Overview

Understanding the key differences between sleeve bearings and ball bearings is crucial for selecting the right component for your application. Sleeve bearings, known for their simplicity and cost-effectiveness, excel in low-speed environments. They operate quietly, making them ideal for applications where noise reduction is a priority. In contrast, ball bearings are engineered for high-speed operations, offering superior load capacities and efficiency. Their design allows for smoother motion and reduced friction, which is essential in demanding conditions.

When considering performance characteristics, sleeve bearings are often favored for their straightforward design, which can lead to lower maintenance costs. However, they may not withstand the same levels of stress as ball bearings, which are built to handle heavier loads and faster speeds. This distinction is vital when assessing the suitability of each type for specific applications.

In conclusion, the choice between sleeve bearings and ball bearings hinges on the specific requirements of your project. By weighing the advantages and limitations of each, you can make an informed decision that aligns with your operational needs.

Introduction

Choosing between sleeve bearings and ball bearings is a decision that can profoundly influence the performance and efficiency of engineering applications. Sleeve bearings are known for their simplicity and cost-effectiveness, while ball bearings excel in load capacity and speed. This pivotal choice presents engineers with a critical challenge.

To navigate this decision, it’s essential to explore the operational characteristics, maintenance requirements, and suitability for various applications of each bearing type. Sleeve bearings, for instance, often require less maintenance and are easier to install, making them ideal for certain low-speed applications. On the other hand, ball bearings, with their superior load-bearing capabilities, are better suited for high-speed and high-load scenarios.

Understanding these distinctions is crucial for making informed choices that align with specific project requirements and performance goals. By weighing the benefits and limitations of each option, engineers can select the most appropriate bearing type, ensuring optimal functionality and efficiency in their designs.

Understand the Basics: Sleeve Bearings vs. Ball Bearings

Understanding Sleeve Supports and Ball Components

Sleeve supports, often known as plain supports, feature a cylindrical sleeve designed to accommodate a rotating shaft. This design facilitates smooth motion through sliding contact, making it a straightforward solution for many applications. They are particularly favored in scenarios where cost-effectiveness and low noise levels are paramount.

In contrast, the comparison of sleeve vs ball bearing components utilizes spherical balls positioned between two tracks, enabling a rolling motion that significantly reduces friction. While this design is more complex, the comparison of sleeve vs ball bearing offers substantial advantages in terms of load capacity and speed, making it ideal for high-performance applications.

For engineers, grasping these fundamental mechanics is crucial when selecting the appropriate type of support for specific applications. By understanding the strengths and limitations of each option, professionals can make informed decisions that enhance performance and efficiency.

