Overview

High static pressure in HVAC systems presents a significant challenge, indicating resistance to airflow that can severely impair system performance. This condition not only increases energy consumption but also leads to uneven heating or cooling throughout the space. Elevated static pressure often arises from issues such as:

- Dirty filters

- Improperly sized ducts

This underscores the necessity for regular maintenance and monitoring. By addressing these problems proactively, operators can ensure efficient operation and prevent costly equipment failures.

To maintain optimal performance, it is crucial to implement a routine maintenance schedule that includes:

- Checking and replacing filters

- Assessing duct systems for proper sizing

Such measures not only enhance system efficiency but also extend the lifespan of the equipment, ultimately leading to cost savings. Therefore, understanding and managing static pressure is essential for anyone involved in HVAC system operation.

Introduction

Understanding static pressure in HVAC systems is paramount for ensuring optimal indoor comfort and energy efficiency. High static pressure presents significant operational challenges, including:

- Increased energy consumption

- Uneven heating or cooling

- The risk of premature equipment failures

What are the underlying causes of high static pressure, and how can HVAC professionals effectively identify and resolve these issues? By exploring these questions, we uncover not only the complexities of HVAC performance but also the critical steps necessary to enhance system efficiency and longevity.

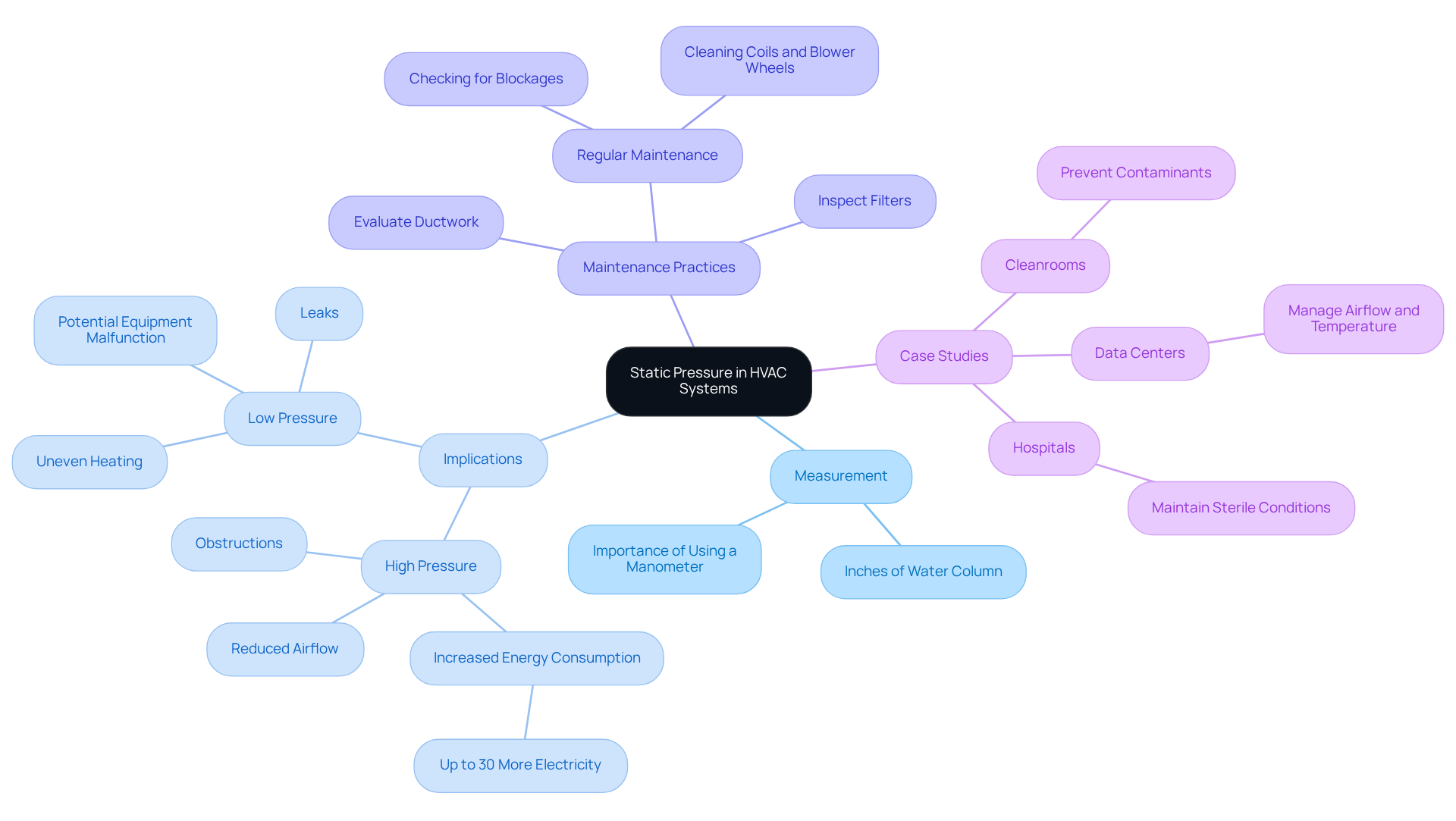

Define Static Pressure in HVAC Systems

Static force in HVAC systems represents the resistance to airflow within ductwork and components when air is at rest. Measured in inches of water column (in. WC), it quantifies the force exerted by air as it navigates through ducts. This measurement is crucial for maintaining balanced airflow, which directly impacts indoor comfort and energy efficiency. Ideally, stable force levels hover around 0.5 in. WC; this benchmark is vital for ensuring balanced airflow, as deviations can lead to significant inefficiencies.

