Overview

This article centers on the identification of high power fan blower models that significantly enhance the efficiency of electronics cooling. It meticulously highlights various models, including the Wathai and Delta blowers, providing detailed performance metrics, energy efficiency ratings, and relevant application scenarios. This examination demonstrates how these fans proficiently manage thermal regulation within electronic systems, underscoring their critical role in optimizing performance.

Introduction

High power fan blowers are increasingly essential in the domain of electronics cooling, where effective thermal management is critical for ensuring optimal performance and extending the longevity of devices. As innovations continue to transform this landscape, engineers are confronted with a variety of advanced solutions that not only enhance cooling efficiency but also significantly reduce energy consumption. Yet, with an abundance of options available, how can one ascertain which models truly fulfill their promises? This article delves into ten exemplary high power fan blower models that are establishing the benchmark for efficient electronics cooling, providing insights into their features, benefits, and applications.

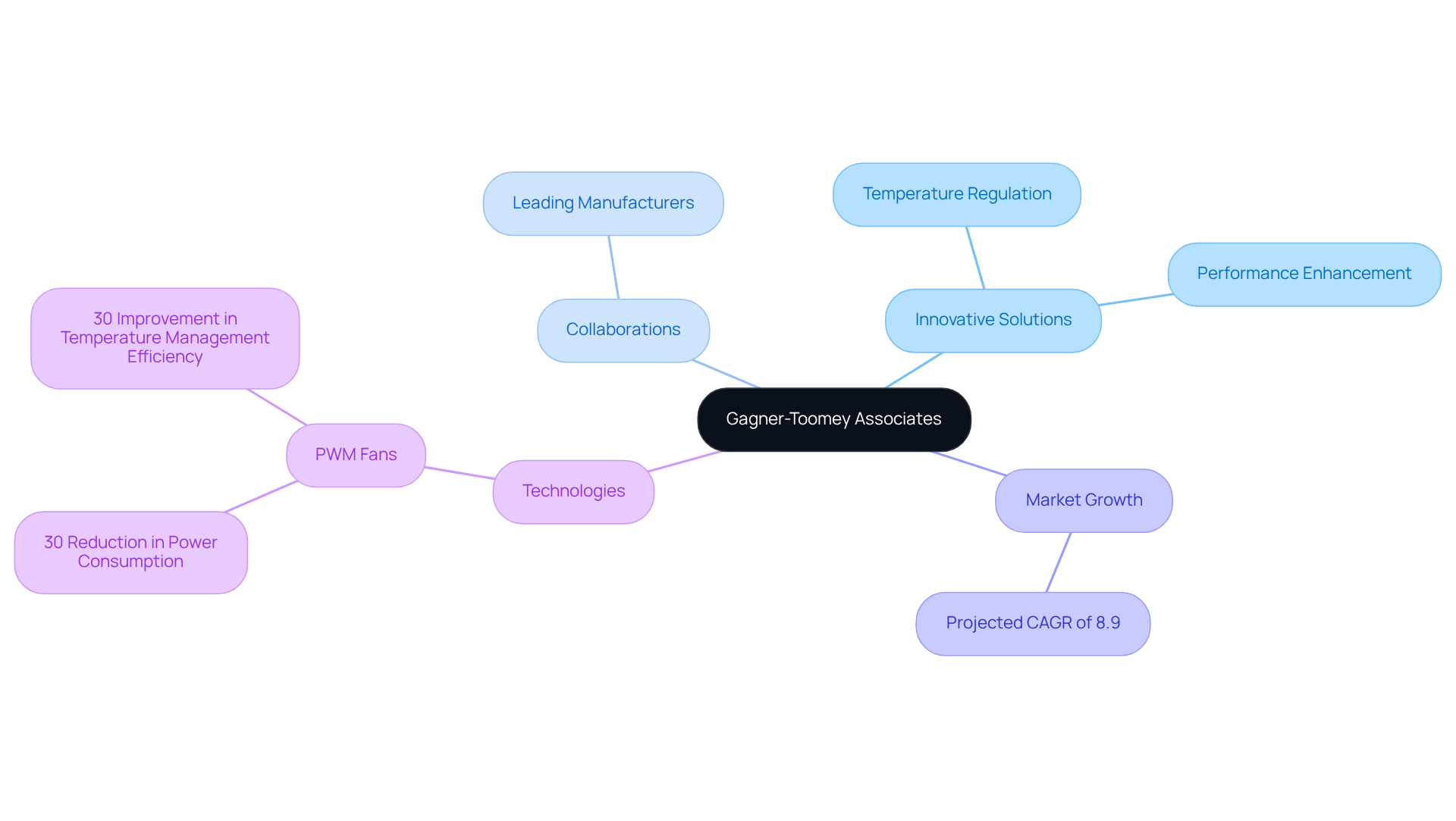

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineering

Gagner-Toomey Associates stands at the forefront of innovative temperature regulation solutions tailored specifically for the electronics engineering sector. By forging collaborations with leading manufacturers, the company delivers high-quality temperature control products that significantly enhance performance and efficiency. Their expertise spans crucial fields such as energy management and thermal dynamics, ensuring that engineers are equipped with advanced technologies to effectively tackle the complex challenges of temperature regulation in electronic systems.

As the market for temperature control technologies in the electronics sector is projected to expand, with forecasts indicating a compound annual growth rate of 8.9% from 2024 to 2031, Gagner-Toomey remains committed to providing solutions that not only meet but exceed industry standards. The integration of cutting-edge technologies, such as PWM fans, has demonstrated a reduction in power consumption by up to 30%, while also enhancing temperature management efficiency by as much as 30% in data centers.

This unwavering dedication to innovation is echoed by industry leaders who emphasize the importance of improving performance in electronics temperature management, further solidifying Gagner-Toomey’s role as a pivotal contributor in this evolving landscape.