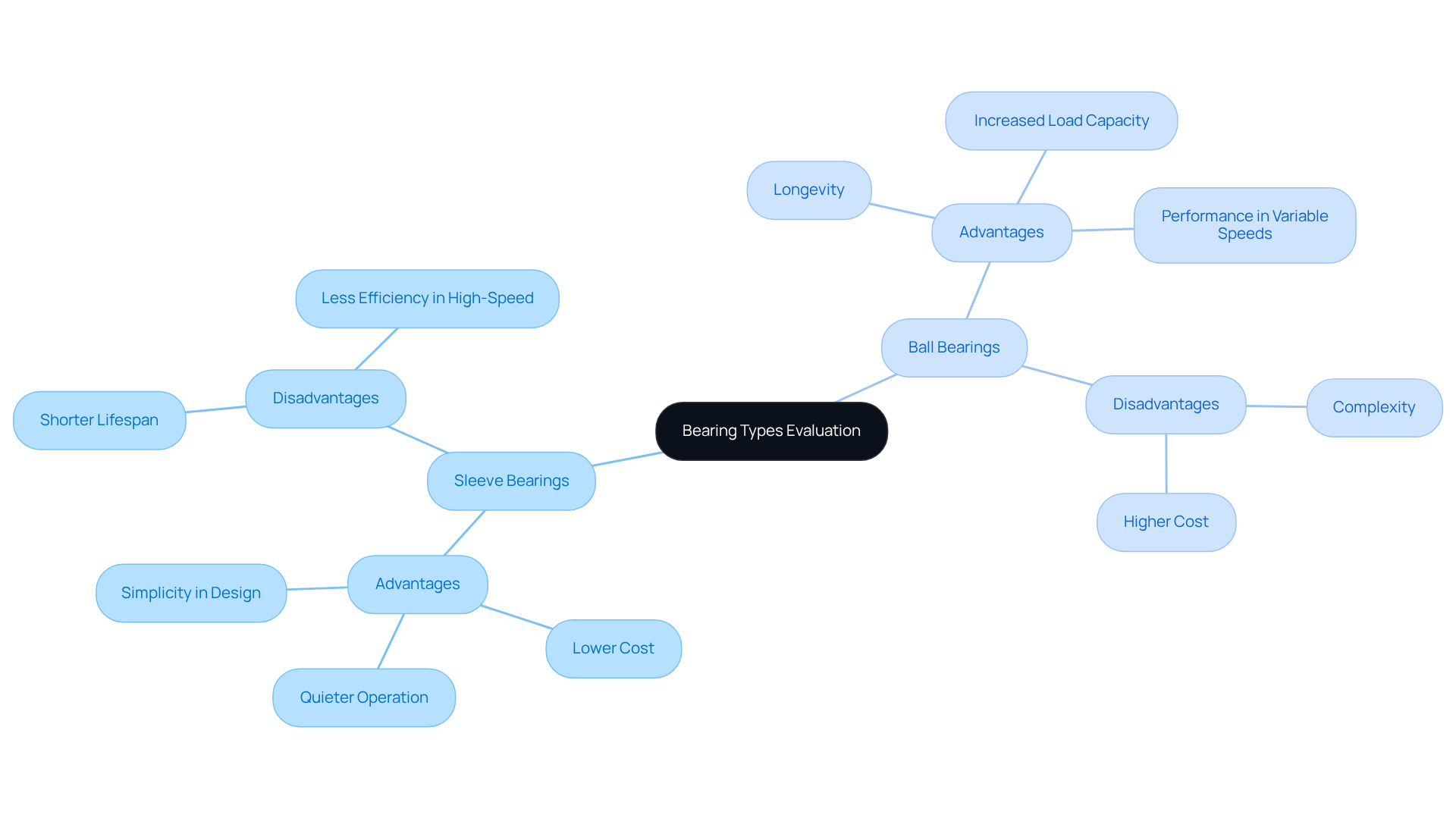

Evaluate Pros and Cons: Strengths and Weaknesses of Each Bearing Type

When evaluating sleeve vs ball bearing choices, it’s crucial to recognize the primary advantages of sleeve bearings: lower cost, quieter operation, and simplicity in design. These bearings excel in applications with reduced speeds and loads, making them ideal for cooling fans and various home devices. However, it’s important to note that when comparing sleeve vs ball bearing, sleeve bearings typically have shorter lifespans and are less efficient in high-speed scenarios.

In contrast, when evaluating sleeve vs ball bearing, sphere rollers are notable for their exceptional longevity, increased load capacities, and enhanced performance in variable speed applications. While they are more complex and generally more expensive, the longevity and efficiency they offer often justify the initial investment.

Understanding these pros and cons is essential for engineers. By weighing the specific needs of their applications against the characteristics of each bearing type, they can make informed decisions that align with performance requirements and budget constraints.

