Overview

Vapor chamber coolers represent a cutting-edge solution in thermal management, leveraging the principles of evaporation and condensation to effectively regulate temperature in compact electronic devices. Their high thermal conductivity, uniform heat distribution, and compact design position them as superior options in the realm of cooling technologies. However, engineers must also weigh the higher costs and design complexities associated with these systems when selecting the most suitable cooling solutions for specific applications.

By understanding both the advantages and disadvantages, professionals can make informed decisions that enhance device performance while navigating the challenges inherent in advanced thermal management.

Introduction

Vapor chamber coolers are transforming thermal management in modern electronics, presenting a groundbreaking solution to the challenges posed by compact device designs. By leveraging the principles of evaporation and condensation, these systems ensure efficient heat distribution, which is essential for preserving the performance and longevity of high-tech devices.

As engineers delve into the potential of vapor chambers, it is imperative to navigate a landscape that encompasses both remarkable advantages and notable limitations. Key factors must be considered when determining whether to adopt this advanced cooling technology in place of traditional methods.

Define Vapor Chambers and Their Functionality

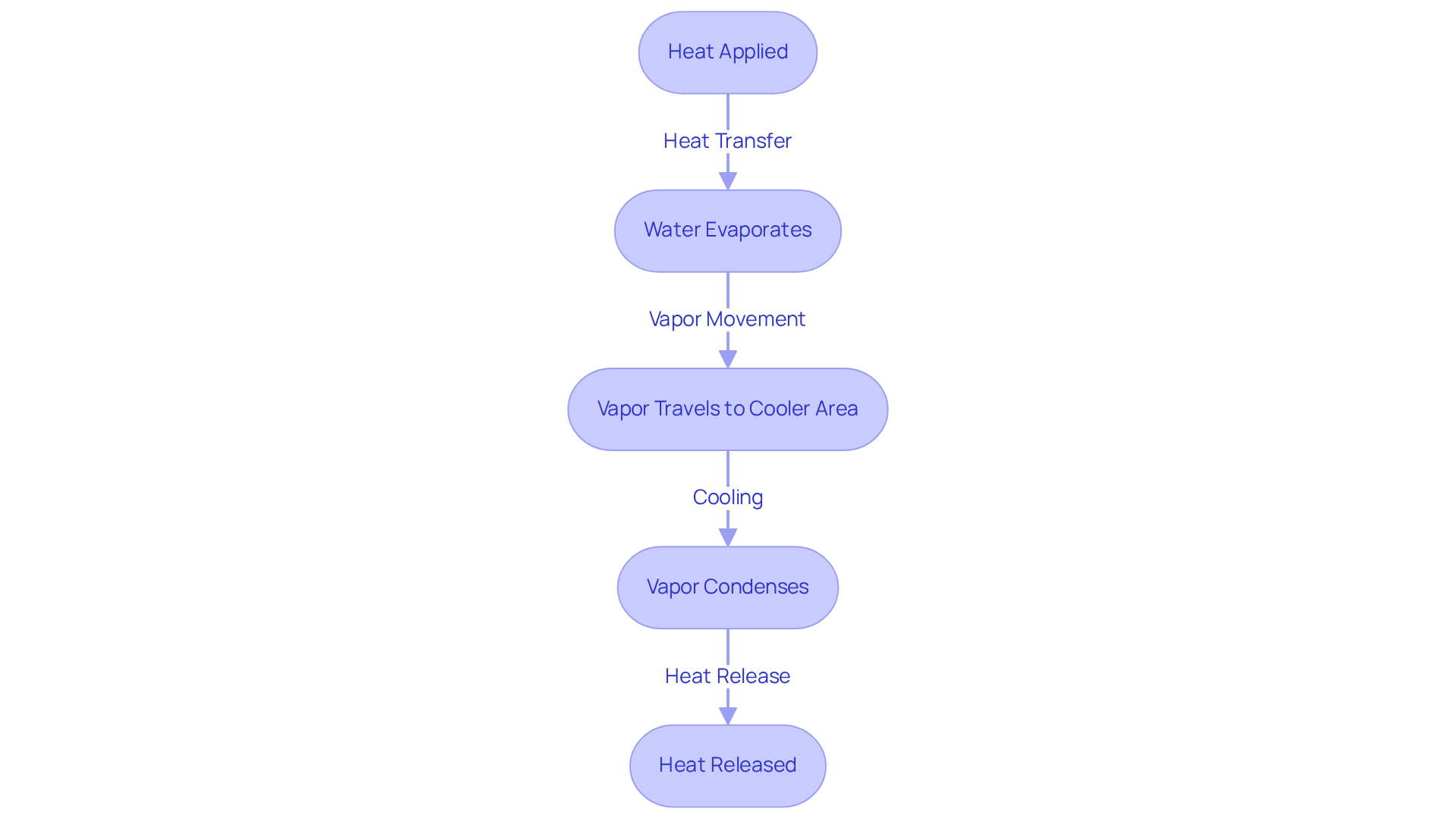

A steam enclosure serves as a two-phase thermal transfer apparatus that utilizes the principles of evaporation and condensation to effectively regulate temperature. It consists of a sealed enclosure filled with a working fluid, typically water, which evaporates when heated. This vapor then migrates to cooler regions of the enclosure, where it condenses back into liquid form, releasing the stored warmth. Such a process enables gas-filled units, like a vapor chamber cooler, to distribute heat over a broader surface area, rendering them particularly efficient in scenarios where space is limited, such as in laptops and smartphones. Moreover, the design of vapor chamber coolers allows for operation in two dimensions, in contrast to conventional pipes that primarily function in one direction, significantly enhancing their performance.

