Overview

Electronically commutated motors (ECMs) represent a significant advancement in HVAC efficiency, primarily through their capability to optimize energy consumption. These motors achieve remarkable energy savings of 25-50% when compared to traditional motors, making them an essential consideration for modern heating and cooling systems.

The adaptability of ECMs is a key feature, as they adjust their speed based on real-time demand. This not only reduces operational costs but also enhances indoor air quality, which is crucial for occupant comfort and health. By integrating ECMs into HVAC systems, stakeholders can realize substantial cost savings while contributing to environmental sustainability.

In summary, ECMs emerge as a cost-effective and sustainable choice for contemporary HVAC solutions. Their ability to significantly reduce energy consumption and operational expenses positions them as a leading option for those seeking to enhance efficiency and performance in heating and cooling applications.

Introduction

The evolution of heating, ventilation, and air conditioning (HVAC) systems signifies a pivotal transition towards energy efficiency and sustainability, prominently featuring electronically commutated motors (ECMs) as key players in this transformation. These advanced motors have the potential to reduce energy consumption by up to 50% compared to traditional systems, leading to significant cost savings and a profound environmental impact.

However, with a plethora of options available, businesses and homeowners may find themselves questioning how to discern the true advantages of integrating ECM technology into their HVAC systems. This article explores ten compelling ways in which ECMs enhance HVAC efficiency, illuminating the potential benefits while addressing the challenges associated with this innovative technology.

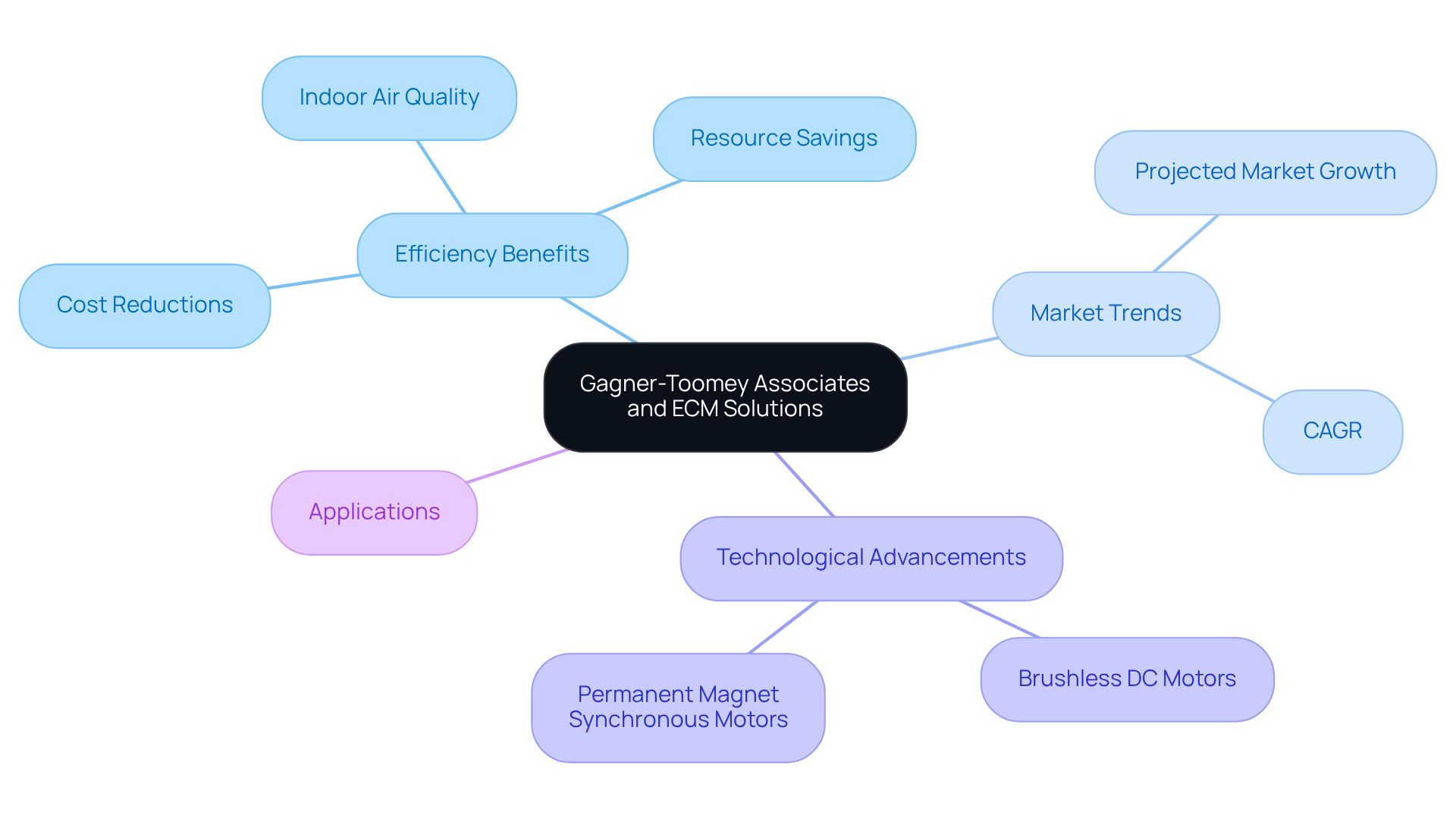

Gagner-Toomey Associates: Pioneering ECM Solutions for Enhanced HVAC Efficiency

Gagner-Toomey Associates is at the forefront of enhancing heating and cooling system efficiency, as an electronically commutated motor (ecm) is designed to optimize their performance. By collaborating with a diverse array of manufacturers, the company champions the integration of advanced technology because an electronically commutated motor (ecm) is designed to play a vital role in achieving significant resource savings and superior system performance. An electronically commutated motor (ecm) is designed to deliver cost reductions ranging from 30% to 50% compared to traditional induction motors, establishing it as a preferred choice for modern climate control systems.

The current market trends reveal an increasing demand for smart, energy-efficient solutions, with the global ECM Motor HVAC market anticipated to reach USD 8.7 billion by 2033, reflecting a compound annual growth rate (CAGR) of 8.7% from its 2024 valuation of $4.1 billion. This growth is driven by stringent efficiency regulations and the escalating adoption of intelligent building technologies.

Recent advancements in ECM technology feature the emergence of brushless DC motors, which dominate the market with a 40% value share, alongside Permanent Magnet Synchronous Motors (PMSMs), which constitute 35%. These innovations not only enhance power efficiency but also ensure that an electronically commutated motor (ecm) is designed to contribute to improved indoor air quality and operational reliability within heating and cooling systems.

The successful deployment of electronic control management systems across various sectors, including commercial buildings, hospitals, and data centers, highlights their versatility and effectiveness. For instance, electronic control modules are increasingly utilized in intelligent heating and cooling systems that automatically adjust temperatures based on occupancy, thereby further enhancing energy efficiency. Gagner-Toomey Associates’ unwavering commitment to excellence and customer service reinforces its status as a leader in delivering innovative HVAC solutions that align with the evolving demands of the electronics industry.