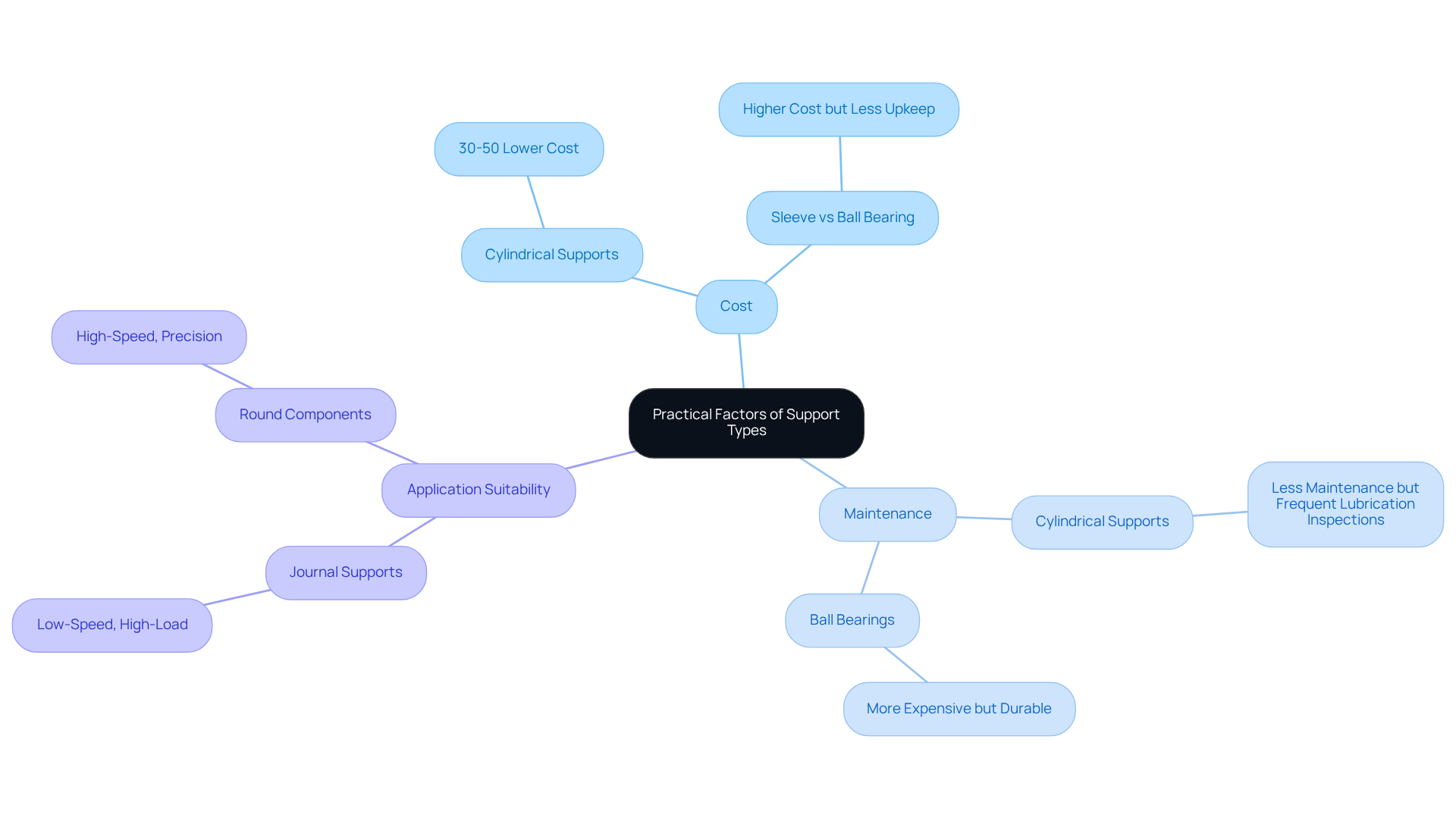

Assess Practical Factors: Cost, Maintenance, and Application Suitability

When considering expenses, cylindrical supports stand out as a cost-effective choice, often priced 30-50% lower than comparable options in the sleeve vs ball bearing category. This affordability makes them particularly appealing for budget-conscious projects. However, while cylindrical supports demand less maintenance due to their straightforward design, they do require more frequent lubrication inspections to maintain optimal performance. In contrast, when considering sleeve vs ball bearing components, the latter, though more expensive, typically require less upkeep over time thanks to their robust design and enhanced durability.

The appropriateness of each application varies significantly; journal supports are commonly preferred in low-speed, high-load scenarios, while round components excel in high-speed, precision applications. Engineers must carefully weigh these practical considerations to select the most suitable type of support for their specific use case. By understanding the strengths and weaknesses of each option, professionals can make informed decisions that align with their project requirements.