Explore Advantages of Vapor Chamber Cooling

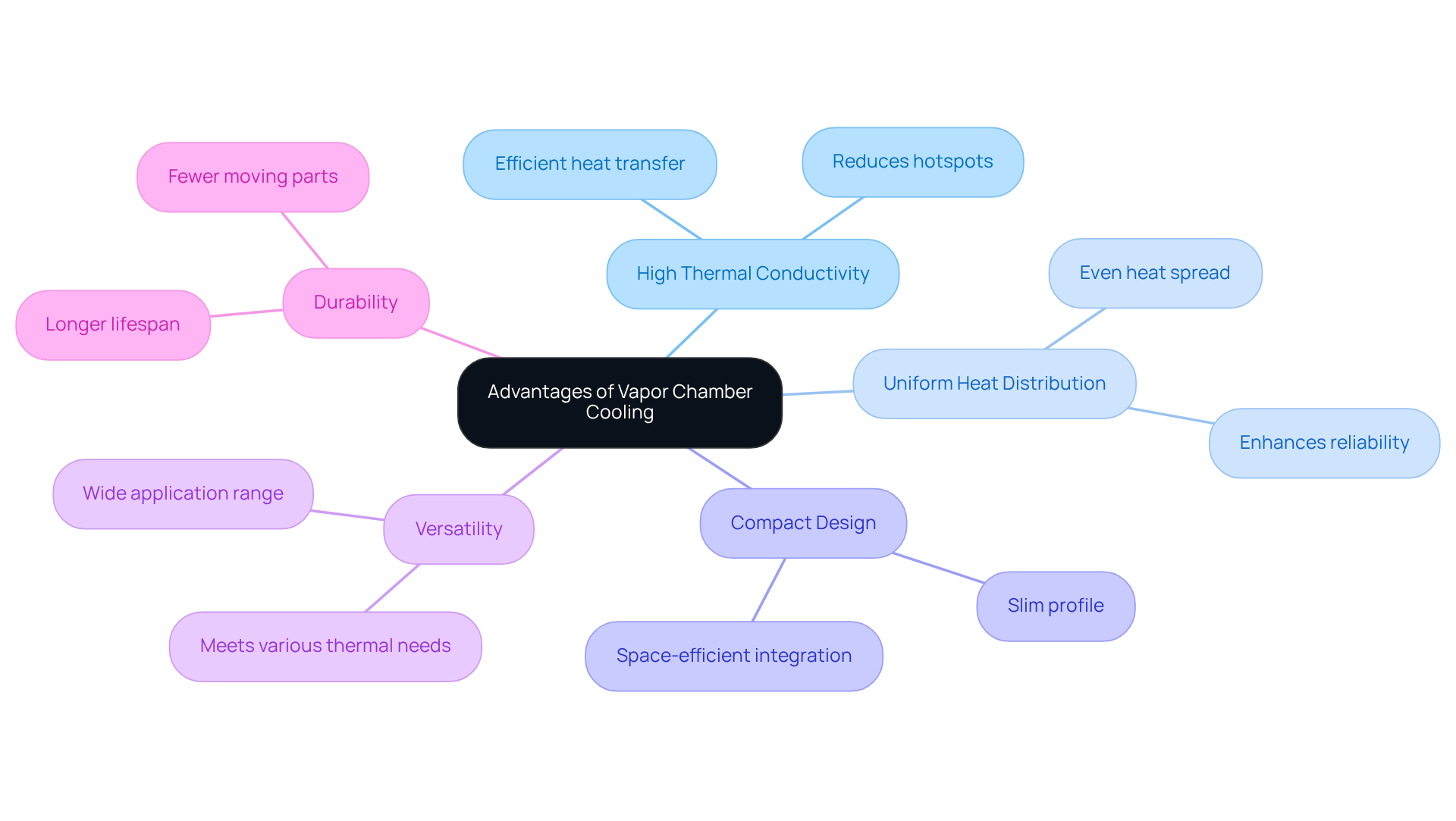

Vapor chamber cooling systems present a multitude of advantages that are essential for modern electronic applications:

- High Thermal Conductivity: These systems excel in transferring heat more efficiently than traditional cooling methods, which significantly reduces hotspots and enhances overall thermal performance.

- Uniform Heat Distribution: A vapor chamber cooler is designed to spread heat evenly across its surface, which is a critical factor in maintaining the reliability and longevity of electronic components.

- Compact Design: The vapor chamber cooler features a slim profile that allows for seamless integration into space-constrained environments, making it particularly suitable for contemporary electronic devices.

- Versatility: Vapor chamber coolers are adaptable for a wide range of applications, from high-performance computing to consumer electronics, effectively meeting various thermal management requirements.

- Durability: With fewer moving parts compared to active temperature control systems, heat transfer plates typically enjoy a longer lifespan and require less maintenance.

In conclusion, the implementation of a vapor chamber cooler not only addresses the pressing thermal management challenges faced by modern electronics but also offers a reliable and efficient solution that enhances performance and longevity.

