Overview

The article provides an in-depth exploration of the various types of air blowers and their applications, serving as essential guidance for electronics engineers in selecting the most suitable blower for their specific needs. It highlights critical factors such as airflow, force, efficiency, and noise levels. By illustrating how a thorough understanding of these principles can lead to optimized performance and enhanced energy efficiency in electronic systems, the article aims to equip engineers with the knowledge necessary to make informed decisions.

Introduction

Understanding the intricacies of air blowers is essential for electronics engineers tasked with ensuring optimal performance in their designs. With a myriad of blower types available, each tailored for specific applications, the stakes are high when it comes to selecting the right solution. However, with so many options and considerations—ranging from airflow requirements to noise levels—engineers face a complex landscape that demands informed decision-making. This guide delves into the fundamental principles of air blower operation, explores various types, and provides key insights to help engineers choose the most effective blower for their unique needs.

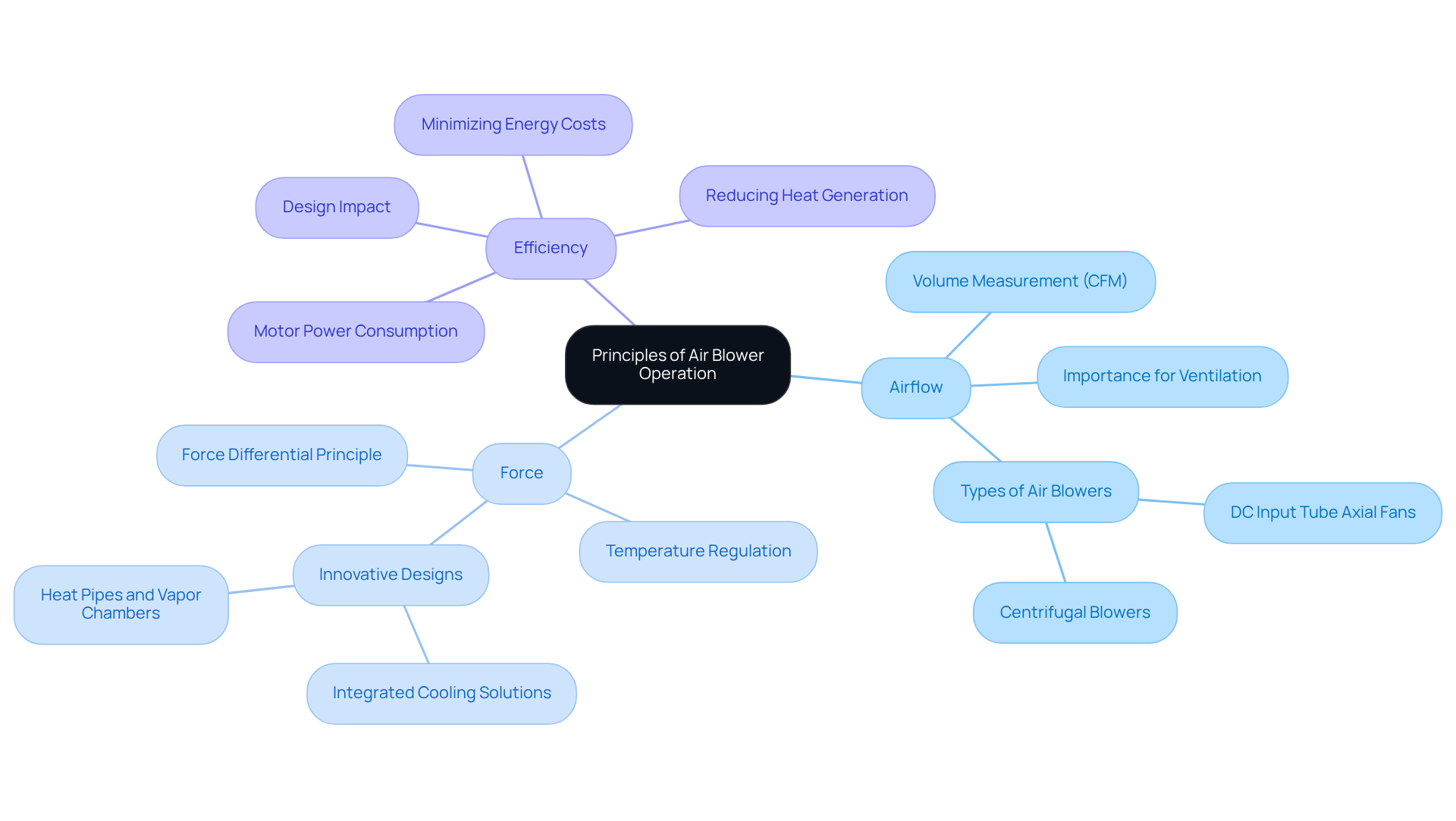

Explore the Principles of Air Blower Operation

Air devices operate on the principle of moving air through mechanical means, typically using a motor-driven fan. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers an extensive variety of temperature regulation solutions optimized for performance, efficiency, and low noise. Understanding the key concepts is essential:

- Airflow: The volume of air moved by the blower, measured in cubic feet per minute (CFM). Comprehending airflow is crucial for guaranteeing sufficient ventilation in electronic systems. Gagner-Toomey’s broad product line features different air blower types, including DC input Tube Axial fans and Centrifugal Blowers, ensuring that engineers can select the right airflow for their specific applications.

- Force: Air blowers create a force differential that allows air to flow from areas of high force to low force. This principle is essential in situations where temperature regulation or air movement is required. Gagner-Toomey’s innovative designs, including integrated cooling solutions with heat pipes and vapor chambers, enhance pressure management in electronic systems.