Understanding ECM Functionality: How Electronically Commutated Motors Operate

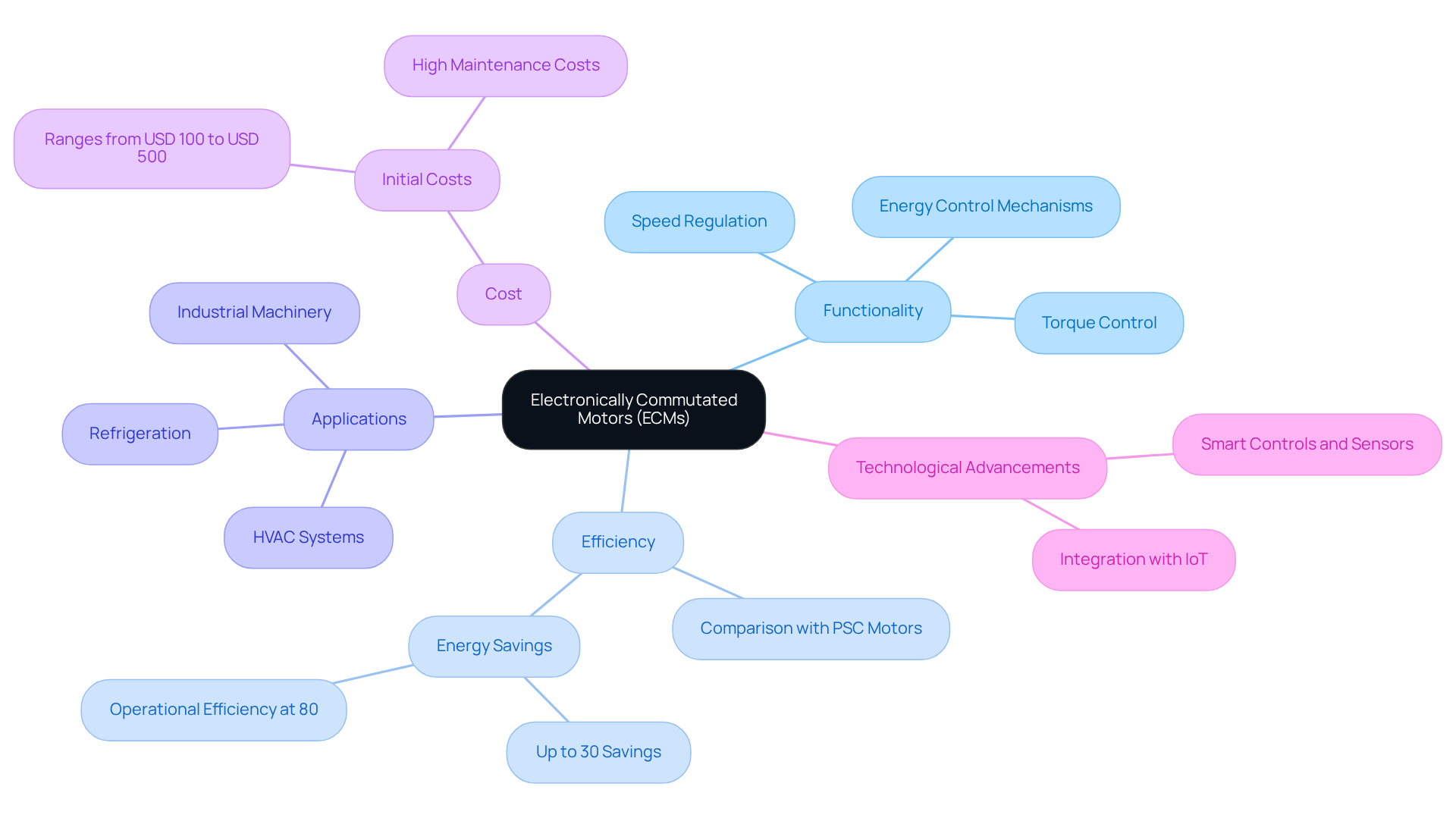

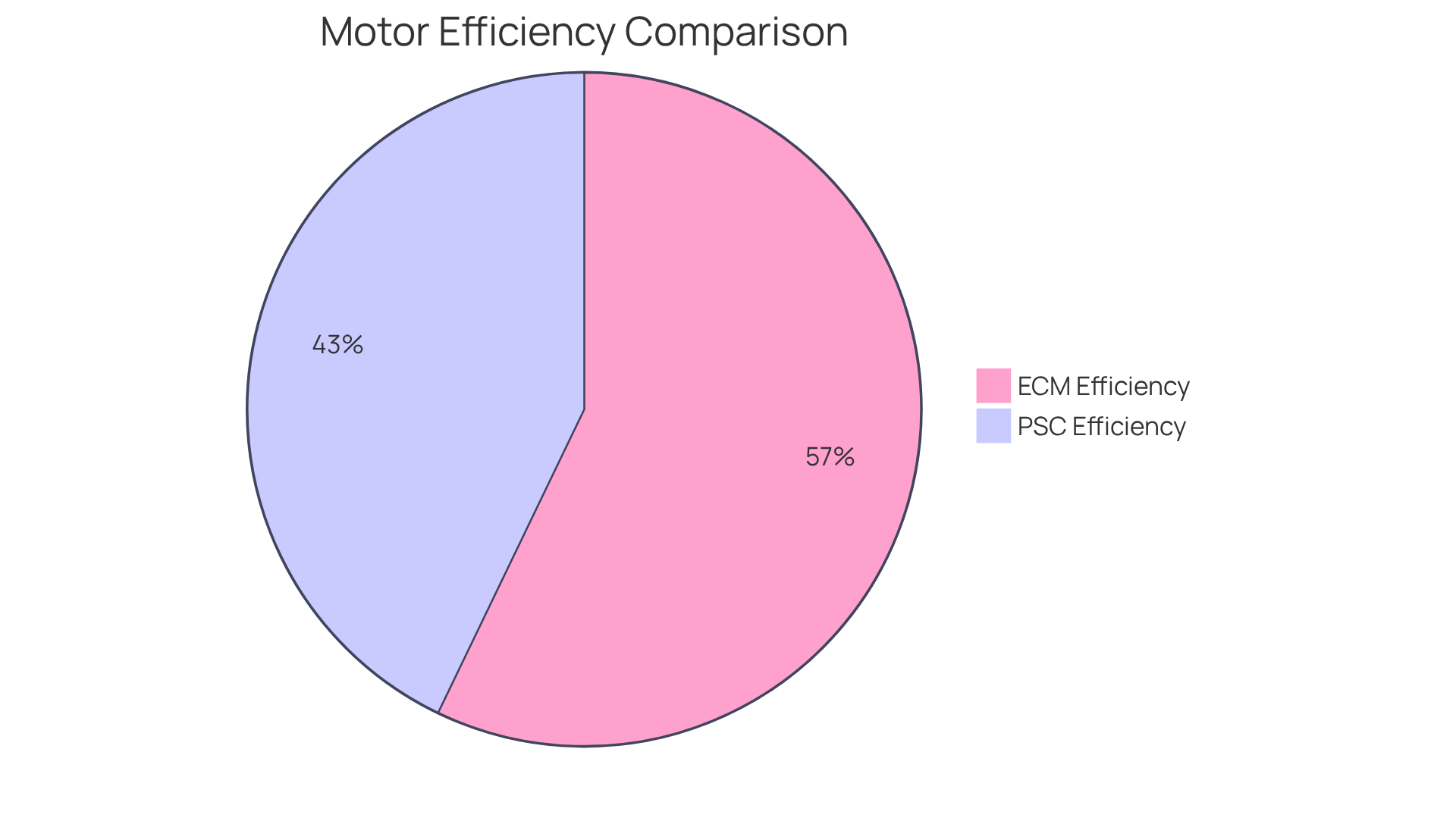

An electronically commutated motor (ecm) is designed to provide a sophisticated solution to the challenges of speed and torque regulation, leveraging advanced electronic controls for precise customization based on system requirements. Unlike conventional engines, ECMs convert AC power into DC, integrating a microprocessor that significantly enhances performance. This cutting-edge technology facilitates energy control mechanisms that ensure consistent airflow while dynamically adapting to varying load conditions, thereby markedly improving overall system efficiency.

For instance, ECMs can achieve energy savings of up to 30% compared to traditional devices, operating at approximately 80% efficiency—substantially higher than the 60% efficiency of top Permanent Split Capacitor (PSC) apparatus. Furthermore, their quiet operation and reduced heat output make them particularly suitable for both residential and commercial HVAC applications.

However, it is crucial to weigh the high initial costs associated with electronic control mechanisms against the benefits they offer over conventional engines. As the demand for energy-efficient solutions escalates, an electronically commutated motor (ecm) is designed to advance ECM technology by incorporating smart controls and sensors that enhance functionality and performance in contemporary systems. This evolution not only enhances efficiency but also positions ECMs as a pivotal choice for future energy management strategies.