Assess Disadvantages of Vapor Chamber Cooling

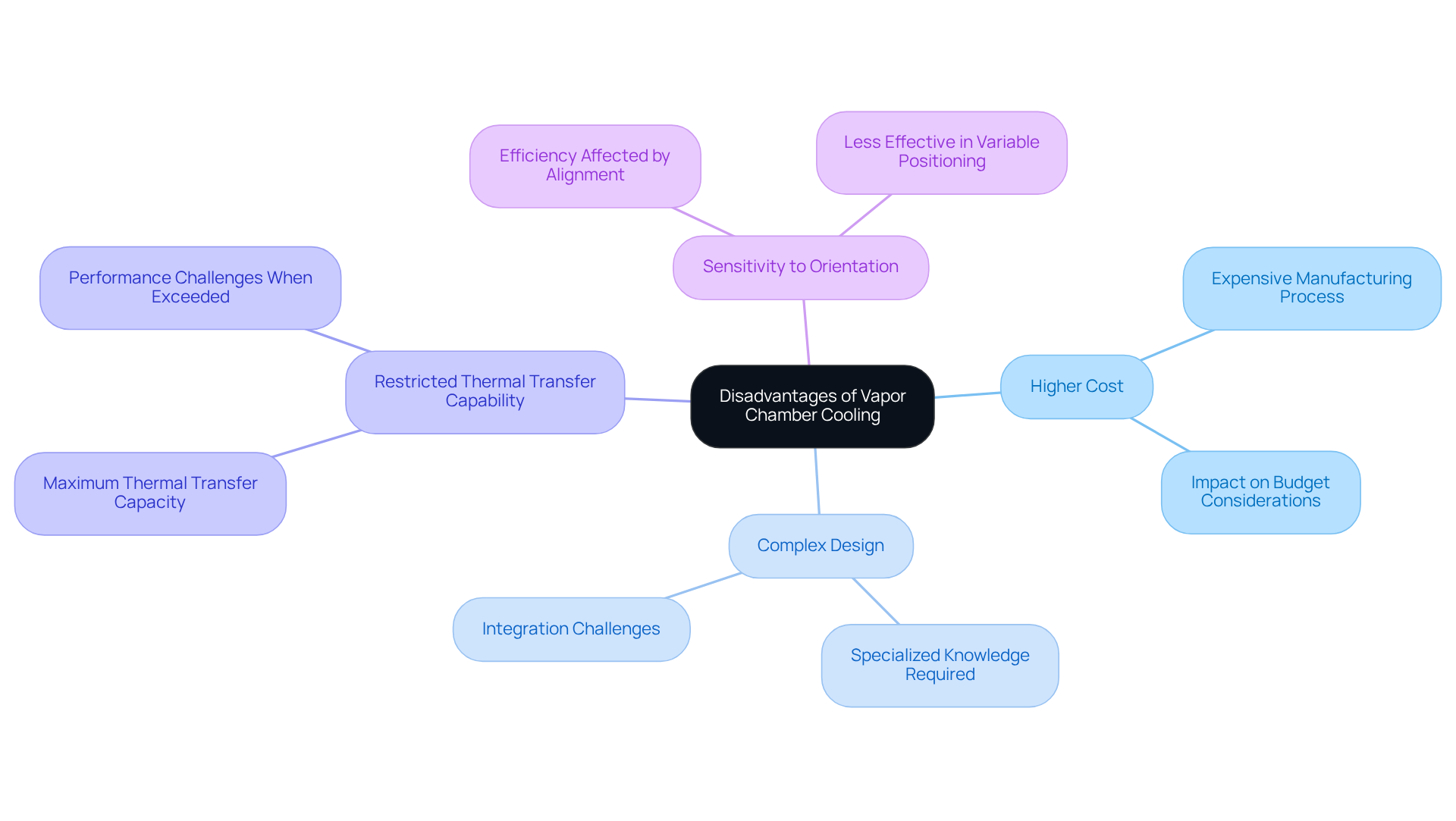

Despite their advantages, vapor chamber cooling systems present several notable disadvantages that warrant careful consideration:

- Higher Cost: The manufacturing process for vapor chambers tends to be more expensive than that of traditional cooling methods, which can significantly impact budget considerations.

- Complex Design: The creation and integration of thermal management systems into existing configurations require specialized knowledge and expertise, complicating the development process.

- Restricted Thermal Transfer Capability: While vaporization units are efficient, they possess a maximum thermal transfer capacity; exceeding this threshold may lead to performance challenges.

- Sensitivity to Orientation: The efficiency of steam compartments can be affected by their alignment, making them less effective in applications where positioning is variable.

Understanding these limitations is crucial for making informed decisions regarding the implementation of vapor chamber cooler systems.