- Efficiency: The effectiveness of an air device is determined by its design and the motor’s power consumption. Gagner-Toomey emphasizes efficiency in its products, helping engineers minimize energy costs and heat generation in electronic systems.

By understanding these principles and utilizing Gagner-Toomey’s extensive portfolio, engineers can better evaluate the performance traits of various air blower types and their suitability for specific applications.

Identify Different Types of Air Blowers and Their Applications

Air blowers are available in various types, each specifically designed for distinct applications:

-

Centrifugal Blowers: These devices utilize a rotating impeller to increase air velocity, proving particularly effective in high-pressure scenarios. They excel in regulating temperatures of electronic components within confined spaces, where efficient heat dissipation is critical. With a maximum speed of 11,250 RPM, centrifugal fans can deliver airflow of up to 2,414 CFM at free delivery. Their capacity to handle elevated static forces makes them essential in electronics thermal management applications, ensuring optimal operating conditions for delicate equipment.

-

Axial Fans: Featuring blades that propel air parallel to the fan’s axis, axial fans are suitable for high airflow at low resistance. Commonly utilized in ventilation systems, they effectively cool large areas and maintain air circulation in various environments. Their design allows for efficient airflow management, which is crucial in applications requiring extensive ventilation.

-

Positive Displacement Devices: By trapping a fixed volume of air and discharging it, positive displacement devices provide consistent airflow and pressure. This characteristic renders them suitable for applications like pneumatic conveying, where maintaining a steady air supply is crucial. Their reliability in delivering uniform airflow enhances performance across various industrial processes.

Understanding these air blower types enables engineers to select the most suitable solution for their specific project needs, thereby ensuring optimal performance and energy efficiency. Moreover, advancements in fan technology have significantly improved energy efficiency and airflow dynamics, essential considerations for engineers in today’s environmentally conscious landscape. Engineers should also consider sound levels when selecting radial-blade fans, as they often generate the highest noise levels among centrifugal fan units, which can be substantial in sensitive environments.