Energy Efficiency: The Key Advantage of Electronically Commutated Motors

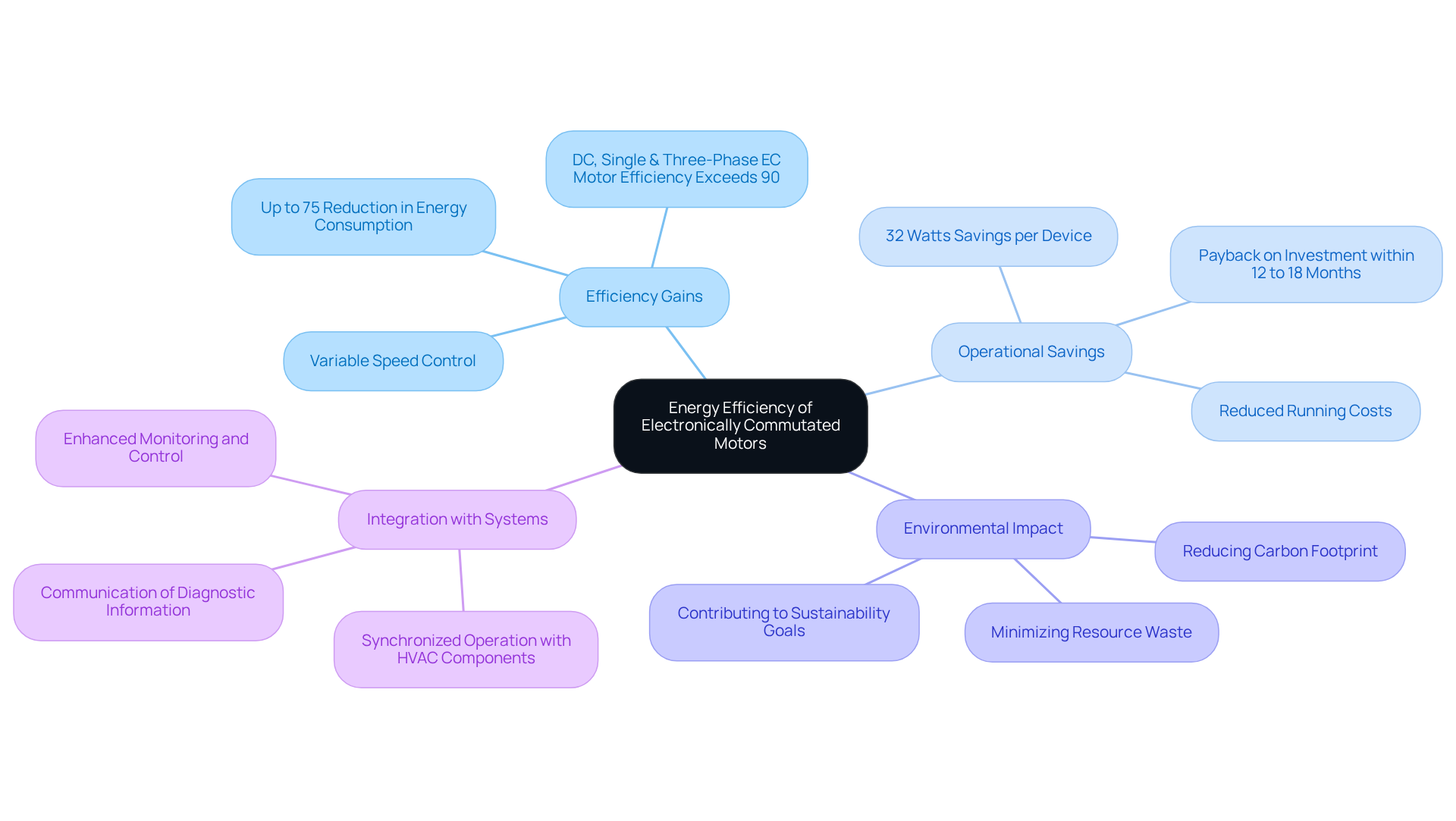

An electronically commutated motor (ecm) is designed to exemplify exceptional efficiency, often achieving reductions of up to 75% compared to conventional motors. This remarkable efficiency stems primarily from the fact that an electronically commutated motor (ecm) is designed to adjust speed based on demand, which significantly lowers power consumption during low-load periods. For instance, in commercial HVAC systems, an electronically commutated motor (ecm) is designed to substantially decrease total kilowatt hours consumed, which leads to considerable savings in operational expenses.

Furthermore, the integration of electronic control modules within building management systems enhances their efficiency, allowing for precise monitoring and adjustments that optimize resource utilization. As a result, conservation measures not only minimize resource waste but also contribute to reducing the carbon footprint, aligning with global sustainability goals.

In practical applications, facilities that have adopted energy conservation measures report considerable savings. Some studies indicate that each efficient device can cut down total power consumption by 32 Watts for equivalent tasks. This transition not only fosters financial benefits for businesses but also advocates for a greener, more sustainable environment.