Compare Vapor Chambers and Liquid Cooling Systems

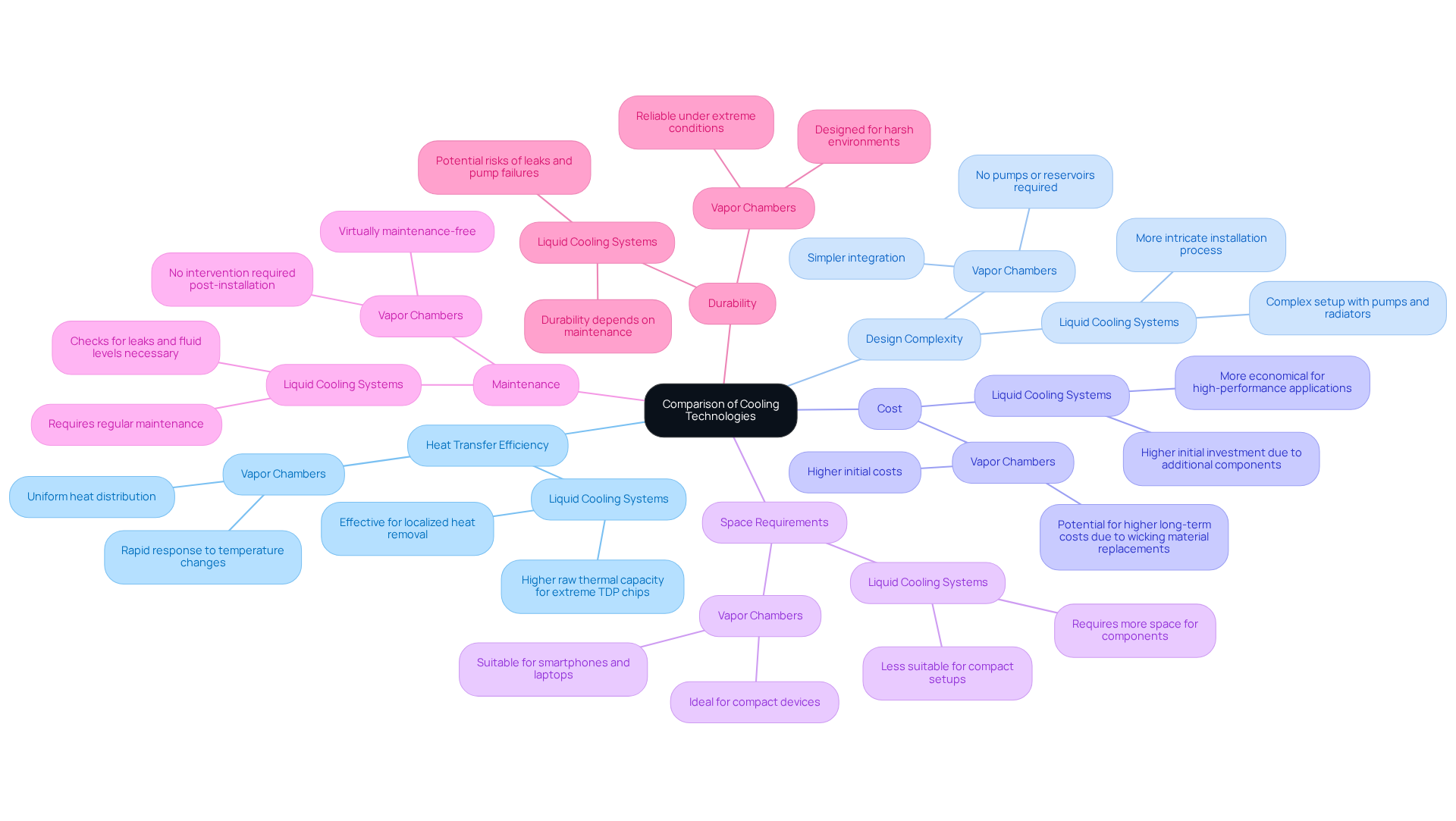

When comparing vapor chambers to liquid cooling systems, several critical factors emerge that warrant attention:

-

Heat Transfer Efficiency: Vapor chamber coolers excel at distributing heat uniformly across surfaces. This capability makes them particularly effective in preventing hotspots in compact devices. Their response to temperature fluctuations is rapid, thanks to the phase-change process, which is ideal for dynamic thermal loads. In contrast, liquid temperature regulation systems are generally more adept at removing heat from localized sources, a characteristic that can be advantageous in specific scenarios.

-

Design complexity is reduced in thermal management systems featuring a vapor chamber cooler, as they do not include pumps or reservoirs. This simplicity facilitates easier integration into space-constrained devices. Conversely, liquid temperature regulation systems necessitate a more intricate configuration of components, including pumps and radiators, complicating installation.

-

Cost: While liquid thermal management systems may present a more economical solution for high-performance applications due to their scalability, vapor chambers often involve higher initial expenses. However, it is important to consider that they may incur higher long-term costs due to the need for more frequent replacements of the wicking material. Their long-term reliability can justify the investment, particularly in demanding environments.

-

Space requirements dictate that vapor chamber coolers are particularly suited for applications with limited space, such as smartphones and laptops, due to their compact design. In contrast, liquid temperature regulation systems typically require additional space for components like pumps and radiators, making them less ideal for compact setups.