For instance, elevated atmospheric force often signals obstructions or constraints, potentially stemming from common issues such as inadequately sized ducts, dirty filters, or sealed vents. This can escalate energy consumption—up to 30% more electricity—due to the system’s increased effort to push air through. Conversely, low atmospheric force may indicate leaks or insufficient airflow, resulting in uneven heating or cooling across spaces and potential equipment malfunction.

The importance of monitoring static force cannot be overstated. Routine maintenance, which includes inspecting and replacing air filters, evaluating ductwork, and verifying appropriate ductwork design, is essential to prevent airflow complications and ensure heating and cooling systems operate efficiently.

Case studies illustrate the impact of static air resistance on system efficiency:

- In cleanroom environments, maintaining elevated air resistance is critical to prevent contaminants from entering.

- Data centers rely on precise air resistance management to ensure optimal equipment performance.

- Furthermore, hospitals utilize elevated atmospheric force in operating rooms to maintain sterile conditions during surgical procedures.

Understanding what high static pressure means is imperative for HVAC professionals, as it directly affects performance and energy efficiency. As noted by Allied Air Conditioning & Heating, “If air resistance is excessively high, it can limit airflow and create issues,” underscoring the need for diligent monitoring and control to guarantee that units function efficiently and effectively. Additionally, employing a manometer to measure static force is essential for accurately assessing performance and identifying potential issues.