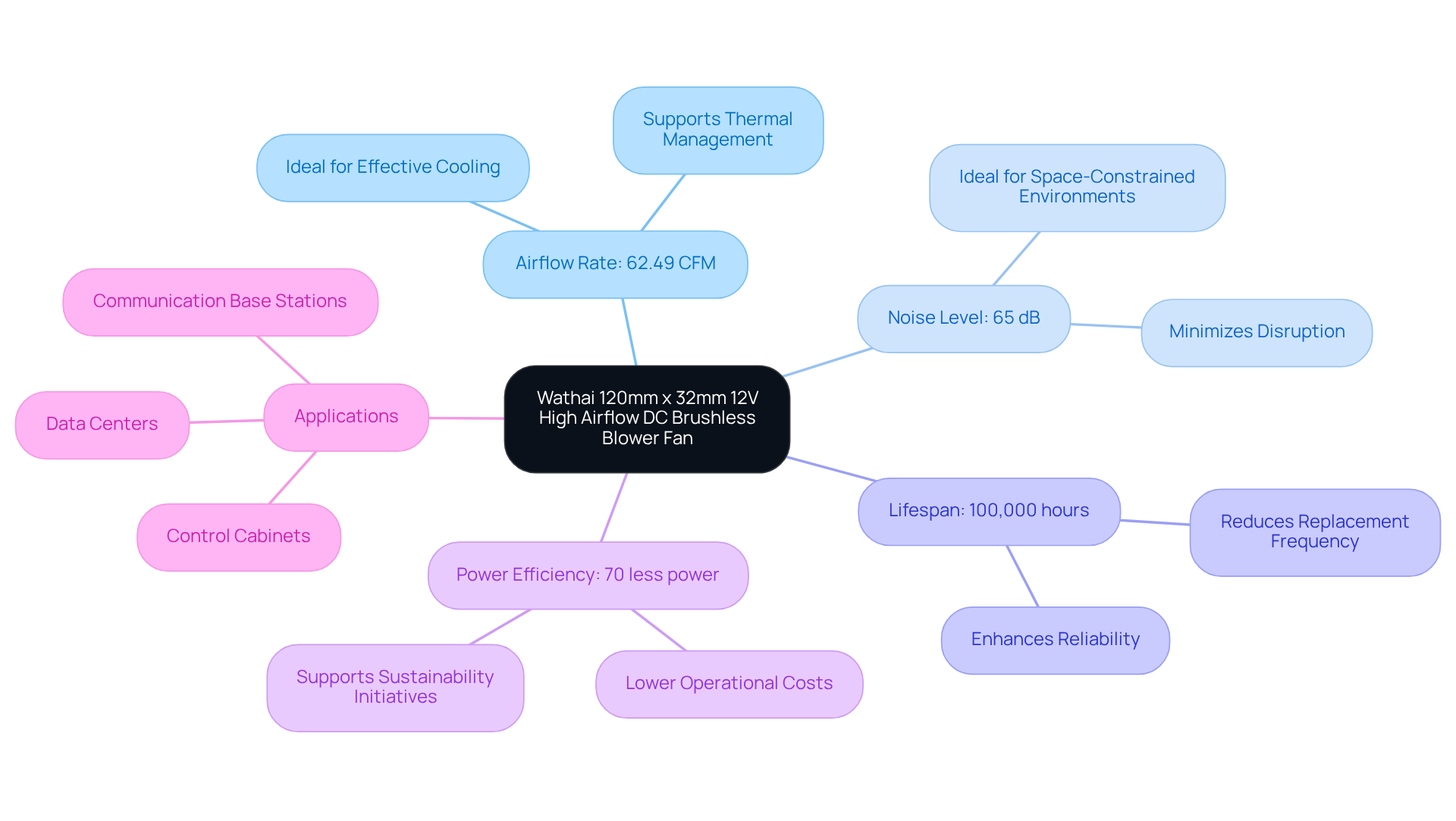

Wathai 120mm x 32mm 12V High Airflow DC Brushless Blower Fan: Efficient Cooling for Electronics

The Wathai 120mm x 32mm 12V High Airflow DC Brushless Blower Fan is a high power fan blower that excels in thermal management capabilities designed for electronic applications. With an impressive airflow rate of 62.49 CFM, this fan is meticulously designed to deliver optimal performance while maintaining a low noise level of just 65 dB, making it ideal for space-constrained environments.

The brushless motor technology significantly extends the fan’s lifespan to approximately 100,000 hours, enhancing reliability—a crucial aspect for engineers dedicated to effective thermal management. As Bruce Rose aptly notes, ‘DC fans are essential to any engineer’s thermal management solution, intended to eliminate heat from an application through efficient forced air circulation.’

This fan exemplifies the advantages of brushless technology, which can consume up to 70% less power than traditional models, thereby lowering operational costs and supporting sustainability initiatives. Its compact design, along with the high power fan blower that offers high airflow capacity, positions it as a prime choice for diverse applications, including:

- Data centers

- Communication base stations

- Control cabinets

where effective temperature management solutions are critical.