Variable Speed Control: Adapting to Load Changes with ECM Technology

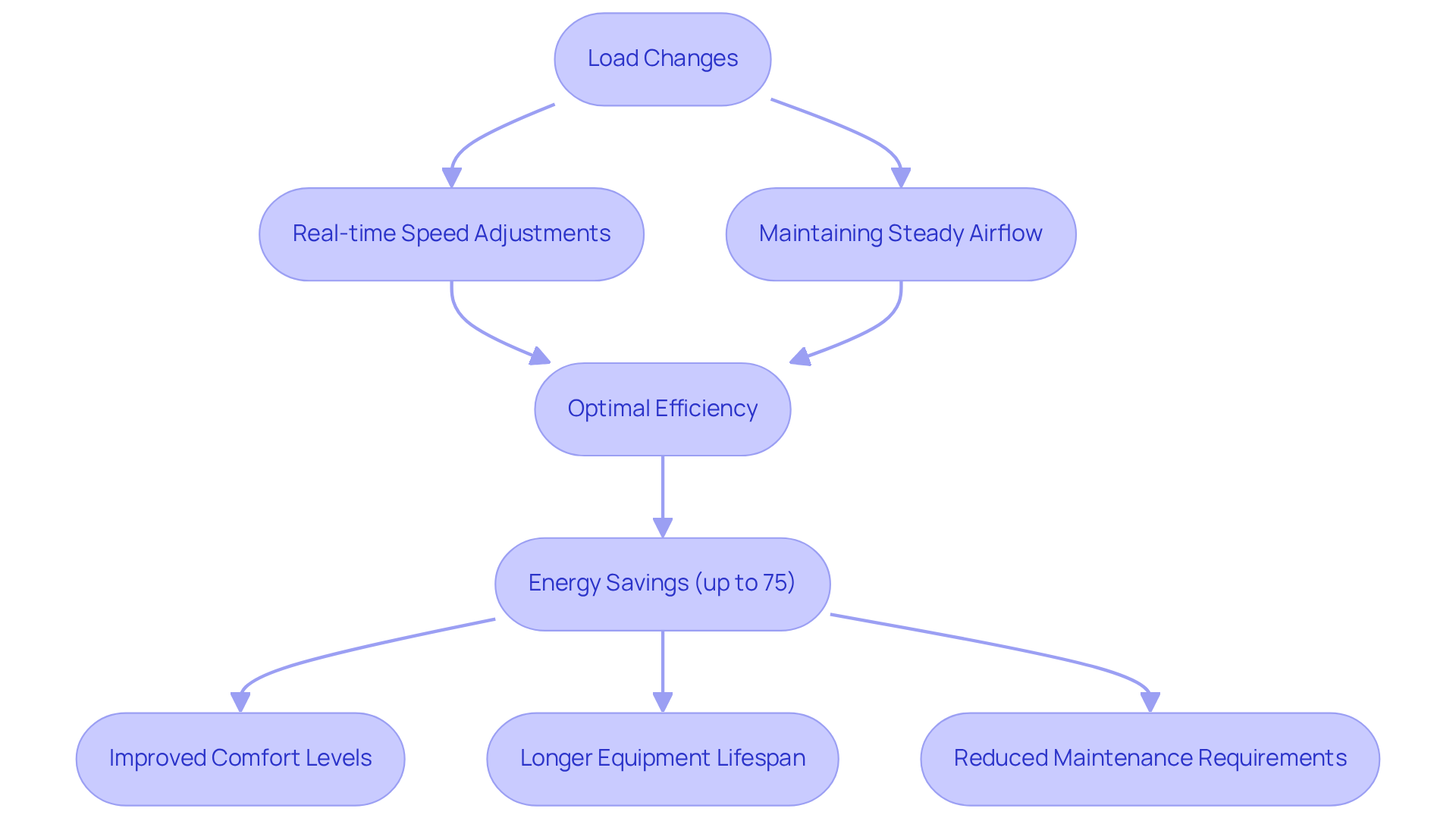

A defining characteristic of an electronically commutated motor (ecm) is its advanced variable speed control, which facilitates real-time adjustments to motor speed based on heating or cooling loads. This dynamic responsiveness ensures that HVAC systems operate at optimal efficiency, significantly enhancing energy savings.

For instance, electronically commutated motors can sustain steady airflow even as total external static pressure (TESP) varies, generating 1,230 cfm at a TESP of 0.9 in. wc., a critical factor for preserving indoor temperature stability.

In practical applications, energy control mechanisms have demonstrated their ability to adapt to varying load conditions, resulting in improved comfort levels in both residential and commercial settings. Data indicates that an electronically commutated motor (ecm) is designed to help systems achieve up to 75 percent savings on annual motor operating costs compared to traditional PSC motors, particularly during continuous fan operation, as noted by Christopher Mohalley, Training Manager at Climate Solutions.

This efficiency is further supported by case studies illustrating how energy conservation measures effectively manage airflow in systems with complex ductwork designs, ensuring that temperature differences between spaces are minimized.

Mohalley emphasizes that the capability of electronic control modules to adjust torque and speed according to system demand not only enhances performance but also contributes to a longer equipment lifespan and reduced maintenance requirements.

Electronic control mechanisms were introduced to the market in the 1980s and have since evolved into essential components of heating, ventilation, and air conditioning systems, particularly with the implementation of energy regulations.