-

Maintenance is minimal with a vapor chamber cooler, as it is virtually maintenance-free and requires no intervention post-installation, enhancing its appeal for long-term use. In contrast, liquid temperature regulation systems necessitate regular maintenance, including checks for leaks and fluid levels, adding complexity for users.

-

Durability: A vapor chamber cooler is designed to endure harsh environments, making it suitable for applications in aerospace and automotive industries, where reliability under extreme conditions is crucial.

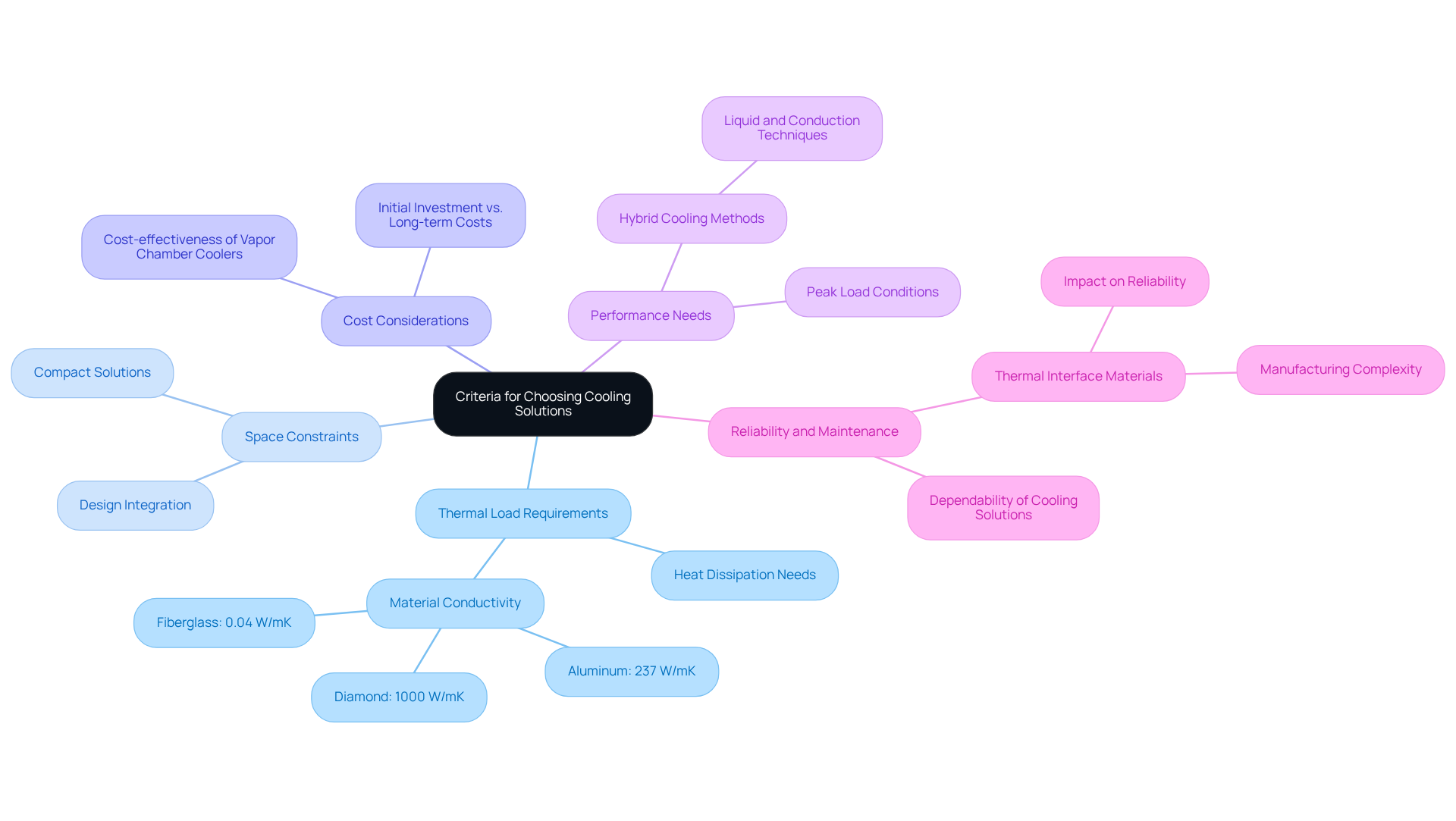

Determine Criteria for Choosing Cooling Solutions

When selecting the optimal cooling solution for a specific application, engineers must evaluate several key criteria to ensure effective temperature regulation.