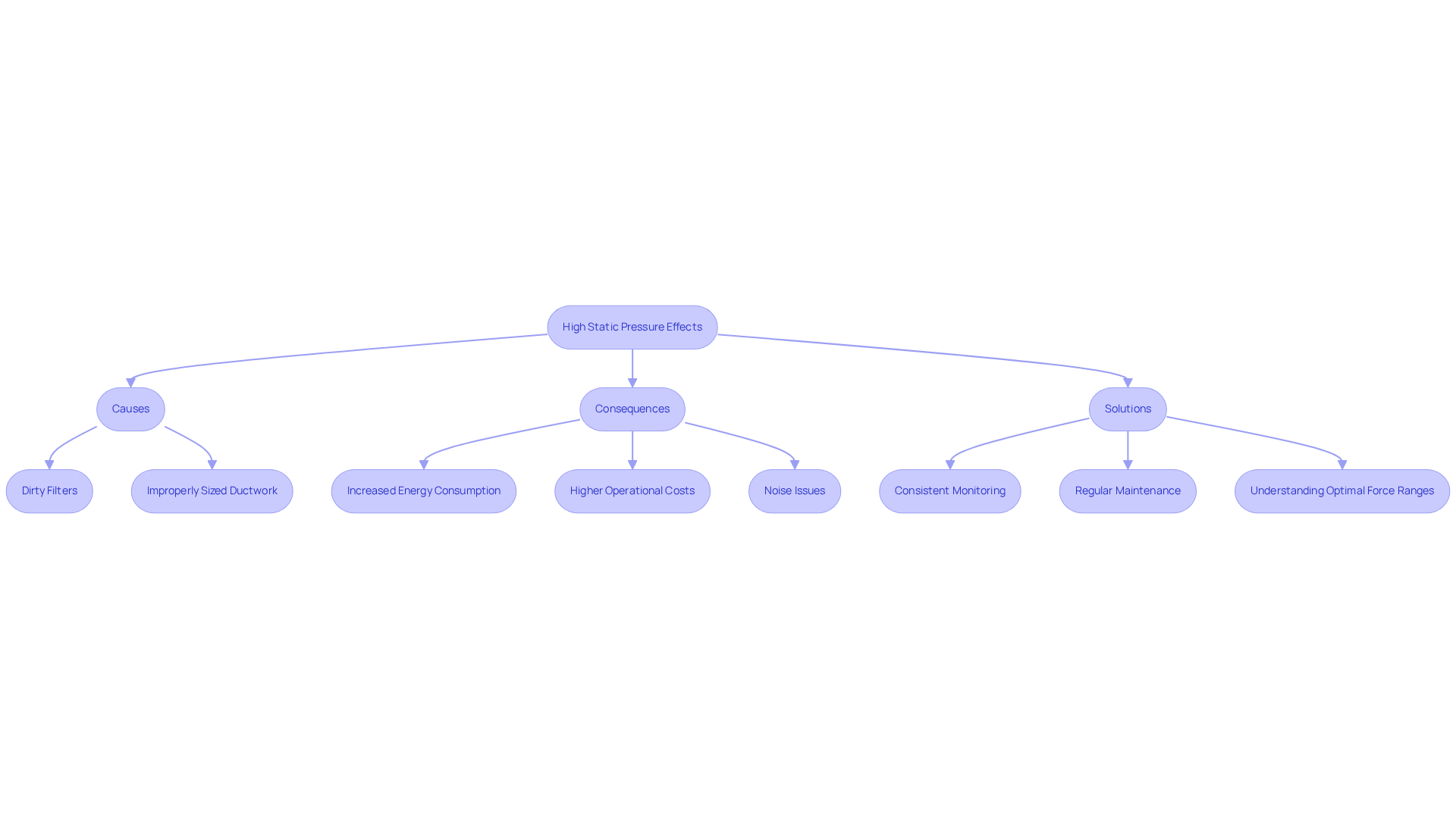

Examine the Effects of High Static Pressure on System Performance

Elevated atmospheric force poses a significant risk to climate control performance. Elevated static pressure restricts airflow, leading to the need to understand what does high static pressure mean, as it compels the mechanism to exert additional effort to achieve desired temperatures. This increased workload can lead to a substantial rise in energy consumption, with HVAC units accounting for approximately 20% of the average U.S. household electricity bill and around 35% in commercial buildings, underscoring their considerable impact on overall energy usage. As the mechanism struggles to push air through the ducts, it incurs not only higher operational costs but also accelerates wear and tear on essential components, resulting in premature failures and increased maintenance demands.

Common causes of elevated resistance include dirty or restrictive filters and improperly sized ductwork, which raises the question of what does high static pressure mean, exacerbating these issues. For example, air handlers may encounter difficulties in delivering consistent airflow, which can lead to uneven heating or cooling across various areas. This inefficiency often manifests as elevated energy costs, as the mechanism expends more effort to maintain comfort levels. Moreover, elevated atmospheric force is frequently associated with noise issues; the strain on the system can produce undesirable sound levels, such as whistling through vents or banging within the ductwork. As Brennan Keelor notes, ‘Elevated atmospheric tension frequently leads to loud airflow—whistling vents and grilles, banging/popping of ductwork, or rattling noises.’