Reliability and Longevity: The Durability of Electronically Commutated Motors

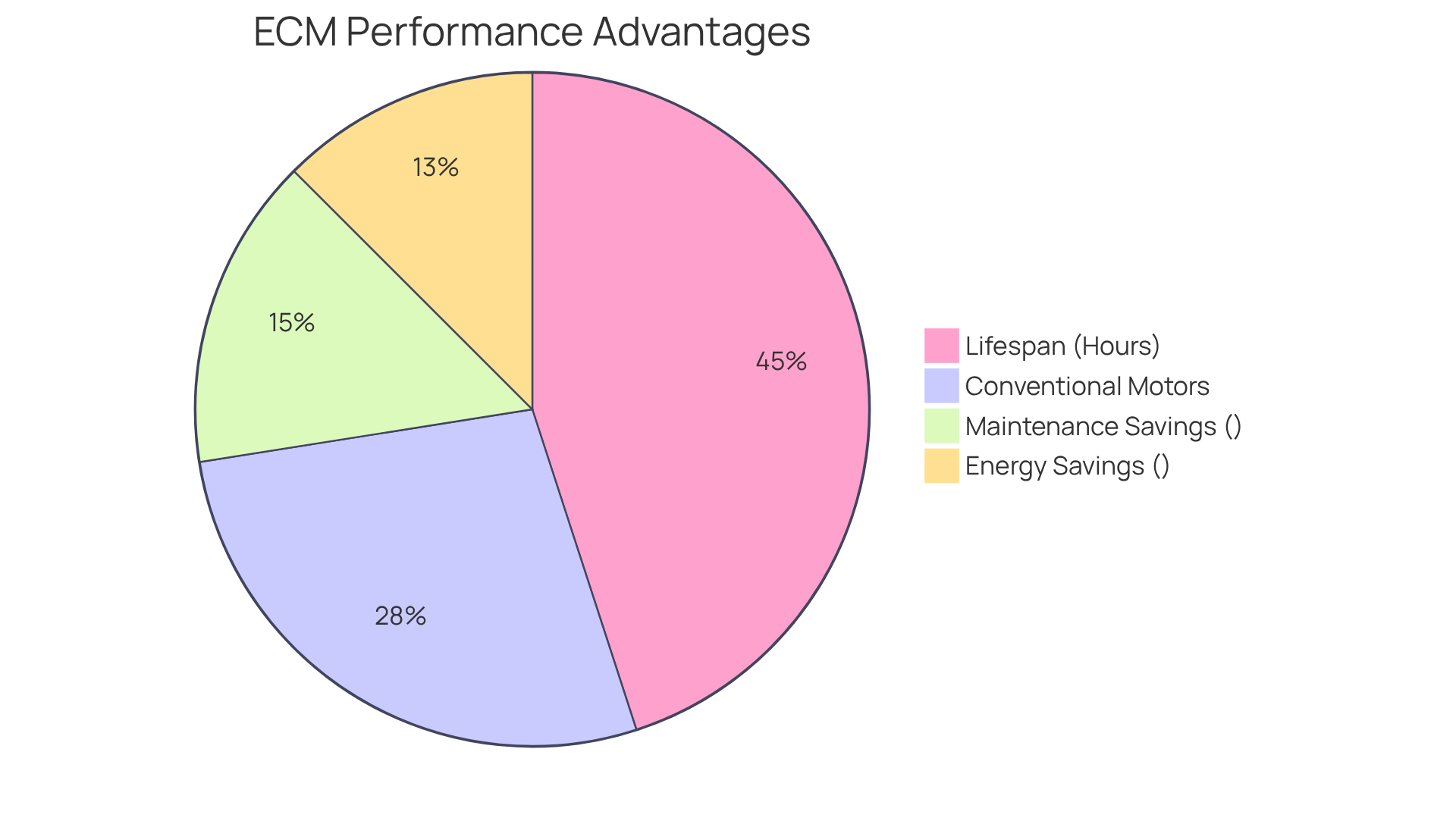

An electronically commutated motor (ecm) is designed to offer exceptional durability, often surpassing the lifespan of conventional engines significantly. An electronically commutated motor (ecm) is designed to minimize wear and tear with its brushless design, resulting in fewer breakdowns and markedly lower maintenance costs. Research indicates that an electronically commutated motor (ecm) is designed to reduce upkeep expenses for electronic control machines by as much as 30% compared to conventional induction motors, establishing them as a cost-effective choice for heating, ventilation, and air conditioning applications. Many energy management systems incorporate technology where an electronically commutated motor (ecm) is designed to operate efficiently for over 90,000 hours, making them ideal for heating and cooling applications that demand reliable performance.

For example, the SyMAX-i® line from LEESON exemplifies this durability, with numerous units exceeding NEMA Premium® (IE4) efficiency standards, ensuring both reliability and efficiency in challenging environments. As LEESON articulates, ‘An electronically commutated motor (ecm) is designed to enhance operational efficiency and contribute to substantial cost savings over time due to its longevity.’ Furthermore, an electronically commutated motor (ecm) is designed to achieve energy savings of 25-30% compared to standard induction units, underscoring their critical role in modern HVAC systems.

ECM vs. PSC Motors: A Comparative Analysis of Efficiency and Performance

The benefits of Electronically Commutated Machines (ECMs) over Permanent Split Capacitor (PSC) devices are strikingly evident. ECMs typically achieve approximately 80% efficiency, significantly surpassing the top PSC devices, which reach about 60%. This results in nearly 30% higher efficiency, particularly notable at reduced speeds. An electronically commutated motor (ecm) is designed to dynamically adjust its speed based on demand, unlike PSC devices which operate at a constant speed. This adaptability allows them to increase and decrease airflow within a span of 5 to 8 minutes.

An electronically commutated motor (ecm) is designed to enhance energy utilization while also contributing to improved airflow and reduced operational expenses, positioning it as the preferred choice for modern HVAC systems. Their efficiency at varying speeds, coupled with reduced locked rotor amps and minimized stress on components due to a gradual startup, further solidifies their status as the leading technology in energy-efficient motor solutions.