Select the Appropriate Air Blower for Your Engineering Needs

When selecting an air blower, engineers must evaluate several key factors to ensure optimal performance in electronic applications:

- Airflow Requirements: It is essential to calculate the necessary airflow in cubic feet per minute (CFM) based on the cooling needs of electronic components. This calculation is crucial for effective heat dissipation, particularly in high-performance systems where overheating can lead to failure.

- Force Requirements: Evaluating the force needs for the specific application is critical. For instance, fans designed for a minimum of 5 inches of water gauge (WG) excel in tasks such as dust collection and cooling in restricted areas, where increased force is vital. Conversely, reduced force may suffice for general ventilation tasks. Additionally, considering static pressure is important, as it indicates how well a fan can handle system resistance.

- Noise Levels: The noise produced by the fan should be considered, particularly in environments where sound levels are critical. Recent advancements have led to devices with sound levels reduced to 72 dB(a), significantly enhancing user experience in sensitive settings. Furthermore, opting for models that consume less power can save energy costs by 20-30%, according to the U.S. Department of Energy.

- Size and Form Factor: Ensuring that the air mover fits within the spatial constraints of the design is imperative. Compact fans are often essential for smaller electronic devices, where space is limited.

- Lifecycle Costs: Evaluating the total cost of ownership, which includes initial purchase price, energy consumption, and maintenance costs, provides a holistic view that aids in making informed decisions aligned with budgetary constraints.

- Sustainability Considerations: With the growing trend towards eco-friendly and energy-efficient ventilation systems, selecting models made from recyclable or sustainably sourced materials can align with sustainability goals.

By thoroughly evaluating these criteria, engineers can select the most suitable air blower, thereby enhancing the performance and reliability of their electronic systems. This careful selection process not only improves operational efficiency but also aligns with sustainability goals, as energy-efficient models can reduce energy costs by up to 40%.

Conclusion

Understanding the various types of air blowers and their operational principles is crucial for electronics engineers seeking to optimize thermal management in their projects. This guide has explored the mechanics of air blowers, highlighting the significance of airflow, force, and efficiency in ensuring effective ventilation and cooling for electronic systems. By leveraging the extensive range of products from Gagner-Toomey, engineers can make informed decisions tailored to their specific application needs.

The article has delved into the distinct categories of air blowers, including:

- Centrifugal blowers

- Axial fans

- Positive displacement devices

Each type is designed for unique applications. Key considerations such as:

- Airflow requirements

- Force needs

- Noise levels

- Size constraints

- Lifecycle costs

- Sustainability

have been outlined to aid engineers in selecting the most appropriate air blower. By carefully evaluating these factors, one can enhance the performance and reliability of electronic systems while aligning with energy efficiency and sustainability goals.

Ultimately, the choice of air blower can significantly impact the operational efficiency of electronic devices. As technology continues to evolve, engineers are encouraged to stay informed about advancements in blower technology and consider innovative solutions that not only meet performance standards but also contribute to a greener future. Embracing these insights will empower engineers to make strategic selections that enhance both functionality and environmental responsibility in their designs.

Frequently Asked Questions

What is the basic principle of air blower operation?

Air blowers operate by moving air through mechanical means, typically using a motor-driven fan.

What is airflow, and why is it important?

Airflow is the volume of air moved by the blower, measured in cubic feet per minute (CFM). It is crucial for ensuring sufficient ventilation in electronic systems.

What types of air blowers does Gagner-Toomey offer?

Gagner-Toomey offers a variety of air blower types, including DC input Tube Axial fans and Centrifugal Blowers, allowing engineers to select the right airflow for their specific applications.

How do air blowers create airflow?

Air blowers create a force differential that allows air to flow from areas of high force to low force, which is essential for temperature regulation and air movement.

What role does efficiency play in air blower operation?

Efficiency determines the effectiveness of an air device based on its design and the motor’s power consumption, helping to minimize energy costs and heat generation in electronic systems.

How can engineers benefit from understanding air blower principles?

By understanding the principles of airflow, force, and efficiency, engineers can better evaluate the performance traits of various air blower types and their suitability for specific applications.