-

Thermal Load Requirements: Accurately assessing the heat that must be dissipated is crucial. The chosen temperature regulation solution should effectively manage the anticipated thermal load, ensuring that components function within safe temperature limits. For instance, understanding that aluminum has a thermal conductivity of 237 W/mK can guide engineers in selecting materials that enhance heat dissipation.

-

Space Constraints: Engineers must consider the physical space available for temperature regulation components. Solutions should be compact enough to fit within the designated area without compromising performance.

-

Cost Considerations: A thorough analysis of both initial investment and long-term operational costs is essential. This includes assessing the cost-effectiveness of the vapor chamber cooler in relation to other temperature regulation technologies, while also considering maintenance and energy usage.

-

Performance Needs: Understanding the performance specifications of the electronic components being cooled is vital. This encompasses accounting for peak load conditions and the effects of thermal cycling on reliability. For instance, the hybrid temperature regulation method that merges liquid and conduction techniques maximizes efficiency and can be particularly advantageous in high-performance applications.

-

Reliability and Maintenance: Evaluating the reliability of the cooling solution and its maintenance requirements is critical. A dependable system minimizes downtime and ensures consistent performance over time. As noted by the Modus Engineering Team, the choice of appropriate thermal interface materials directly affects device reliability and manufacturing complexity.

By integrating these considerations, engineers can make informed decisions that enhance the efficiency and longevity of electronic devices, ultimately leading to improved product reliability and performance.

Conclusion

Vapor chamber coolers present an advanced solution for thermal management, effectively utilizing the principles of evaporation and condensation to regulate temperature in compact electronic devices. Their unique design facilitates superior heat distribution and performance, establishing them as vital components in modern engineering applications.

This exploration has underscored the advantages of vapor chamber cooling systems, such as:

- High thermal conductivity

- Uniform heat distribution

- Compact design

These features render them particularly suitable for space-constrained environments, while their durability and minimal maintenance requirements further enhance their appeal. However, it is essential to acknowledge the challenges associated with vapor chambers, including:

- Higher costs

- Sensitivity to orientation

These factors must be considered by engineers when evaluating cooling solutions.

Ultimately, selecting the appropriate cooling system is crucial for optimizing electronic performance and reliability. Engineers are urged to carefully weigh thermal load requirements, space constraints, cost considerations, and maintenance needs when choosing between vapor chambers and other cooling technologies. By doing so, they can ensure that their designs not only meet current demands but also anticipate future challenges in thermal management.

Frequently Asked Questions

What is a vapor chamber and how does it work?

A vapor chamber is a two-phase thermal transfer device that regulates temperature by utilizing evaporation and condensation. It consists of a sealed enclosure filled with a working fluid, typically water, which evaporates when heated. The vapor then moves to cooler areas of the chamber, where it condenses back into liquid, releasing stored heat.

What are the benefits of using vapor chamber cooling systems?

Vapor chamber cooling systems offer several advantages, including high thermal conductivity for efficient heat transfer, uniform heat distribution to maintain reliability in electronic components, a compact design for integration in space-constrained environments, versatility for various applications, and durability due to fewer moving parts requiring less maintenance.

In what applications are vapor chamber coolers typically used?

Vapor chamber coolers are used in a wide range of applications, including high-performance computing and consumer electronics, effectively addressing various thermal management requirements.

How does the design of vapor chamber coolers improve their performance?

Vapor chamber coolers operate in two dimensions, allowing for more efficient heat distribution across their surface, unlike conventional pipes that primarily function in one direction. This design significantly enhances their thermal performance, particularly in limited spaces.

Why is uniform heat distribution important in electronics?

Uniform heat distribution is critical for maintaining the reliability and longevity of electronic components, as it helps prevent hotspots that can lead to overheating and potential failure.