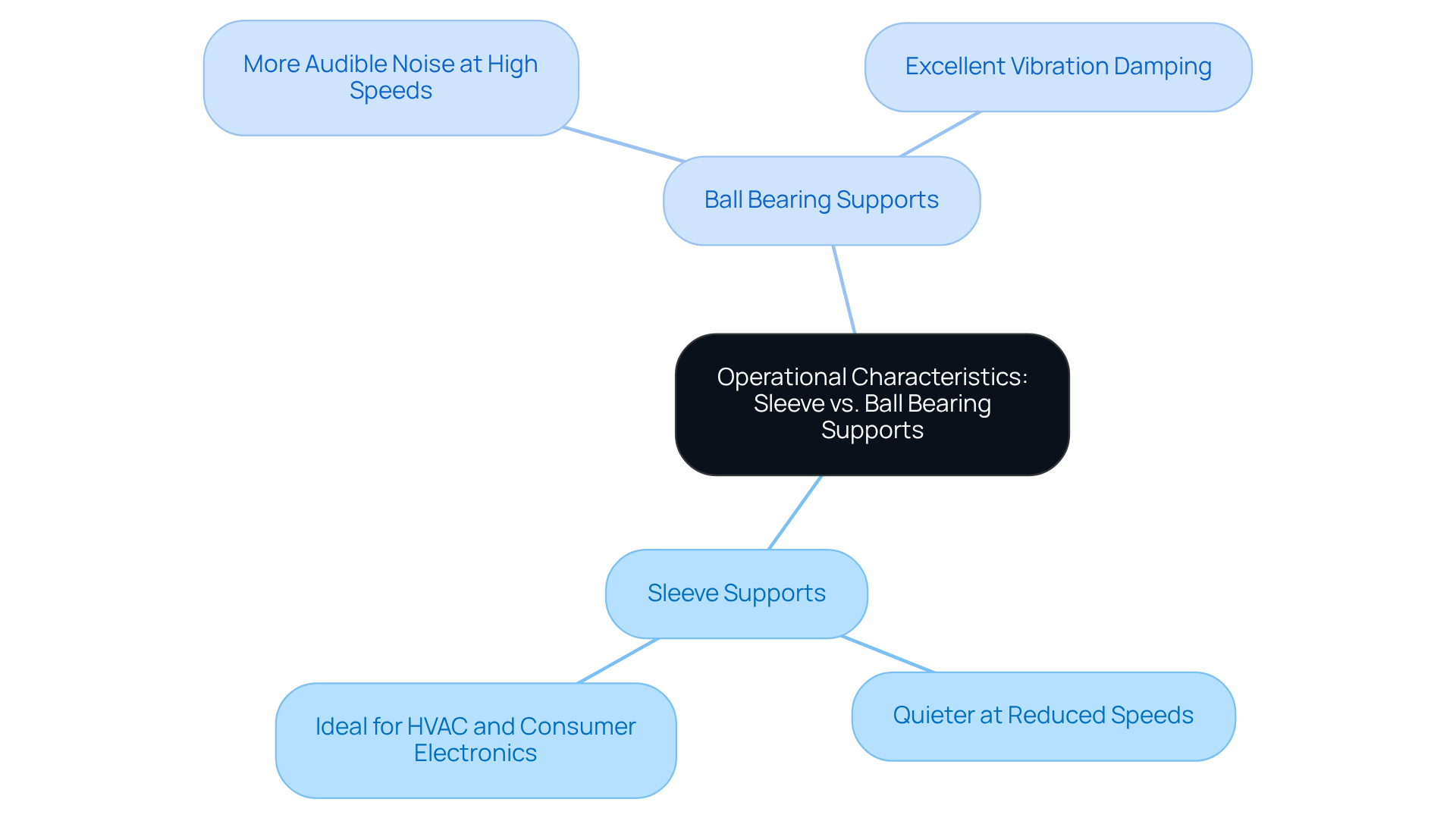

Consider Noise and Vibration: Operational Characteristics

Noise levels play a crucial role when comparing sleeve and sphere supports. When comparing sleeve vs ball bearing supports, sleeve supports are generally quieter, especially at reduced speeds, making them ideal for applications where noise minimization is essential, such as HVAC systems and consumer electronics. In contrast, when comparing sleeve vs ball bearing components, the ball bearings can produce more audible noise during operation, particularly at high speeds. However, they excel in environments where vibration damping is vital, as their rolling motion effectively reduces the transmission of vibrations.

Engineers must carefully evaluate the operational environment and user expectations when assessing the noise and vibration characteristics of each type, specifically sleeve vs ball bearing. By understanding these dynamics, they can make informed decisions that align with performance requirements and user needs.

Conclusion

Understanding the differences between sleeve bearings and ball bearings is crucial for engineers who need to select the right support for their applications. Sleeve bearings present a cost-effective and straightforward solution, particularly in low-speed, low-load scenarios. In contrast, ball bearings deliver superior performance in high-speed and high-load situations, which justifies their higher cost and complexity.

Key insights indicate that sleeve bearings excel in quiet operation and simplicity, making them ideal for consumer electronics and HVAC systems. However, their shorter lifespan and maintenance requirements may limit their use in demanding environments. Conversely, ball bearings, with their enhanced load capacity and durability, are engineered for high-performance applications, despite necessitating a greater initial investment and potentially generating more noise.

Ultimately, the decision between sleeve and ball bearings depends on specific project requirements, including cost constraints, maintenance capabilities, and operational conditions. Engineers must carefully weigh these factors to ensure optimal performance and efficiency in their designs. By comprehensively understanding the unique characteristics and applications of both bearing types, professionals can make informed decisions that significantly enhance the effectiveness of their engineering solutions.

Frequently Asked Questions

What are sleeve bearings?

Sleeve bearings, also known as plain supports, feature a cylindrical sleeve designed to accommodate a rotating shaft, facilitating smooth motion through sliding contact.

What are the advantages of sleeve bearings?

Sleeve bearings are favored for their cost-effectiveness and low noise levels, making them suitable for many applications.

How do ball bearings differ from sleeve bearings?

Ball bearings utilize spherical balls positioned between two tracks, enabling a rolling motion that significantly reduces friction, unlike the sliding contact in sleeve bearings.

What are the benefits of using ball bearings?

Ball bearings offer substantial advantages in terms of load capacity and speed, making them ideal for high-performance applications.

Why is it important for engineers to understand the differences between sleeve and ball bearings?

Understanding the strengths and limitations of each type of bearing allows engineers to make informed decisions that enhance performance and efficiency in their applications.