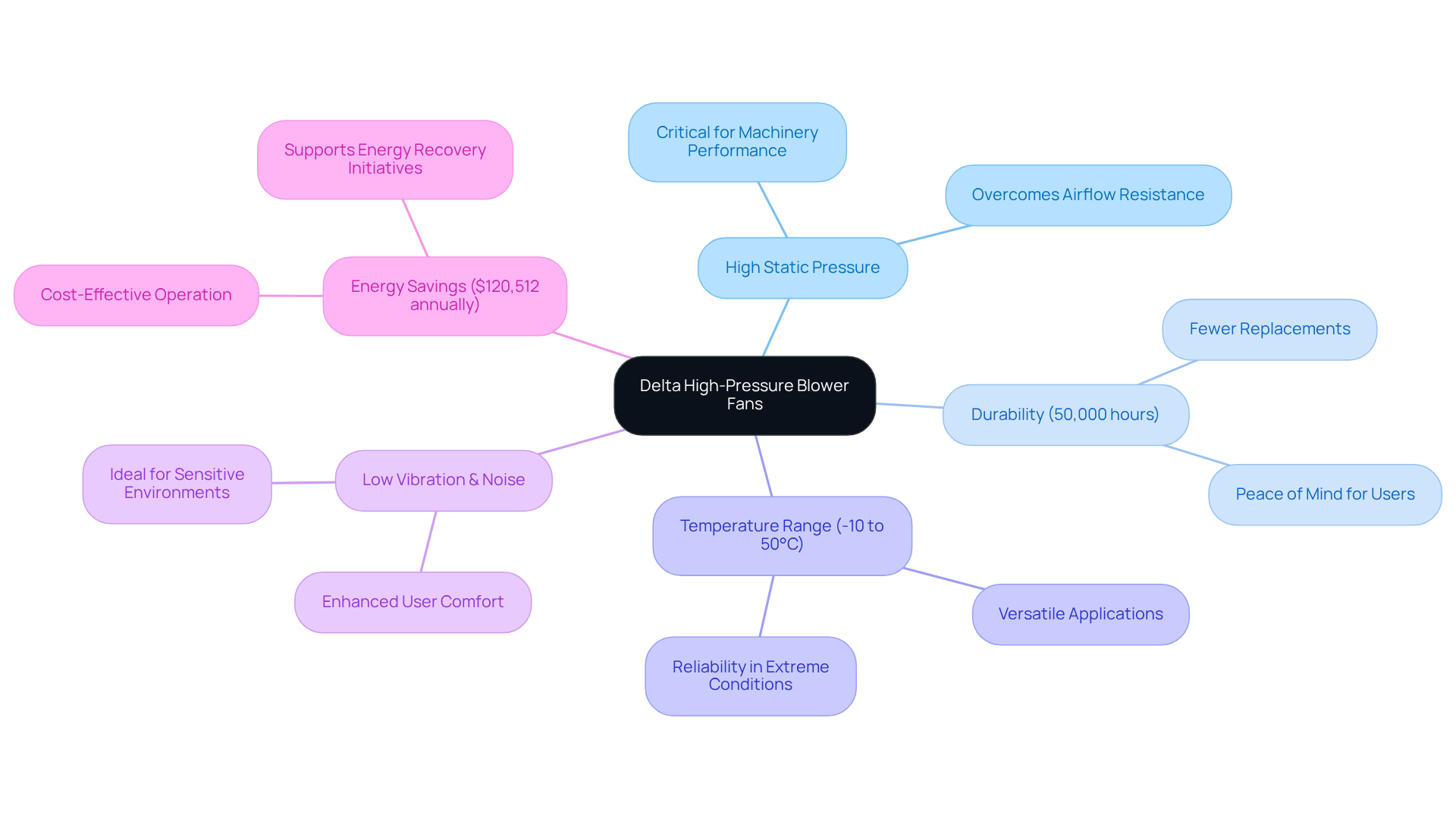

Delta High-Pressure Blower Fans: Reliable Performance for Critical Applications

Delta high power fan blower systems are expertly engineered for demanding applications that necessitate reliable performance in challenging environments. These devices excel in delivering high static pressure, making them ideal for machinery that requires a high power fan blower to overcome significant airflow resistance challenges. Their robust design, featuring durable 2-ball bearings with a lifespan exceeding 50,000 hours, guarantees longevity and minimizes the frequency of replacements, providing peace of mind for manufacturers and users alike.

In the realm of electronics temperature control, maintaining optimal temperatures is paramount for system reliability. Delta units operate efficiently across a broad voltage range of 10 to 18V and can effectively function in temperatures from -10 to 50°C, showcasing their versatility for various applications. Their low vibration and noise levels enhance user comfort, particularly in sensitive environments such as medical technology, where quiet operation is essential.

Real-world performance highlights the effectiveness of these devices; for instance, a facility utilizing a high power fan blower reported substantial energy savings of approximately $120,512 annually, alongside improved temperature regulation. The ability to sustain steady airflow under high resistance conditions is critical for essential mechanisms, ensuring they operate within safe temperature limits. As noted by industry experts, the incorporation of high power fan blowers is crucial for optimizing thermal management systems in electronics, ultimately enhancing overall performance and reliability.