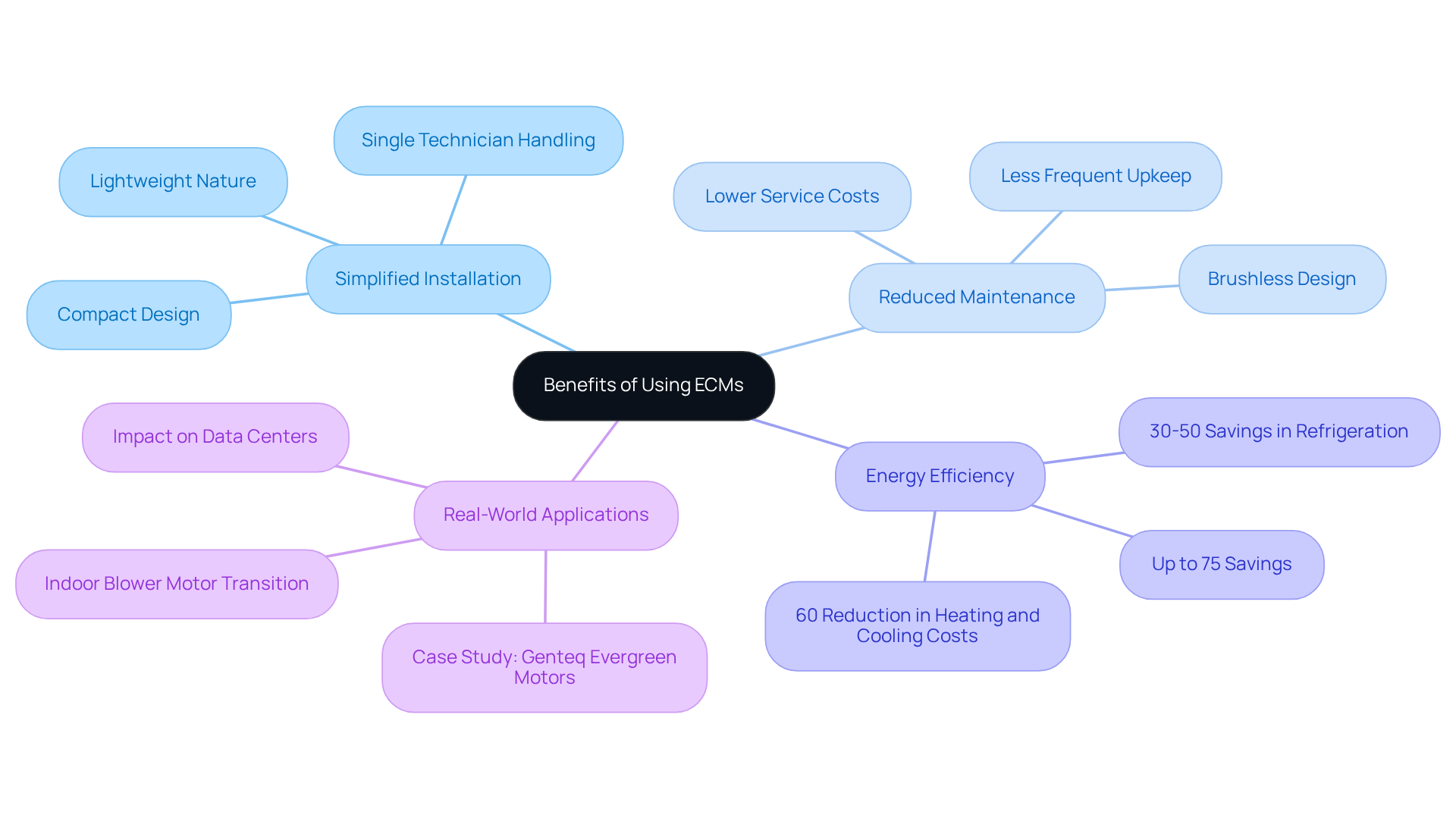

Simplified Installation and Maintenance: Benefits of Using ECMs

An electronically commutated motor (ecm) is designed to be engineered for straightforward installation, significantly streamlining the setup process. Their compact design and integrated controls minimize wiring complexity, enabling HVAC technicians to complete installations more swiftly. This efficiency is further enhanced by the brushless design of electric motors, which reduces maintenance frequency. Consequently, technicians can allocate less time to upkeep, leading to lower service costs for end-users.

For instance, energy-efficient motors can cut annual operating expenses by up to 75% during constant fan demand compared to traditional Permanent Split Capacitor (PSC) motors; however, actual savings may vary based on specific operational circumstances. Additionally, the lightweight nature of these systems simplifies handling and installation, often allowing a single technician to manage the process, thereby lowering labor costs and enhancing compliance with safety regulations.

Real-world applications, as highlighted in the Genteq Evergreen Motors case study, demonstrate that utilizing electronic control motors not only boosts operational efficiency but also results in substantial energy savings, with some installations reporting reductions in heating and cooling energy expenses by as much as 60%.

An electronically commutated motor (ecm) is designed to provide a combination of simple installation and minimal upkeep requirements, positioning it as an attractive option for modern heating and cooling systems. Technicians in heating, ventilation, and air conditioning are encouraged to consider ECM upgrades when replacing PSC motors to maximize efficiency and cost savings.

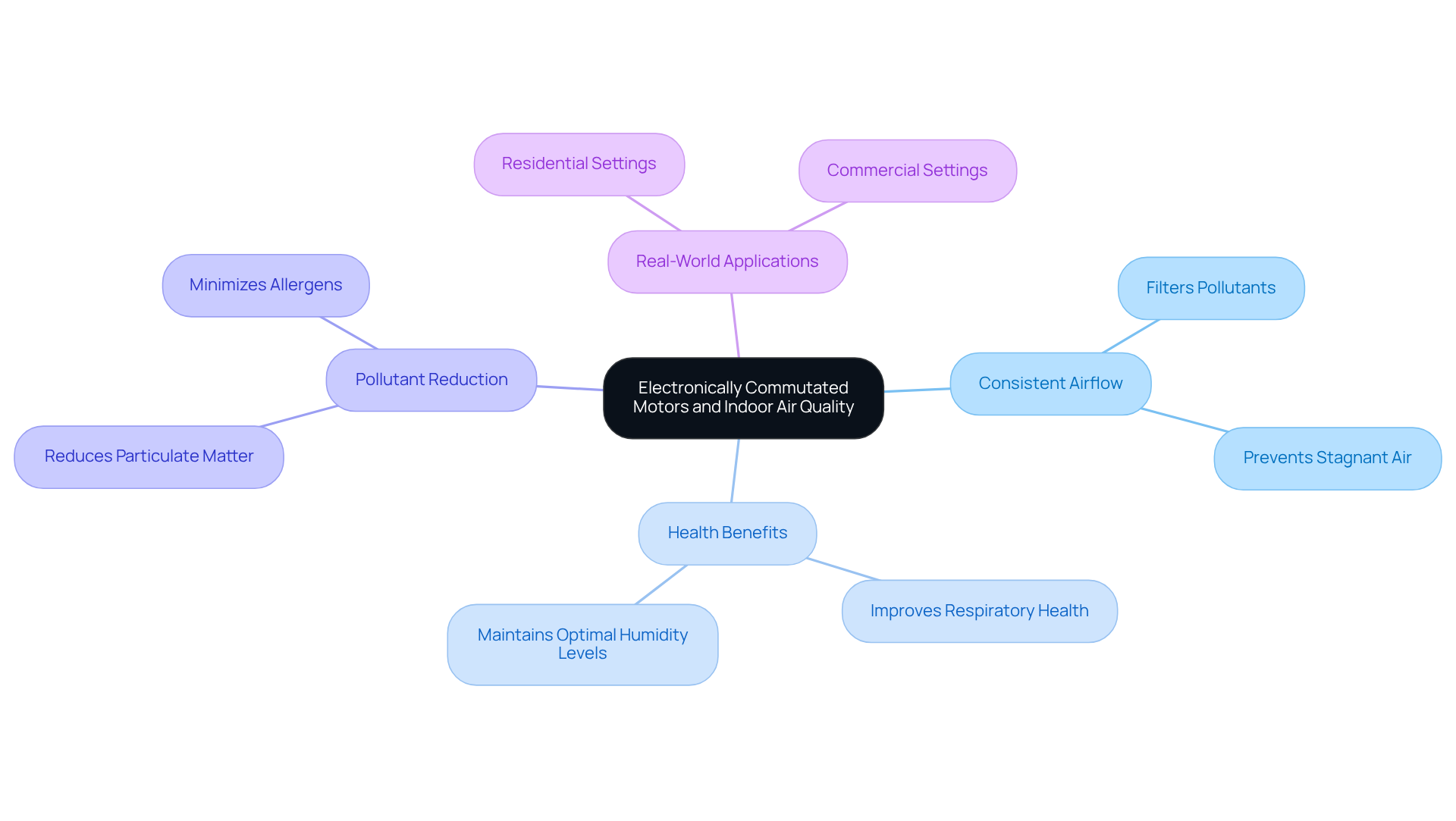

Improving Indoor Air Quality: The Role of Electronically Commutated Motors

An electronically commutated motor (ecm) is designed to be pivotal in enhancing indoor air quality by ensuring consistent airflow within HVAC systems. This continuous circulation effectively filters out pollutants and allergens, resulting in cleaner air for both residential and commercial settings.

