Overview

Engineers face a critical challenge: optimizing cooling in electronic systems. One effective solution lies in the strategic use of Pulse Width Modulation (PWM) for PC fan control. By adjusting the duty cycle of PWM signals, engineers can precisely regulate fan speeds. This not only enhances cooling efficiency but also reduces noise and power consumption, ultimately leading to improved system performance and component longevity.

The ability to control fan speeds with precision is paramount in today’s high-performance computing environments. PWM allows for a dynamic response to thermal conditions, ensuring that fans operate only as needed. This capability not only conserves energy but also minimizes acoustic disturbances, creating a more pleasant user experience.

Incorporating PWM into cooling strategies can significantly impact overall system reliability. By maintaining optimal temperatures, engineers can extend the lifespan of critical components, reducing the risk of thermal-related failures. This proactive approach to cooling management is essential for maximizing the performance of electronic systems.

In conclusion, leveraging PWM for PC fan control presents a compelling opportunity for engineers to enhance cooling efficiency while addressing noise and power consumption concerns. By adopting this technology, professionals can ensure their systems operate at peak performance, ultimately benefiting both the hardware and the end-user.

Introduction

Pulse Width Modulation (PWM) has transformed how engineers tackle cooling solutions in electronic systems, providing a precise method for controlling fan speeds. By adjusting the duty cycle of PWM signals, professionals can enhance efficiency, minimize noise, and extend the lifespan of components. Yet, the complexities of implementing PWM control can pose challenges that demand a thorough understanding of both the technology and its configuration.

How can engineers adeptly navigate these intricacies to optimize cooling performance and ensure system reliability?