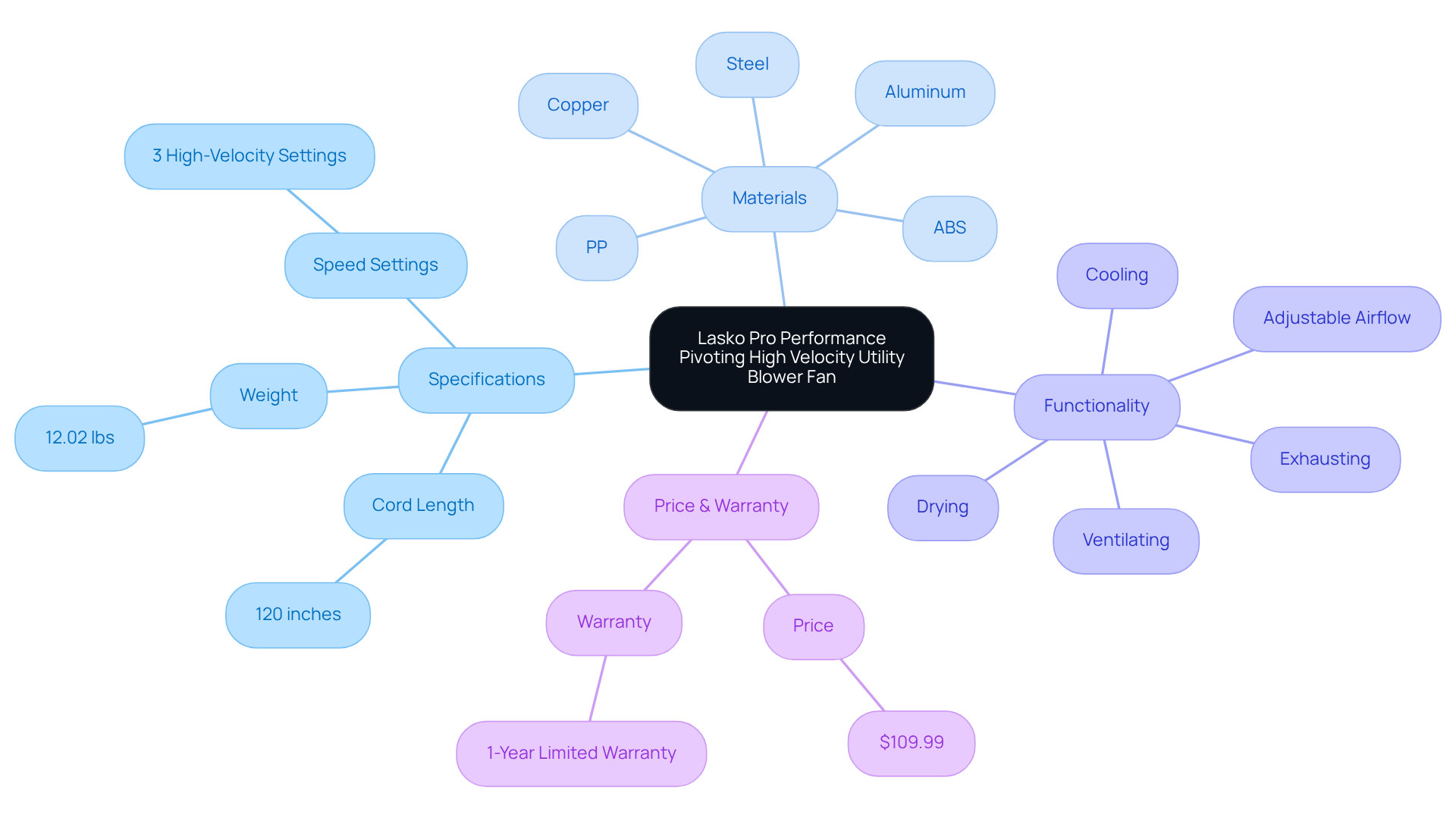

Lasko Pro Performance Pivoting High Velocity Utility Blower Fan: Versatile Airflow Solutions

The Lasko Pro Performance Pivoting High Velocity Utility Blower Fan (Model/SKU: U15617) is a high power fan blower engineered to deliver versatile air circulation solutions across diverse environments.

With an impressive cord length of 120 inches and a weight of 12.02 lbs, this fan is tailored for practicality in industrial applications.

Its innovative pivoting head facilitates precise directional airflow, making it exceptionally suited for both expansive workshops and confined industrial spaces.

This high power fan blower excels in scenarios where adjustable airflow is vital for maintaining optimal temperatures across various equipment types.

Constructed from robust materials such as ABS, PP, Steel, Copper, and Aluminum, it guarantees longevity and reliability.

Featuring three high-velocity speed settings, the high power fan blower efficiently cools, ventilates, exhausts, and dries, allowing operators to customize airflow to meet specific temperature requirements.

Priced at $109.99 and supported by a 1-year limited warranty, the high power fan blower features durable construction and a user-friendly design that further enhance its utility, positioning it as a dependable choice for professionals aiming for effective airflow management in demanding industrial contexts.

As noted by an engineer, “This fan’s adjustable airflow capabilities are essential for optimizing cooling in our workshop environments.