Consistent monitoring and management of fixed force are essential to improve the efficiency of heating and cooling systems, reduce energy loss, and extend the lifespan of the equipment. Maintaining appropriate fixed air levels enhances comfort, decreases operational costs, and promotes a healthier indoor environment. It is vital to understand the optimal fixed force ranges for heating and cooling systems to effectively identify and regulate airflow.

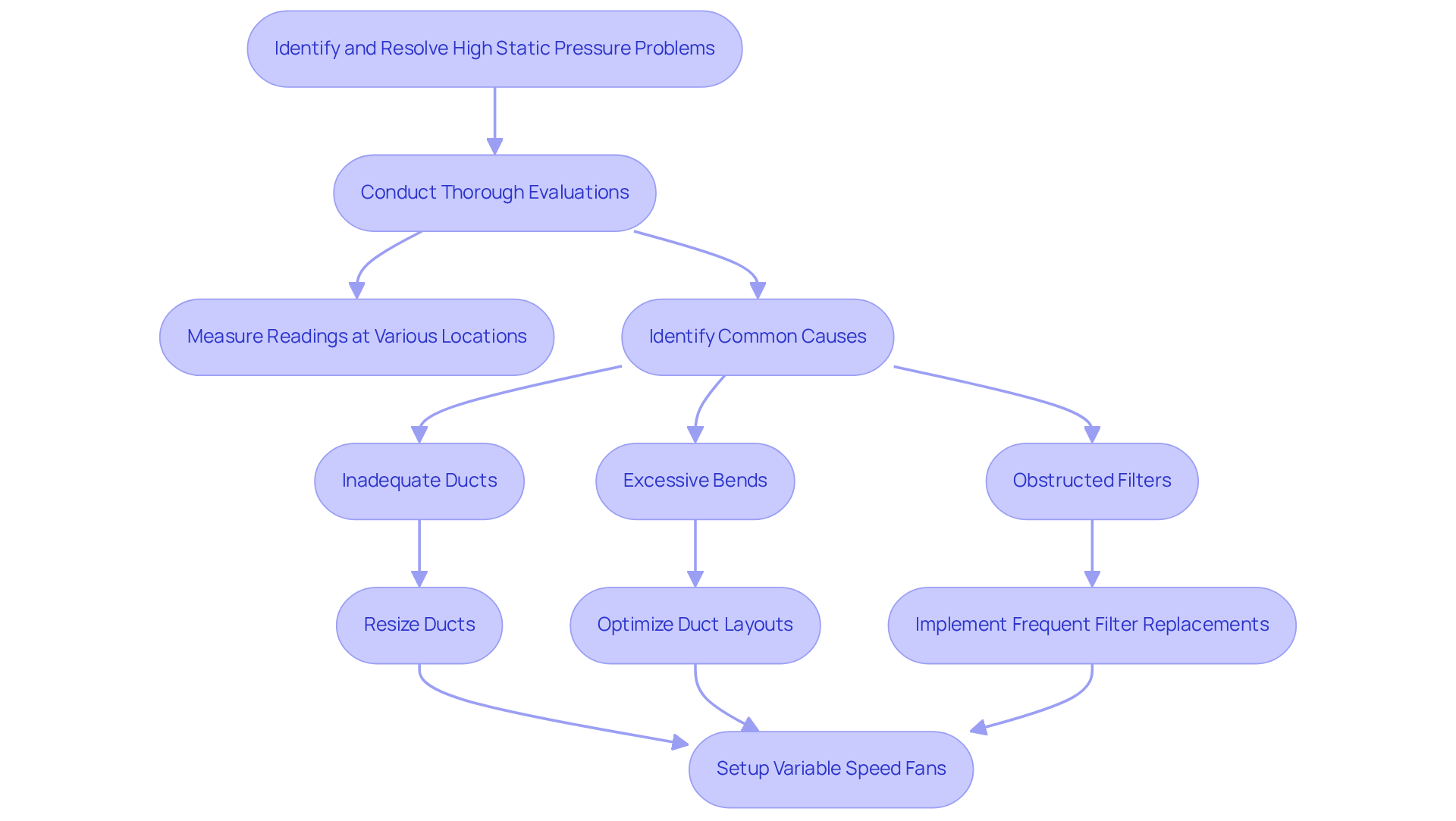

Identify and Resolve High Static Pressure Problems

To effectively identify significant high readings issues, HVAC professionals must conduct thorough evaluations of the setup. This involves measuring readings at various locations within the ductwork using tools such as a digital manometer and measurement probes. Common causes of elevated resistance include:

- Inadequate ducts

- Excessive bends or turns in the duct system

- Obstructed filters

The optimal fixed force level is 0.5 inches, which is essential for peak performance of the setup.

Once these issues are pinpointed, solutions may involve:

- Resizing ducts to enhance airflow

- Optimizing duct layouts to minimize resistance

- Implementing a more frequent filter replacement schedule to prevent blockages

Additionally, the setup of variable speed fans can dynamically modify airflow, thus decreasing resistance and improving overall system efficiency. Elevated atmospheric force can lead to higher energy expenses and potential equipment breakdown, making it crucial to address these matters swiftly.

Regular maintenance and systematic evaluations are essential to prevent issues that relate to what does high static pressure mean, ensuring optimal HVAC performance and longevity. For complex issues, seeking professional assistance is advisable to ensure accurate diagnosis and effective resolution.

Conclusion

Understanding high static pressure is crucial for optimizing HVAC system performance and ensuring energy efficiency. High static pressure serves as a measure of airflow resistance within ductwork, making its importance paramount. Maintaining optimal static pressure levels is essential; deviations can lead to increased energy consumption, operational strain, and ultimately, costly repairs.

Common causes of high static pressure include dirty filters and improperly sized ducts. These issues can result in significant implications for system performance, including uneven heating or cooling and increased noise levels. Regular maintenance and monitoring are essential to prevent these problems. Proactive measures, such as resizing ducts and implementing variable speed fans, can enhance airflow efficiency and mitigate the risks associated with high static pressure.