Understand Pulse Width Modulation (PWM) Basics

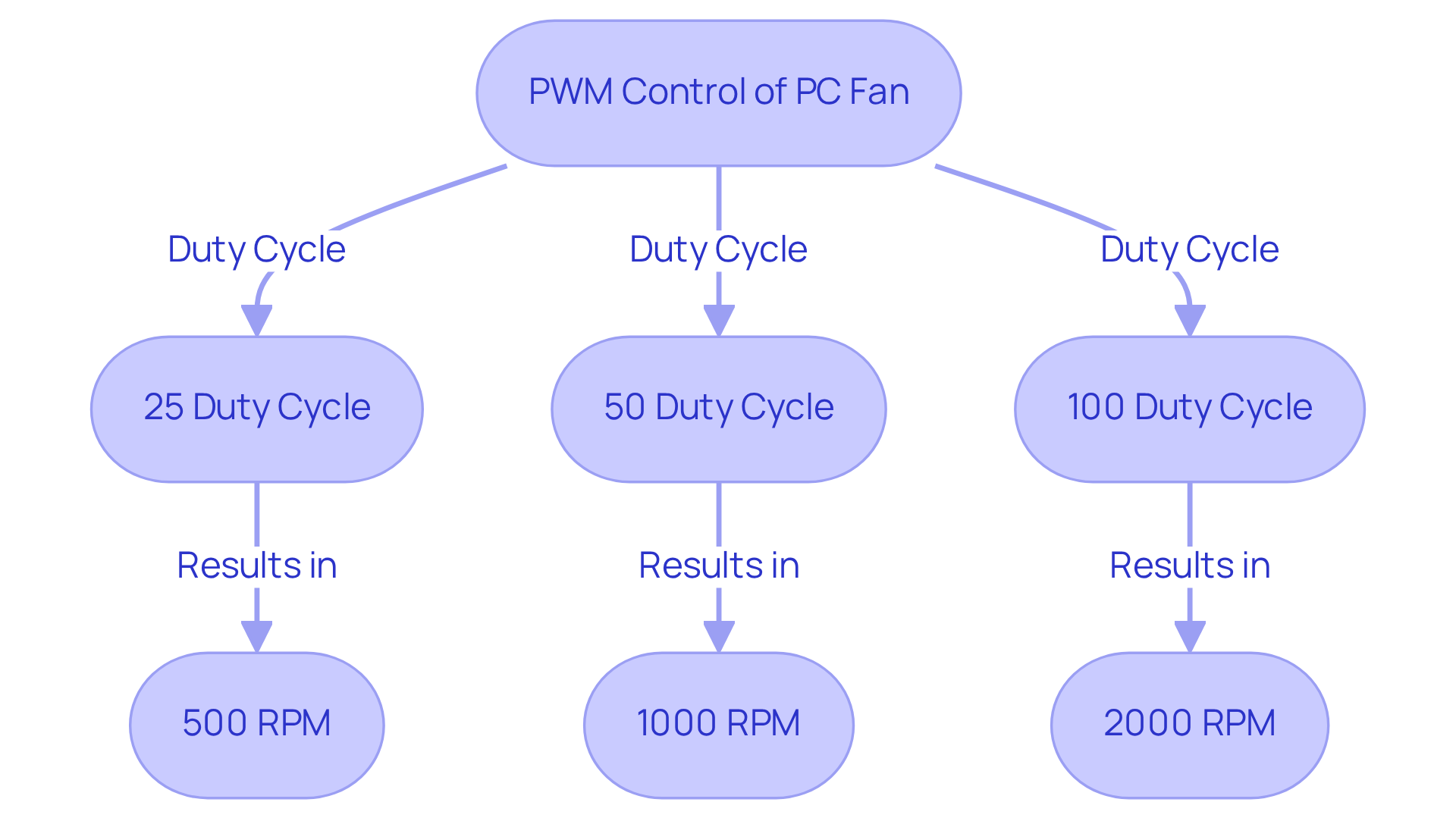

Pulse Width Modulation (PWM) is a pivotal technique for regulating the operation of electronic devices, particularly in PWM PC fan applications. By adjusting the width of the pulses in a waveform, a PWM PC fan is provided with a sequence of high-frequency on/off signals. This modulation allows the fan to adjust its speed based on the duration of the ‘on’ period relative to the ‘off’ period, known as the duty cycle. For example, a 50% duty cycle indicates that the fan operates half the time, resulting in a moderate speed. Understanding this concept is essential for optimizing cooling solutions in electronic systems.

The PWM PC fan facilitates precise control over fan velocities, with the duty cycle having a direct impact on the fan’s operational rate. Typically, high-frequency waves exceeding 20 kHz are utilized to minimize noise and ensure smooth performance. Consider a fan with a maximum speed of 2000 RPM; operating it at a 25% duty cycle would yield approximately 500 RPM. This approach effectively reduces noise and power consumption while still delivering sufficient cooling performance for the system.

Engineers acknowledge the critical role of the PWM PC fan in fan control, recognizing its capacity to enhance system efficiency and longevity through optimized cooling management. By leveraging PWM, professionals can ensure that electronic systems operate at peak performance, ultimately leading to improved reliability and reduced operational costs.