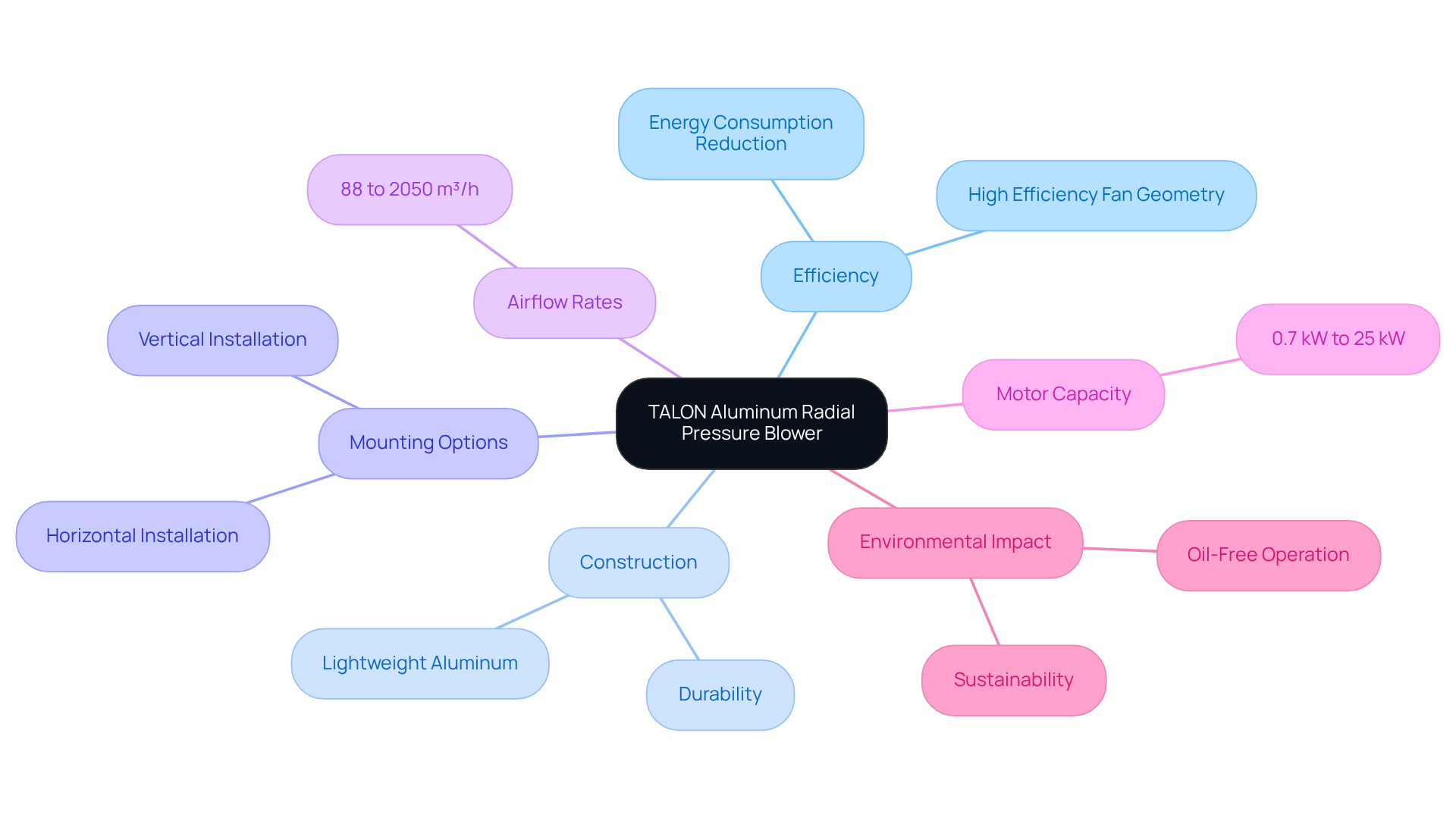

TALON Aluminum Radial Pressure Blower: High Efficiency for Industrial Use

The TALON Aluminum Radial Pressure Blower is a paragon of high efficiency and is specifically designed as a high power fan blower for demanding industrial applications. Its construction from lightweight aluminum not only guarantees durability but also allows for seamless integration into various systems. With flexible mounting options, this blower accommodates both horizontal and vertical installations, catering to diverse operational needs. The high power fan blower achieves airflow rates ranging from 88 to 2050 m³/h, minimizing energy consumption and offering motor capacity options between 0.7 kW and 25 kW for double-stage models. This combination makes it an ideal choice for engineers who prioritize sustainability and cost-effectiveness.

Moreover, the oil-free operating principle of MIT blowers ensures clean air contact, aligning perfectly with contemporary environmental goals. Energy consumption statistics reveal that the high power fan blower can significantly reduce operational costs, positioning the TALON model as a forward-thinking solution in the pursuit of environmentally friendly industrial equipment. Industry leaders emphasize that sustainable blower design is crucial for enhancing efficiency and mitigating environmental impact, making the TALON Aluminum Radial Pressure Blower a vital asset in modern industrial settings.

Nyb Industrial High Pressure Blowers: Power and Efficiency for Demanding Applications

Nyb Industrial High Pressure Blowers are engineered to deliver exceptional strength and efficiency in demanding applications. These blowers excel at managing substantial volumes of air while sustaining optimal pressure levels, rendering them ideal for a variety of industrial processes. Their robust construction guarantees longevity and reliability—qualities that are essential in environments where downtime can incur significant costs. By choosing Nyb blowers, industries can ensure continuous operation and enhanced productivity.