Recognizing and addressing high static pressure is vital not only for the longevity of HVAC systems but also for achieving an energy-efficient environment. By prioritizing proper airflow management, HVAC professionals can significantly reduce operational costs and improve indoor comfort. Taking action to monitor and resolve static pressure issues will lead to a more sustainable and effective climate control solution, benefiting both users and the environment.

Frequently Asked Questions

What is static pressure in HVAC systems?

Static pressure in HVAC systems represents the resistance to airflow within ductwork and components when air is at rest. It is measured in inches of water column (in. WC) and quantifies the force exerted by air as it moves through ducts.

Why is measuring static pressure important?

Measuring static pressure is crucial for maintaining balanced airflow, which directly impacts indoor comfort and energy efficiency. Stable force levels ideally hover around 0.5 in. WC, and deviations can lead to significant inefficiencies.

What can elevated static pressure indicate?

Elevated static pressure often signals obstructions or constraints in the system, which may be caused by inadequately sized ducts, dirty filters, or sealed vents. This can lead to increased energy consumption, potentially up to 30% more electricity.

What does low static pressure signify?

Low static pressure may indicate leaks or insufficient airflow within the system, resulting in uneven heating or cooling across spaces and potential equipment malfunction.

How can static pressure be monitored and maintained?

Routine maintenance is essential for monitoring static pressure. This includes inspecting and replacing air filters, evaluating ductwork, and ensuring appropriate ductwork design to prevent airflow complications and ensure efficient operation of heating and cooling systems.

What are some specific applications of static pressure management?

Static pressure management is critical in various environments, such as cleanrooms to prevent contaminants, data centers for optimal equipment performance, and hospitals in operating rooms to maintain sterile conditions during surgeries.

How can HVAC professionals assess static pressure?

HVAC professionals can assess static pressure using a manometer, which allows for accurate measurement of static force and helps identify potential issues affecting system performance.