Explore 4-Pin Fan Configuration and PWM Control

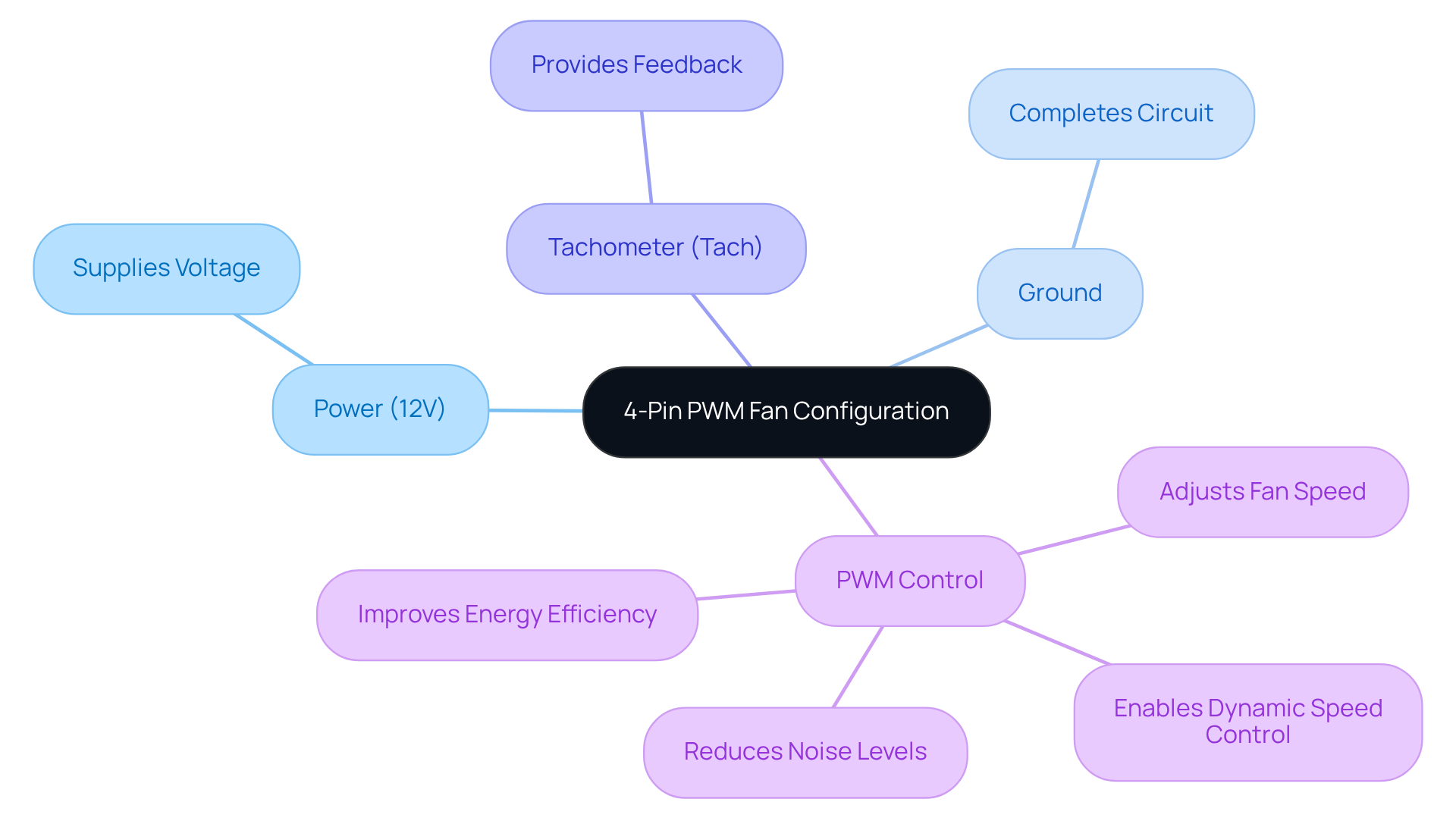

A 4-pin PWM PC fan configuration consists of four essential wires: power, ground, tachometer, and PWM control. The PWM PC fan utilizes the PWM control pin, which is crucial as it receives the PWM data from the motherboard or fan controller, directly influencing the fan’s velocity. Below is a detailed breakdown of the pin configuration:

- Power (12V): Supplies the necessary voltage for the fan’s operation.

- Ground: Completes the electrical circuit, ensuring proper functionality.

- Tachometer (Tach): Provides feedback to the motherboard about the fan’s rate, allowing for real-time observation and modifications.

- PWM Control: Receives the PWM input that adjusts the fan rate according to thermal requirements.

Importance of Each Pin:

The power and ground pins are standard across all fan types, while the tachometer and PWM control pins are specific to 4-pin fans. This specificity allows for dynamic speed adjustments in the PWM PC fan that enhance cooling efficiency.

Example:

When the PWM control pin receives a signal with a 50% duty cycle, the fan operates at half its maximum speed. This capability not only guarantees efficient cooling but also reduces noise levels, making the PWM PC fan especially beneficial in settings where sound sensitivity is essential.

The application of PWM PC fan technology in 4-pin units allows for precise regulation over rotational rates, significantly improving energy efficiency. For instance, PWM units can function at velocities as low as 10% of their maximum capacity, contrasting sharply with conventional DC devices that typically operate at a minimum of 50% speed. This efficiency is particularly advantageous in modern electronics cooling systems, where maintaining optimal temperatures is essential for performance and longevity.

Gagner-Toomey Associates, the globe’s largest producer of standard and custom air-movers, offers an extensive selection of PWM PC fans optimized for performance, efficiency, and low noise. Their product range includes DC input Tube Axial units and Centrifugal Blowers, available in sizes from 15 to 280mm, catering to diverse cooling requirements. Furthermore, PWM PC fan controllers significantly reduce power consumption during low-load conditions, making them particularly beneficial in modern electronics cooling systems. This efficiency is vital for maintaining optimal temperatures, crucial for the performance and longevity of electronic components. Moreover, a PWM PC fan can extend the lifespan of electronic components by up to 50%, thereby enhancing their value in electronic systems. Finally, PWM PC fans generate reduced noise levels at diminished rates, making them particularly beneficial in sound-sensitive environments.