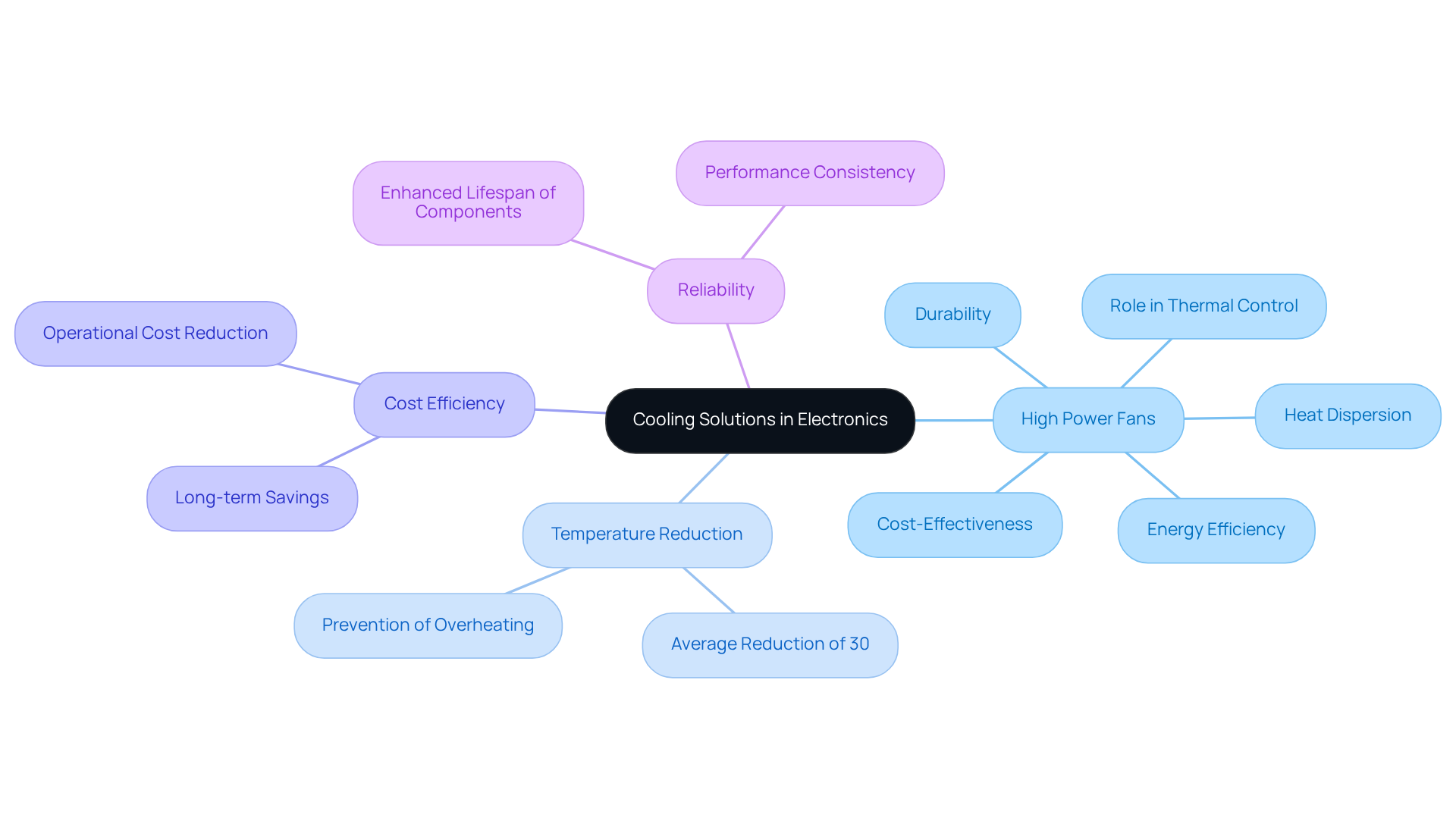

Cooling Solutions in Electronics: The Role of High Power Fans in System Performance

High-capacity blowers, such as a high power fan blower, are indispensable for the optimal functioning of electronic devices, significantly impacting thermal control and heat dispersion. By maintaining ideal operating temperatures, these blowers enhance the lifespan and reliability of electronic components.

For instance, systems utilizing high-pressure blowers can achieve average temperature reductions of up to 30%, which is crucial for preventing overheating and ensuring consistent performance. Moreover, high-pressure blowers can substantially reduce operational costs by effectively dispersing heat, making them a cost-efficient choice for engineers.

As Gagner Toomey notes, “In the rapidly evolving landscape of electronics, effective thermal management stands as a critical factor in ensuring optimal performance and longevity of devices.” Engineers must carefully assess the thermal dynamics of their designs, as the effective integration of high power fan blowers can lead to remarkable improvements in system efficiency.

Designed to withstand demanding environments characterized by extreme temperatures, dust, and moisture, high-pressure blowers demonstrate their reliability across diverse conditions. In challenging environments, these blowers have proven their capacity to maintain airflow and prevent thermal issues, underscoring their crucial role in modern electronic applications.