Health experts underscore the importance of maintaining optimal humidity levels and preventing stagnant air as essential for fostering healthier indoor environments. For example, studies have shown that buildings implementing energy conservation measures achieve significant reductions in particulate matter and other harmful pollutants, thereby improving respiratory health for occupants.

Real-world applications of these systems demonstrate that an electronically commutated motor (ecm) is designed to enhance air circulation, which in turn reduces indoor air pollution and promotes a healthier living and working atmosphere.

Cost-Effectiveness: Long-Term Savings with Electronically Commutated Motors

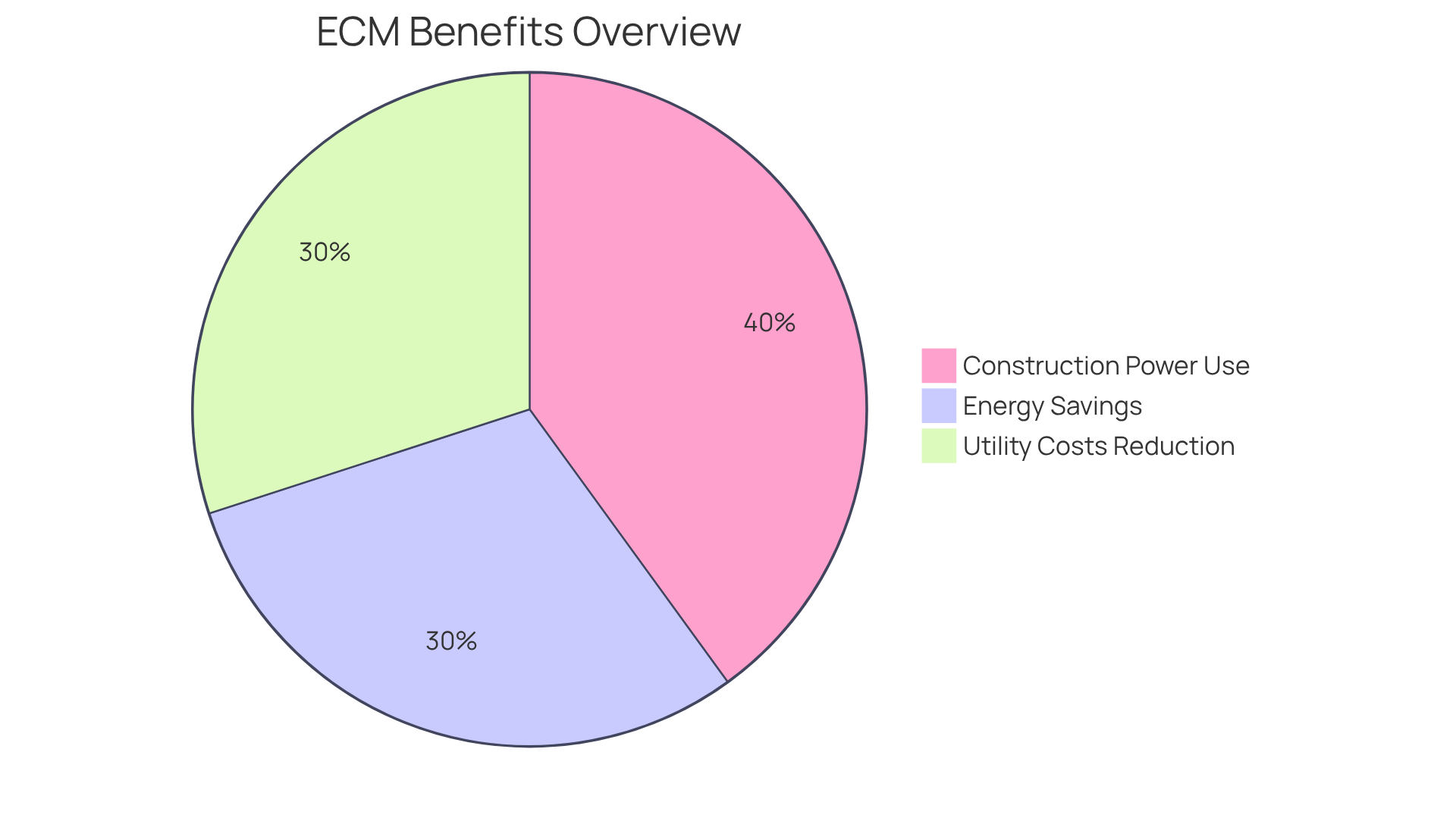

An electronically commutated motor (ecm) is designed to offer an opportunity for significant long-term savings through investment in this technology. While the initial investment may exceed that of conventional motors, the enhanced power efficiency of electronic commutation motors typically leads to a break-even point within a few years.

For instance, variable speed electronic commutation motors can achieve energy savings of 25-30% compared to standard induction models, thereby reducing utility expenses over time. Additionally, electronic cash management systems have been in use for over 35 years, underscoring their reliability and established market presence. Designed for longevity, these systems contribute to lower maintenance costs and extended operational lifespans.

Notably, energy conservation methods can yield savings of up to 80% in electricity, making them a financially prudent choice for both residential and commercial HVAC systems. Financial analysts highlight that an electronically commutated motor (ecm) is designed to offer cost-efficiency, particularly due to its ability to adjust speed according to load requirements, which enhances performance and further decreases utility costs.

Given that the construction industry accounts for 40% of global power consumption and is responsible for 33% of greenhouse gas emissions, transitioning to solutions where an electronically commutated motor (ecm) is designed to facilitate personal cost reductions also supports broader sustainability goals.