Implement PWM Control for Effective Fan Speed Management

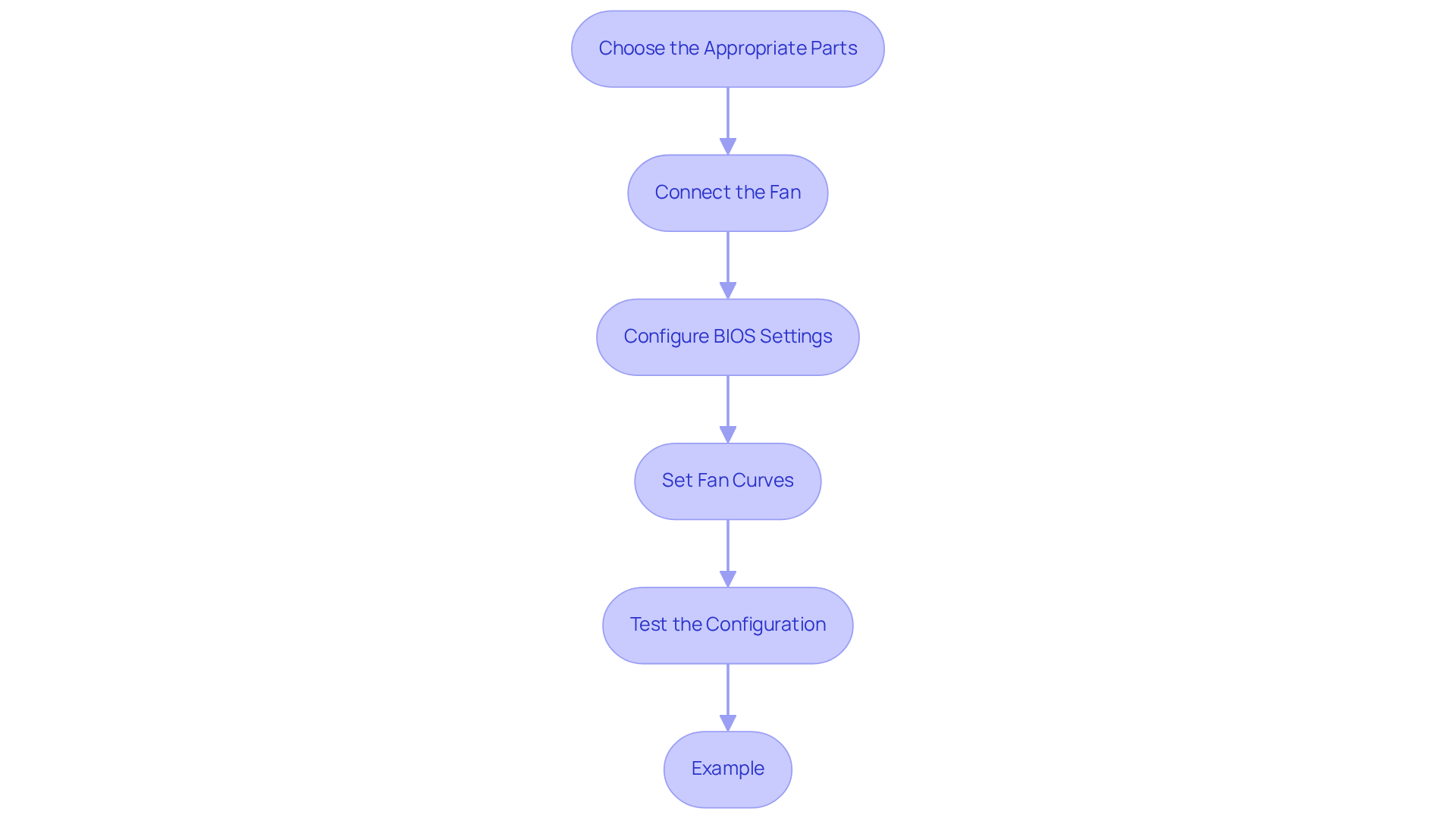

To effectively implement PWM control for fan speed management, follow these steps:

-

Choose the appropriate parts: Ensure you have a compatible 4-pin PWM PC fan and a motherboard or controller that supports PWM outputs. Most modern motherboards are designed for PWM devices, facilitating optimal performance.

-

Connect the Fan: Plug the fan into the appropriate 4-pin header on the motherboard. Secure connections are crucial to avoid operational issues; a loose connection can disrupt PWM transmission.

-

Configure BIOS Settings: Access the BIOS setup during system boot. Navigate to the fan control settings and select PWM mode for the connected fan. This configuration allows the motherboard to transmit PWM signals, enabling precise control of the PWM PC fan’s rotation based on thermal requirements.