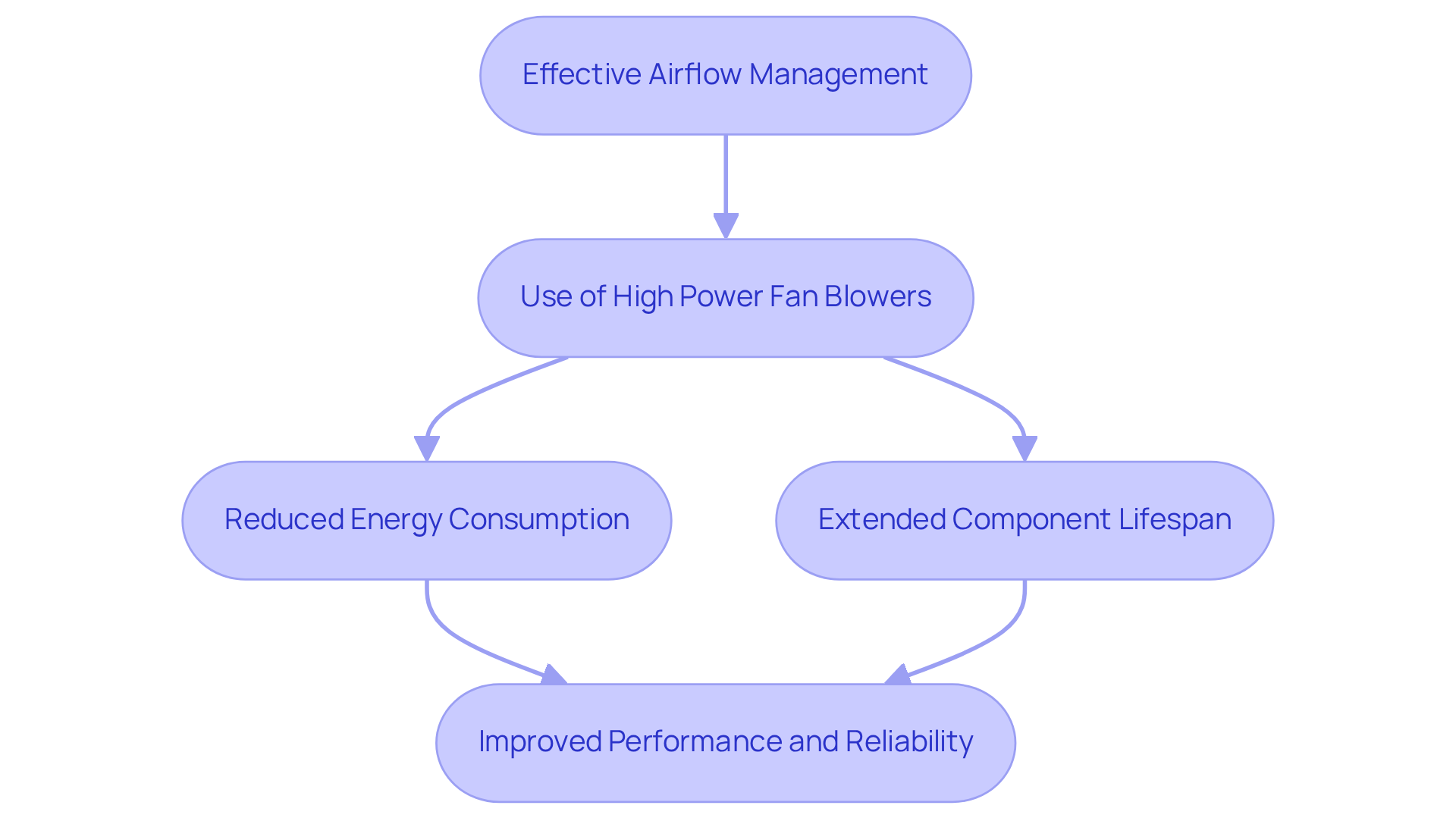

Airflow Management: Enhancing Electronics Performance with High Power Fans

Effective airflow management is crucial for optimizing the performance of electronic devices. A high power fan blower is instrumental in this process, directing air to critical components and thereby maintaining a stable thermal environment. Engineers must prioritize airflow paths in their designs; improper management can lead to hotspots that compromise operational efficiency. For instance, setups utilizing PWM devices can reduce energy consumption by up to 30% while extending the lifespan of electronic components by as much as 50%, according to industry research.

Real-world applications demonstrate the effectiveness of high power fan blowers in preventing thermal throttling and ensuring reliable operation. A case study on instability illustrates that insufficient thermal management can lead to unexpected shutdowns, underscoring the necessity for robust cooling solutions. Engineers have noted that the use of a high power fan blower not only enhances airflow but also significantly improves overall performance, making it indispensable in modern electronic design.

As John Doe, an industry leader, asserts, “The integration of advanced PWM technology is transforming thermal management solutions, making them more efficient and reliable than ever before.” By integrating these devices into their systems, engineers can achieve superior thermal management, ultimately enhancing reliability and efficiency.

Benefits of High Power Blower Fans: Enhancing Cooling Efficiency Across Applications

High-capacity blower units from Gagner-Toomey Associates play a crucial role in enhancing cooling efficiency across diverse applications, delivering significant advantages such as improved airflow rates and reduced energy consumption. As the world’s largest producer of both standard and custom air-movers, Gagner-Toomey’s devices are engineered to perform optimally in high-pressure environments, making them ideal for demanding thermal management scenarios. By selecting the appropriate high power fan blower, engineers can achieve remarkable reductions in energy usage—up to 70% less compared to traditional AC motors—while ensuring superior performance and reliability in their systems.

The integration of cutting-edge technologies, including Pulse Width Modulation (PWM), allows these devices to adjust their speeds dynamically based on real-time thermal demands, further boosting energy efficiency. For example, data centers that implement PWM technology have reported efficiency gains in temperature management of up to 30%, illustrating the concrete benefits of these advanced systems.

Real-world applications highlight the impact of high-capacity blower units on energy efficiency. A logistics warehouse improved air circulation and effectively managed humidity levels, resulting in better working conditions and lower operational costs. Similarly, a food processing facility experienced enhanced employee comfort and productivity following the installation of large ventilators from Gagner-Toomey, which addressed elevated temperatures caused by cooking equipment.

Industry leaders stress the significance of energy-efficient blower technology. As Mike Chin from Silent PC Review notes, “The efficacy of particular models in minimizing noise emissions underscores the importance of selecting the right fan for specific applications.” The adoption of high power fan blower units not only drives down operational costs but also aligns with sustainability goals in electronics design. By investing in these advanced temperature control solutions, engineers can ensure reliable performance while reducing their environmental footprint.