Future Innovations: The Evolving Role of ECMs in HVAC Efficiency

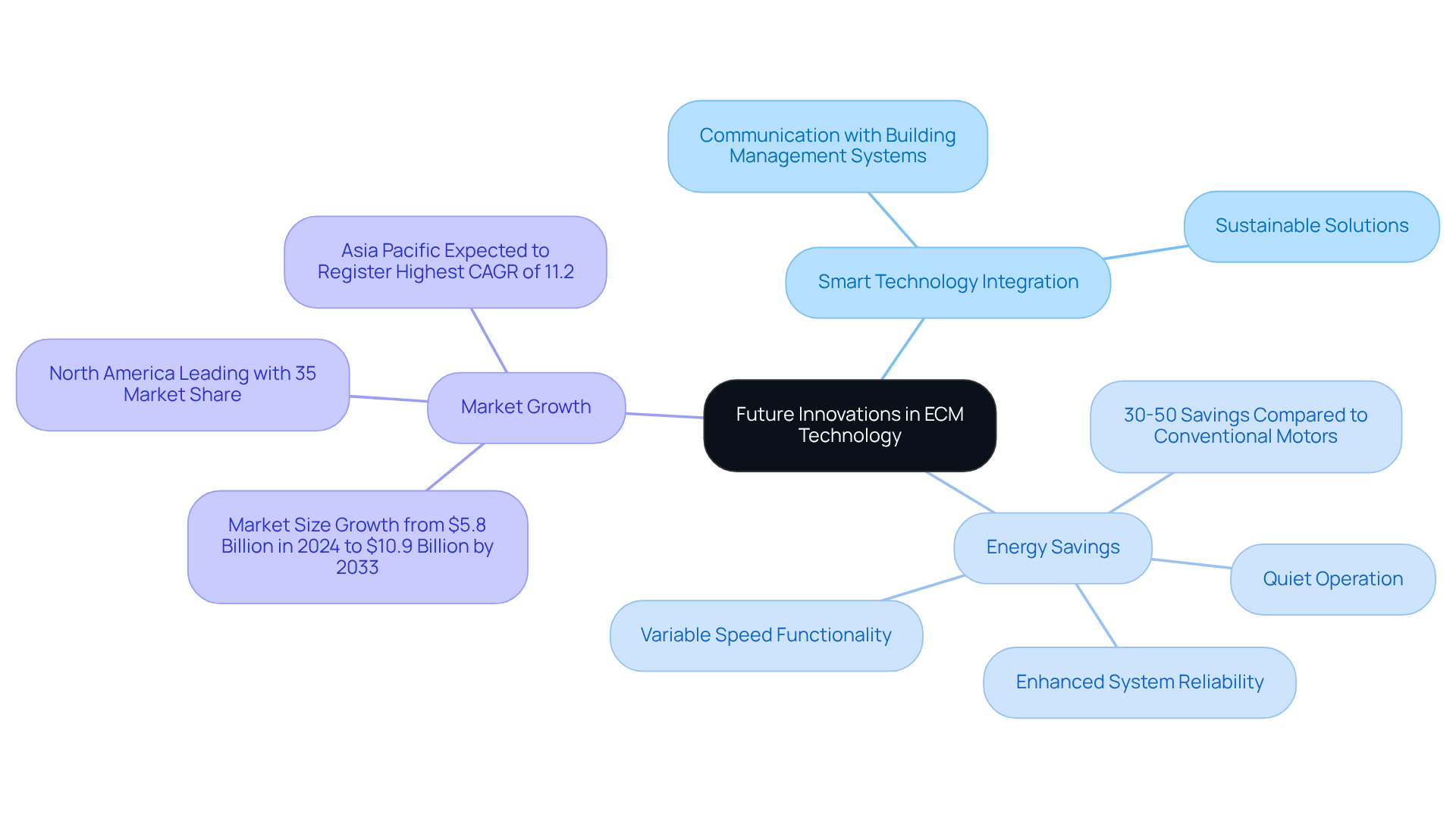

The future of electronically commutated machinery (ECM) technology is exceptionally promising, propelled by ongoing innovations that significantly enhance both efficiency and performance. Key trends shaping this landscape include:

- Integration of Smart Technology: ECMs are increasingly designed to communicate seamlessly with building management systems. This capability not only optimizes energy usage but also aligns with the rising demand for sustainable solutions.

- Energy Savings: Electronically commutated motors can deliver remarkable energy savings, ranging from 30% to 50% compared to conventional motors. They also offer variable speed functionality, quiet operation, enhanced system reliability, and smooth integration with intelligent controls and building management systems.

- Market Growth: The global ECM Motor heating, ventilation, and air conditioning market size reached USD 5.8 billion in 2024 and is projected to grow to USD 10.9 billion by 2033. This trajectory indicates robust growth and underscores the significance of an electronically commutated motor (ecm) is designed to serve as a foundational element of energy-efficient heating and cooling systems.

Expert insights indicate that the ongoing evolution of ECMs will prioritize enhancing compatibility with IoT devices, setting the stage for smarter and more efficient climate control solutions in the future. As Raksha Sharma aptly noted, “The ECM HVAC market is experiencing accelerated expansion, driven by increasing regulatory emphasis on energy efficiency.” However, this market also encounters challenges, including fierce competition, rapidly advancing technology, and the necessity to adapt to shifting market demands.

Conclusion

The integration of electronically commutated motors (ECMs) into HVAC systems represents a pivotal advancement in energy efficiency and operational effectiveness. These innovative motors not only reduce energy consumption by up to 75% compared to traditional motors, but they also enhance indoor air quality, simplify installation, and lower maintenance costs. This shift towards ECM technology underscores a broader commitment to sustainability and cost-effectiveness in climate control solutions.

Key benefits of ECMs include:

- Their ability to adapt to varying load conditions through variable speed control, leading to optimized energy usage and improved comfort levels.

- The durability and longevity of ECMs, which further establish them as a reliable choice for both residential and commercial applications, characterized by reduced upkeep and extended operational lifespans.

- The promising market growth for ECMs, indicating a strong trend towards smarter, more efficient HVAC systems that align with regulatory demands for energy conservation.

As the HVAC industry continues to evolve, embracing ECM technology transcends mere operational efficiency; it is a crucial step towards achieving sustainability goals. By investing in electronically commutated motors, stakeholders can significantly reduce their carbon footprint while enjoying long-term financial savings. It is imperative for businesses and consumers alike to recognize the transformative potential of ECMs in fostering a more energy-efficient and environmentally friendly future.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for enhancing heating and cooling system efficiency through the use of electronically commutated motors (ECMs), which optimize performance and contribute to significant resource savings.

What are the cost benefits of using electronically commutated motors (ECMs)?

ECMs can deliver cost reductions ranging from 30% to 50% compared to traditional induction motors, making them a preferred choice for modern climate control systems.

What is the projected growth of the ECM Motor HVAC market?

The global ECM Motor HVAC market is anticipated to reach USD 8.7 billion by 2033, growing at a compound annual growth rate (CAGR) of 8.7% from a 2024 valuation of $4.1 billion.

What advancements are being made in ECM technology?

Recent advancements include the emergence of brushless DC motors, which hold a 40% market value share, and Permanent Magnet Synchronous Motors (PMSMs), which account for 35%. These innovations enhance power efficiency and improve indoor air quality.

Where are electronic control management systems being deployed?

Electronic control management systems are successfully deployed in various sectors, including commercial buildings, hospitals, and data centers, particularly in intelligent heating and cooling systems that adjust temperatures based on occupancy.

How do electronically commutated motors (ECMs) operate?

ECMs convert AC power into DC and use a microprocessor for precise customization based on system requirements, allowing for energy control mechanisms that ensure consistent airflow and adapt to varying load conditions.

What is the efficiency of ECMs compared to traditional motors?

ECMs can achieve energy savings of up to 30% and operate at approximately 80% efficiency, significantly higher than the 60% efficiency of top Permanent Split Capacitor (PSC) motors.

What are the environmental benefits of using ECMs?

The use of ECMs contributes to reducing the carbon footprint and aligns with global sustainability goals by minimizing resource waste and lowering power consumption during low-load periods.

What are the financial benefits of implementing energy conservation measures with ECMs?

Facilities adopting energy conservation measures report considerable savings, with studies indicating that each efficient device can reduce total power consumption by 32 Watts for equivalent tasks, leading to lower operational expenses.