embracing these insights not only improves individual projects but also fosters innovation in thermal management solutions.

Frequently Asked Questions

What are micro blowers?

Micro blowers are compact devices designed to facilitate air movement, primarily used in electronics cooling and air circulation.

How do micro blowers operate?

They operate based on fluid dynamics principles, utilizing impellers or fans to create a pressure differential that propels air.

What factors influence the performance of micro blowers?

The performance is influenced by the impeller design, motor efficiency, and control systems integrated into the device.

Why is impeller design important in micro blowers?

The shape and size of the impeller significantly impact the airflow rate and pressure, making it essential for selecting the appropriate device for specific applications.

What types of motors are used in micro blowers?

Micro blowers can use different types of motors, with brushless motors being preferred for their effectiveness and durability.

What are the benefits of using brushless motors in micro blowers?

Brushless motors offer better energy consumption and overall performance, making them suitable for diverse cooling solutions.

Do micro blowers have control systems?

Yes, advanced micro blowers may integrate electronic control systems that allow for variable speed and pressure adjustments to optimize performance based on real-time demands.

What additional features do some micro blowers offer?

Many models offer IP protection upon request, enhancing their adaptability to various environments.

How can users make informed decisions when selecting micro blowers?

By understanding the principles of operation and recognizing the standard and custom designs provided by manufacturers, users can better select and implement micro fans in their projects.