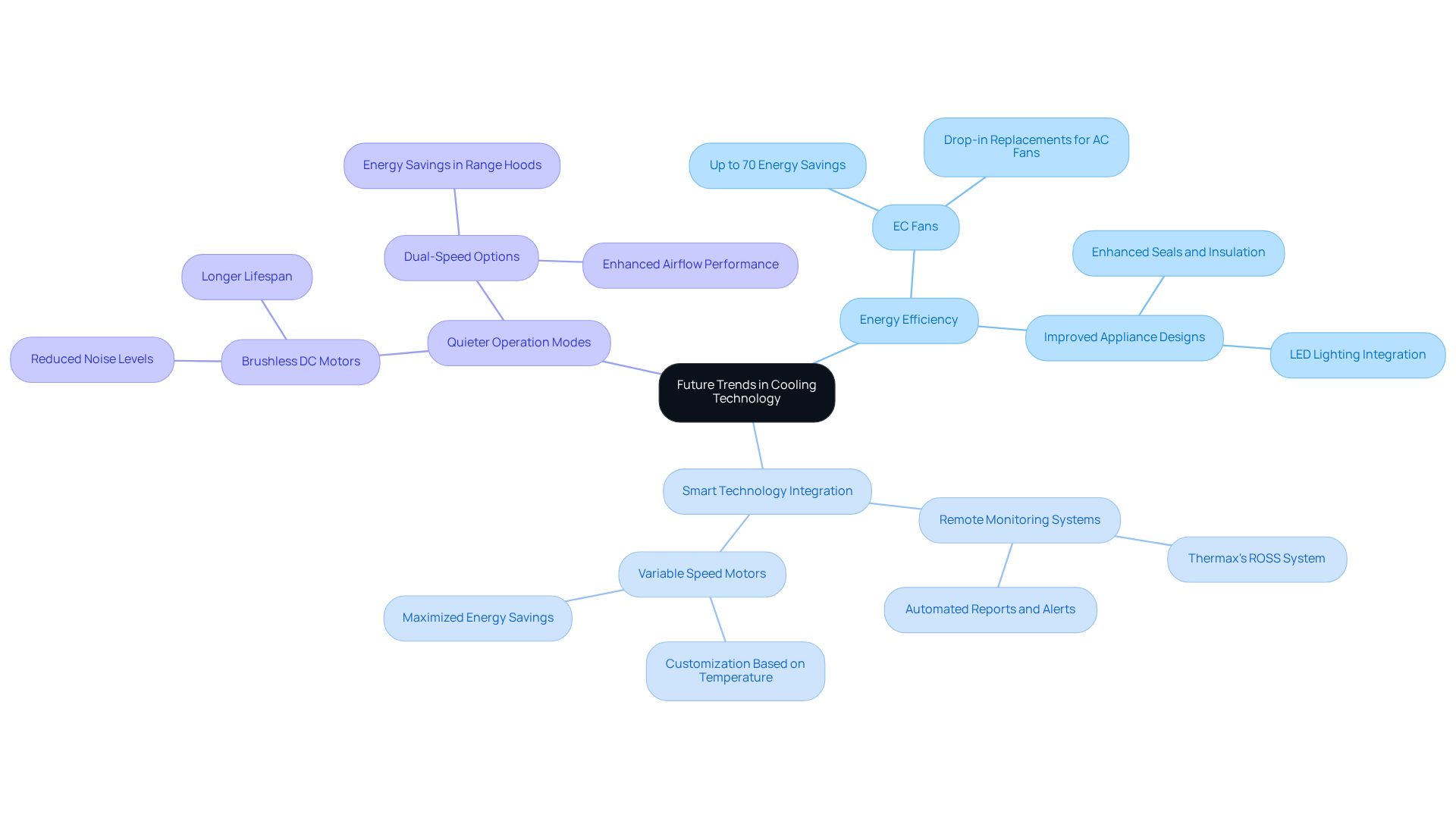

Future Trends in Cooling Technology: The Evolving Role of High Power Fans in Electronics

As technology continues to advance, the role of high power fans in electronics temperature regulation is undergoing a significant transformation. Future trends indicate a pronounced shift towards more energy-efficient designs, seamless integration with smart technologies, and the emergence of quieter operation modes. Engineers must remain vigilant and informed about these trends to effectively leverage advancements in cooling technology. By doing so, they can ensure that their designs not only remain competitive but also excel in managing thermal challenges.

Conclusion

High power fan blowers are indispensable tools in the domain of electronics cooling, playing a crucial role in sustaining optimal temperatures while enhancing the performance and reliability of electronic systems. These sophisticated cooling solutions, as demonstrated by models from Gagner-Toomey Associates and other industry frontrunners, are meticulously engineered to address the escalating demands of contemporary electronics, especially as the market for temperature control technologies continues to flourish.

The article highlights various high power fan blower models, each showcasing unique features and advantages. From the energy-efficient Wathai 120mm blower fan to the reliable Delta high-pressure systems, every model presents specific benefits tailored to a range of applications. Moreover, the significance of effective airflow management and the integration of innovative technologies, such as PWM, is underscored, which can yield substantial energy savings and enhance thermal dynamics.

Ultimately, the necessity of investing in high power fan blower technology cannot be overstated. As the electronics industry progresses, engineers must prioritize efficient cooling solutions to guarantee optimal system performance and reliability. By adopting these advanced technologies, professionals not only enhance their designs but also contribute to sustainability efforts within the industry. The future of electronics cooling is promising, and staying ahead of the curve in cooling technology will be vital for achieving success.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in innovative temperature regulation solutions specifically for the electronics engineering sector, collaborating with leading manufacturers to deliver high-quality temperature control products.

What is the projected growth rate for temperature control technologies in the electronics sector?

The market for temperature control technologies in the electronics sector is projected to expand at a compound annual growth rate of 8.9% from 2024 to 2031.

How do Gagner-Toomey’s solutions impact power consumption and temperature management?

Gagner-Toomey integrates cutting-edge technologies, such as PWM fans, which can reduce power consumption by up to 30% and enhance temperature management efficiency by as much as 30% in data centers.

What features does the Wathai 120mm x 32mm 12V High Airflow DC Brushless Blower Fan offer?

This fan has an airflow rate of 62.49 CFM, operates at a low noise level of 65 dB, and uses brushless motor technology that extends its lifespan to approximately 100,000 hours.

In what applications is the Wathai blower fan particularly suitable?

The Wathai blower fan is ideal for applications such as data centers, communication base stations, and control cabinets where effective temperature management is critical.

What are the advantages of Delta high-pressure blower fans?

Delta high-pressure blower fans are designed for demanding applications, offering high static pressure, longevity with a lifespan exceeding 50,000 hours, and efficient operation across a voltage range of 10 to 18V.

What is the significance of maintaining optimal temperatures in electronics?

Maintaining optimal temperatures is crucial for system reliability in electronics, as it prevents overheating and ensures the proper functioning of devices.

How do Delta blower fans perform in terms of energy savings?

Facilities using Delta high power fan blowers have reported substantial energy savings, such as approximately $120,512 annually, alongside improved temperature regulation.

What environments benefit from the low vibration and noise levels of Delta blower fans?

The low vibration and noise levels of Delta blower fans are particularly beneficial in sensitive environments, such as medical technology, where quiet operation is essential.