-

Set Fan Curves: Adjust the fan curves according to temperature thresholds. For example, configure the fan to ramp up its rotation as the CPU temperature increases. A common strategy is to set the fan to achieve 100% performance at 70°C, ensuring efficient cooling while maintaining lower levels (around 30%) during idle or low-load conditions to minimize noise. PWM PC fans can operate at a minimum rate lower than that of DC fans, with rotations reduced by up to 40% of the rated speed, which enhances operational flexibility.

-

Test the Configuration: After setup, monitor fan speeds and temperatures using software tools. Make necessary adjustments to the fan curves to strike a balance between cooling performance and noise levels. Effective temperature regulation solutions utilizing PWM technology can extend the lifespan of electronic components by up to 50%. The tachometer output provides real-time information on current fan velocity, allowing for precise modifications and ensuring optimal performance.

Example:

If your CPU temperature reaches 70°C, configure the fan to operate at 100% speed for adequate cooling, while at lower temperatures, it could run at 30% speed for quieter operation. This dynamic adjustment not only enhances cooling efficiency but also reduces unnecessary wear on the fan, prolonging its lifespan. PWM PC fans significantly reduce noise levels compared to conventional units, making them ideal for noise-sensitive environments.

Troubleshoot Common PWM Fan Control Issues

When implementing PWM control, engineers may encounter several common issues. Here are some troubleshooting steps to consider:

-

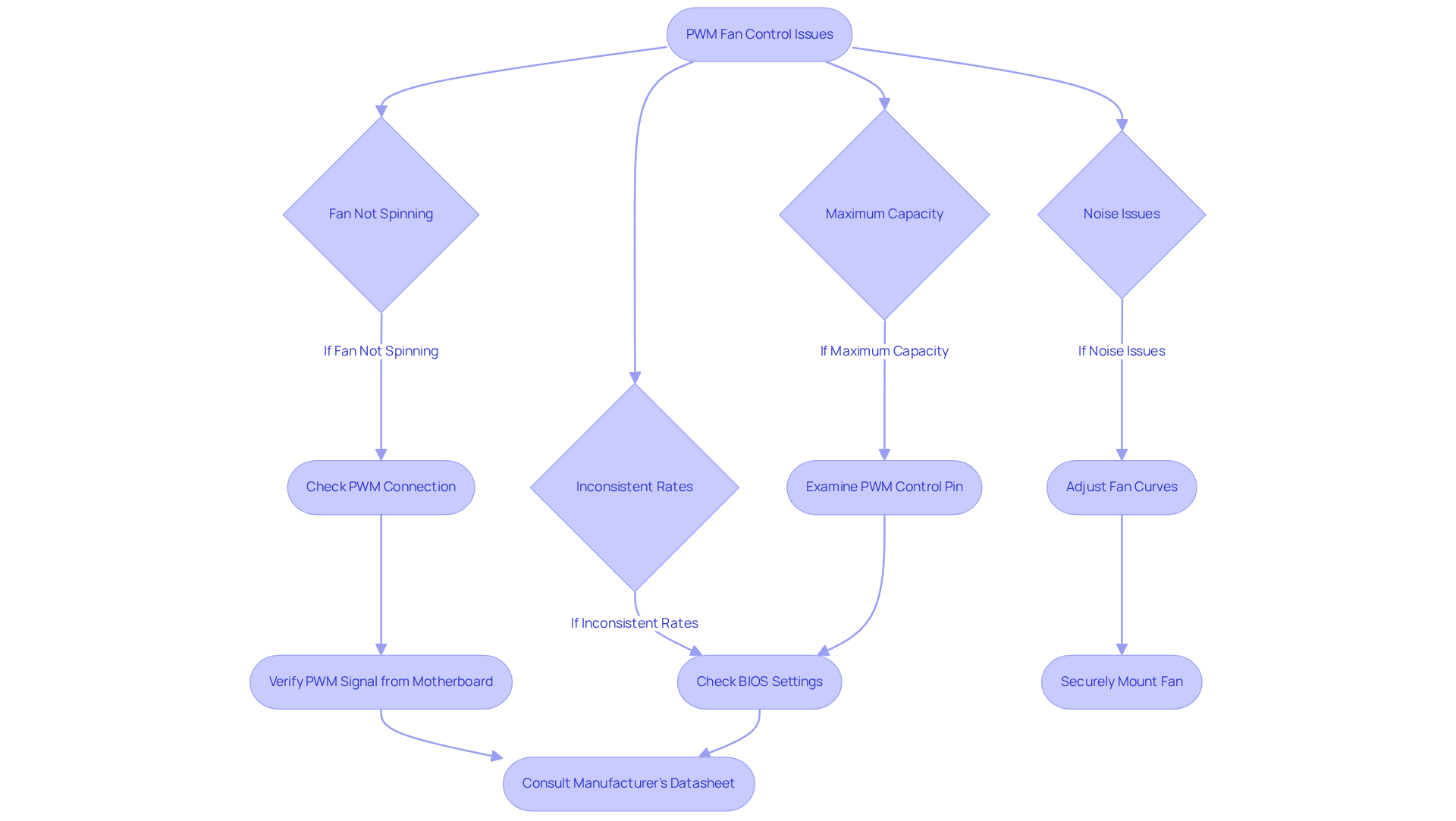

Fan Not Spinning: Ensure the PWM PC fan is properly connected to the 4-pin header and verify that the PWM communication is being transmitted from the motherboard. If the PWM PC fan model requires a specific PWM frequency, consult the manufacturer’s datasheet for guidance.

-

Inconsistent Rates: If the fan rotation varies unexpectedly, check that the PWM signal frequency is correctly set in the BIOS. Most PWM PC fans operate optimally at a frequency of around 25 kHz, which helps maintain stable performance.

-

If the PWM PC fan operates at maximum capacity regardless of temperature, confirm that PWM mode is enabled in the BIOS settings. Furthermore, examine the functionality of the PWM PC fan control pin, as a failure here can hinder proper regulation of velocity.

-

Noise Issues: Excessive noise from the fan can often be mitigated by adjusting the fan curves to lower speeds at reduced temperatures. Ensure the fan is securely mounted to minimize vibrations, which can contribute to noise.

Example:

If a fan is unresponsive to PWM signals, first check the BIOS settings to confirm that PWM mode is enabled. If the issue persists, inspect the PWM PC fan’s control pin for any damage or loose connections. Engineers have reported that implementing a low-pass filter can also smooth PWM output, enhancing fan responsiveness and reducing noise levels.

Conclusion

Mastering PWM PC fan control is crucial for engineers aiming to optimize cooling in electronic systems. This technique not only boosts cooling efficiency but also significantly prolongs the lifespan of components by enabling precise adjustments in fan speed according to thermal needs. By implementing Pulse Width Modulation, professionals can ensure their systems operate smoothly, quietly, and reliably.

This article explores the fundamentals of PWM, the configuration of 4-pin fans, and the essential steps for effective fan speed management. Key insights include:

- The critical role of duty cycles in regulating fan speeds

- The specific functions of each pin in a 4-pin fan setup

- Practical troubleshooting tips for common PWM control issues

Collectively, these elements underscore the advantages of utilizing PWM technology, such as reduced noise levels and enhanced energy efficiency in modern cooling systems.

In conclusion, grasping and applying PWM control in PC fan management is not merely a technical necessity; it represents a strategic advantage in maintaining optimal performance and longevity of electronic devices. Engineers are urged to adopt these techniques to bolster system reliability and efficiency, ultimately contributing to the advancement of cooling solutions in the ever-evolving landscape of technology.

Frequently Asked Questions

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a technique used to regulate the operation of electronic devices by adjusting the width of the pulses in a waveform, allowing for control over the speed of devices like PC fans.

How does PWM control the speed of a PC fan?

PWM controls the speed of a PC fan by varying the duty cycle, which is the ratio of the ‘on’ period to the ‘off’ period in the signal. For example, a 50% duty cycle means the fan is on half the time, resulting in moderate speed.

What is a duty cycle in the context of PWM?

The duty cycle in PWM refers to the percentage of time the signal is in the ‘on’ state compared to the total time of one cycle. It directly affects the operational rate of the fan.

What frequency is typically used in PWM for PC fans?

PWM for PC fans typically uses high-frequency waves exceeding 20 kHz to minimize noise and ensure smooth performance.

How does the duty cycle affect the RPM of a fan?

The duty cycle affects the RPM of a fan by determining how long the fan operates at its maximum speed. For example, a fan with a maximum speed of 2000 RPM operating at a 25% duty cycle would run at approximately 500 RPM.

What are the benefits of using PWM in PC fans?

The benefits of using PWM in PC fans include reduced noise, lower power consumption, and effective cooling performance, which enhances system efficiency and longevity.

Why is PWM important for electronic systems?

PWM is important for electronic systems because it allows for optimized cooling management, ensuring that systems operate at peak performance, which leads to improved reliability and reduced operational costs.